A control method for segregation and mesh carbon of 86-grade high-strength cord steel wire rod

A control method and steel wire rod technology, applied in the field of cord steel production, can solve the problems of long process route, lack of competitiveness, high cost, etc., achieve the effect of shallow decarburization layer, enhance competitiveness, reduce cycle time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

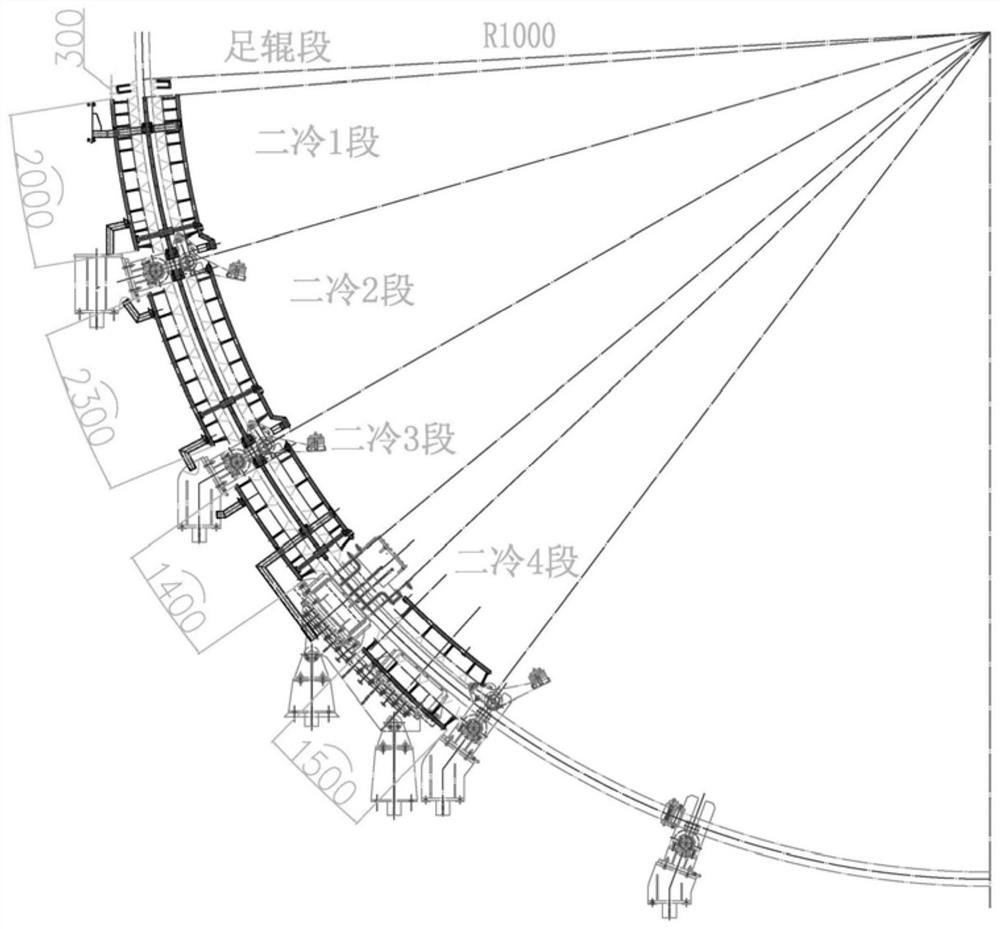

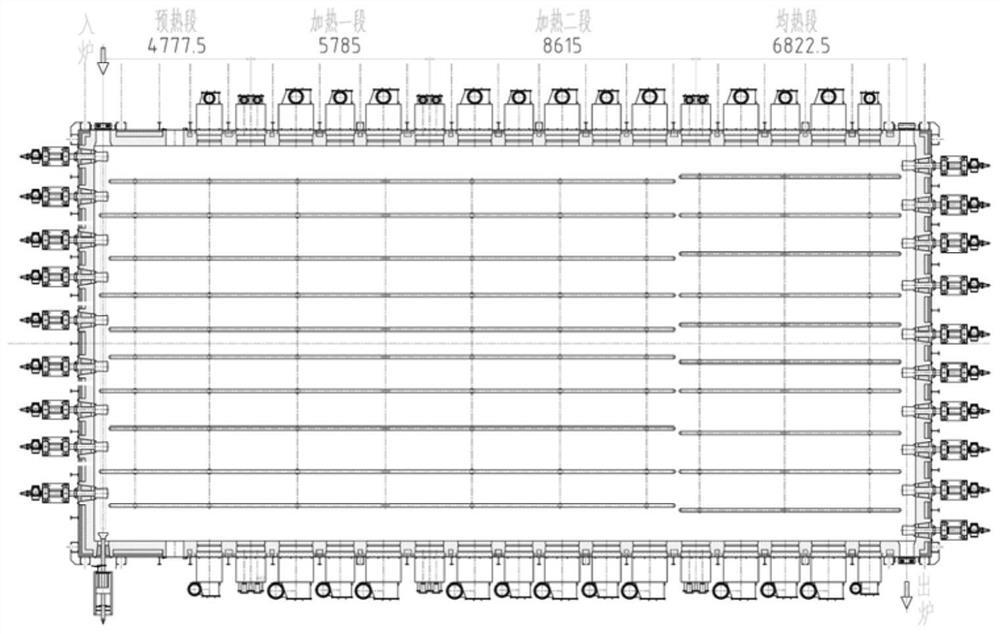

[0027] The control method of segregation and net carbon of grade 86 high-strength cord steel wire rod includes processes: KR molten iron pre-desulfurization process→BOF converter smelting process→LF furnace refining process→continuous casting CC process→slab surface treatment process→slab heating process→ Controlled rolling process → controlled cooling process.

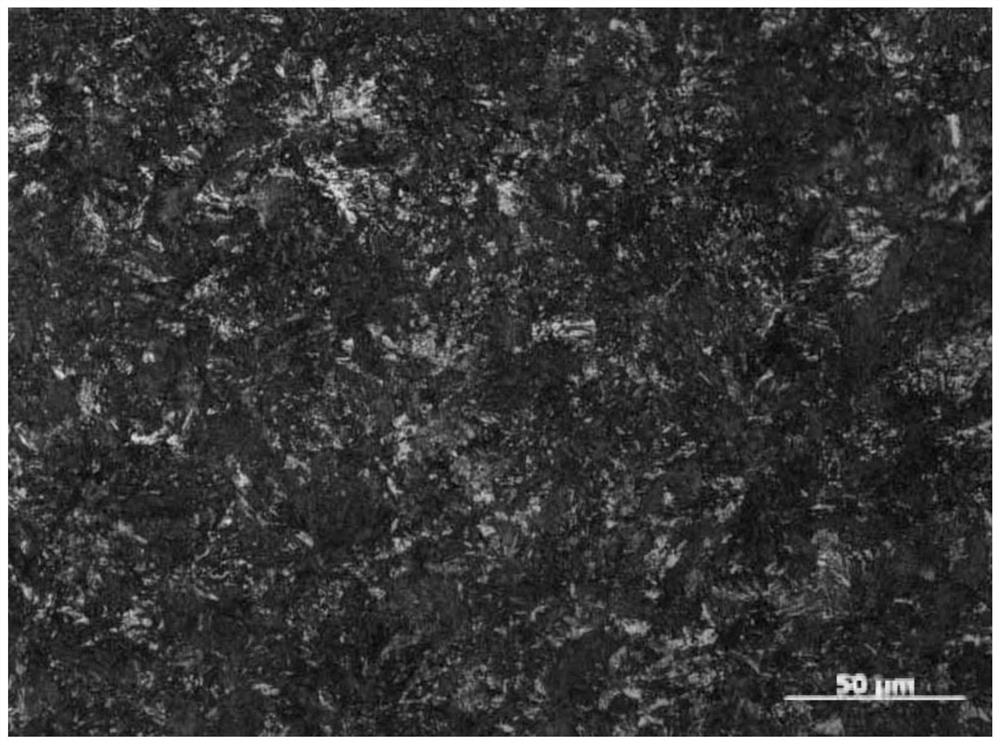

[0028] Smelting product composition control: C: 0.85-0.90%, Si: 0.15-0.35%, Mn: 0.40-0.60%, P: ≤0.010%, S: ≤0.010%, Cr: ≤0.010%, Al: ≤0.005%, The rest is Fe and unavoidable impurity elements.

[0029] The hot metal is pretreated by KR hot metal, the S content is ≤0.003%, and the special clean steel scrap for the cord is used (the main components are Fe, C, Si, Mn and other unavoidable trace elements, and the total amount accounts for 10% of the total metal loading. %~30%). In addition, the converter BOF smelting adopts the "double slag" process, that is, at the end of the silicomanganese oxidation period of 4 to 5 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com