Strength and color uniform transition dentistry zirconium oxide repairing material and preparing method thereof

A technology for repairing materials and uniform color, applied in dental preparations, dentistry, dental prosthesis, etc., can solve problems such as jaw and tooth damage, achieve high neck strength and reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

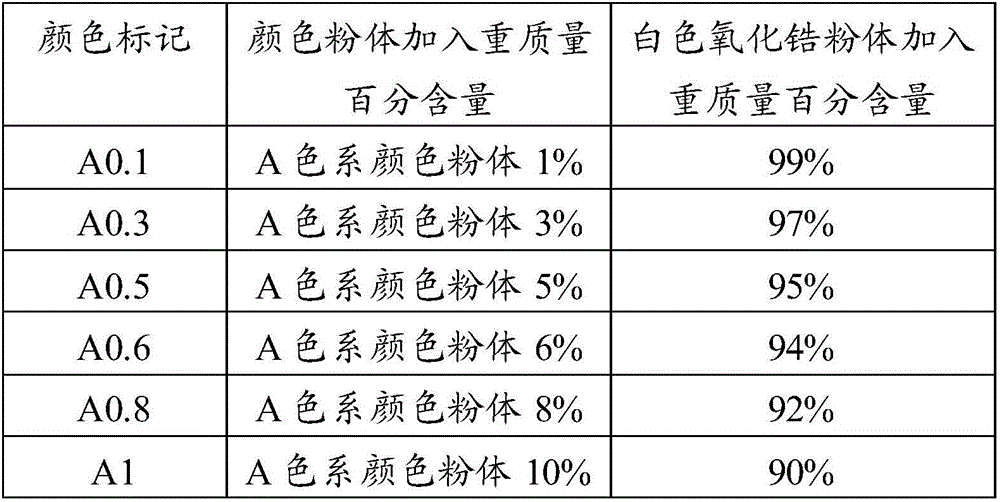

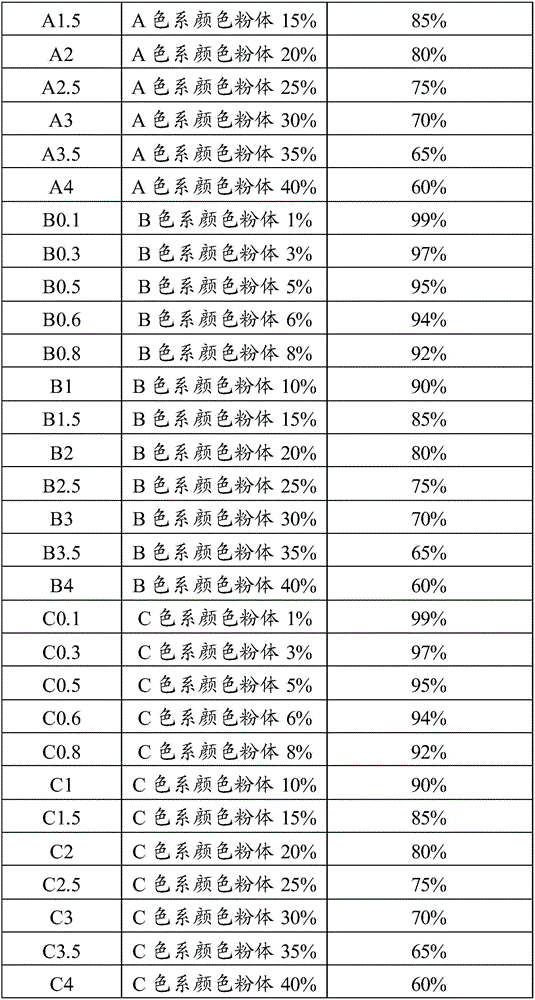

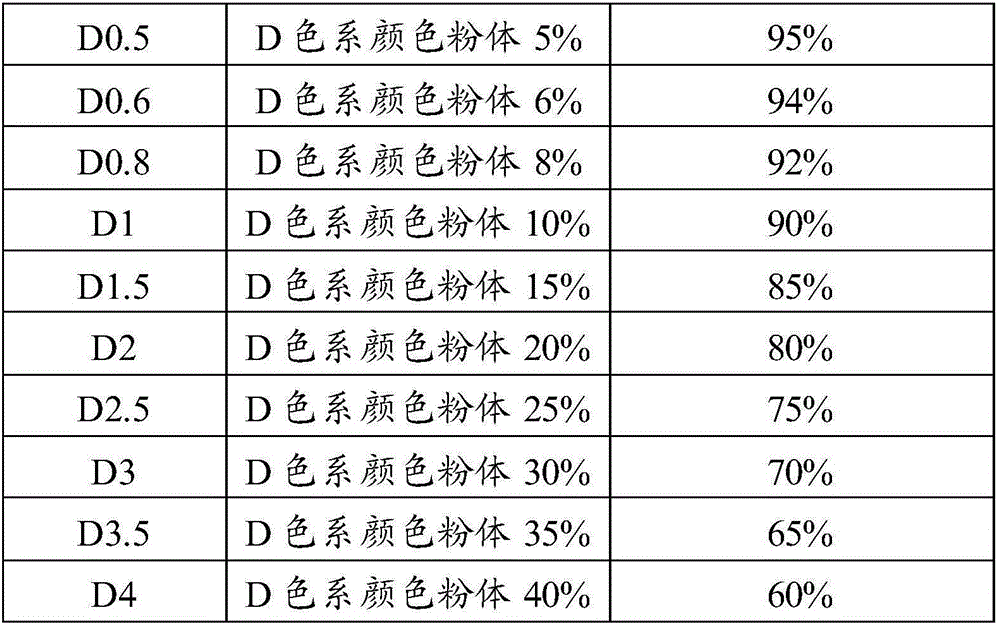

[0019] The invention provides a preparation method of dental zirconia repair material with uniform transition in strength and color, comprising the following steps:

[0020] (1) Pour the colored zirconia powder into the dry pressing mold in the order of the intensity of each layer from high to low and the color from dark to light;

[0021] (2) Cold isostatic pressing is carried out after dry pressing;

[0022] (3) pre-sintering after cold isostatic pressing to obtain a blank;

[0023] (4) CAD / CAM (Computer Aided Design / Computer Aided Manufacturing) is used to cut the raw embryo, and finally, final sintering is performed to obtain a dental zirconia repair material.

[0024] The invention can not only meet the clinical requirements for the color of the zirconia restoration, but also the strength from the neck to the incisal end is gradually reduced, which can greatly reduce the damage to the adjacent teeth and the opposite teeth during the chewing movement, so that the zirconia...

Embodiment 1

[0046] A method for preparing a dental zirconia restorative material with uniform strength and color transition, comprising the following steps:

[0047] (1) Pour the colored zirconia powder into the dry pressing mold in the order of strength from high to low and color from dark to light for each layer, and dry press molding. The dry pressing molding pressure is 10MPa, and the pressing time is 15s;

[0048] (2) After dry pressing, cold isostatic pressing is carried out, the pressure of cold isostatic pressing is 180MPa, and the pressure is maintained for 150s;

[0049] (3) Pre-sintering is carried out after cold isostatic pressing to obtain a plain embryo. The pre-sintering temperature is 1000°C and the time is 150 minutes;

[0050] (4) CAD / CAM cutting is used for the plain blank, and final sintering is carried out in the final process to obtain dental zirconia restorative materials. The final sintering temperature is 1530° C. and the time is 120 minutes.

Embodiment 2

[0052] A method for preparing a dental zirconia restorative material with uniform strength and color transition, comprising the following steps:

[0053] (1) Pour the colored zirconia powder into the dry pressing mold in order of strength from high to low and color from dark to light for each layer, and dry press molding. The dry pressing molding pressure is 15MPa, and the pressing time is 5s;

[0054] (2) After dry pressing, cold isostatic pressing is carried out, the pressure of cold isostatic pressing is 270MPa, and the pressure is maintained for 60s;

[0055] (3) Pre-sintering is carried out after cold isostatic pressing to obtain a plain embryo. The pre-sintering temperature is 800°C and the time is 180 minutes;

[0056] (4) CAD / CAM cutting is used for the plain blank, and final sintering is carried out in the final process to obtain dental zirconia restorative materials. The final sintering temperature is 1450° C. and the time is 60 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com