Stelmor air-cooled line controlled cooling process for improving structure and performance of spring steel 55SiCrA coil rod

A Steyrmore air-cooled, spring steel technology, used in manufacturing tools, metal processing equipment, workpiece cooling devices, etc., can solve the problem that the strength and hardness cannot meet the requirements, and it is prone to martensite and bainite, soxhlet. The problem of limited sintering rate, etc., can increase the sorbite rate, reduce the existence of retained austenite, and avoid the increase of hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

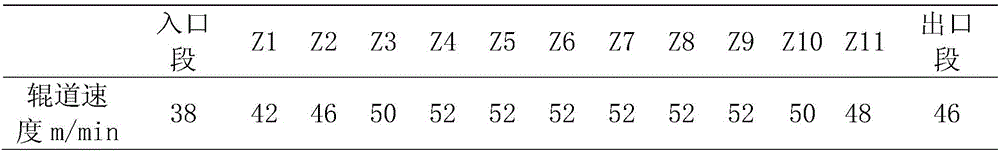

[0015] The rolling mill produces φ16mm55SiCrA, the rolling temperature is 990°C, the temperature of the sizing mill is 820°C, and the spinning temperature is 790°C. The first 10 insulation covers on the Stelmore air-cooled line are opened, the last two insulation covers are opened, and the middle insulation covers are closed. Control the air volume of 1 to 3 fans at 85%, 4 to 5 at 30%, 6 to 7 at 50%, and the rest of the fans off. The speed of the roller table is shown in Table 1 below.

[0016] Table 1 Corresponding roller table speed for each insulation cover of φ16mm55SiCrA Stelmo air-cooled line

[0017]

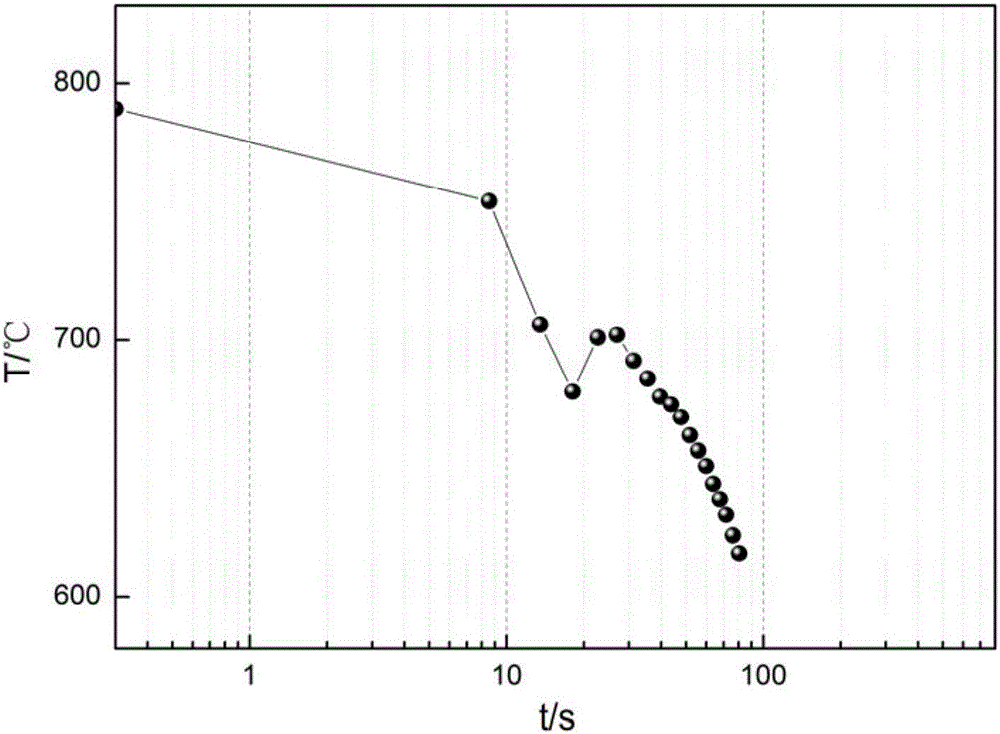

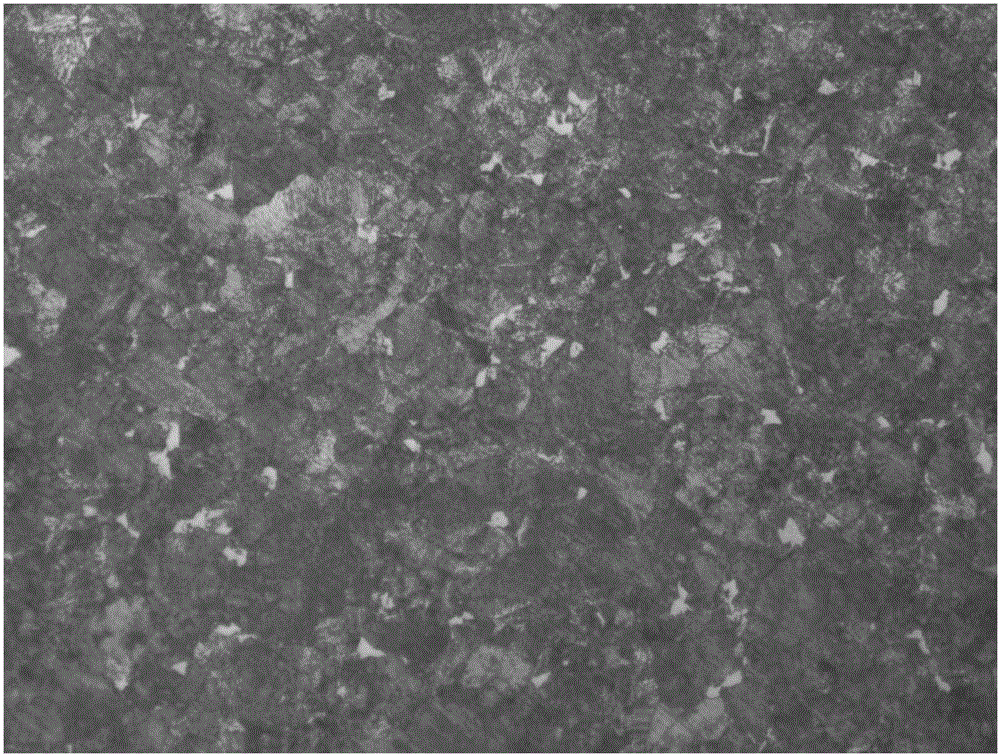

[0018] The corresponding relationship between the end temperature of each fan and time measured on site is as follows: figure 1 As shown, under the air cooling of the first three fans, the cooling speed of the wire rod is about 8°C / s, the lowest temperature at the third blower is 680°C, the return temperature of the fourth and fifth fans is 25°C, and the temperature o...

Embodiment 2

[0021] The steel rolling mill produces φ16mm55SiCrA, the rolling start temperature is 980°C, the temperature of the sizing mill is 810°C, and the spinning temperature is 800°C. The first 10 insulation covers on the Stelmore air-cooled line are opened, the last two insulation covers are opened, and the middle insulation covers are closed. The air volume of 1 to 3 fans is 85%, 4 to 5 is 28%, 6 to 7 is 50%, and the rest of the fans are turned off. The speed of the roller table is shown in Table 1.

[0022] On-site measurements show that the cooling speed of the wire rod is about 6°C / s under the air cooling of the first two fans, the lowest temperature at the third fan is 700°C, the return temperature of the fourth and fifth fans is 20°C, and the temperature of the sixth fan is 20°C. The cooling rate from the fan to the closing of the heat preservation cover is about 1.5°C / s, the temperature entering the heat preservation cover is 680°C, the cooling rate inside the heat preservati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com