Bulging bag type cooling structure for binary spray pipe

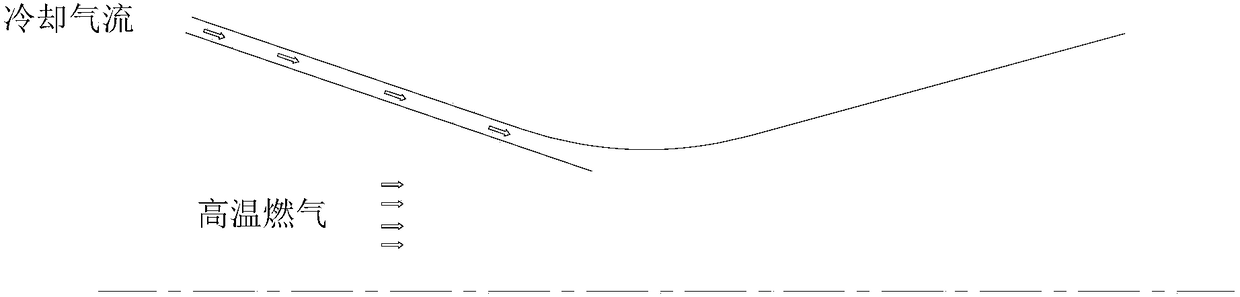

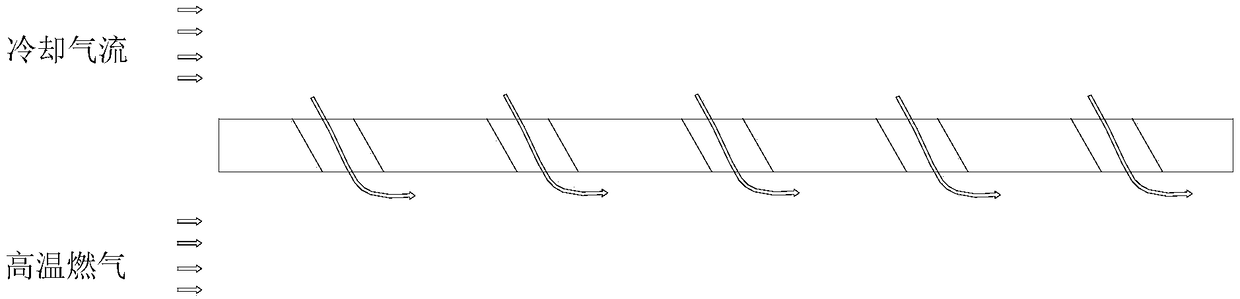

A cooling structure, binary nozzle technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problem of not ensuring effective wall cooling, and achieve enhanced convective heat transfer, high cooling efficiency, and span direction. with the effect of uniform temperature distribution in the axial direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

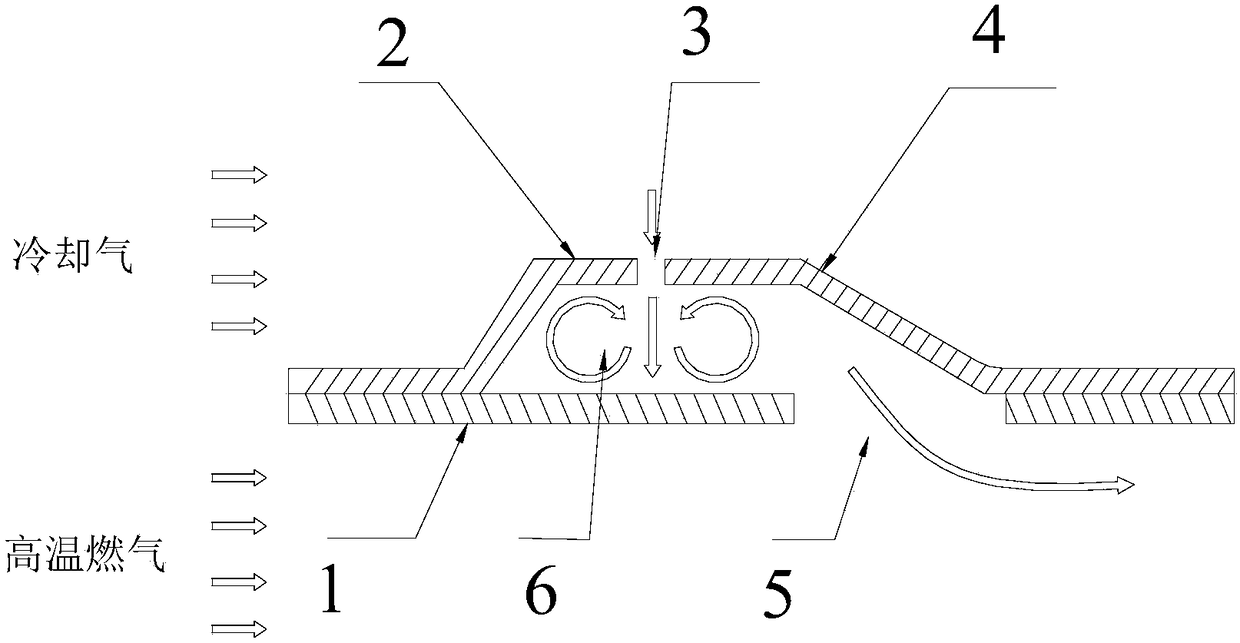

[0020] For an embodiment of the invention see Figure 4-5 .

[0021] In the present embodiment, the height of the trapezoidal gas collection chamber (6) is h=3mm, the left inner angle α=45°, the right outer angle β=150°, the impact hole (3) diameter d=0.8mm, and the air film hole (5) Side length w=2.5mm. Under the condition that the aerodynamic structure parameters allow, a larger β angle should be selected as much as possible to ensure that the cooling airflow can flow against the wall after flowing out of the air film hole (5).

[0022] Figure 5 As a specific embodiment of the present invention, the cooling structure of the present invention is arranged on the heat shield of the converging section (12), the heat shield of the expanding section (10) and the heat shield of the side wall (11).

[0023] The cooling air of the binary nozzle is introduced from the cooling passage formed by the round-turned square section (7) and the round-turned square section heat shield (13)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com