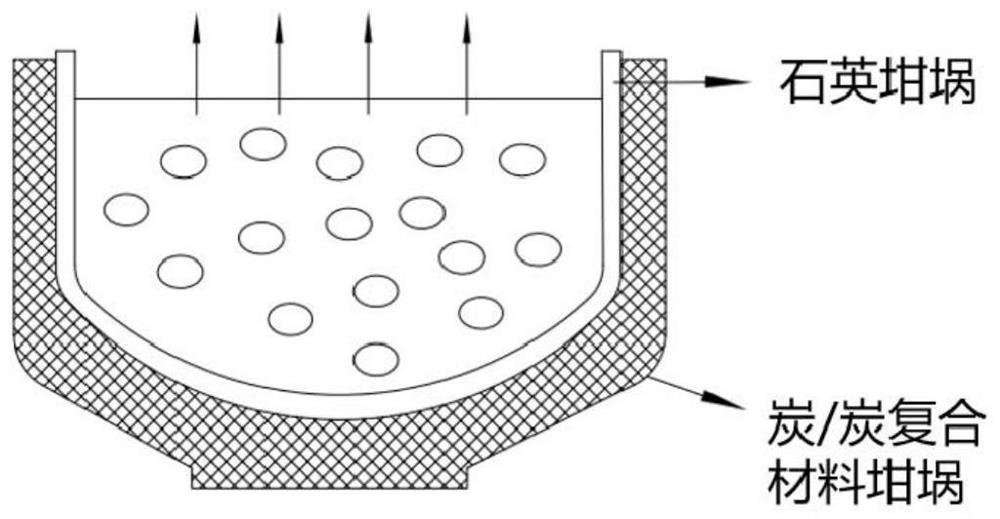

High-density C/C-SiC composite material crucible containing alpha-Al2O3 coating

A composite material and high-density technology, applied in the field of thermal field components for single crystal silicon drawing furnaces, can solve the problems of inability to replace quartz, complicated preparation process, high manufacturing cost, etc., achieve shortened preparation cycle, high bonding strength, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

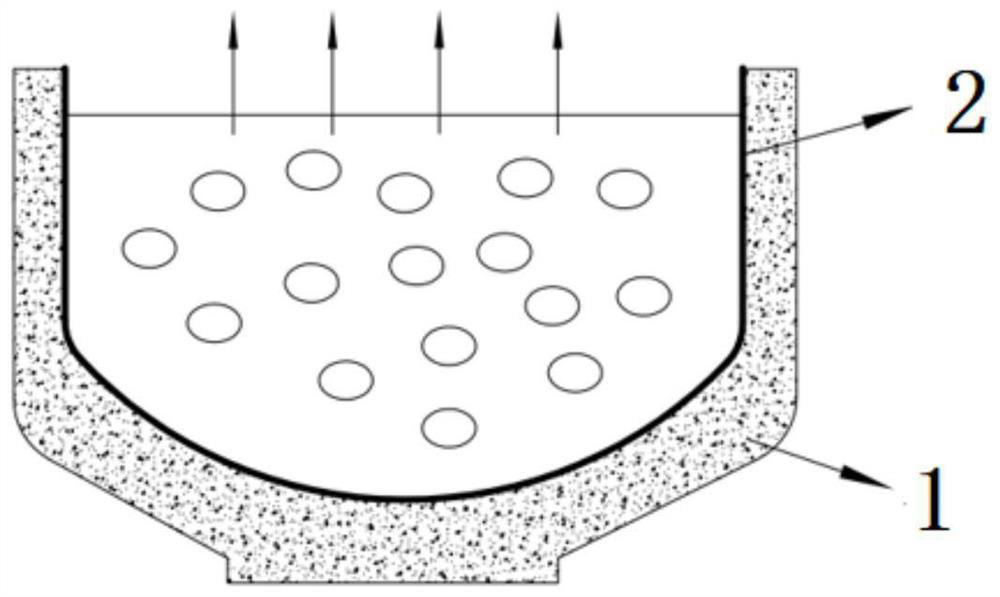

[0031] A containing α-Al 2 o 3 A coated high-density C / C-SiC composite material crucible, the composite material crucible includes a crucible body 1 and α-Al coated on the inner surface of the crucible body 1 2 o 3 Coat 2, such as figure 2 Shown; The concrete preparation steps of described composite material crucible are as follows:

[0032] (1) The bulk density is 0.3g / cm3 prepared in the form of axial carbon fiber non-weft cloth / carbon mesh tire composite layup and circumferential carbon fiber continuous winding layer alternately stacked and needle punched 3carbon fiber prefabricated body;

[0033] Among them, the carbon fiber non-weft cloth / carbon mesh tire composite layer contains a layer of carbon fiber non-weft cloth and a layer of carbon mesh tire, and the carbon fiber non-weft cloth / carbon mesh tire composite layer and a layer of carbon fiber continuous winding layer Alternate superposition;

[0034] (2) First, the carbon fiber preform is subjected to pyrolytic ...

Embodiment 2

[0042] A containing α-Al 2 o 3 A coated high-density C / C-SiC composite material crucible, the composite material crucible includes a crucible body 1 and α-Al coated on the inner surface of the crucible body 1 2 o 3 Coat 2, such as figure 2 Shown; The concrete preparation steps of described composite material crucible are as follows:

[0043] (1) The bulk density is 0.4g / cm3 prepared in the form of axial carbon fiber non-weft cloth / carbon mesh tire composite layup and circumferential carbon fiber continuous winding layer alternately stacked and needled 3 carbon fiber prefabricated body;

[0044] Among them, the carbon fiber non-weft cloth / carbon mesh tire composite layer contains a layer of carbon fiber non-weft cloth and a layer of carbon mesh tire, and the carbon fiber non-weft cloth / carbon mesh tire composite layer and a layer of carbon fiber continuous winding layer Alternate superposition;

[0045] (2) First, the carbon fiber preform is subjected to pyrolytic carbon...

Embodiment 3

[0053] A containing α-Al 2 o 3 A coated high-density C / C-SiC composite material crucible, the composite material crucible includes a crucible body 1 and α-Al coated on the inner surface of the crucible body 1 2 o 3 Coat 2, such as figure 2 Shown; The concrete preparation steps of described composite material crucible are as follows:

[0054] (1) The bulk density is 0.5g / cm3 prepared in the form of axial carbon fiber non-weft cloth / carbon mesh tire composite layup and circumferential carbon fiber continuous winding layer alternately stacked and needle punched 3 carbon fiber prefabricated body;

[0055] Among them, the carbon fiber non-weft cloth / carbon mesh tire composite layer contains a layer of carbon fiber non-weft cloth and a layer of carbon mesh tire, and the carbon fiber non-weft cloth / carbon mesh tire composite layer and a layer of carbon fiber continuous winding layer Alternate superposition;

[0056] (2) First, the carbon fiber preform is subjected to pyrolytic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com