Backlight module and display device

A backlight module and display device technology, applied in the direction of identification devices, instruments, etc., can solve problems such as unfavorable, high cost of reflective sheets, and reduce costs, and achieve the effects of uniform light transition, saving production costs, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

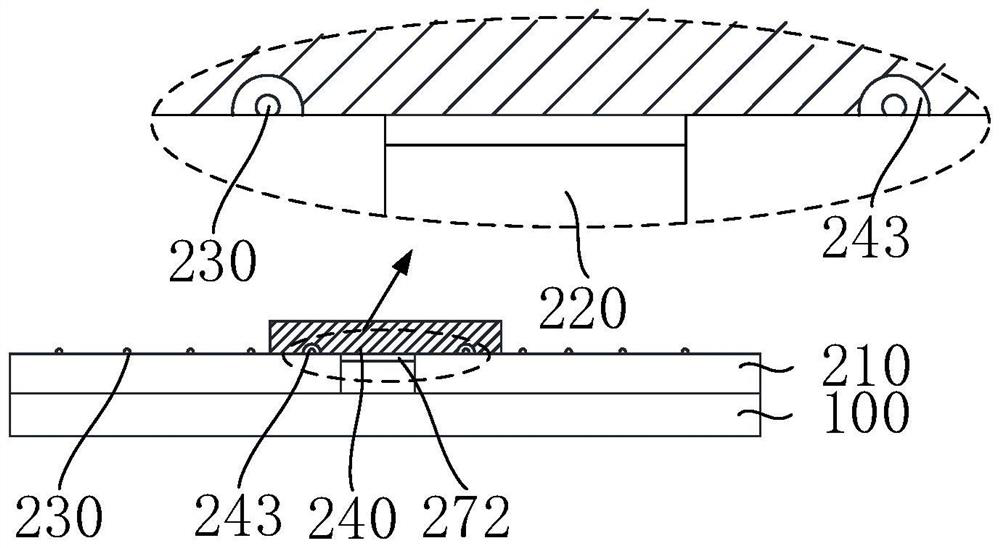

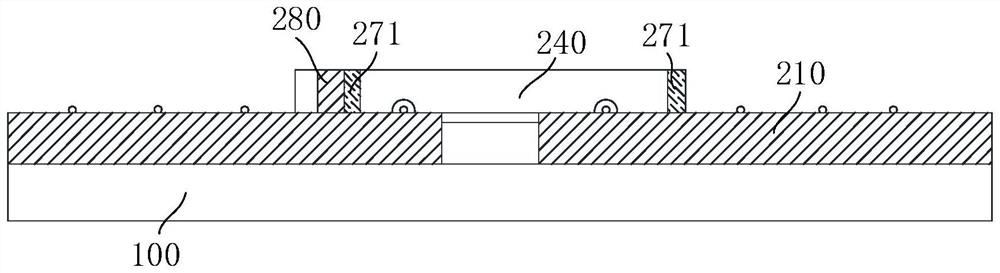

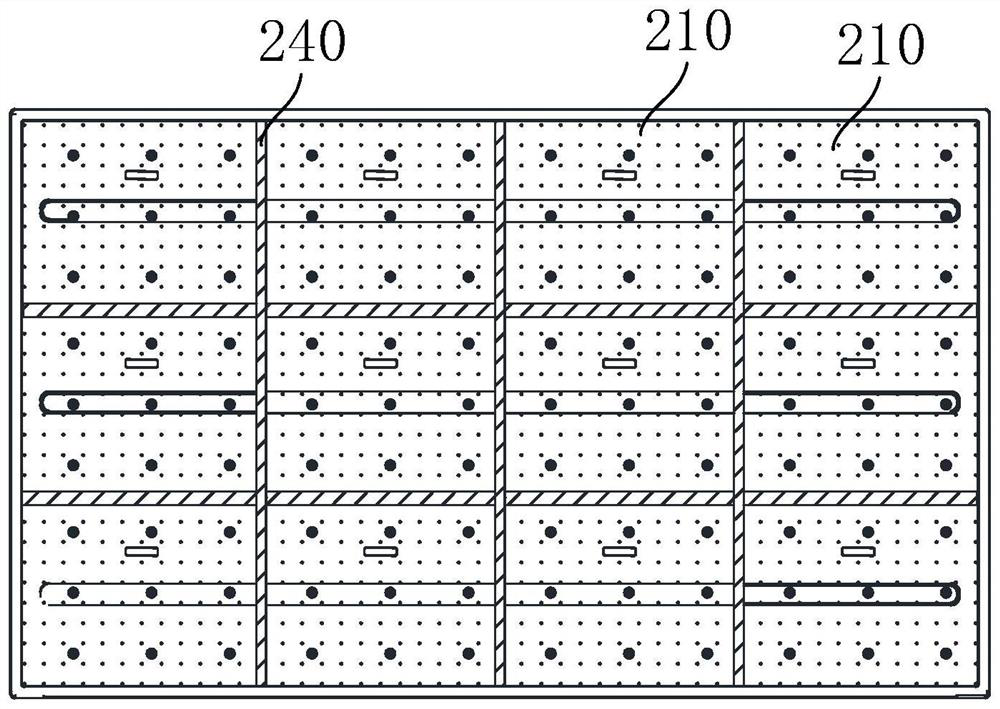

[0029] figure 1 It is a cross-sectional schematic diagram of a diffuser plate installed in the gap of a spliced lamp panel according to the first embodiment of the present application, as shown in figure 1 As shown, a backlight module 20 is disclosed. The backlight module includes a spliced lamp panel 200. The spliced lamp panel 200 is formed by splicing a plurality of lamp panels 210. There are gaps between adjacent lamp panels 210. 220, the backlight module 20 further includes a diffuser plate 240, the diffuser plate 240 is arranged at a position corresponding to the gap 220, and the diffuser plate 240 covers at least one row of light-emitting elements on at least one of the lamp panels 210 Diodes 230, at least part of the light emitting diodes 230 on the lamp board 210 are not covered.

[0030] Specifically, the diffuser plate 240 can only cover the light emitting diodes 230 on one lamp panel 210, and the diffuser plate 240 can also cover the light emitting diodes 23...

Embodiment 2

[0049] Figure 5 It is a cross-sectional schematic diagram of a diffuser plate installed in the gap of a spliced lamp panel according to the second embodiment of the present application, as shown in Figure 5 As shown, as the second embodiment of the present application, the difference from the first embodiment is that a diffuser plate 240 is disclosed, and the diffuser plate 240 includes a horizontal portion 244 and a vertical portion 245, and the horizontal portion 244 Set horizontally with the lamp panel 210, the vertical portion 245 is vertically set with the horizontal portion 244, and the vertical portion 245 is set at the gap 220, one end is connected with the horizontal portion 244, and the other end It is fixedly connected with the backplane 100 . And there is a safety distance between the vertical part 245 and the lamp panel 210, and the diffusion plate 240 is fixed on the back panel 100 through the vertical part 245, which can prevent the thermal expansion of the...

Embodiment 3

[0051] Figure 6 It is a cross-sectional schematic diagram of a diffuser plate installed in the gap of a spliced lamp panel according to the third embodiment of the present application, as shown in Figure 6 As shown, as the second embodiment of the present application, the difference from the first embodiment is that a lamp panel 210 is disclosed, and the lamp panel 210 includes a support part 212 of a main body part 211, and the support part 212 is set On the side of the main body part 211 close to the slit 220 , the diffuser plate 240 covers the slit 220 , the side of the diffuser plate 240 away from the slit 220 is the first surface, and the side of the diffuser plate 240 close to the slit 220 One side is the second surface, the first surface abuts against the support portion 212, the second surface is flush with the light-emitting surface of the lamp board 210, and the light-emitting diodes 230 covered by the diffusion plate 240 are located on the Between the supportin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com