Control method for improving heat treatment steel wire metallographic structure

A technology of metallographic structure and control method, which is applied in the field of improving the control of the metallographic structure of heat-treated steel wire, can solve problems such as abnormal structure of steel wire, and achieve the effects of increasing the number of times, accelerating the cooling rate, and improving the sorbite rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

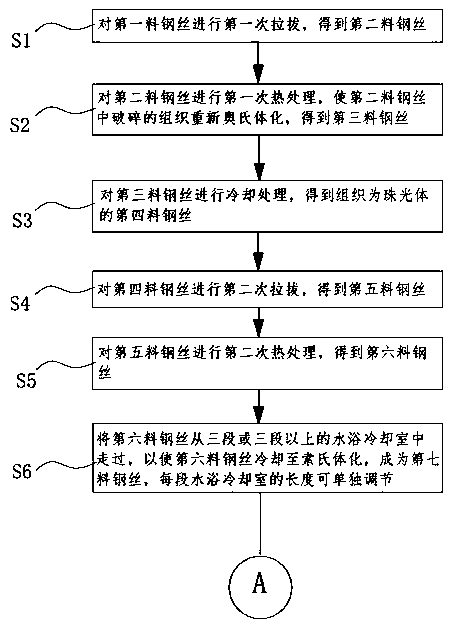

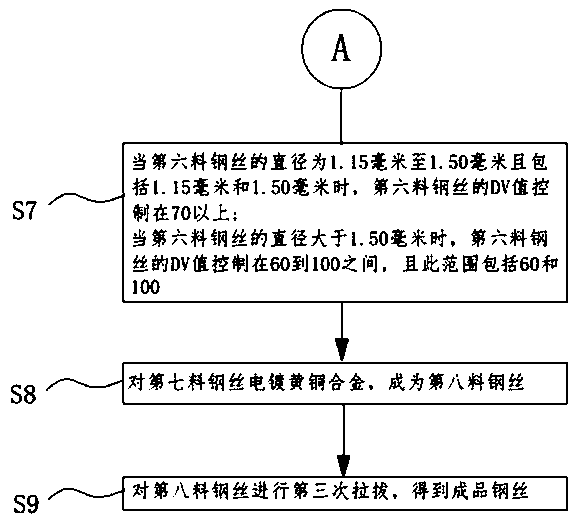

[0022] Please refer to Figure 1 to Figure 2 , Figure 1 to Figure 2 It is a flowchart of a control method for improving the metallographic structure of a heat-treated steel wire according to an embodiment of the present invention. A control method for improving the metallographic structure of heat-treated steel wire according to the present invention comprises the following steps:

[0023] S1. The first steel wire is drawn for the first time to obtain the second steel wire. Preferably, the first drawing is rough drawn by dry drawing. In practical application, the diameter of the first material steel wire can be 5.5 mm, and the diameter of the second material steel wire obtained through the first drawing can be 2.8 mm.

[0024] S2. Carrying out the first heat treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com