A Stelmer Cooling Method for Improving the Sorbitization Rate of 82b Steel Wire Rod

A sorbitizing and cooling method technology, which is applied in workpiece cooling devices, manufacturing tools, metal rolling, etc., can solve problems such as the gap of sorbitization rate, improve the sorbitization rate, and improve the comprehensive mechanical properties. , good economy and promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details.

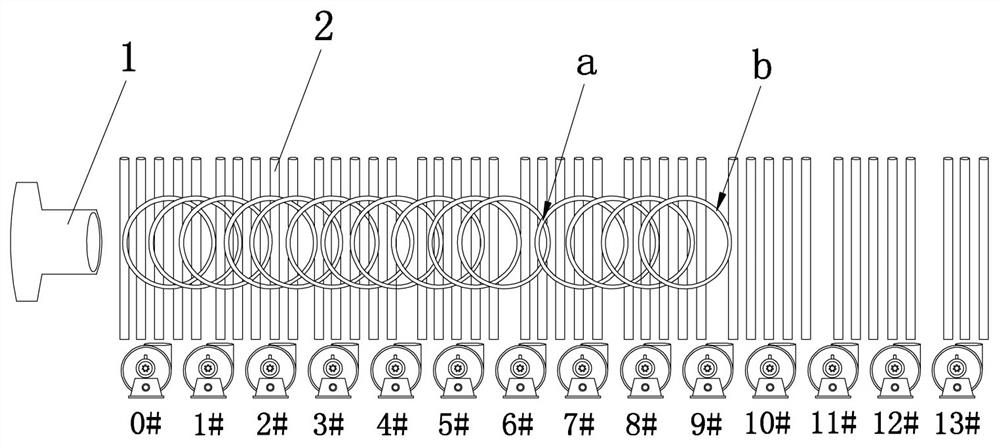

[0021] refer to figure 1 , a Stelmore cooling method to increase the sorbitization rate of 82B steel wire rod, mainly through comprehensive consideration of the factors such as the spinning temperature, the air volume of each fan, the number of fans turned on, the room temperature, the speed of the roller table, and the specification of the wire rod. , optimize the design of the cooling process, and use precise coordinated control methods to ensure that the wire rod is first cooled rapidly to the sorbite phase transformation zone on the Stellm air cooling line, and then slowly cooled to the end of the phase transformation, and as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com