Patents

Literature

38results about How to "Easy tooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

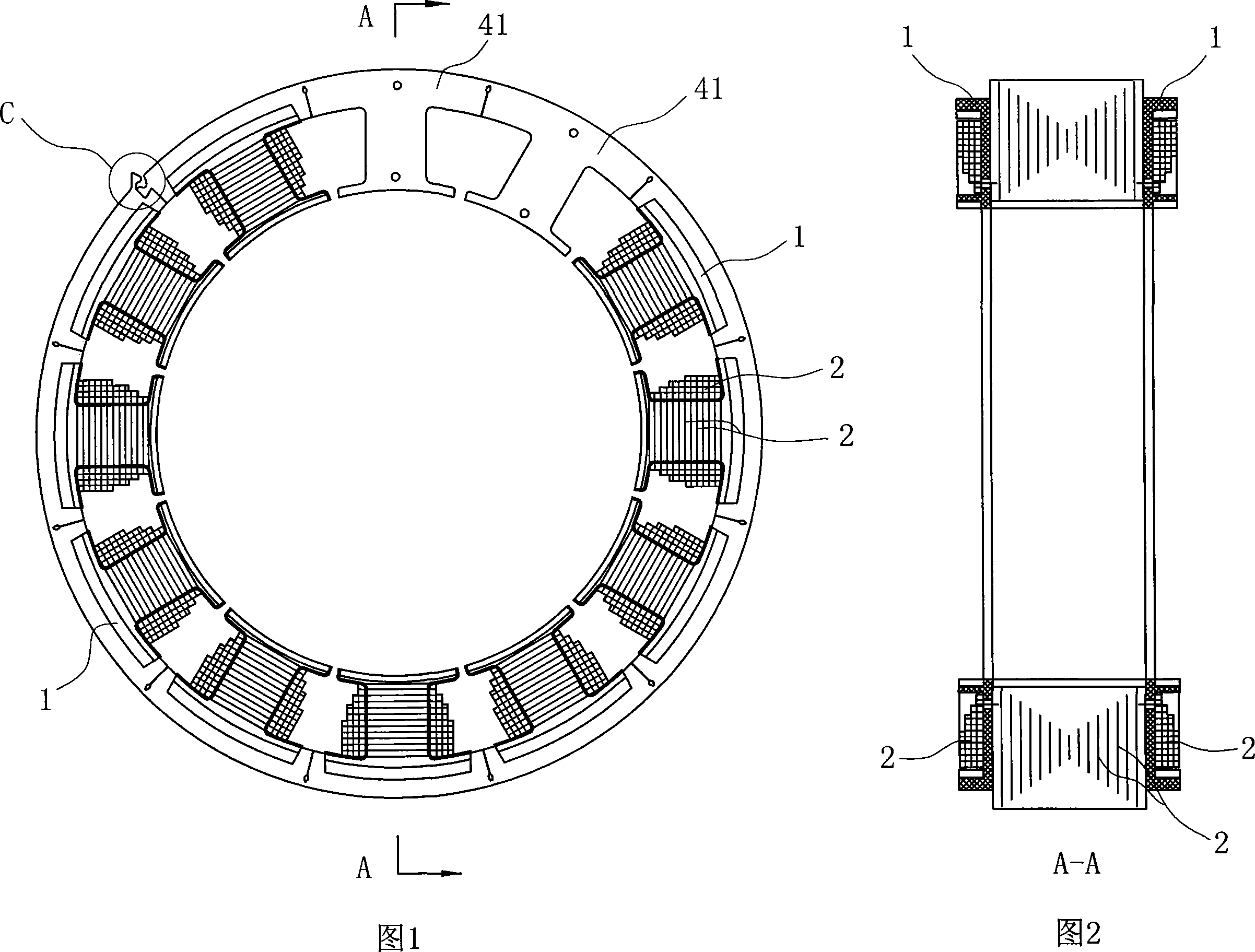

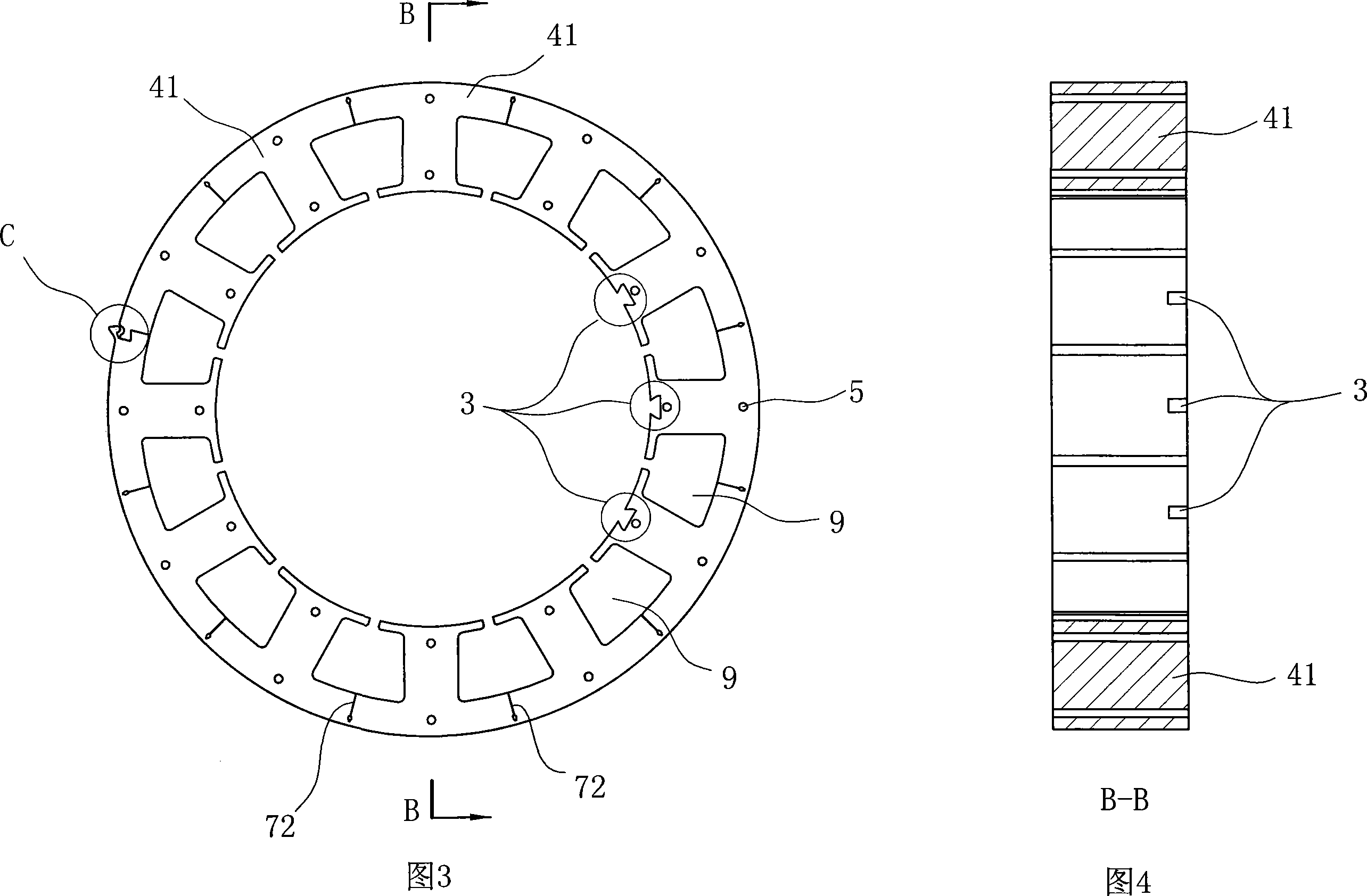

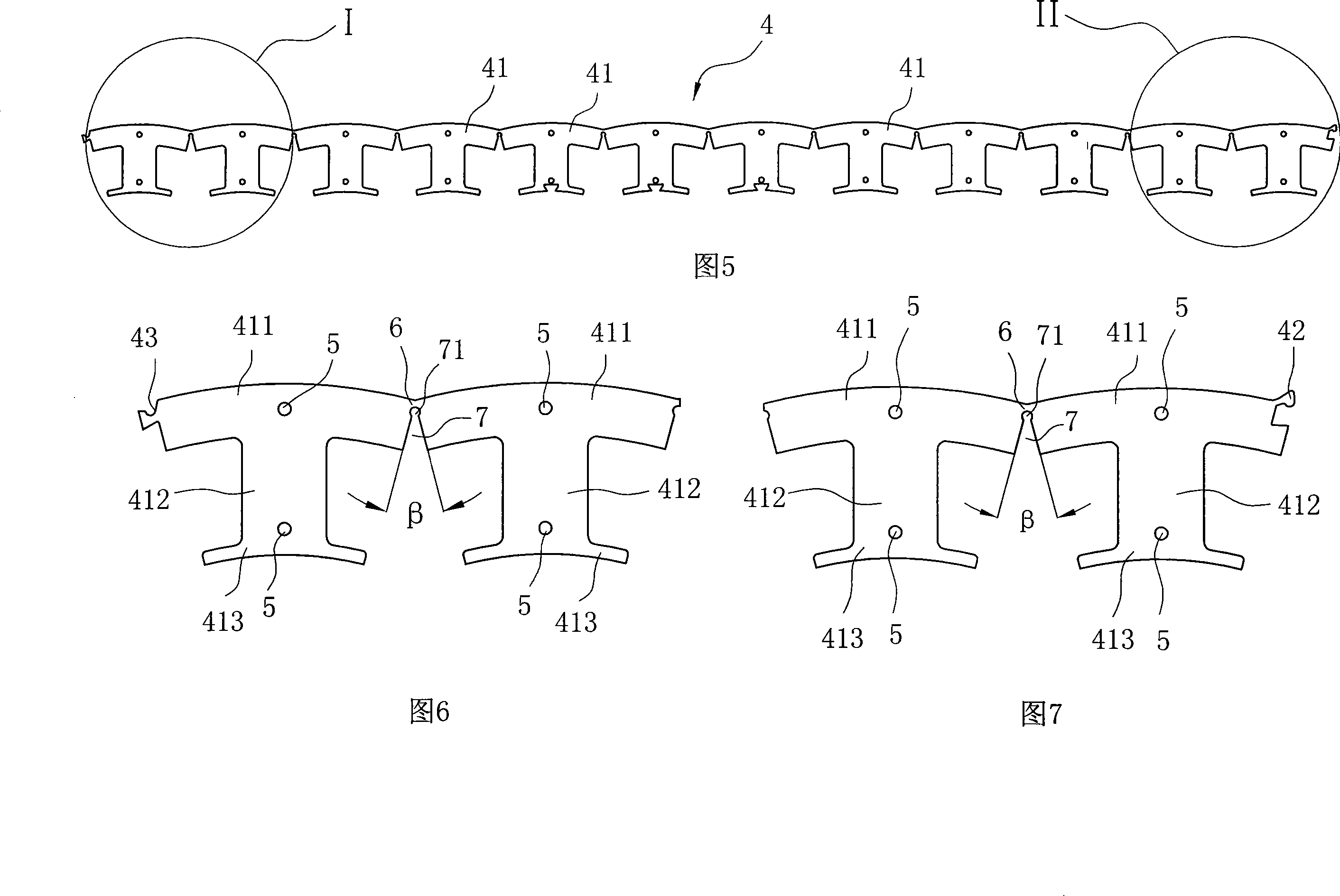

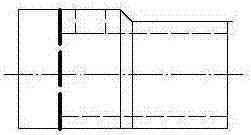

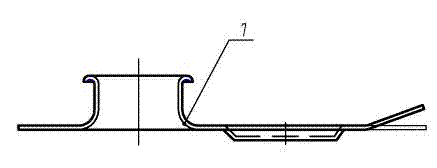

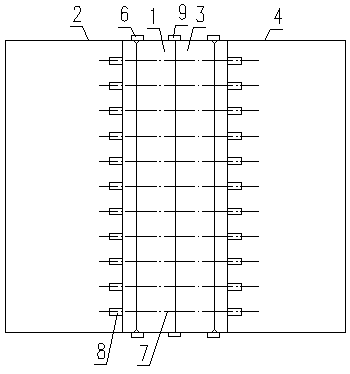

Inline type electric machine iron core and manufacturing method thereof

InactiveCN101227106AHigh material utilizationSave punching costsManufacturing stator/rotor bodiesMagnetic circuit shape/form/constructionEngineeringClosed angle

An inline motor iron core comprises a plurality of iron core punching sheets which are mutually pressed and stacked and take circular shape, which is characterized in that the iron core punching sheet is formed through coiling an inline strip-shaped punching sheet, each strip-shaped punching sheet comprises a plurality of arc unit tooth blocks which are mutually connected, two adjacent arc unit tooth blocks are connected with each other through a connecting portion which is bent under the exogenic action and is arranged on the outer rim direction, the lower portion of the connecting portion is opened, the opening is opened with an inner groove mouth on the closed angle portion, and head and tail arc unit tooth blocks on the same strip-shaped punching sheet are respectively provided with a buckle head and a clipping mouth which are mutually matched. The invention designs non-molding iron core punching sheets into inline strip-shaped punching sheets, which can greatly increase material utilization when in punching, an inner groove mouth is added on the connecting portion of the arc unit tooth block, which reduces stress between the adjacent arc unit tooth blocks which is caused by curling to shape, and ensures more stable and firmer attachment between the arc unit tooth sheets which are curled.

Owner:NINGBO POLARIS TECH

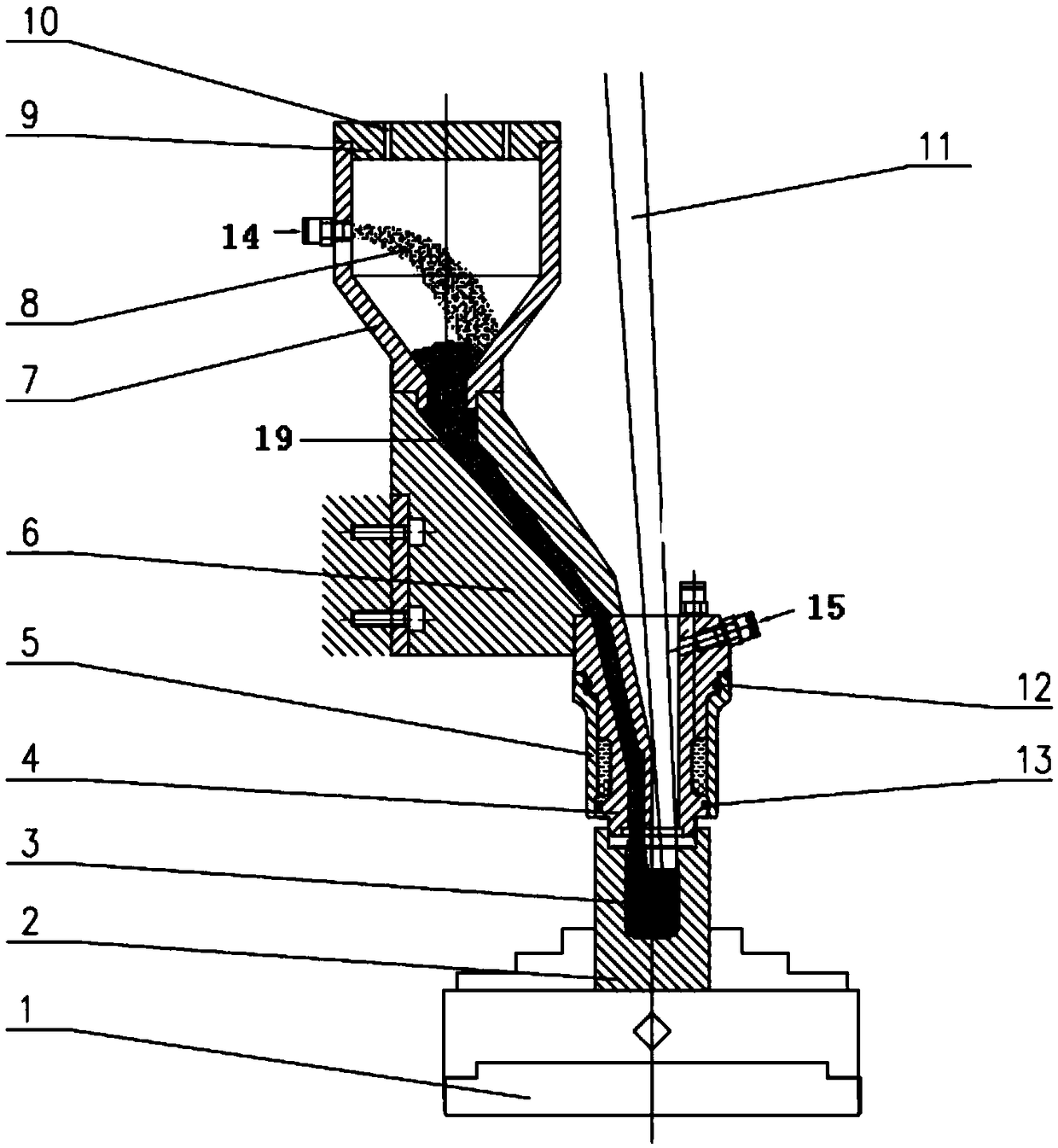

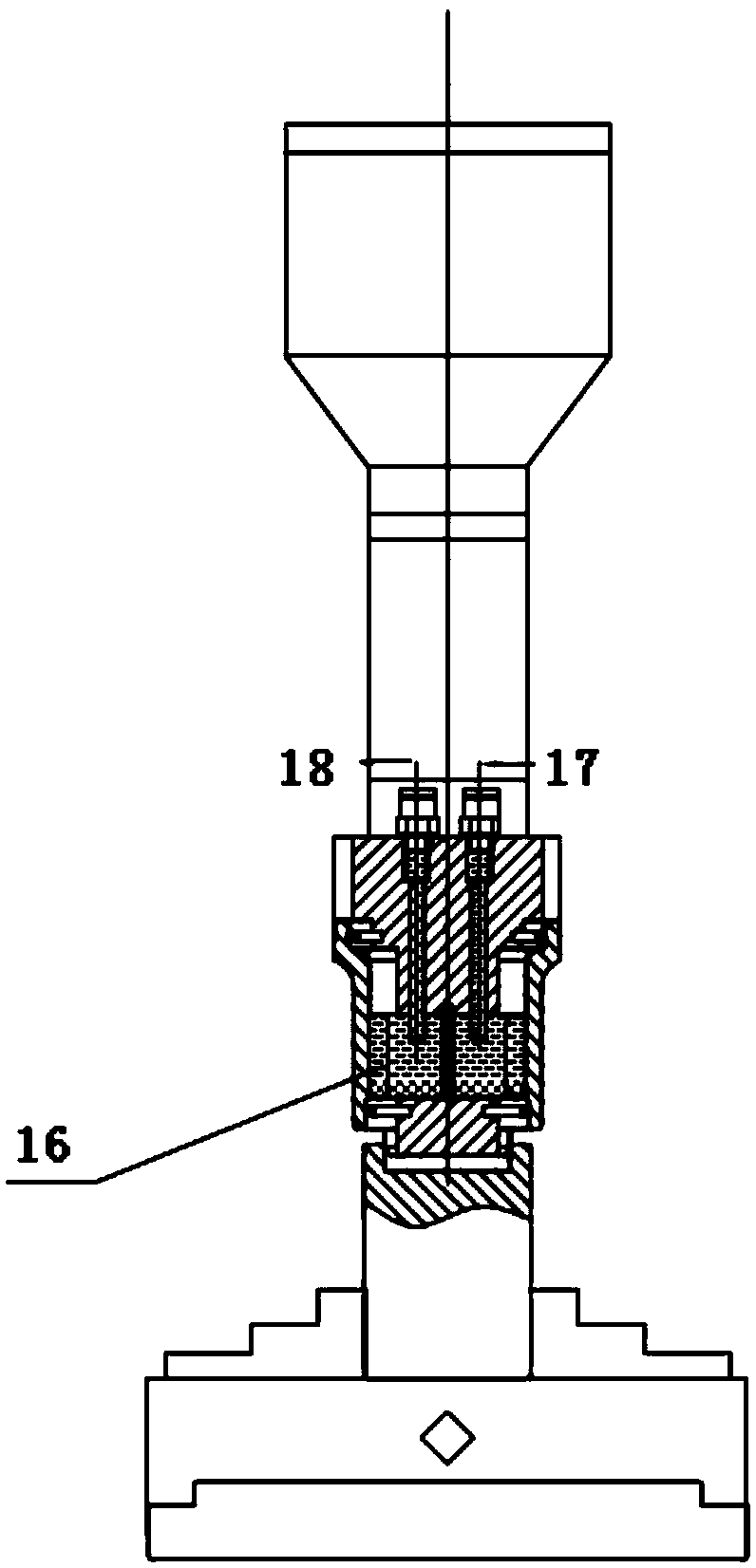

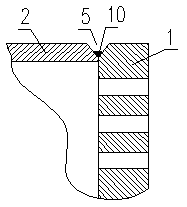

Powder conveying device suitable for small-specification in-hole laser bead welding

ActiveCN108817716AEasy toolingImprove processing efficiencyLaser beam welding apparatusSlagSmall caliber

The invention discloses a powder conveying device suitable for small-specification in-hole laser bead welding, and relates to the technical field of laser bead welding. The powder conveying device comprises a chuck, an internal hole sample, a bead welding layer, a powder conveying seat, an outer sleeve, a connecting seat, a powder conveying channel, a funnel and a funnel cover. The internal hole sample is fixed to the chuck, the powder conveying seat and the connecting seat are connected through the powder conveying channel, the powder conveying seat and the internal hole sample are connectedthrough a powder outlet in the lower end of the powder conveying seat, and the funnel is externally connected with an inlet channel. The powder conveying device suitable for small-specification in-hole laser bead welding of 15 mm or below, machining efficiency is high, and tool matching is easy and convenient; and a cladding layer is high in quality and has no slag inclusion, air holes or other defects, and the problem about inner wall bead welding of a small-caliber inner hole sample can be solved.

Owner:SHANGHAI JIAO TONG UNIV

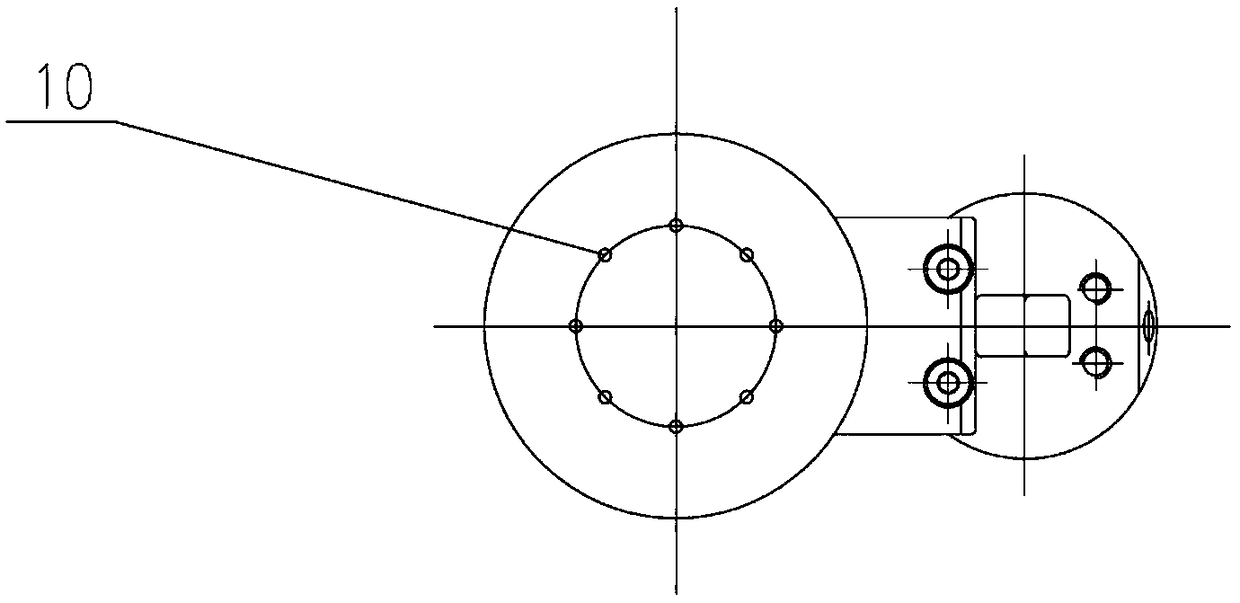

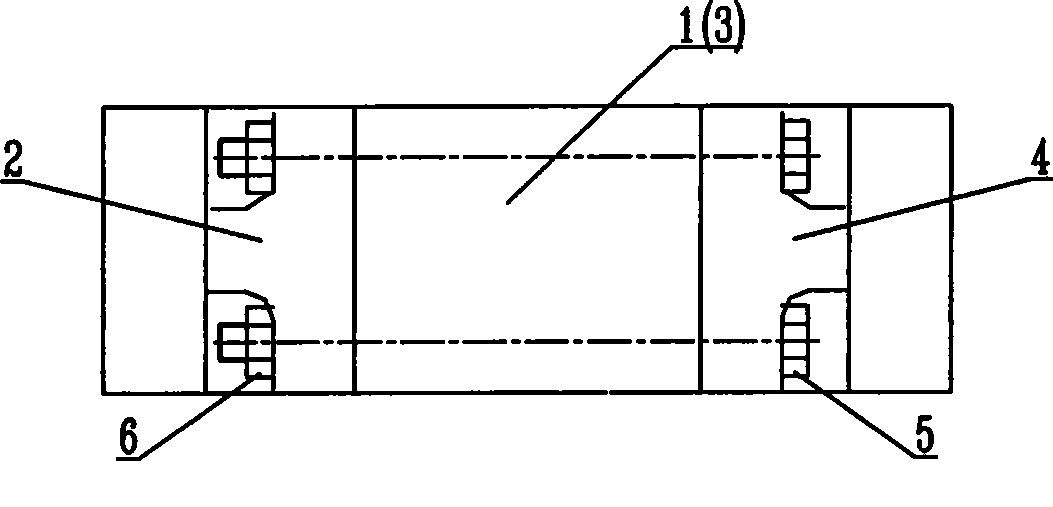

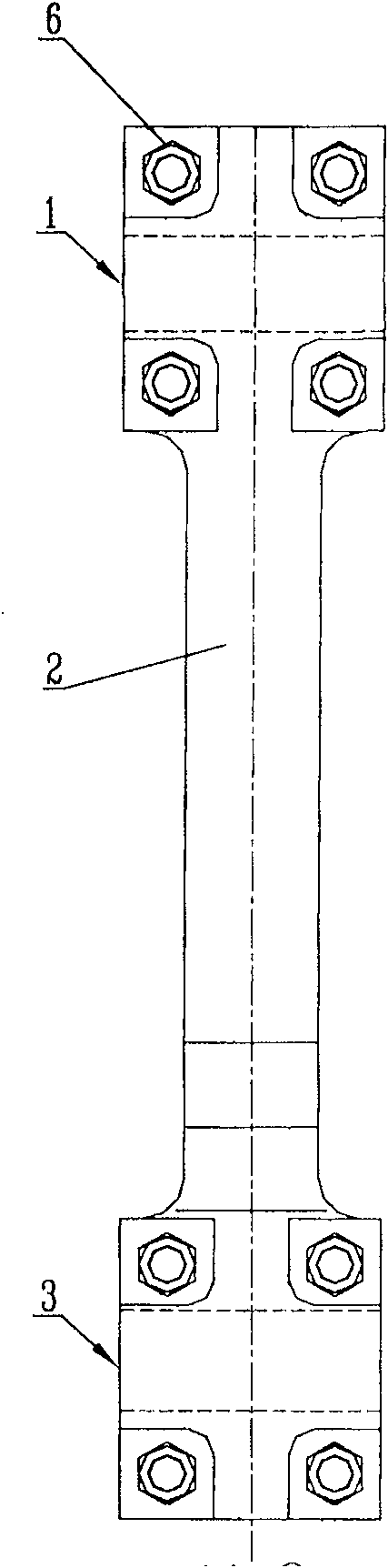

Flange machining tool

InactiveCN102990374ASolve the problems that occur when processing drilling holesCutting costsPositioning apparatusMetal-working holdersScrew threadMachine tool

The invention relates to a flange machining tool which comprises a bolt, a pressing block, a template, a workpiece and a nut, wherein the head part of the bolt is embedded in a transverse groove in the machining surface of a drilling machine, and a screw rod of the bolt is vertically arranged on the machining surface of the drilling machine, passes through a central through hole in the workpiece and is closely clung to the machining surface of the drilling machine; the size of the circular template is equal to that of the workpiece, the central part of the circular template is provided with a through hole, the diameter of the through hole is larger than that of the screw rod of the bolt, and the screw rod of the bolt passes through the through hole in the template, so that the position of the template is over against that of the workpiece; the central part of the trapezoidal pressing block is provided with a through hole, and the diameter of the through hole is larger than that of the screw rod of the bolt; and the pressing block is clamped above the template and the nut is fixed above the pressing block in a threaded connection manner. The flange machining tool disclosed by the invention has the advantages of greatly shortening the working hour, improving the working efficiency, greatly reducing the expenditure of personnel and supplies and motivating the production activeness of assembly personnel.

Owner:XUZHOU ZHIDIAN ELECTROMECHANICAL EQUIP

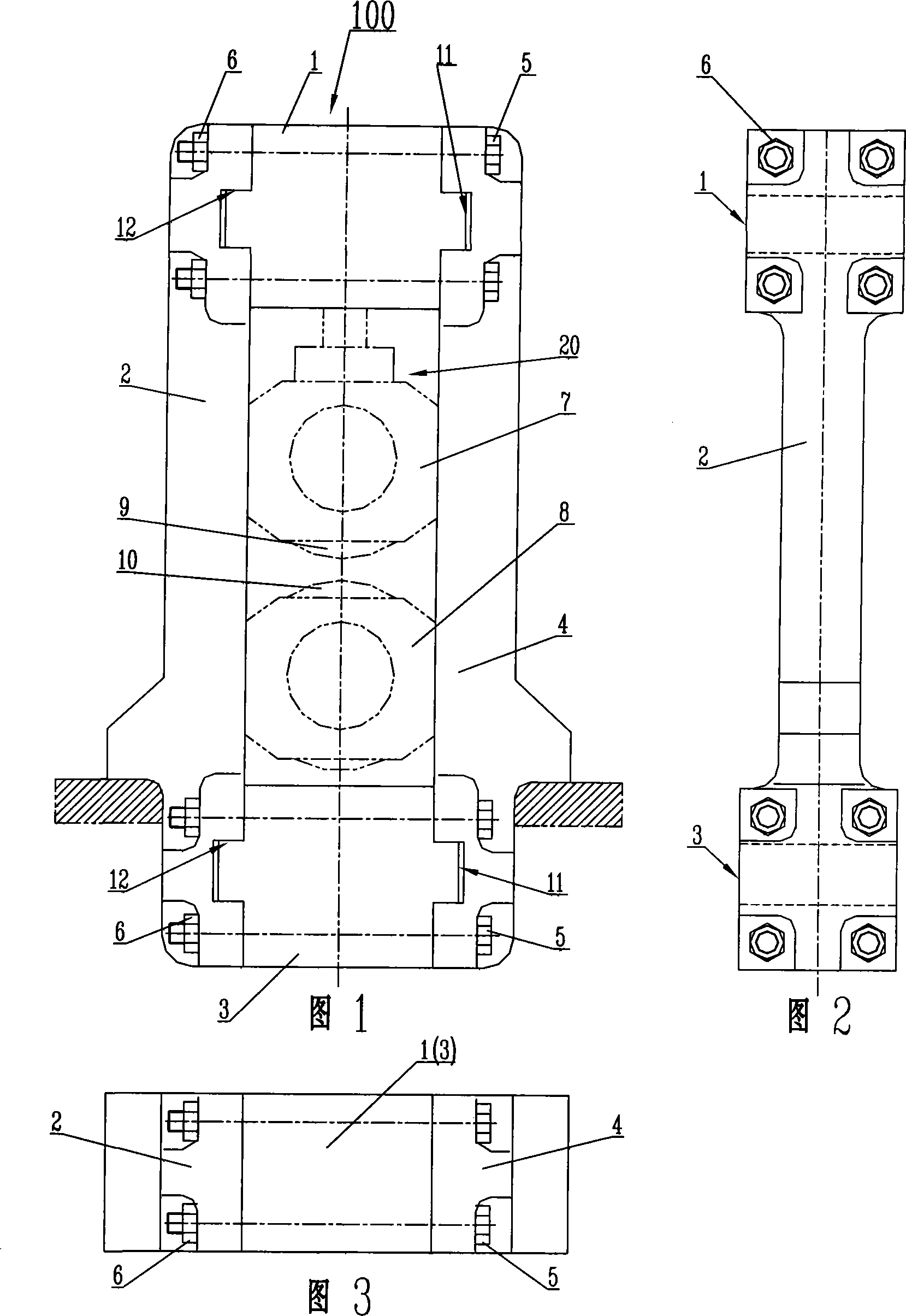

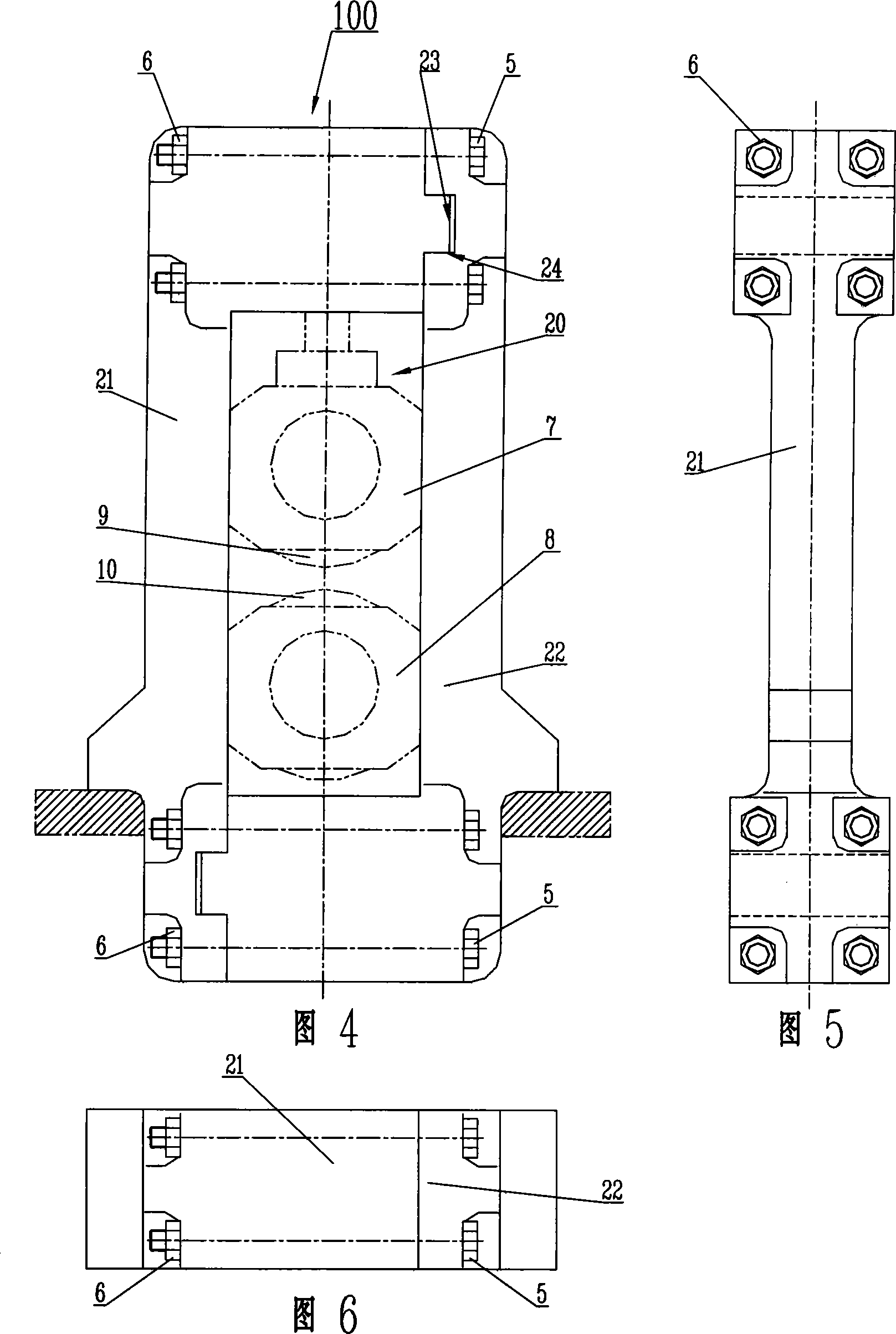

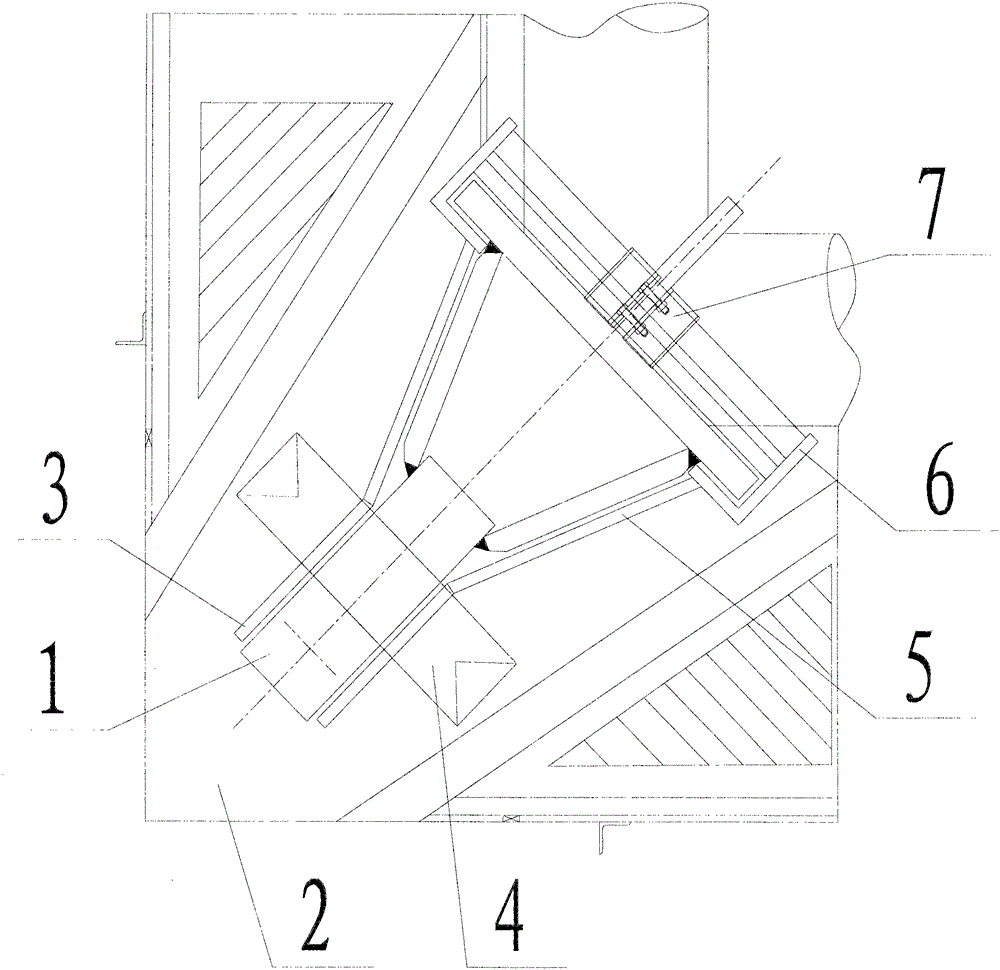

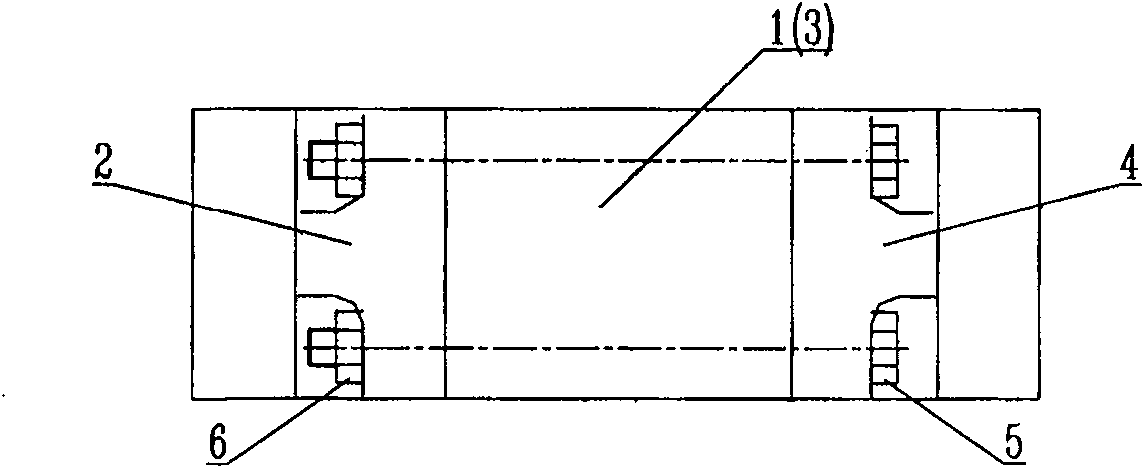

Combined memorial archway

ActiveCN101134206AAvoid difficultiesEasy to processMetal rolling stand detailsMetal rolling arrangementsThick plateEngineering

The present invention provides one kind of combined housing window comprising assembled parts. Changing the integral housing window into the combined housing window can facilitate the machining, tool set, transportation, installation, etc of large housing window for wide steel strip rolling production line and thick plate rolling production line with large mill roller and frame. The present invention makes it possible to machine large housing window with relatively small machines.

Owner:中重科技(天津)股份有限公司

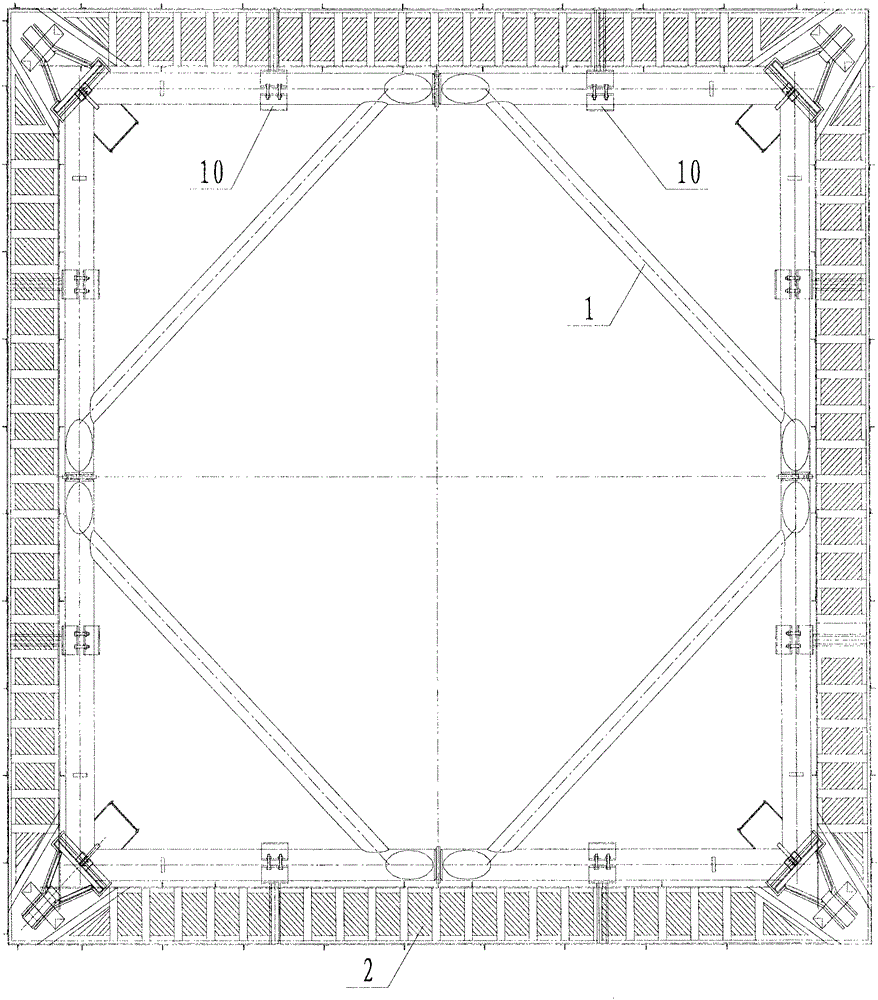

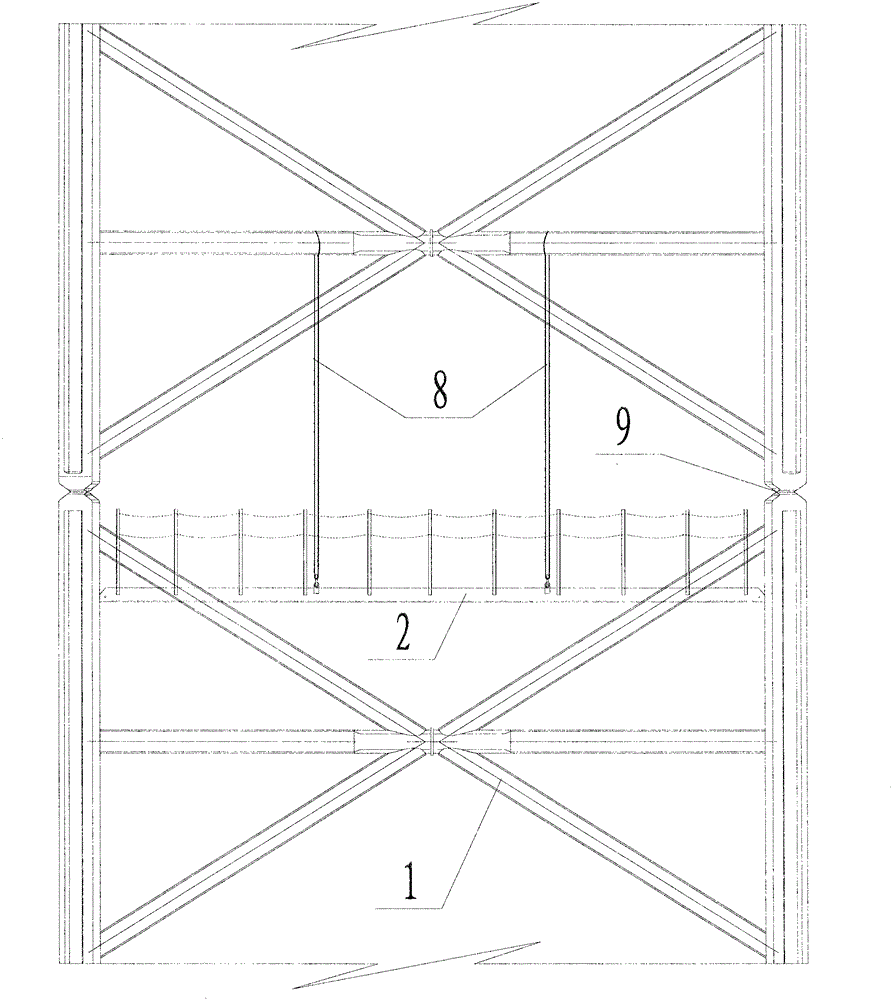

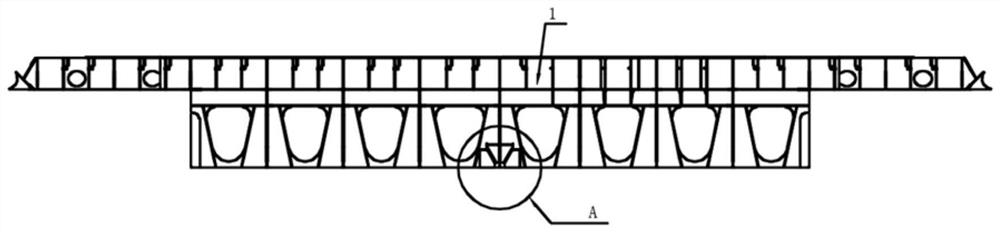

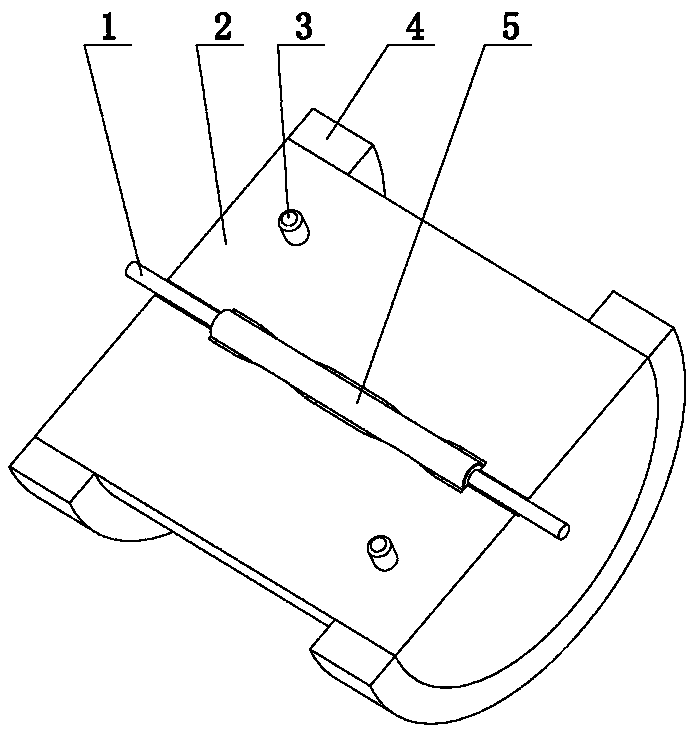

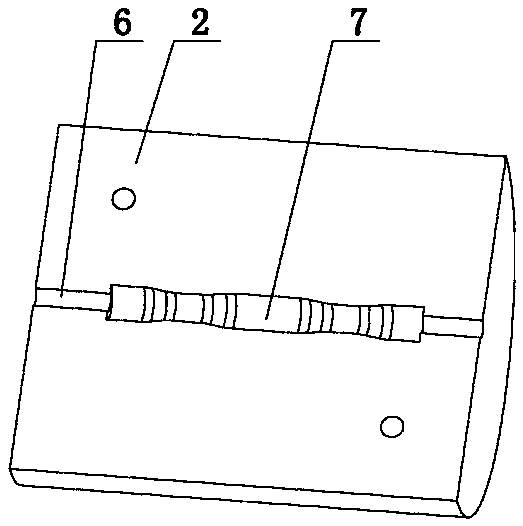

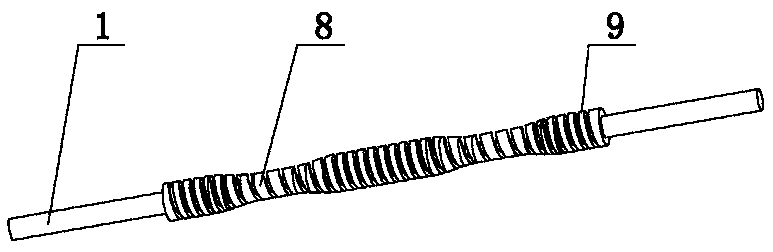

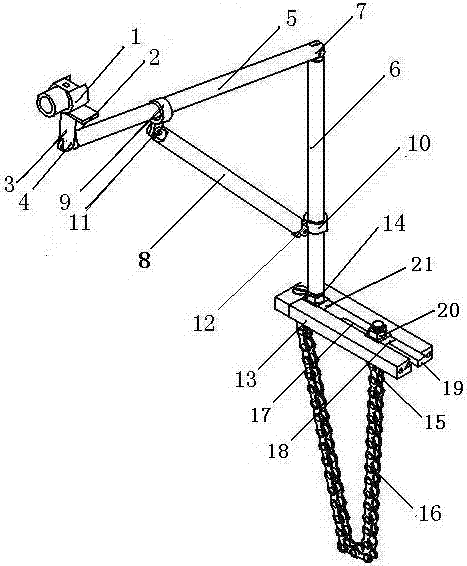

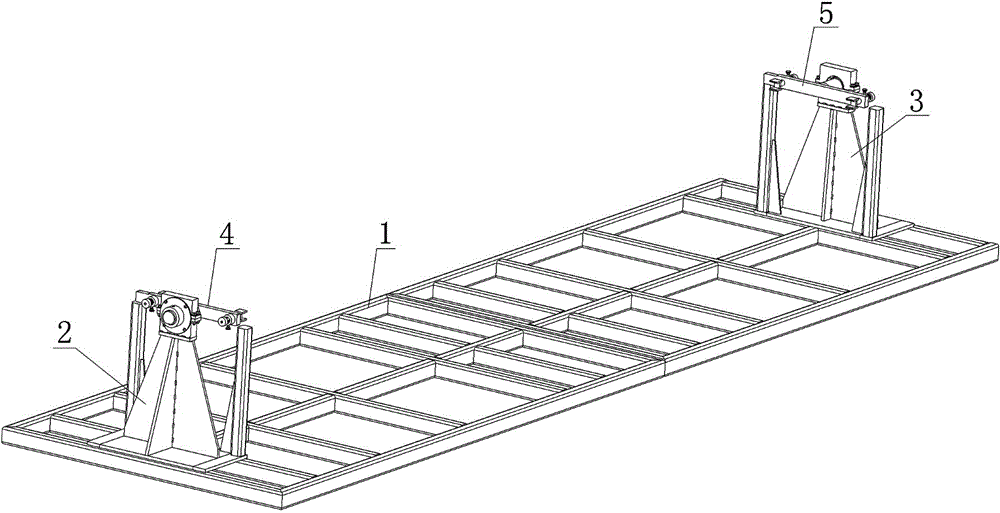

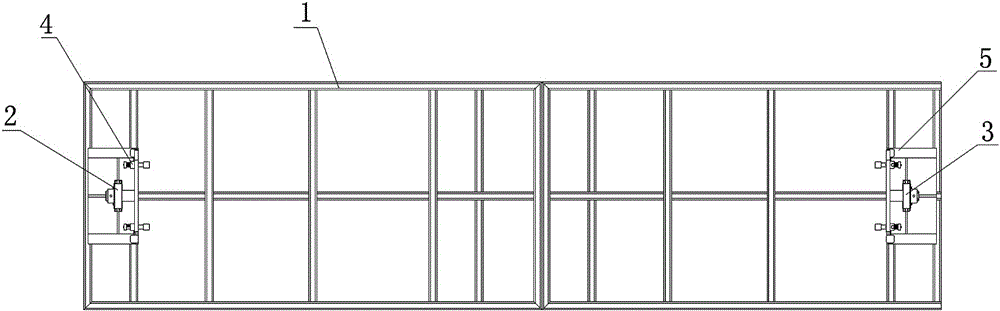

Subsection assembly auxiliary tool

InactiveCN106245615ASave scaffolding and construction periodImprove securityArtificial islandsUnderwater structuresBuilding construction

The invention discloses a subsection assembly auxiliary tool which is used in cross section closure in a manufacturing process of a pile leg on a drilling platform. The subsection assembly auxiliary tool is characterized in that in a manufacturing process of a quadrangular pile leg with a single rack on a self-elevating drilling platform, the pile leg is required to be manufactured by sections and then is hoisted onto a slipway, and the sections of the pile leg are connected one by one and the closure is carried out from the bottom up; the construction of a scaffold on the very high pile leg is a big problem, so that a construction platform is arranged at each subsection closure seam, hanging ropes are arranged at the peripheries of the construction platforms by employing a pile leg structure for hanging the outer sides, fixture tools are arranged inside for fixing the inner sides, clamping bars and connecting devices are arranged at rack structures for fixing the four corners, and four platforms are fixed to the pile leg for the cross section closure at the periphery. The subsection assembly auxiliary tool has the beneficial effects that the construction problem of the cross section closure of the pile leg in a high position is solved, a large number of scaffolds and a construction period for the cross section closure are saved substantially, the construction safety is improved, and a new pile leg closure technology is created.

Owner:江叔能

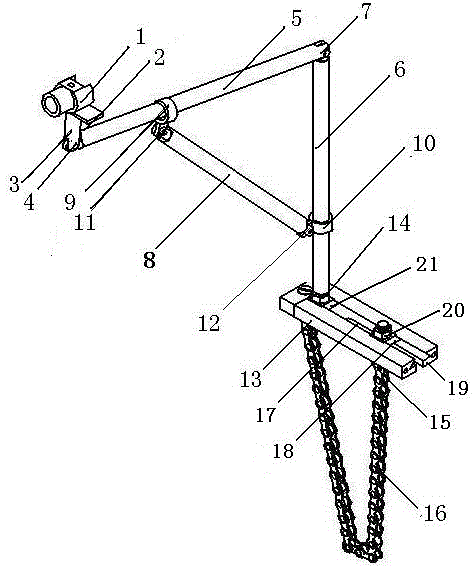

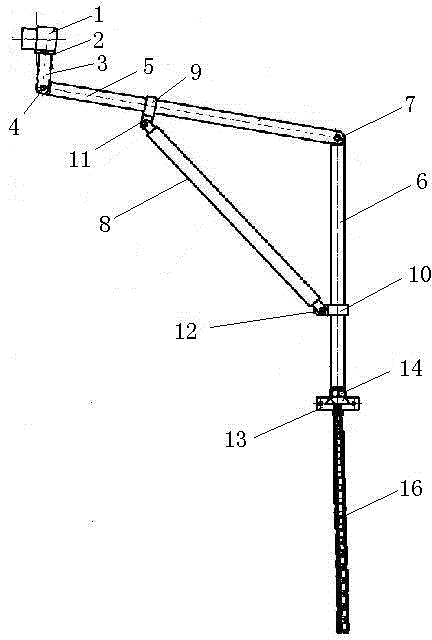

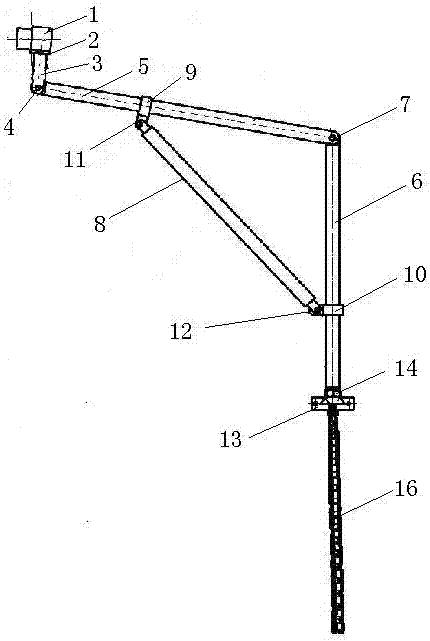

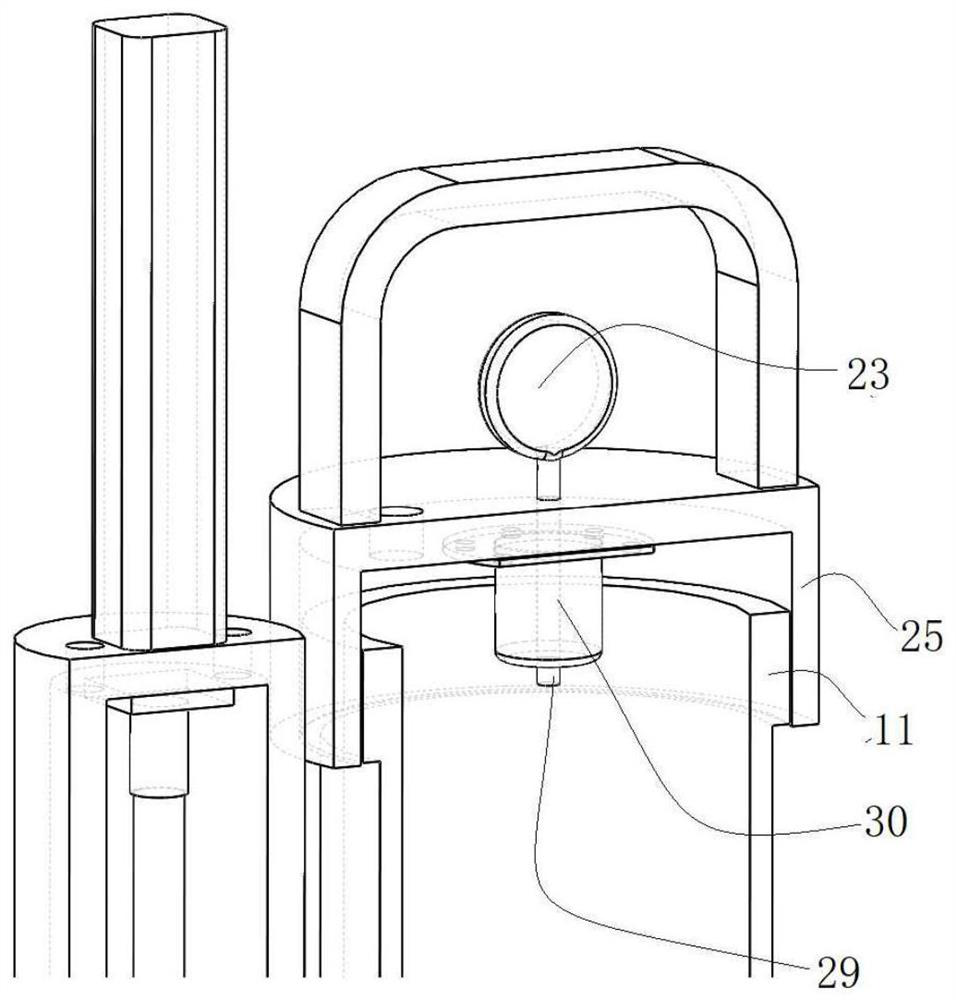

Special gamma ray detection tool for small diameter tube butt joints

ActiveCN104897702AQuality improvement and breakthroughSecurity Improvements and BreakthroughsMaterial analysis by transmitting radiationButt jointEngineering

The invention discloses a special gamma ray detection tool for small diameter tube butt joints. The tool comprises a gamma ray source fixing mechanism, an adjusting mechanism and a fastening mechanism. The gamma ray source fixing mechanism comprises a fixing sleeve, a lead shield fixing plate, a source support arm and fastening bolts, and the adjusting mechanism comprises a horizontal support arm, a vertical support arm, an adjusting support arm, an upper sliding sleeve and a lower sliding sleeve. The fastening mechanism comprises a sliding balance plate, two fastening bolts, a center point adjusting slider, a sizing slider, a screw-type connecting hook and a locking chain. The tool has the advantages that the tool is flexible, convenient and reliable, detection efficiency is improved greatly, detection period is shortened, number of auxiliary personnel is reduced, labor cost is saved, detection quality is guaranteed, detection radiation is reduced, and personnel safety protection is heightened.

Owner:中国石油天然气第一建设有限公司

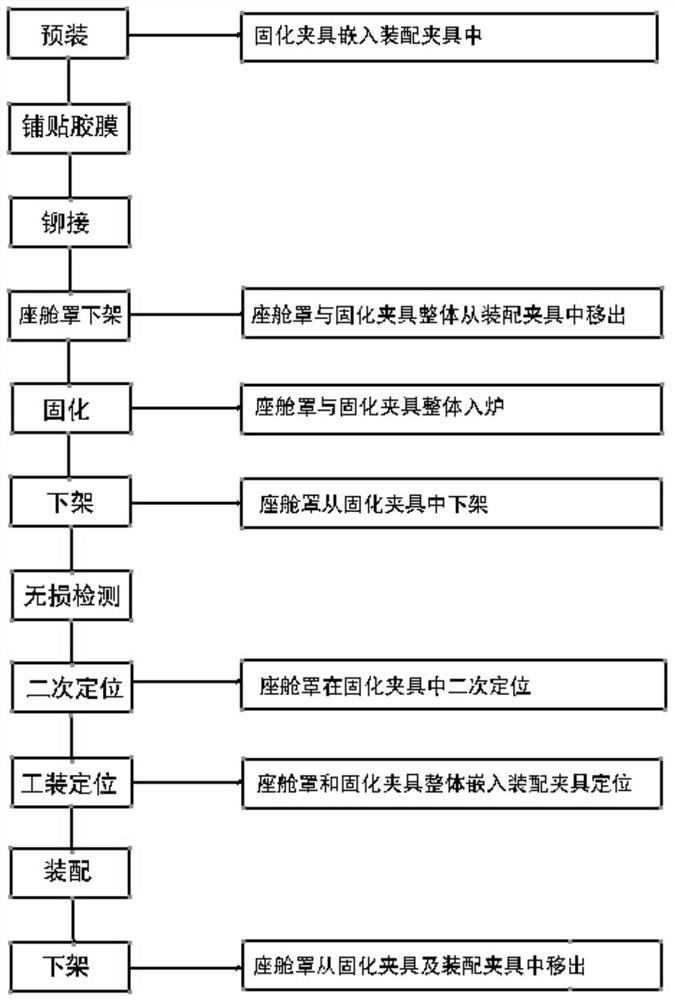

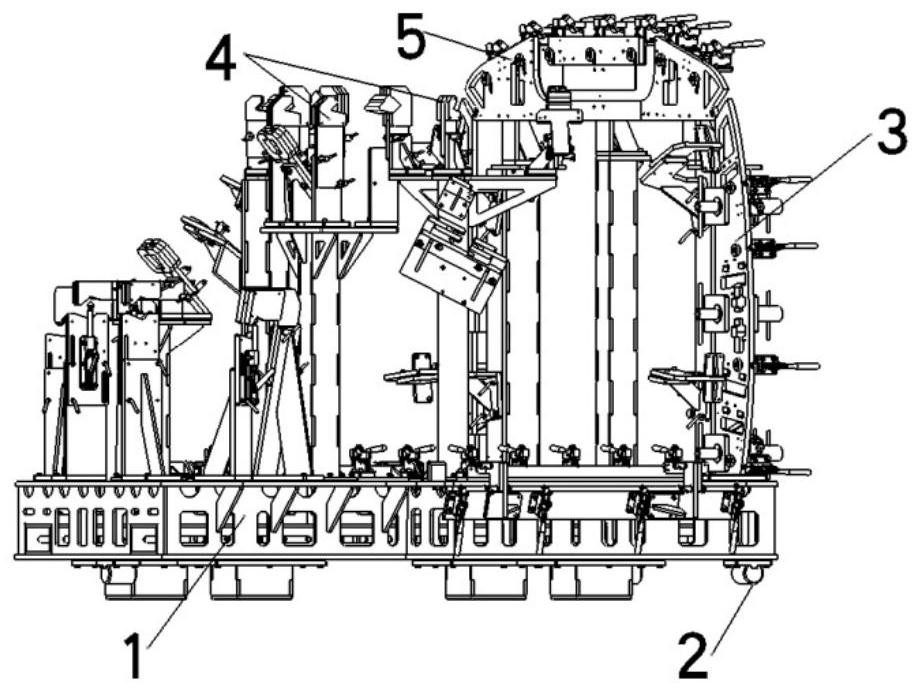

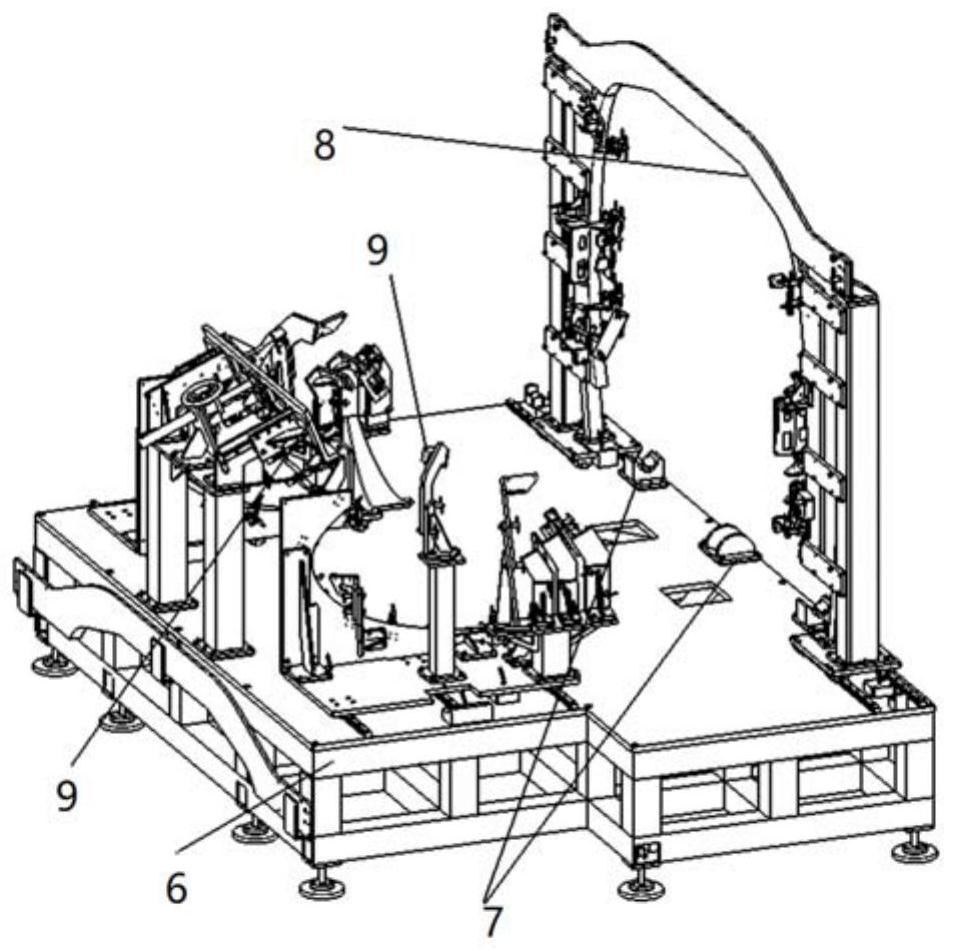

Helicopter cockpit cover gluing assembly method and clamp

ActiveCN112357112AImprove curing methodControl deformationWeight reductionAircraft assemblyButt jointAirframe

The invention belongs to the technical field of composite material assembling and manufacturing, and discloses a helicopter cockpit cover gluing assembling method and a clamp. A brand-new tool form for curing and assembling a cockpit cover is adopted, an embedded separable tool structure is provided, a simple curing bracket is changed into a curing clamp tool with an appearance clamping plate, a curing clamp and an assembling clamp form a whole in the assembling process, and the curing clamp can be separated from the assembling clamp in the curing process. An INVAR steel material with the expansion coefficient similar to that of a composite material is selected as a curing clamp tool material, and deformation of the cockpit cover in the curing process is effectively controlled; and meanwhile, the positioning reference of the cockpit cover is transferred to the curing clamp from the assembling clamp so that the unification of the positioning reference of the cockpit cover in the pre-assembling, curing and assembling processes is ensured, the off-frame frequency of the cockpit cover is reduced, and the deformation of the cockpit cover in the curing process is effectively controlled.The problems that a butt joint assembling gap between the cockpit cover and a fuselage is out of tolerance, and assembling with a cockpit door and a radome is not coordinated are solved.

Owner:哈尔滨哈飞航空工业有限责任公司

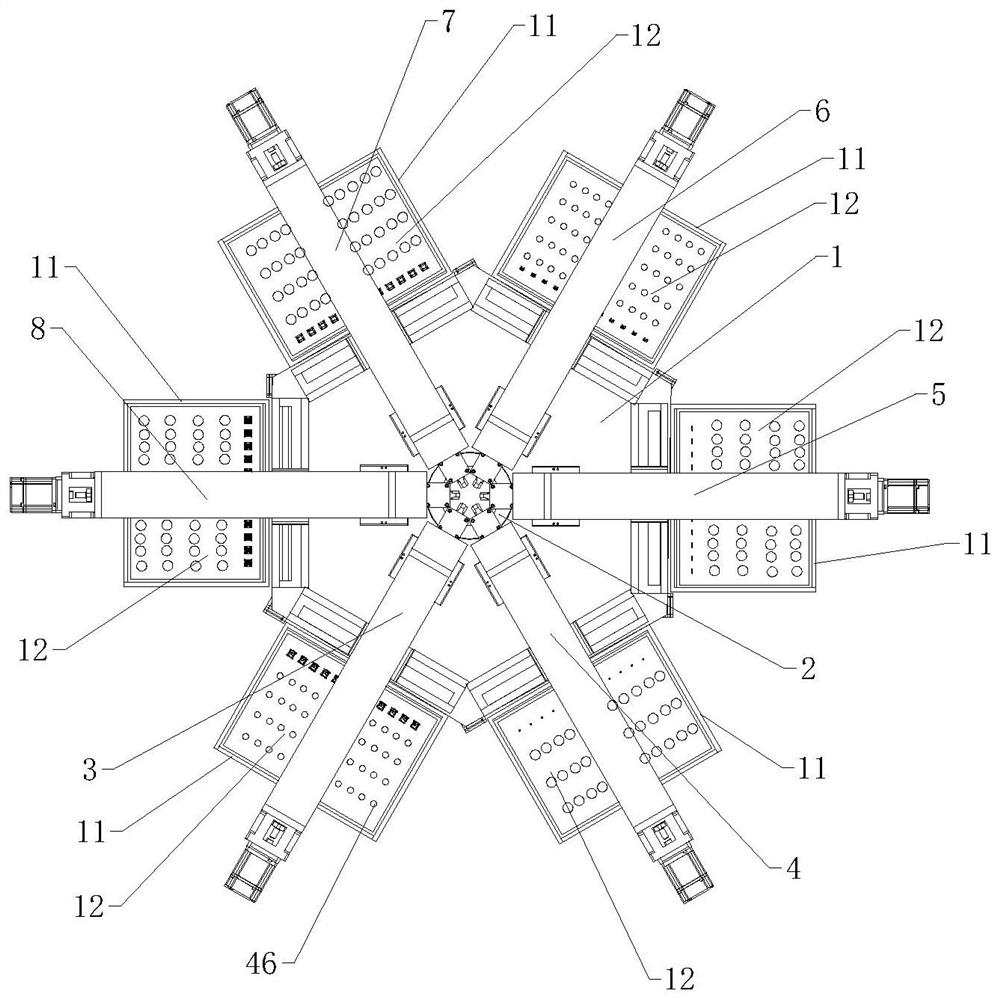

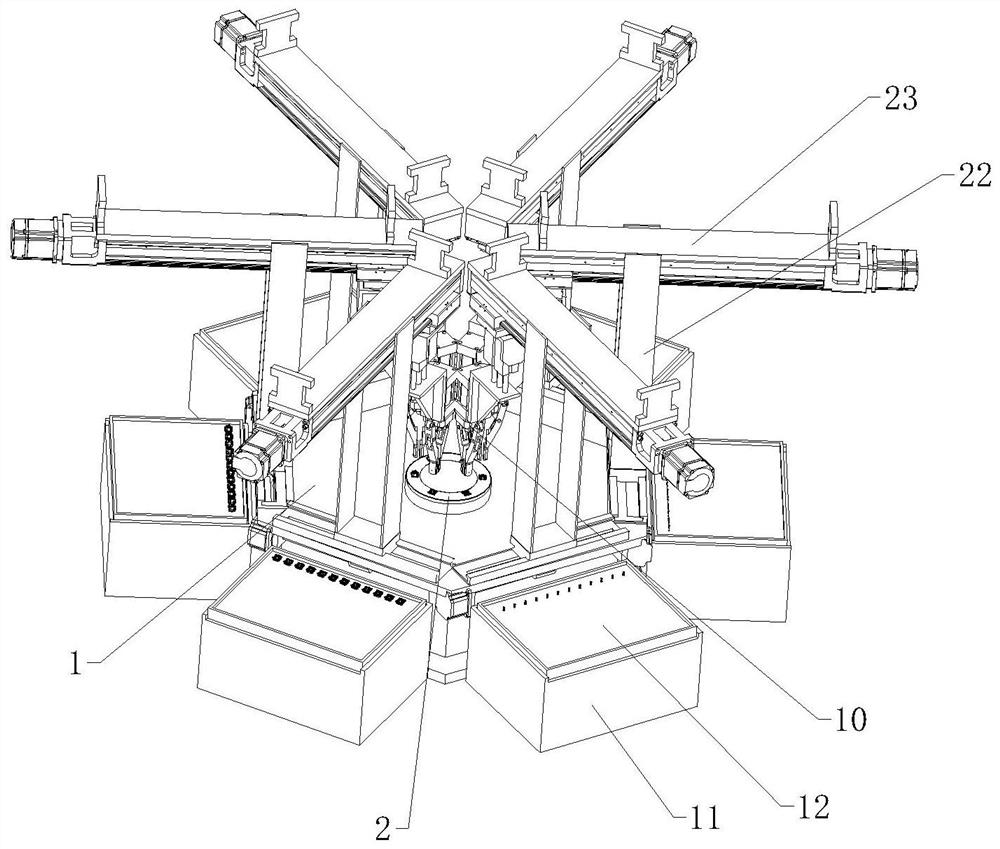

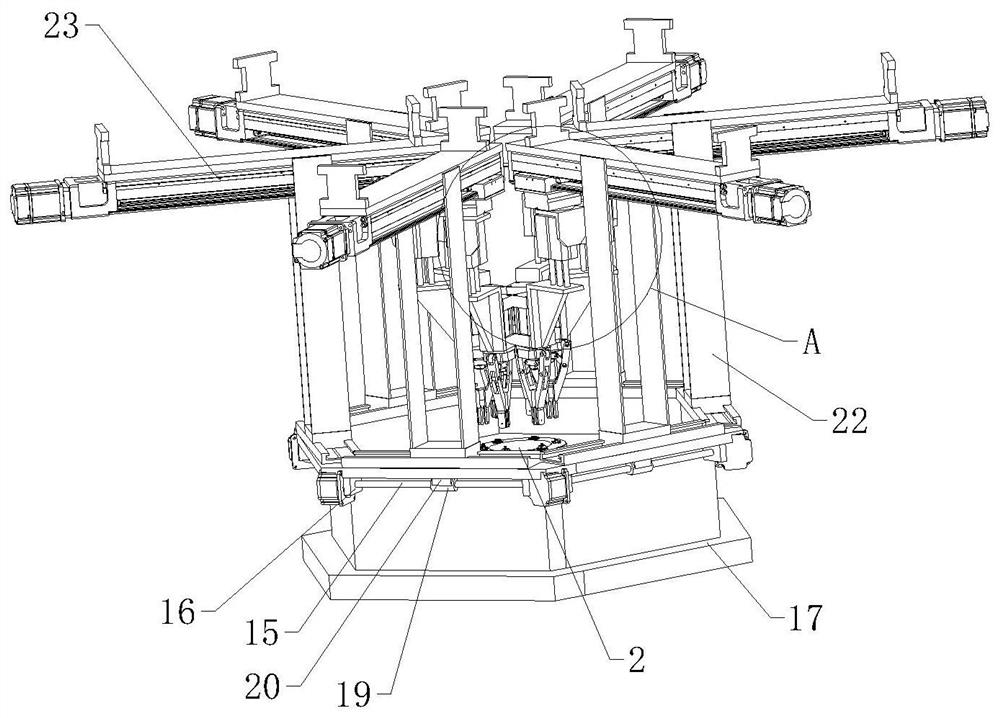

Rotary disc type automatic assembly device for keyboard shaft body

InactiveCN111890027APrevent overclampingEasy to adjust the angleAssembly machinesMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of keyboard shaft body processing, in particular to a rotary disc type automatic assembly device for a keyboard shaft body. The assembly device comprises ahexagonal processing table, and rotary discs, a shaft bottom feeding mechanism, a spring tool mechanism, an elastic support tool mechanism, a connector tool mechanism, a shaft cap tool mechanism anda discharging mechanism which are mounted on the hexagonal processing table separately, wherein the top edges of the rotary discs are provided with workpiece positioning grooves corresponding to the shaft bottom feeding mechanism, the spring tool mechanism, the elastic support tool mechanism, the connector tool mechanism, the shaft cap tool mechanism and the discharging mechanism, and each of theshaft bottom feeding mechanism, the spring tool mechanism, the elastic support tool mechanism, the connector tool mechanism, the shaft cap tool mechanism and the discharging mechanism comprises a clamping jaw capable of lifting and linearly moving between each material box and the corresponding rotary disc. According to the technical scheme, the problems that during mass production, a large amountof manpower is needed for operation, and the parts are prone to be damaged by manual operation; and tooling can be automatically performed, and the efficiency and the tooling quality are improved.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

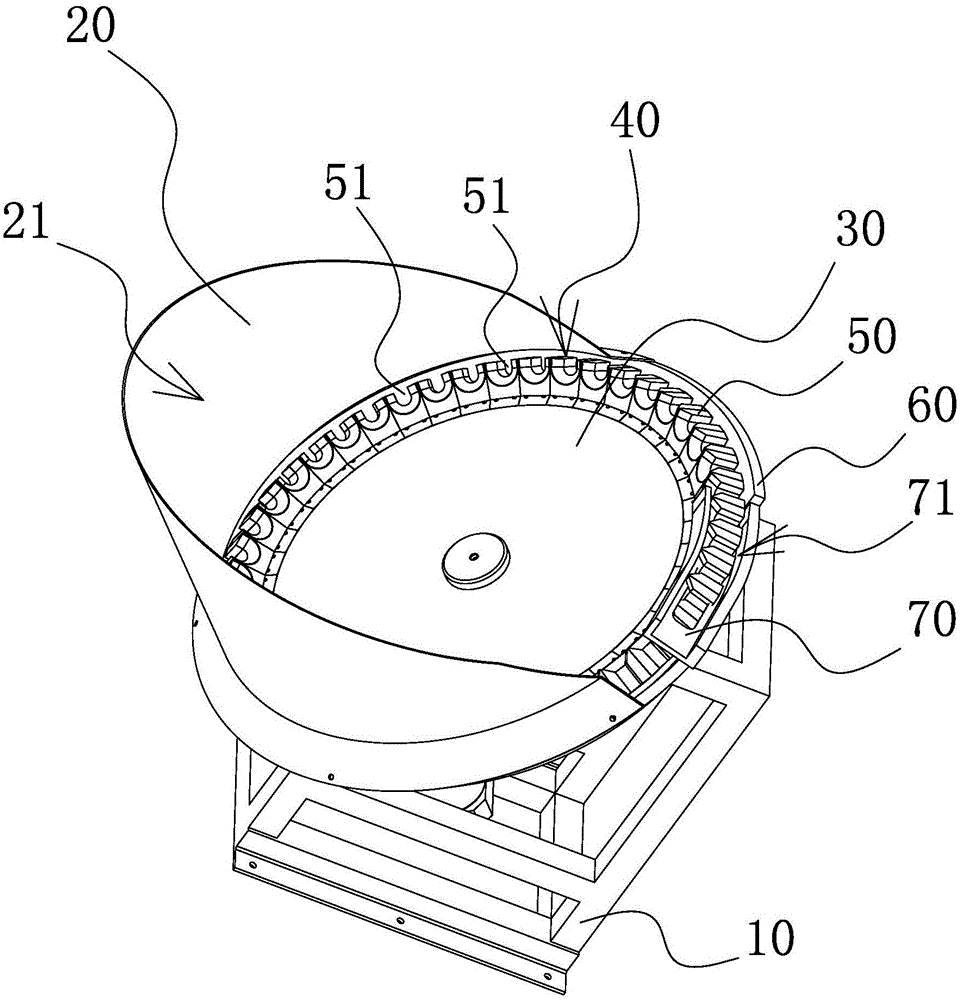

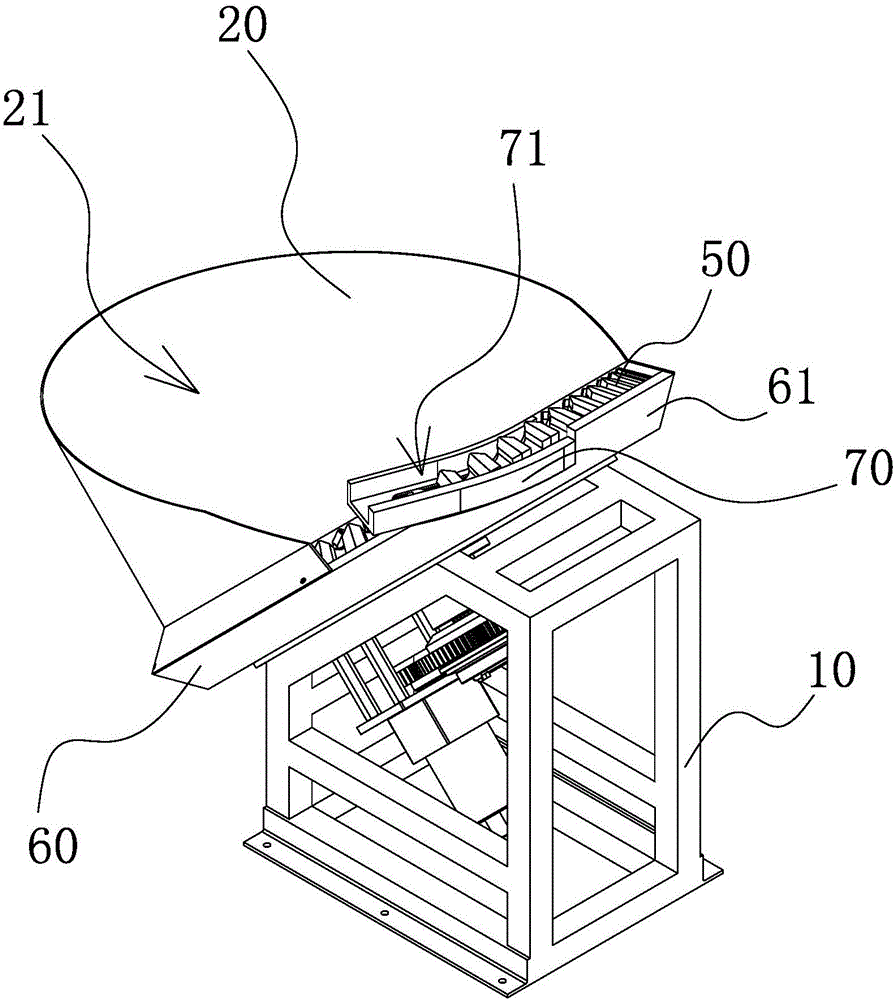

Battery arraying device

InactiveCN105905577AQuicklyThe effect of the whole column is idealConveyor partsRotary conveyorsArray elementEngineering

Owner:ZHONGYIN NINGBO BATTERY CO LTD

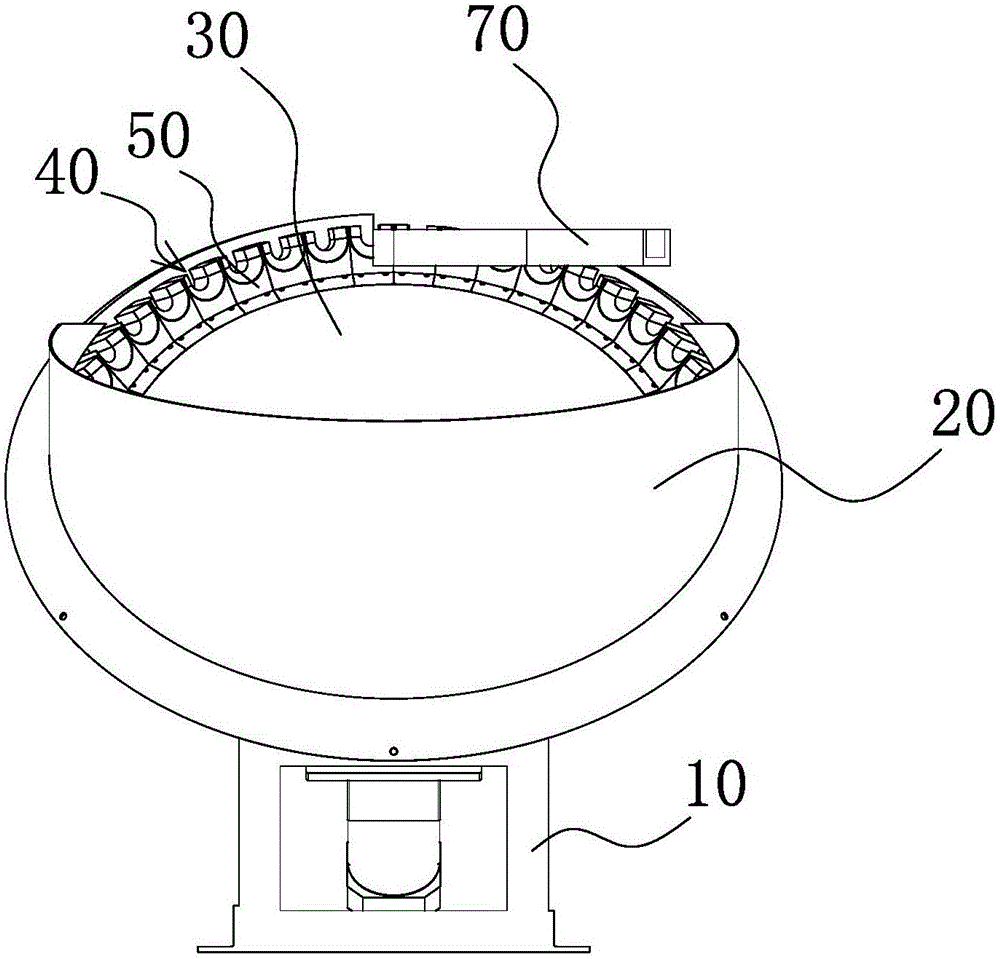

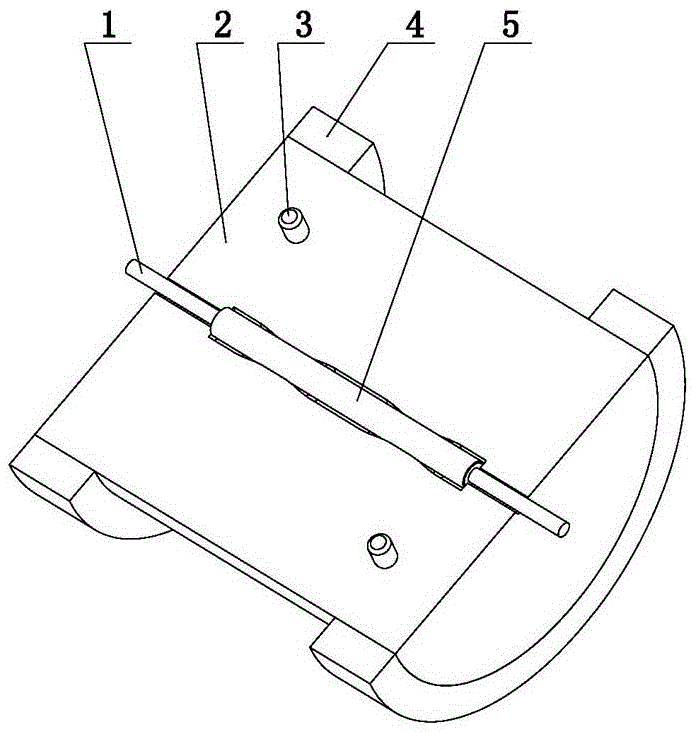

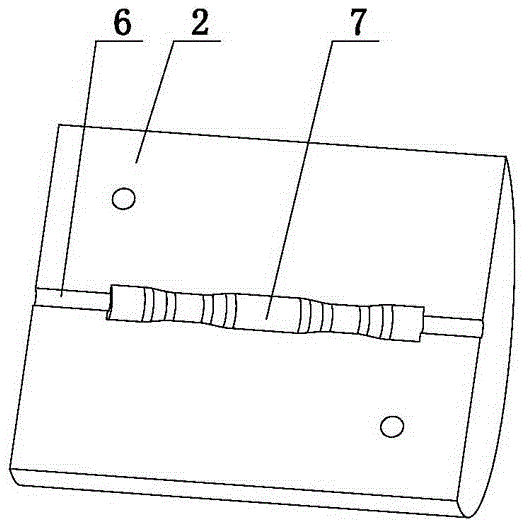

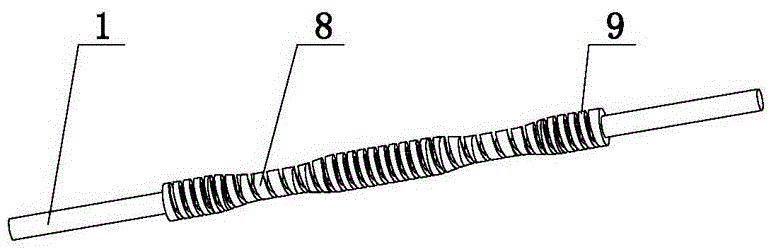

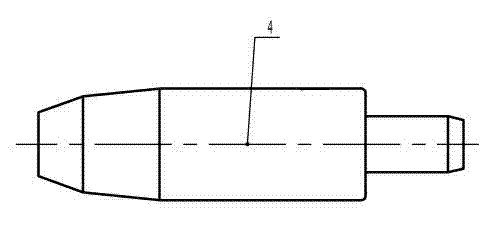

Forming device for machining complex variable section small-scale tubes and forming method

InactiveCN105665513APrecise control of magnetic force distributionGuaranteed molding accuracyShaping toolsEngineeringNon magnetic

The invention discloses a forming device for machining complex variable section small-scale tubes and a forming method, belongs to the technical field of forming of variable section small-scale tubes (phi 10 mm or above), and particularly relates to a forming device for machining complex variable section small-scale tubes and a forming method. The invention provides a forming device for complex variable section small-scale tubes, which replaces a traditional coil by a magnetic coil based on controllable degree of closeness, and is simple to operate and high in product precision. The forming device comprises a nonmagnetic die body and a magnetic coil, wherein a model slot is formed in the die body; the forming device is characterized in that the magnetic coil is a metal tube; the metal tube, corresponding to the model slot, is provided with a spiral coil part machined in a spiral machining way.

Owner:SHENYANG POLYTECHNIC UNIV

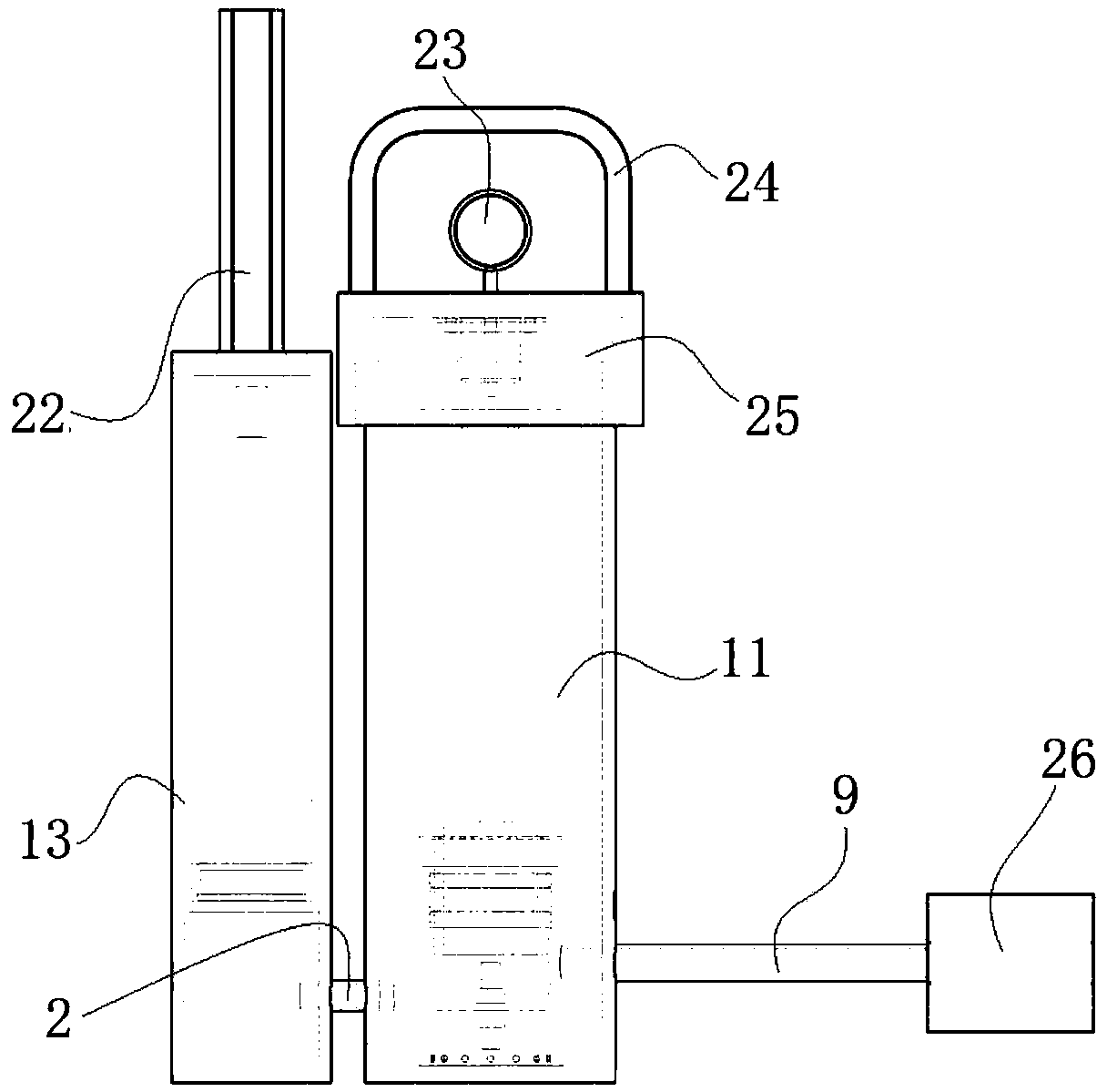

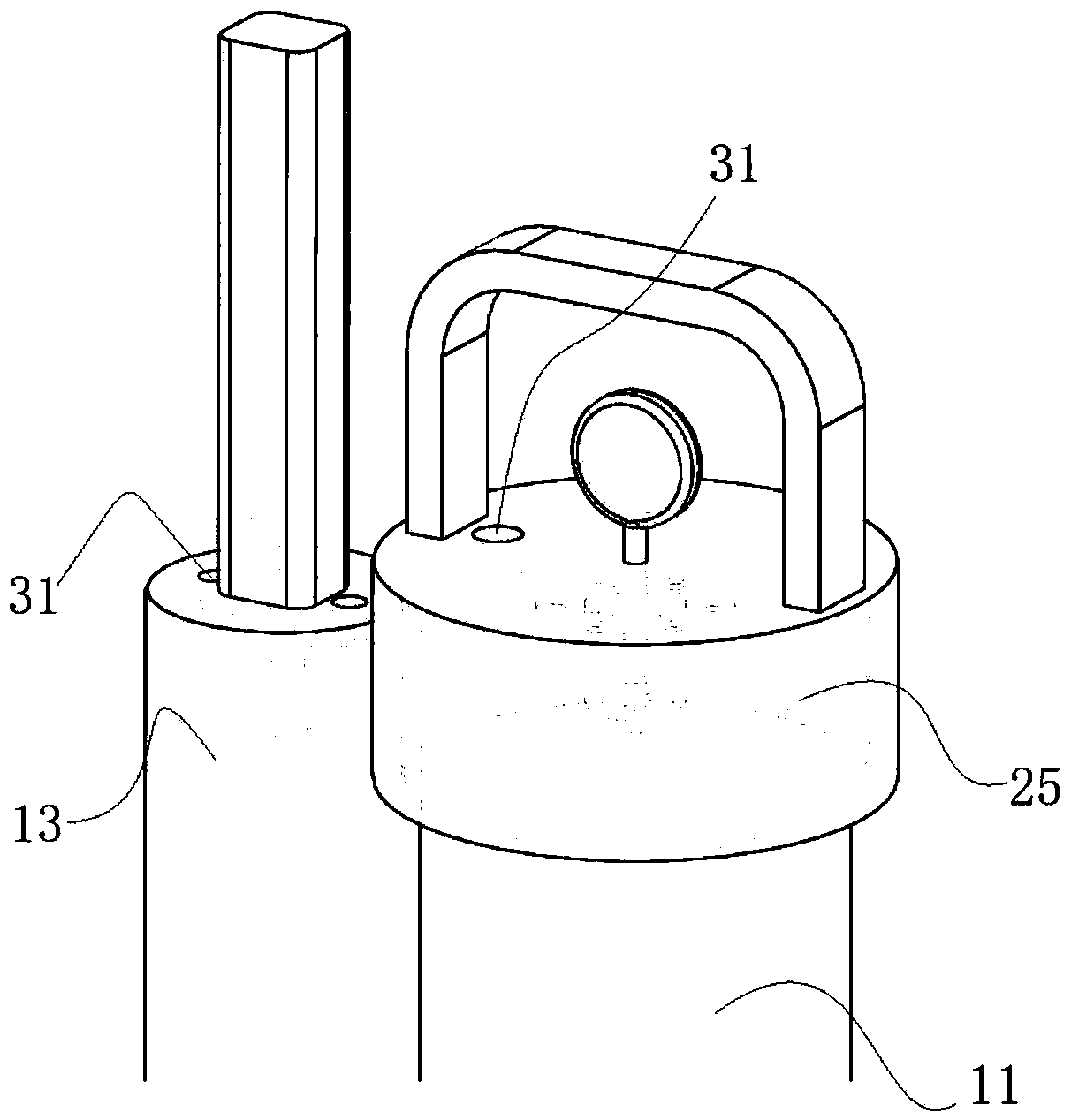

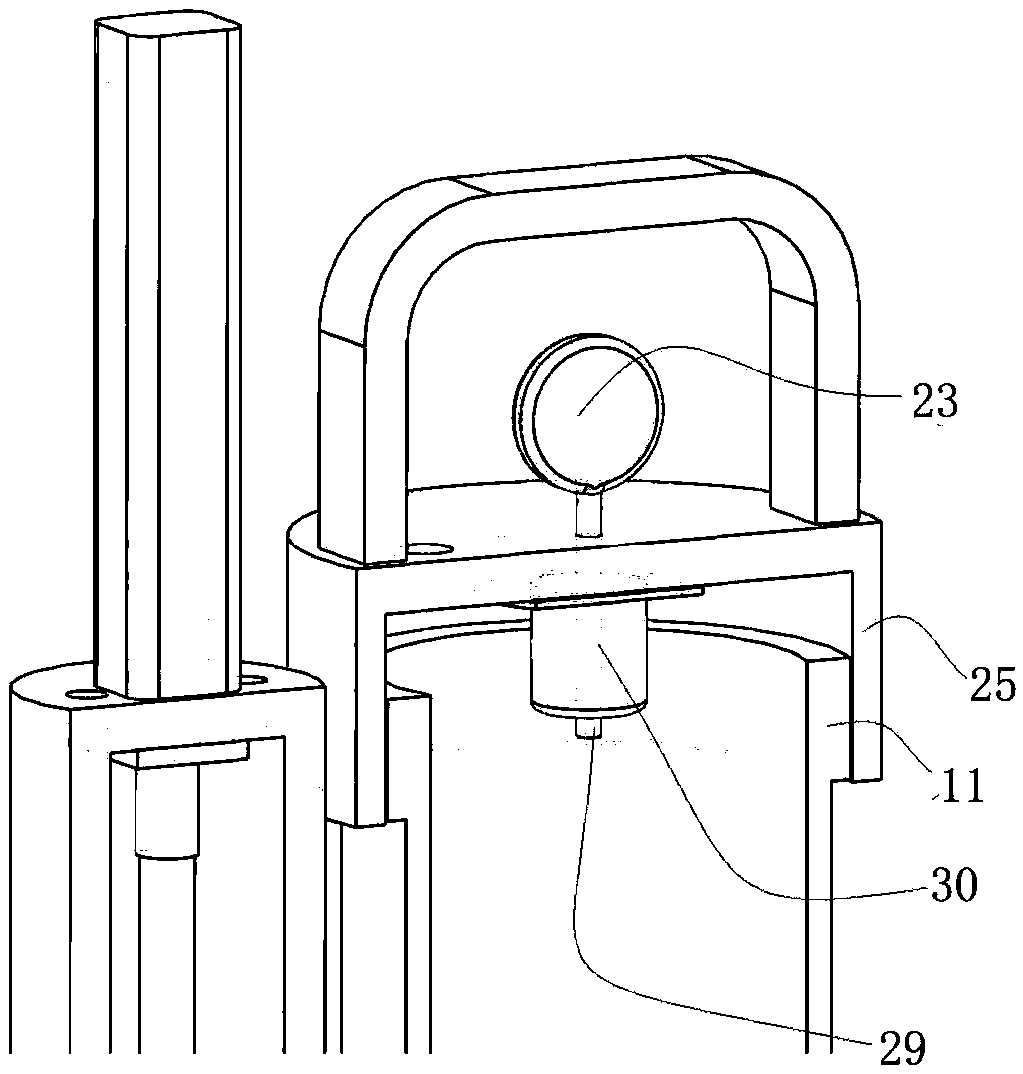

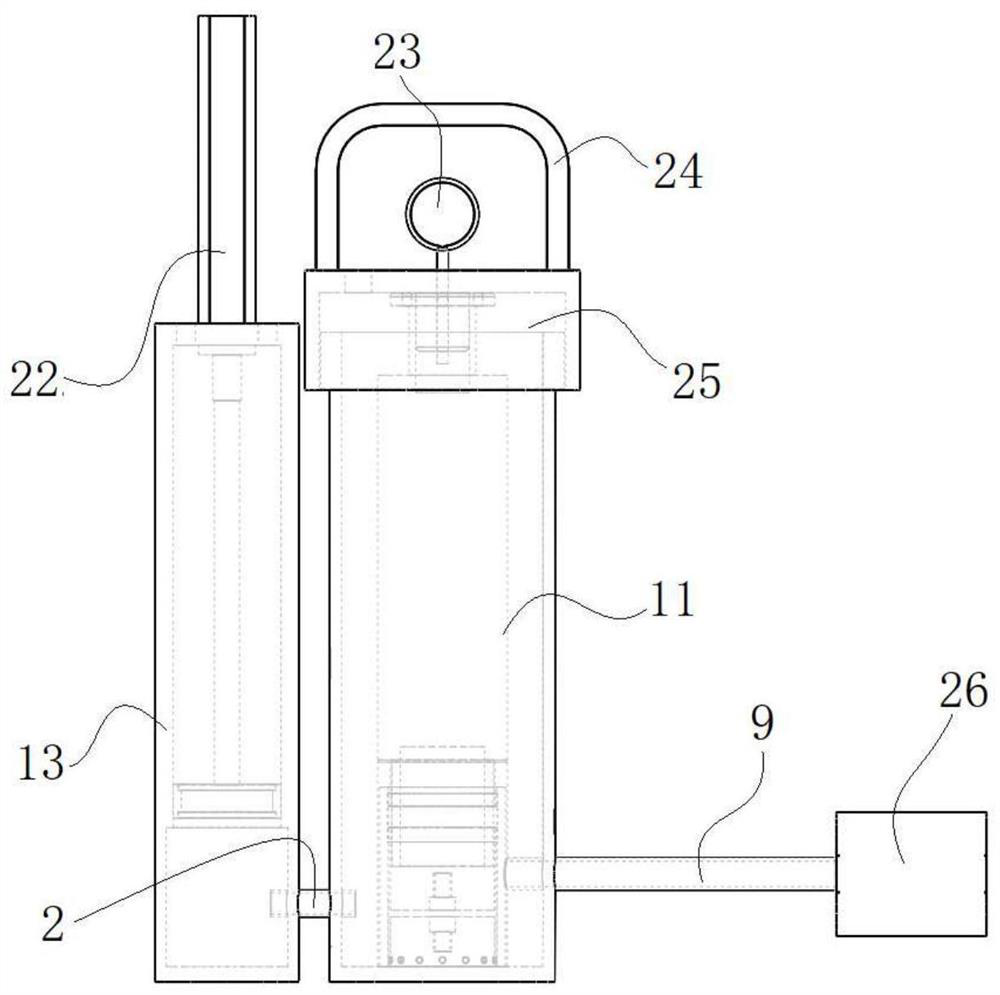

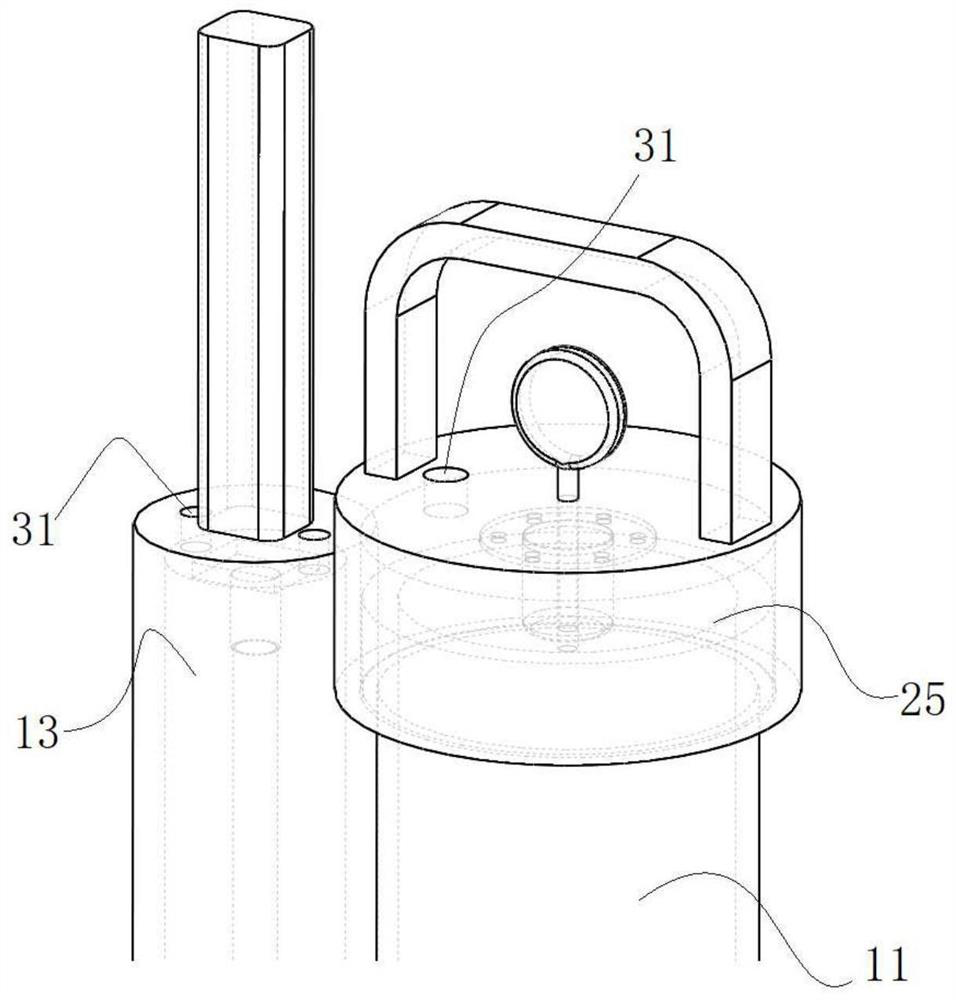

Test tool for air leakage of silencer of automobile engine and method of test tool

ActiveCN109506851ASimple structureImprove socket sealing performanceMeasurement of fluid loss/gain rateEngineeringInjection air

The invention discloses a test tool for air leakage of a silencer of an automobile engine and a method of the test tool. The test tool comprises a vertical air impermeability detection cylinder, a liquid injection and pumping unit, a pressure boost air injection unit and a tested silencer body; the tested silencer body is detachably installed in the air impermeability detection cylinder, and the pressure boost air outlet end of the pressure boost air injection unit is communicated with the air inlet end of the air impermeability detection cylinder through an air injection pipe; the liquid injection and pumping unit is communicated with the lower end of a liquid cavity in the air impermeability detection cylinder through a liquid communication pipe. The test tool is simple in structure, andthe outer wall of an air discharging cylinder and the inner wall of the wall body of an inner annular column are converted into sealing fit without air leakage from conveniently-detached clearance fit. The test tool is beneficial to a tool of the tested silencer and also helps to improve the sleeving sealing performance in the detection process.

Owner:宁波远亚车辆检测有限公司

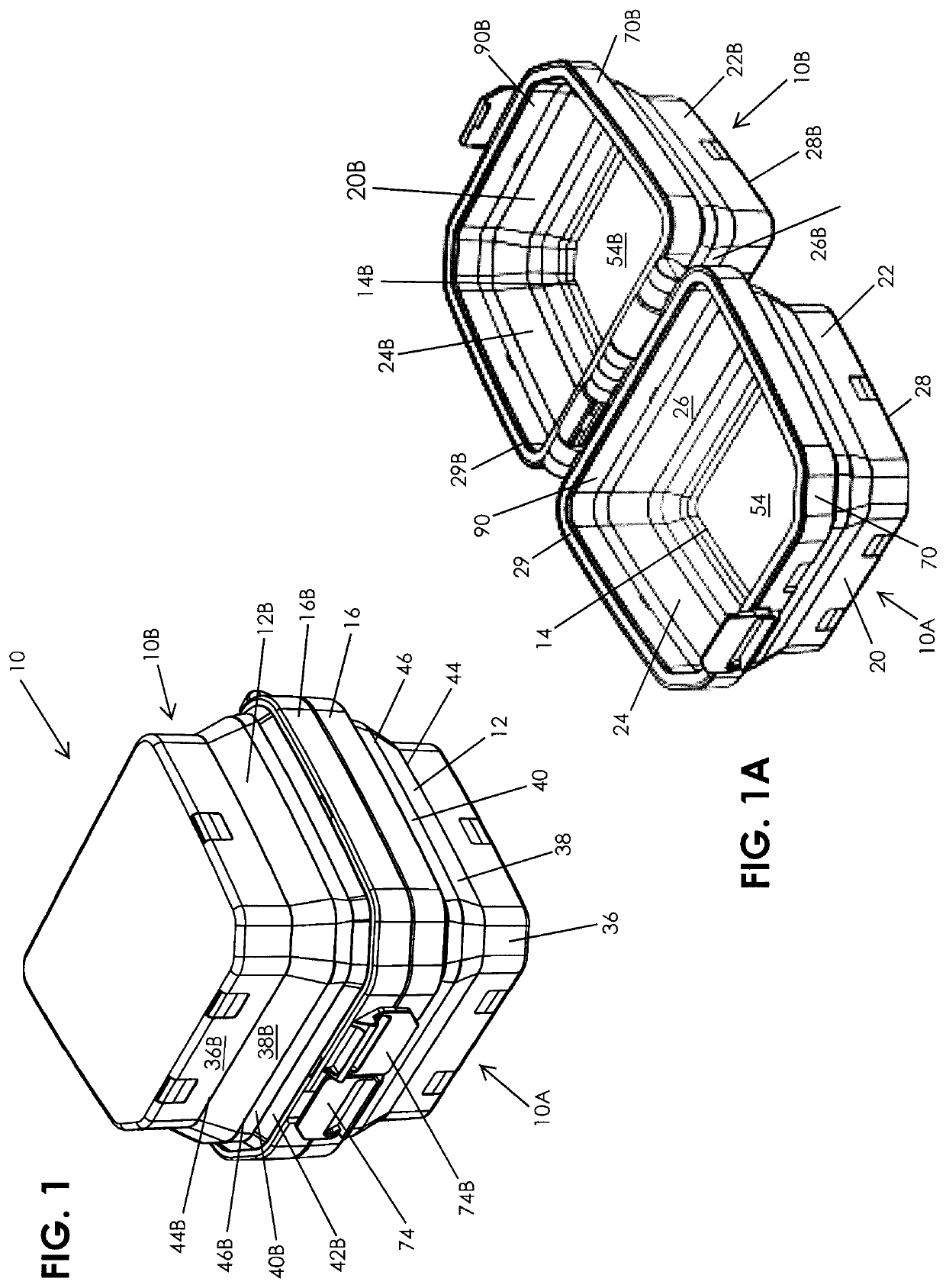

Magnetic tray

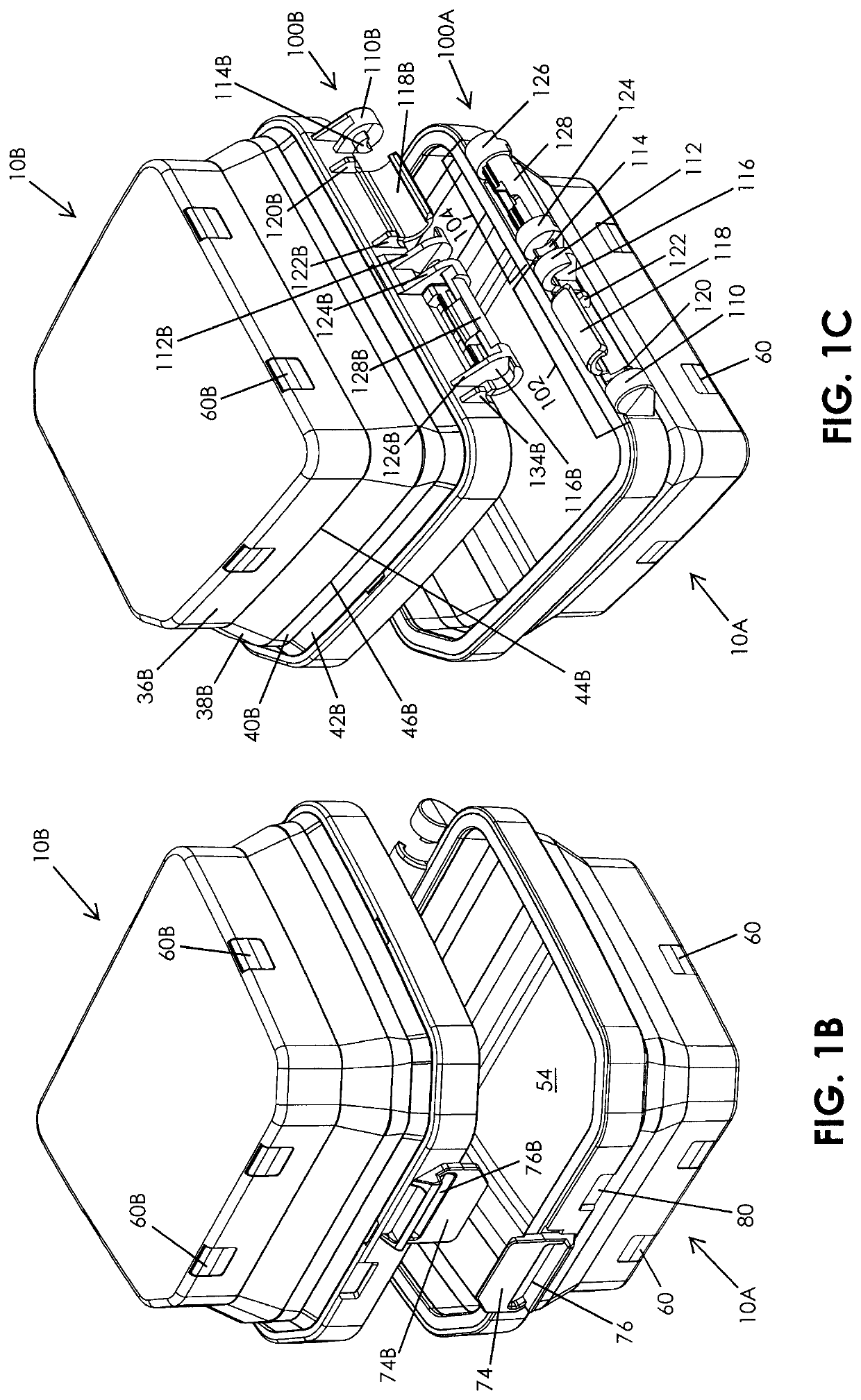

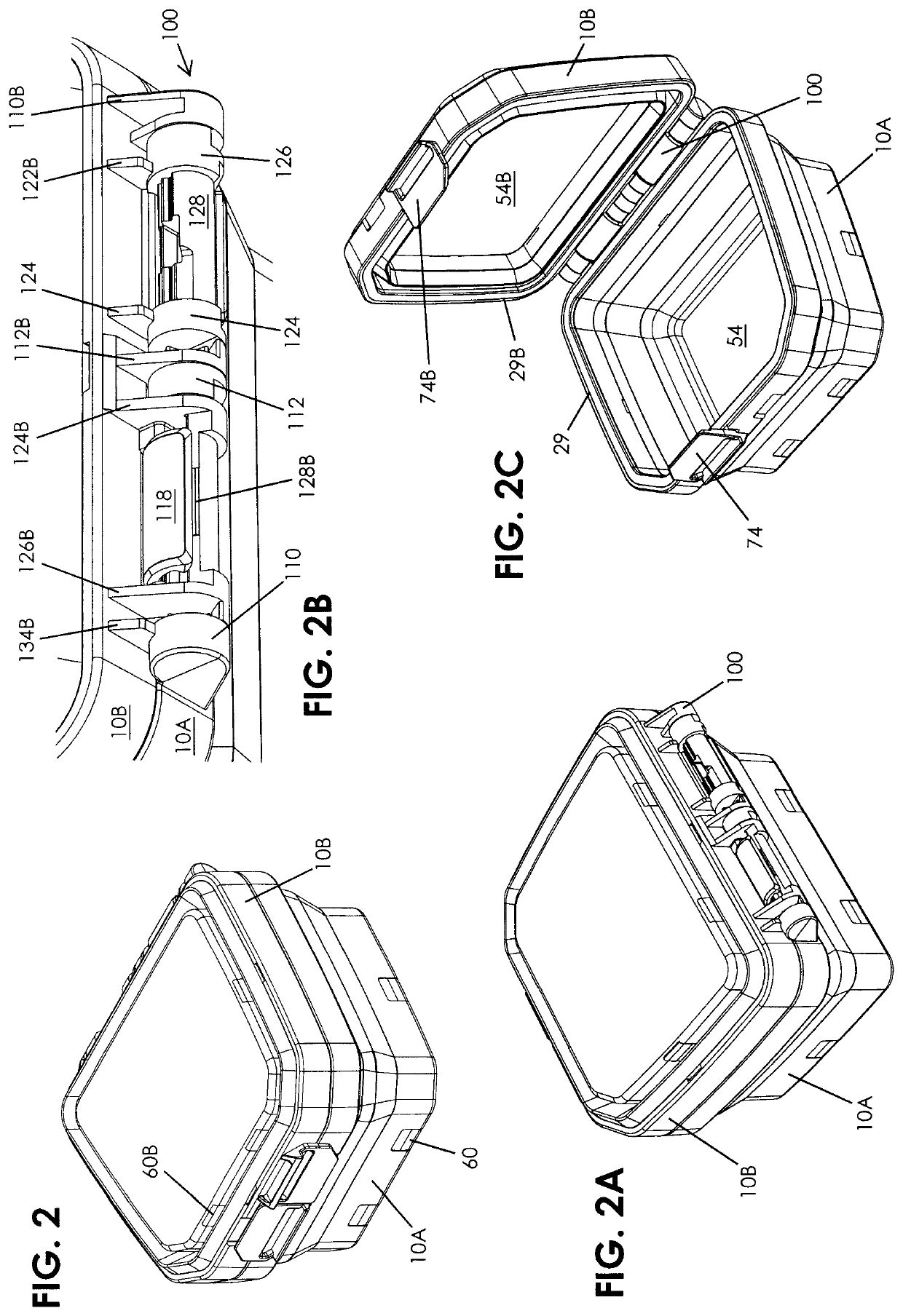

ActiveUS11485538B1Easy toolingEasy to manufactureLidsNon-removalbe lids/coversEngineeringMechanical engineering

There is disclosed a magnetic tray having a first tray and a second tray connected to each other and which are the same or substantially the same. The first and second trays are collapsible and expandable. The first and second trays each include a body member adapted to be collapsible and expandable; a base member adapted to fit in the bottom of the body member and having a magnet on a first side of the base member and one or more magnets on a second side of the base member; and a collar member having a hinge member and a lock member. The first tray and the second tray are connected to each other by the hinge members. The first tray and the second trays are adapted to be separable by the hinge members.

Owner:WALTER R TUCKER ENTERPRISES LTD D B A E Z RED

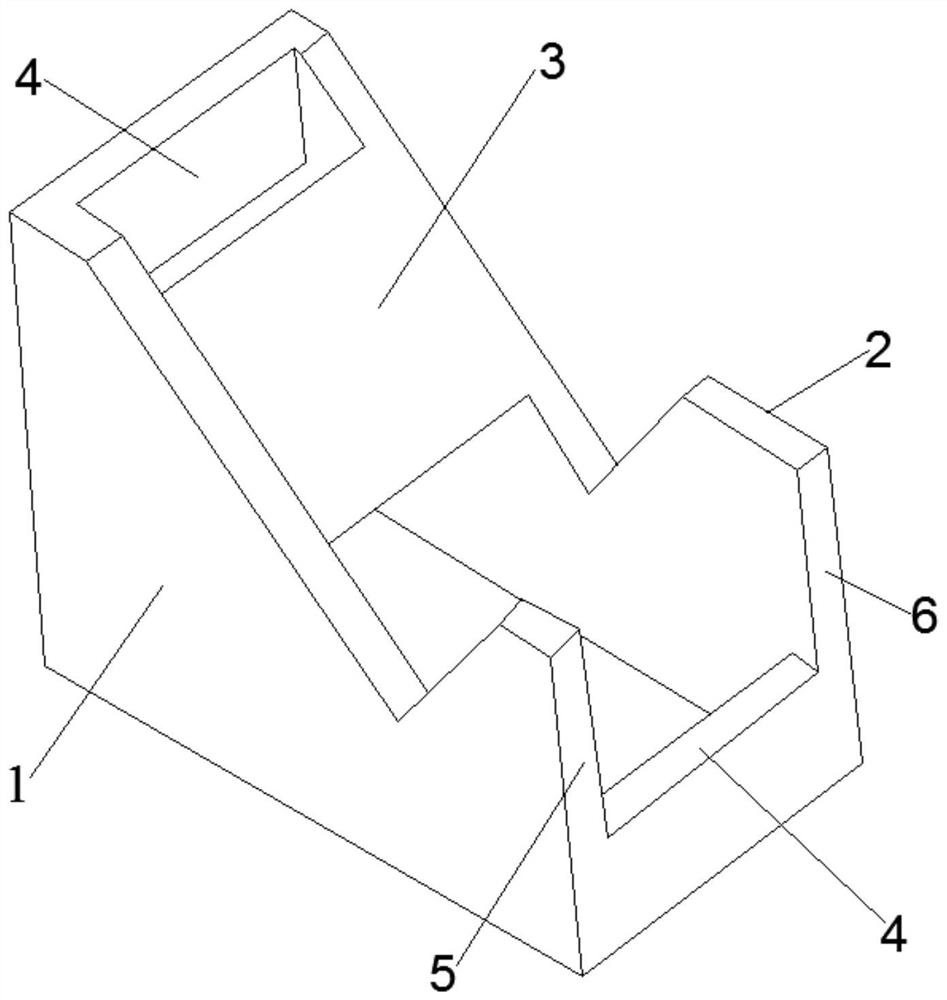

Combined memorial archway

InactiveCN101502847AAvoid difficultiesEasy to processMetal rolling stand detailsMetal rolling arrangementsEngineeringManufacturing line

The invention provides a combined memorial archway which is formed by splicing and combing components comprising a left post and a right post; both the left post and the right post have the same structure and each has an L-shaped cross section; after the combination of the left post and the right post, a sealed through hole is formed in the middle. The invention has the beneficial effect that: the invention divides the integral memorial archway in the prior art into a plurality of parts for being combined, which thoroughly solves the difficulty that the memorial archway is expanded owing to the expansion of the size of roller and frame in broadband rolling production line and middle thickness plate rolling production line, facilitates processing, assembly, transportation and installation of the memorial archway, and solves the difficult problem of processing a large memorial archway with a small apparatus.

Owner:中重科技(天津)股份有限公司

Positioning method for single-shell fuel tank block

The invention discloses a positioning method for a single-shell fuel tank block. The positioning method comprises the following steps that S1, a guide sliding block is installed on a fuel tank beforethe fuel tank is hoisted; S2, the relative position of the guide sliding block on the fuel tank is determined; S3, according to the relative positions, corresponding sliding block bases are installedon the double-layer bottom of a ship body; S4, the fuel tank is hoisted in place, the position of the fuel tank is adjusted, and a folding line on the guide sliding block is aligned with the folding line on the corresponding sliding block bases; and S5, assembling and welding are performed after the fuel tank is positioned. The positioning sliding block is adopted for positioning, the tool is simple and convenient, operation is easy, and on-site construction is facilitated.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

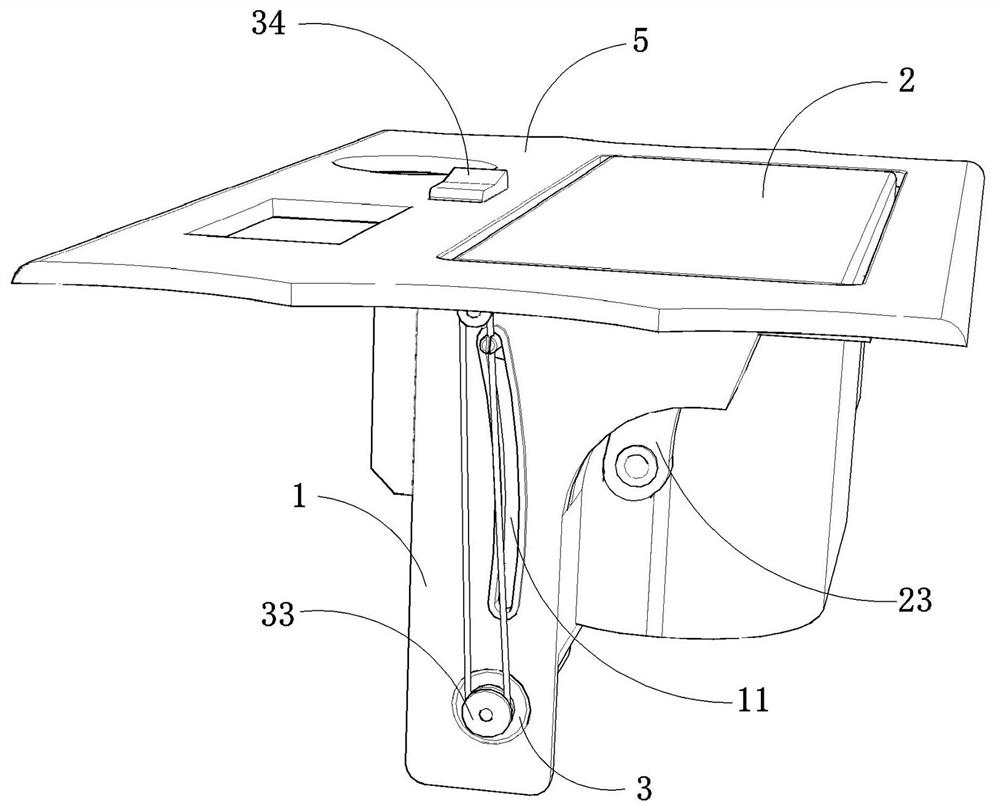

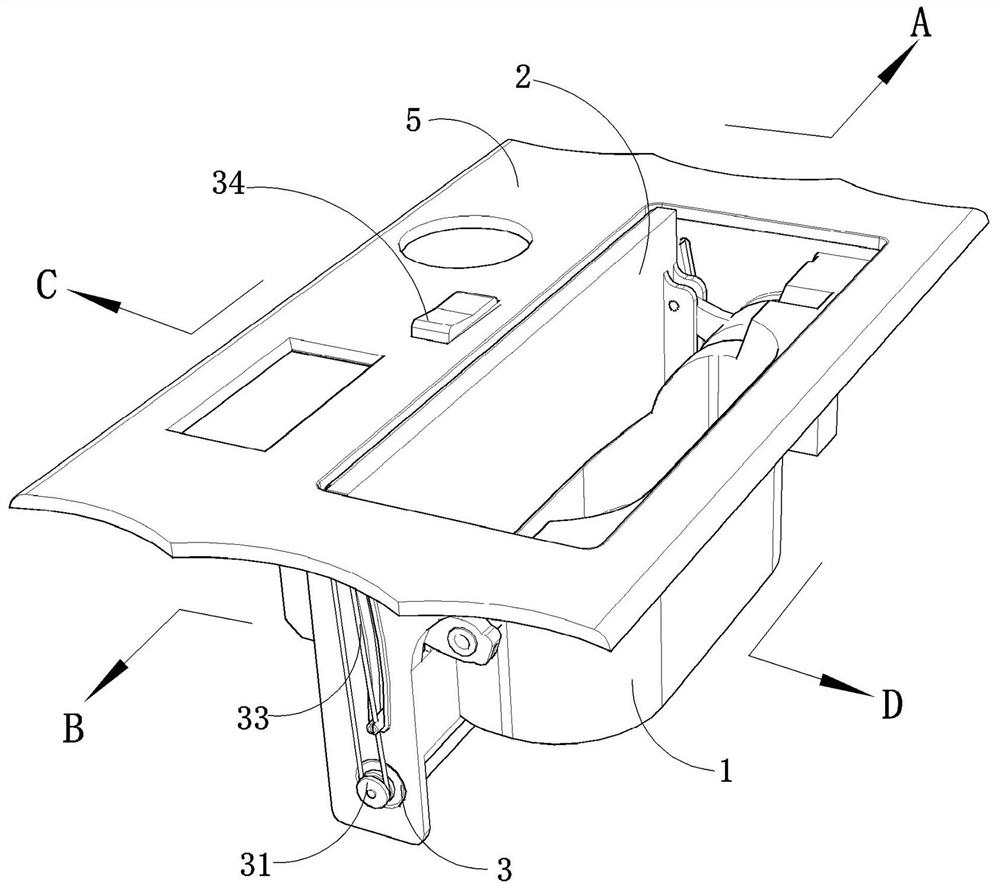

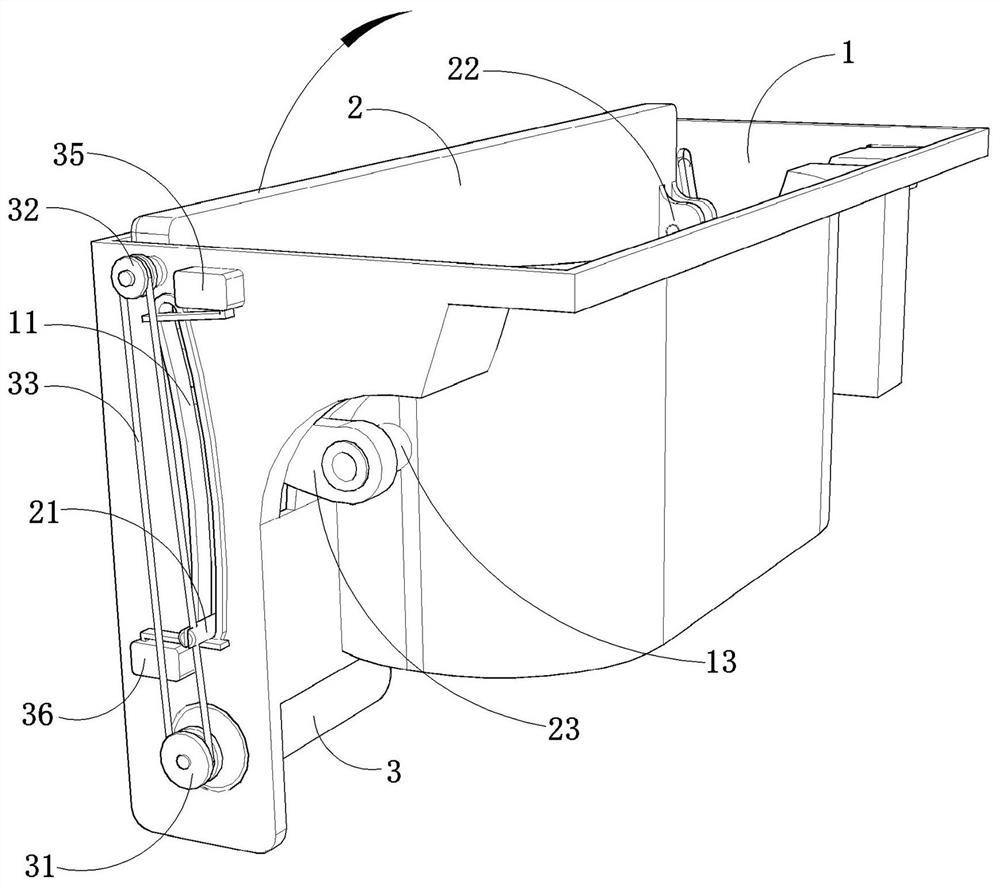

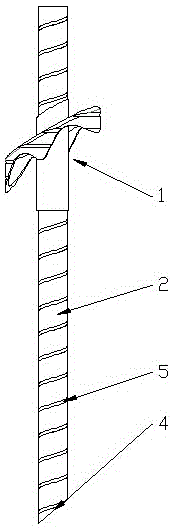

Automatic flipping device for car cup box

ActiveCN111923838BOperational securityEasy to operateVehicle arrangementsPassenger spaceDriver/operatorReduction drive

The invention discloses an automatic cover turning device for a vehicle cup box. The device comprises a box body frame, a cover plate and a power mechanism, wherein connecting bases are fixedly arranged on the coaxial lines of the front side and the rear side of the box body frame correspondingly; rotating arms are respectively coupled between the front and rear connecting bases and the corresponding fixed coupling pieces on the lower sides of the two ends of the cover plate; traction sliding shafts are respectively arranged on the left sides of the front and rear fixed coupling pieces; limiting sliding grooves are formed in the front side and the rear side of the box body frame. A power mechanism is arranged in the box body frame below the limiting sliding groove and comprises a motor anda speed reducer, a traction sheave is arranged on the outer side of the speed reducer, a guide sheave is arranged on the upper side of the limiting sliding groove on the same side, a traction belt isarranged between the traction sheave and the guide sheave, and the outer end of the traction sliding shaft on the same side is fixed to one point of the traction belt. Compared with the prior art, the automatic cover turning device for the vehicle cup box has the advantages that the cover plate is completely hidden under the panel when being opened, so that the operation of a driver is safer andmore convenient. The structure is simple, the automation degree is high, and tidiness and attractiveness are achieved.

Owner:NINGBO SHUAITELONG GRP CO LTD

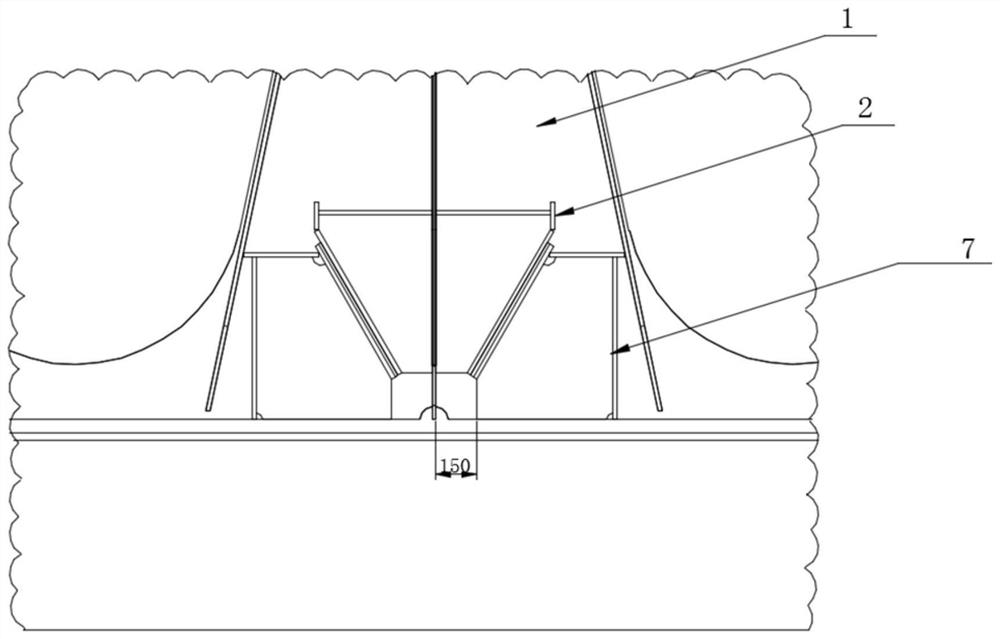

Nonmetallic connection piece

ActiveCN105113666AAvoid damageReduced insertion resistanceWallsClimate change adaptationRebarPlastic foam

The invention discloses a nonmetallic connection piece which comprises a PVC loop bar and a basalt rebar arranged in the PVC loop bar in a sleeved mode. The PVC loop bar comprises a sleeve arranged on the basalt rebar in a sleeved mode and a fixing piece arranged on the sleeve in a sleeved mode. The fixing piece is a hollow pillar without a lower cover. Both the upper end face and the lower end face of the fixing piece are inclined upwards, and the lower end face is in a wavelike shape. The nonmetal connection piece has the advantages that firm occlusion of a basalt rebar rod piece and plastic foam is guaranteed; damage to a foam plastic plate in the rebar inserting process is reduced, foam plastic brought into concrete and inserting resistance are greatly reduced, and tooling is convenient to conduct.

Owner:欧联(杭州)节能建筑技术研究有限公司

Combined memorial archway

ActiveCN100548521CAvoid difficultiesEasy to processMetal rolling stand detailsMetal rolling arrangementsEngineeringBroadband

The invention provides a combined arch, which is composed of components plugged together. The beneficial effects of the present invention are: the present invention decomposes the integral archway in the prior art into multiple part combinations, and completely solves the problem that the size of the rolls and frames in the wide-band steel rolling production line and the medium-heavy plate steel rolling production line become larger, resulting in the enlarging of the archway. The difficulties brought about provide convenience for the processing, tooling, transportation and installation of the archway, and solve the problem of processing a large archway with small equipment.

Owner:中重科技(天津)股份有限公司

A molding method for processing complex variable cross-section small-sized pipes

InactiveCN105665513BPrecise control of magnetic force distributionGuaranteed molding accuracyShaping toolsEngineeringNon magnetic

A forming device and forming method for processing small-size pipes with complex variable cross-sections belong to the technical field of forming small-size pipes with complex variable cross-sections (φ10mm and above), and specifically relate to a forming device and forming method for processing small-size pipes with complex variable cross-sections. The invention provides a forming device and a forming method of a complex variable cross-section small-size tube based on a controllable density magnetic coil instead of a traditional coil, which is easy to operate and high in product precision. The molding device of the small size pipe with variable cross-section of the present invention comprises a non-magnetic mold body and a magnetic ring, a mold groove is arranged in the mold body, and it is characterized in that: the magnetic ring is a metal pipe, and the metal pipe is provided with a groove corresponding to the mold groove The helical part processed by helical processing.

Owner:SHENYANG POLYTECHNIC UNIV

A gamma-ray detection method for butt joints of small-diameter pipes

ActiveCN104950003BWide range of transillumination thicknessImprove ergonomicsMaterial analysis by transmitting radiationButt jointEngineering

The invention introduces a gamma ray detection method for butt joints of small-diameter pipes. The special tooling for detection includes a fixing mechanism for fixing the adjustment mechanism, an adjustment mechanism for adjusting the position of the gamma ray source, and a tightening device for fixing the gamma ray source. fixed mechanism; fix the tooling on the pipeline to be tested, and adjust the adjustment mechanism so that the height of the gamma ray source that can be installed is at a suitable position; adjust to make the horizontal position of the gamma ray source suitable; Place the film that needs to be exposed in the corresponding position; move the gamma ray source to the working position; the gamma ray source performs radiation exposure on the film, and understand the weld quality of the butt joint through the exposure results of the film. The method of the invention greatly improves the detection efficiency, shortens the detection cycle, reduces the number of auxiliary personnel, saves labor costs, ensures the detection quality, reduces detection radiation, and improves personal safety protection.

Owner:中国石油天然气第一建设有限公司

Method for installing explosion-proof plate on matched piece, namely flap of heavy-duty tyre

InactiveCN102126195AFew requirementsEasy toolingTyre-inflating valvesMetal-working hand toolsEngineeringHeavy duty

The invention discloses a method for installing an explosion-proof plate (7) on a matched piece, namely a flap (6) of a heavy-duty tyre. The method comprises the following steps of: fixing the explosion-proof plate (7) through a support (9), supporting a supporting shaft (4), expanding a through hole of the flap (6) to the required diameter through the supporting shaft (4) by manually operating the pressing of a pressing mechanism, making the flap (6) slip, guiding the flap (6) to the seam allowance of the explosion-proof plate (7), and finishing installing the explosion-proof plate (7) on the flap (6) with the aid of a gland. When the method is operated, the method is not limited by places or energy media; a used tool has reasonable structure and light dead weight, and can move flexibly;meanwhile, the operation is simple and reliable; and the method is low in operating cost.

Owner:SICHUAN TYRE & RUBBER CO LTD

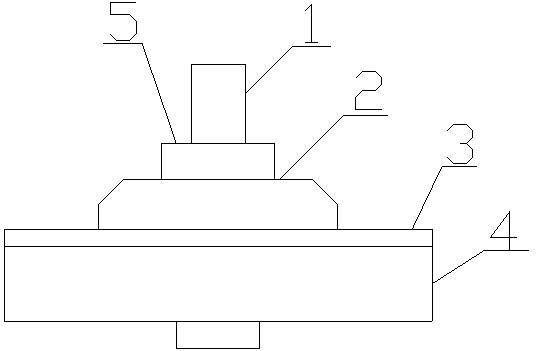

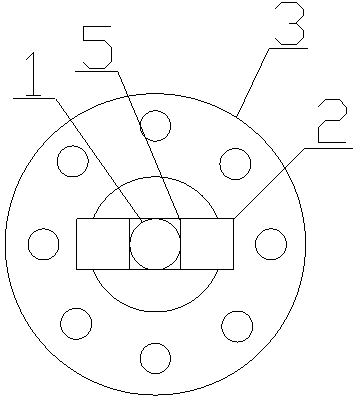

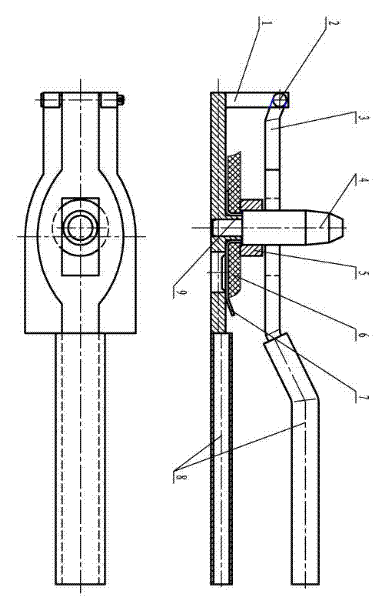

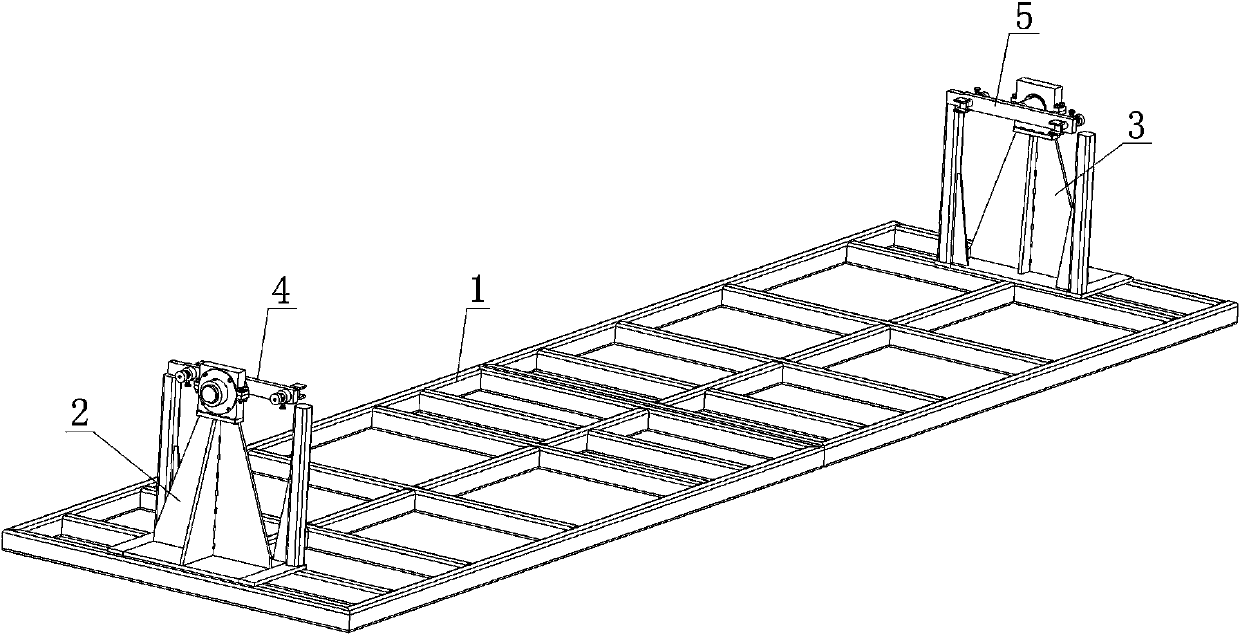

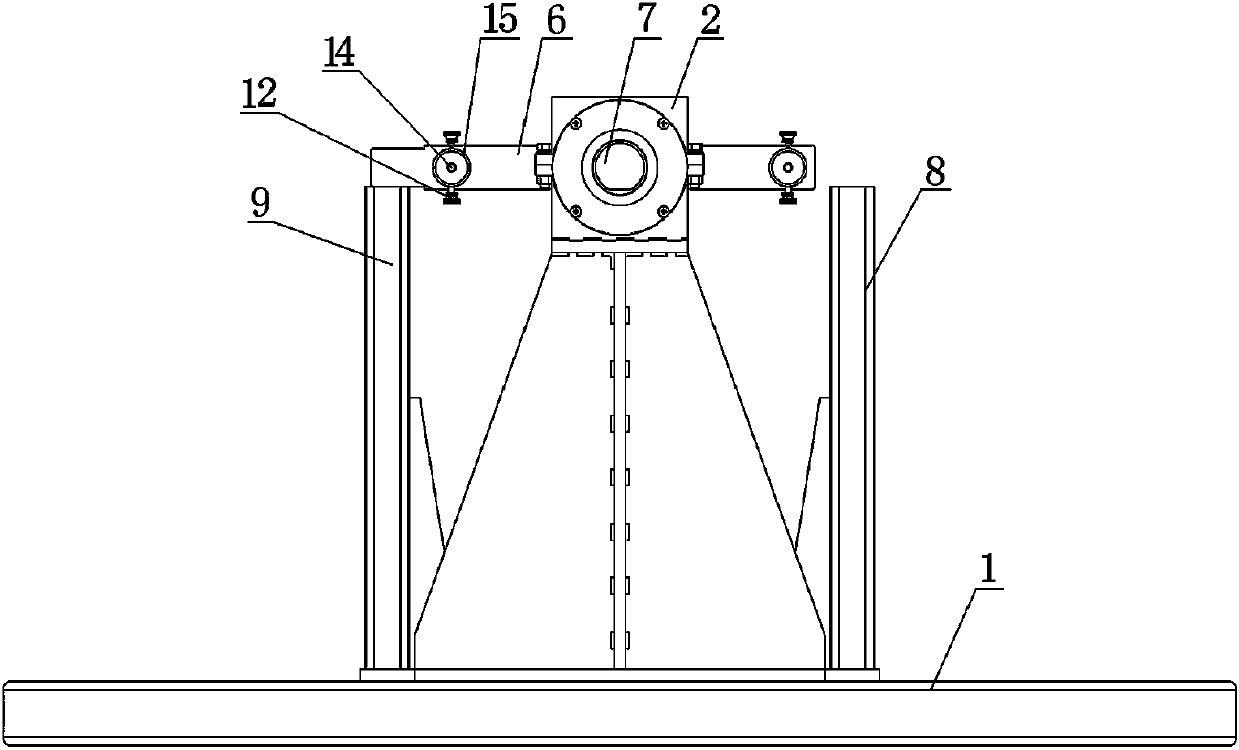

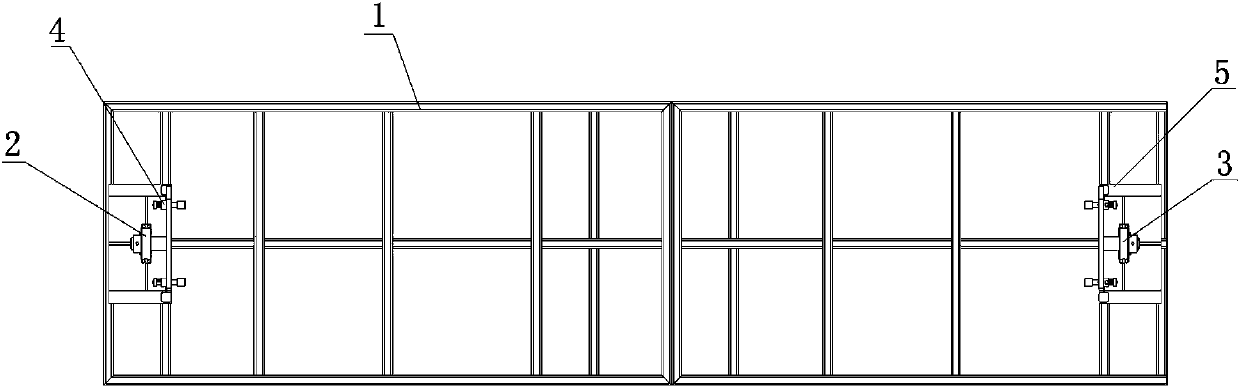

A tooling fixture for swing-mounting a box body

ActiveCN106141699BReduce labor intensityEasy toolingLarge fixed membersEngineeringMechanical engineering

Owner:AEROSPACE WANXIN SCI & TECH CHENGDU

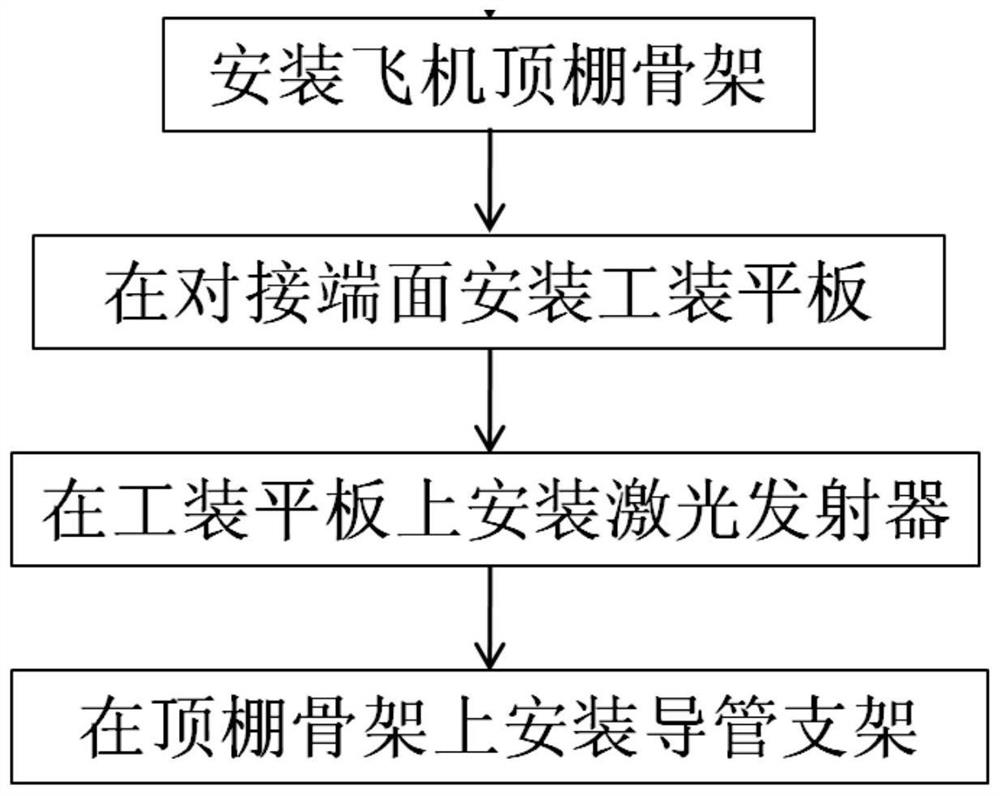

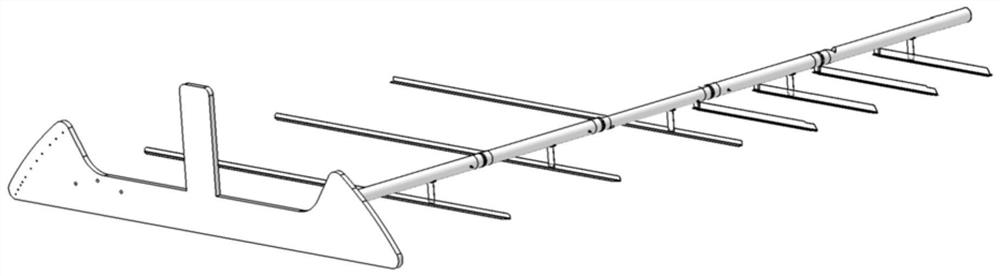

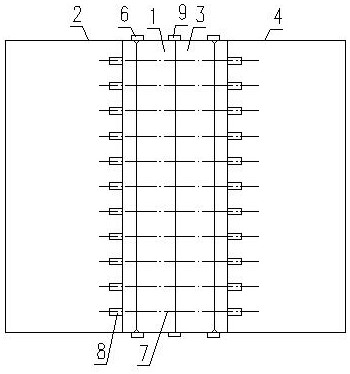

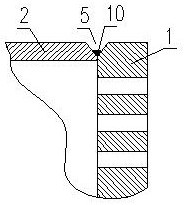

Mounting method of aircraft conduit bracket

InactiveCN113320712AImprove coordinationPrecise toolingAircraft assemblyLaser transmitterStructural engineering

The invention discloses a mounting method of an airplane conduit bracket. The mounting method comprises the following steps: respectively mounting an airplane ceiling framework on an airplane middle section part and an airplane tail section part; arranging tool flat plates at the butt joint positions of the aircraft middle section component and the aircraft tail section component respectively, the tool flat plates being parallel to the plane where butt joint holes of the aircraft middle section component and the aircraft tail section component are located, and forming mounting holes of laser pens in the tool flat plates; inserting a laser emitter into the mounting hole in the tool flat plate, the laser emitter being turned on, and laser rays emitted by the laser emitter being perpendicular to the tool flat plate; installing guide pipe supports on ceiling frameworks of the aircraft middle section component and the aircraft tail section component according to laser rays emitted by the laser emitters, and the guide pipe supports being used for supporting guide pipes penetrating through the aircraft middle section component and the aircraft tail section component. And the conduit bracket can be quickly, simply, conveniently and accurately mounted.

Owner:SHAANXI AIRCRAFT CORPORATION

A Welding Process of Large-diameter Thin-walled Double Tube Sheet and Cylinder Circumferential Seam

ActiveCN109551080BAvoid deformationReduce distortionArc welding apparatusManufacturing cost reductionDouble tube

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

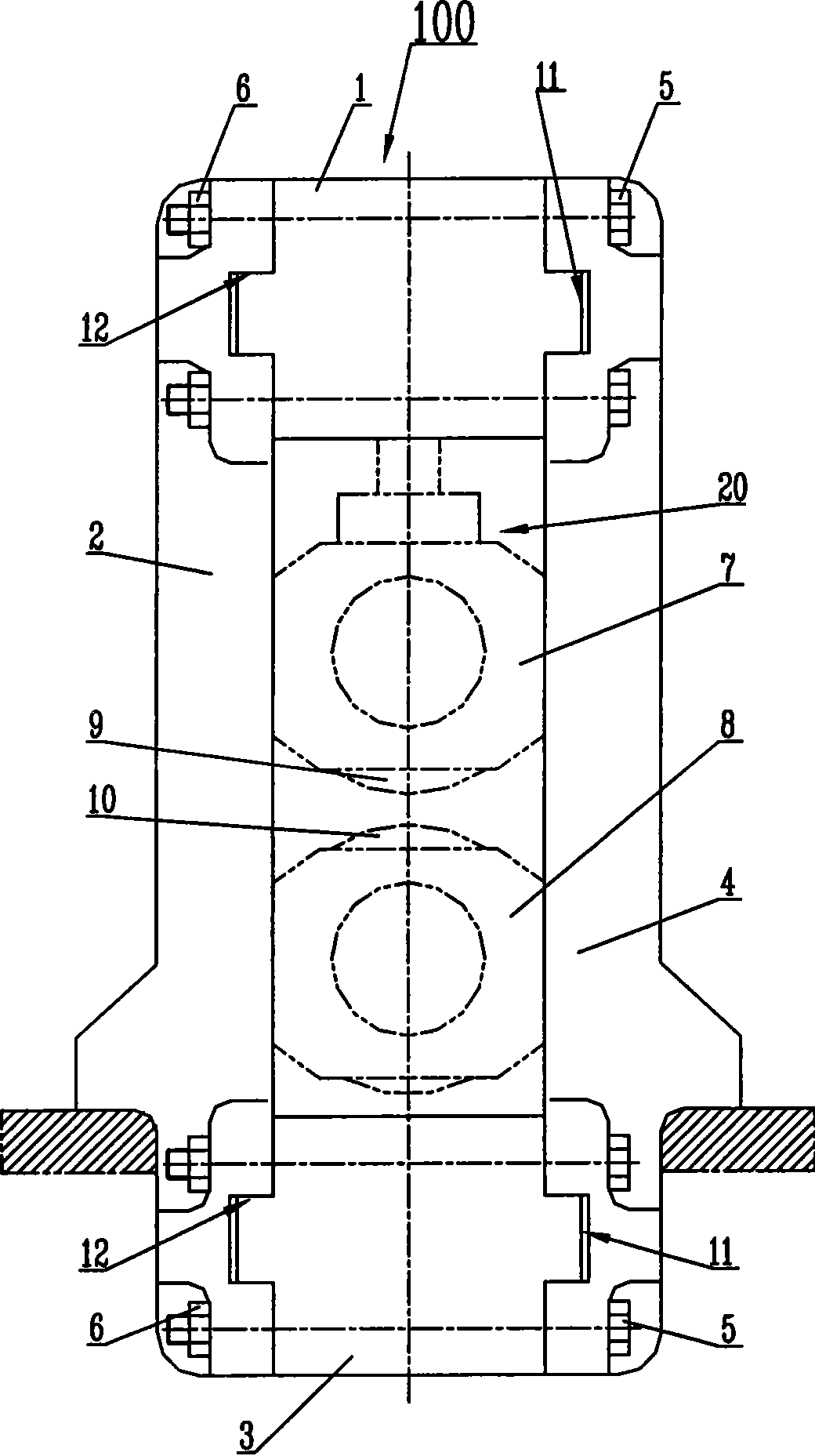

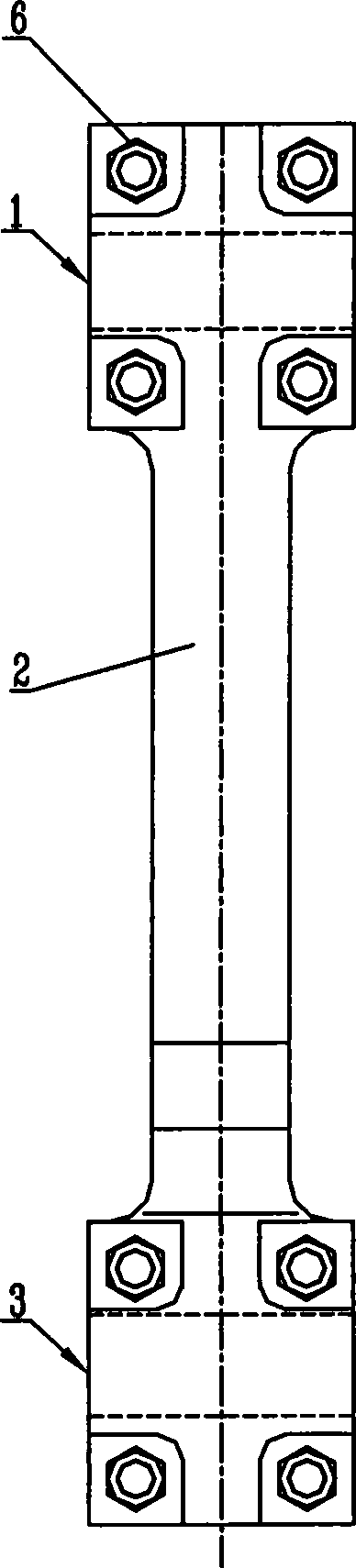

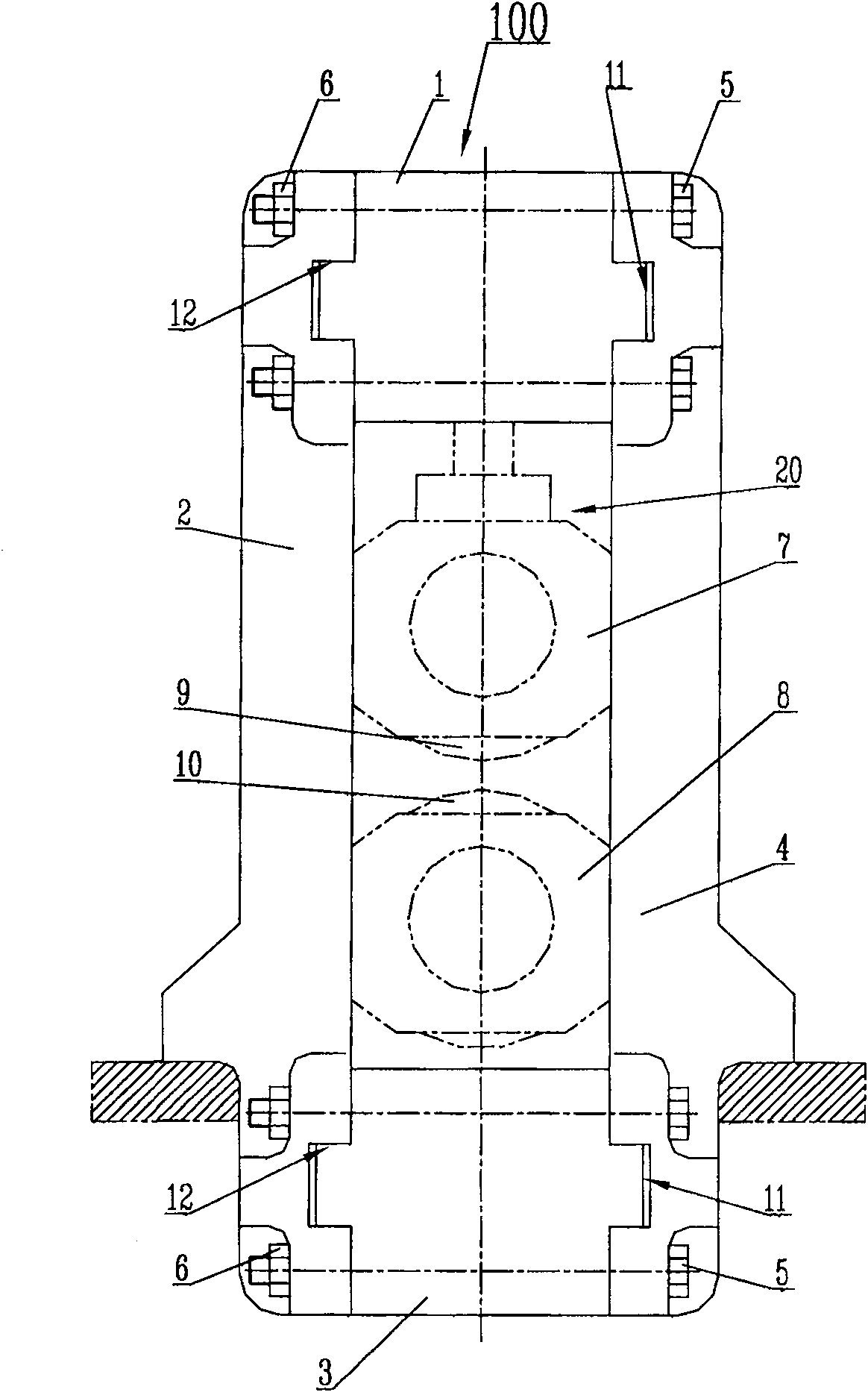

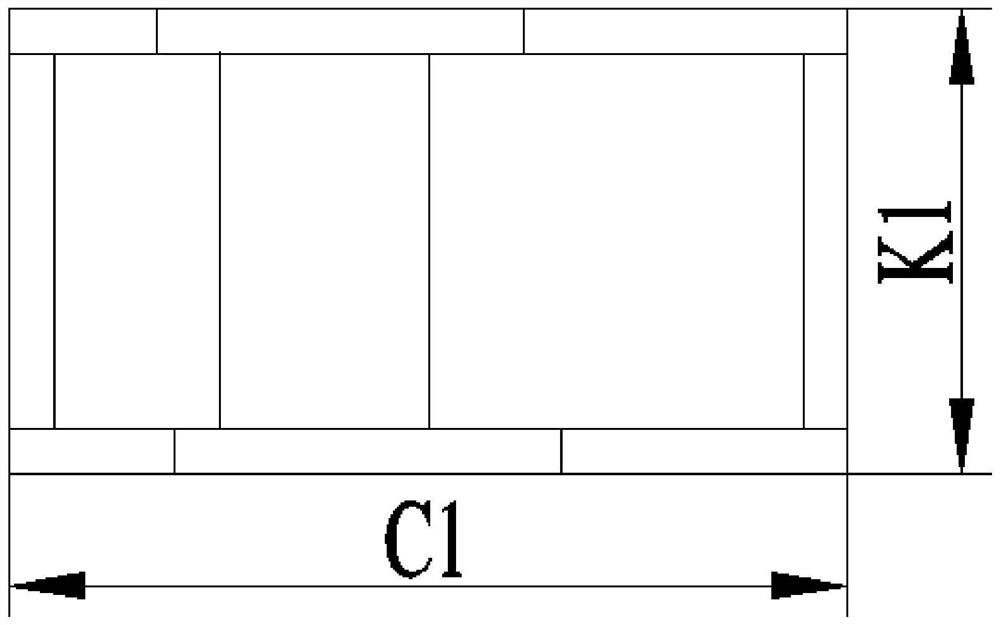

Large-diameter thin-wall double-tube sheet and cylinder body circular seam welding process

ActiveCN109551080AAvoid deformationReduce distortionArc welding apparatusManufacturing cost reductionDouble tube

The invention discloses a large-diameter thin-wall double-tube sheet and cylinder body circular seam welding process. The large-diameter thin-wall double-tube sheet and cylinder body circular seam welding process comprises following steps of firstly, assembling, wherein two sets of pie plates and cylinder joints are assembled in place, grooves of the pipe plates and the cylinder joints are same, and the pipe plates in the same group and the cylinder joints are subjected to spot welding fixing through multiple tie bar plates; secondly, connection, wherein the front faces of two pipe plates cling together, multiple pull rods are adopted to penetrate through pipe holes of two pipe plates, two ends of the pull rods are fastened through nuts, and relative positions of the two pipe plates are fixed; thirdly, welding, wherein annular seam welding of more than two times are carried out in the grooves of each set of pipe plates and the cylinder joints, and annular seam welding of the two sets of pipe plates and the cylinder joints is alternatively carried out; fourthly, heat treatment, wherein annular seams of the two sets of pipe plates and the cylinder joints are subjected to heat treatment; and fifthly pull rod and tie bar plate dismounting and mounting. Deforming of the pipe plates can be greatly reduced, the hole position matching degree of the two pipe plates and the subsequent pipe penetrating smooth operation can be ensured, construction is easy and convenient, work efficiency is high, and manufacturing cost is greatly reduced.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

A quick installation method for vehicle glass

ActiveCN112080210BGuaranteed curing effectQuick installationNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesFirming agentEngineering

The invention provides a quick installation method for vehicle glass. The method undergoes base surface treatment, gluing assembly and infrared radiation curing treatment to complete the installation of the vehicle and glass; the heat-cured one-component polyurethane sealant used in gluing Including the following raw materials: polyether-type aliphatic polyurethane prepolymer with isocyanate groups at the end, isocyanate-modified epoxy resin, ketimine latent curing agent A, dicyandiamide and imidazole in a mass ratio of 1:0.1-0.6 Composed of latent curing agent B, fillers, plasticizers, epoxy soybean oil and other additives. The installation method uses infrared radiation to cure the heat-curing one-component polyurethane sealant, which can shorten the installation time of the vehicle glass, has simple tooling, can ensure the installation quality of the vehicle glass, and can improve the installation efficiency of the vehicle glass and reduce costs. , to ensure its safe use.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD +1

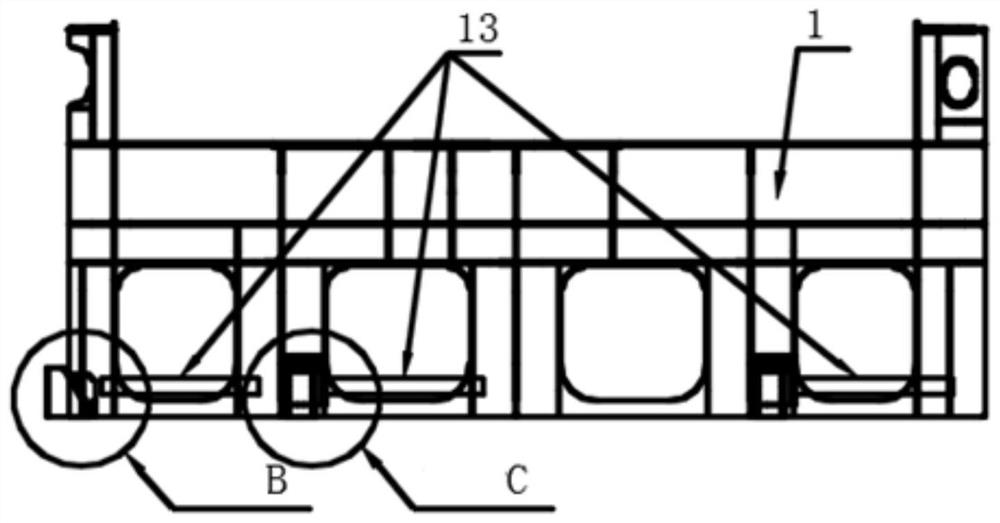

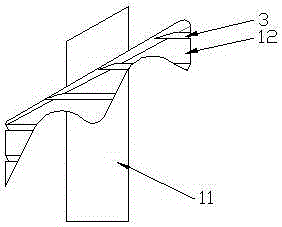

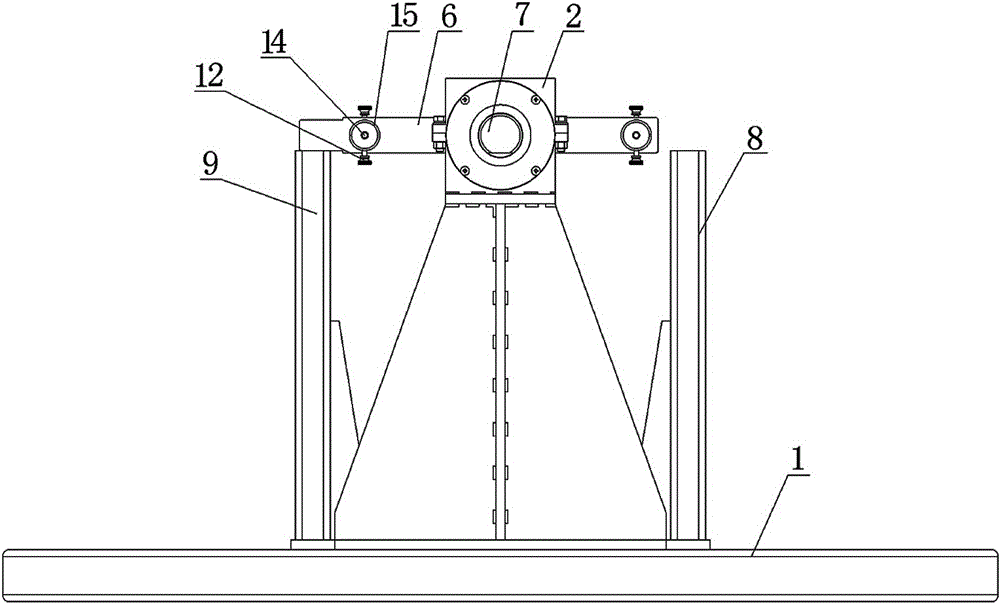

Swinging box body mounting tool fixture

The invention discloses a swinging box body mounting tool fixture. The tool fixture comprises a base (1), a bearing base A (2) arranged on the base (1), and a bearing base B (3); a rotating shaft (7) is mounted on the bearing base A (2); two locking devices are symmetrically arranged around the rotating shaft (7); the locking devices consist of springs (10), main shafts (11), locking screws (12) and buckles (13); the main shafts (11) penetrate through brackets (6); baffle plates (15) are mounted on small shafts (14); the main shafts (11) are coated with the springs (10) between the baffle plates (15) and the brackets (6); the locking screws (12) penetrate through the brackets (6), and are fixed in waist-shaped holes (16); the back end parts of the brackets (6) are joined at the tops of stand columns II (9); and gaps are formed between the front end parts of the brackets (6) and stand columns I (8). The tool fixture has the following beneficial effects: the labor intensity of workers is relieved; the assembly efficiency of sealing plates is improved; and the installation by the workers is convenient.

Owner:AEROSPACE WANXIN SCI & TECH CHENGDU

Preparation method of resin binder capable of realizing CO2 gas hardening

InactiveCN105195669ASimple processEasy to prepareFoundry mouldsFoundry coresAtmospheric pressureHot Temperature

A preparation method of a resin binder capable of realizing CO2 gas hardening is provided; the concentration of a sodium acrylate monomer is 20-35%, ammonium persulfate is used as an initiator, the addition amount of ammonium persulfate is 2.5-3.5% of the monomer mass, and a polymerization temperature is 75-85 DEG C. The resin binder can be synthesized at atmospheric pressure, autoclaves, high temperature and complicated equipment have no need of use, the synthesis process is simple and is easy to control, no pollution gas is discharged in the synthetic process, the cost is low, and the binder is good in stability and easy to preserve.

Owner:JIUJIANG UNIVERSITY

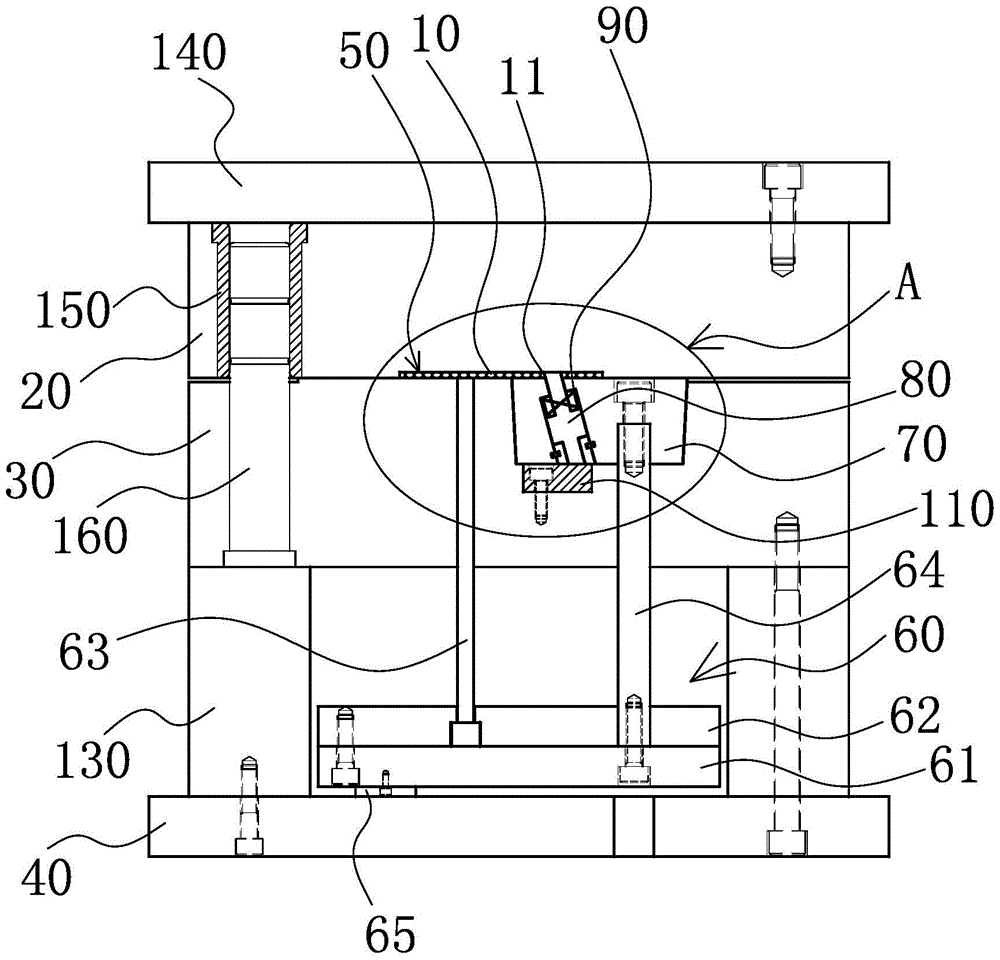

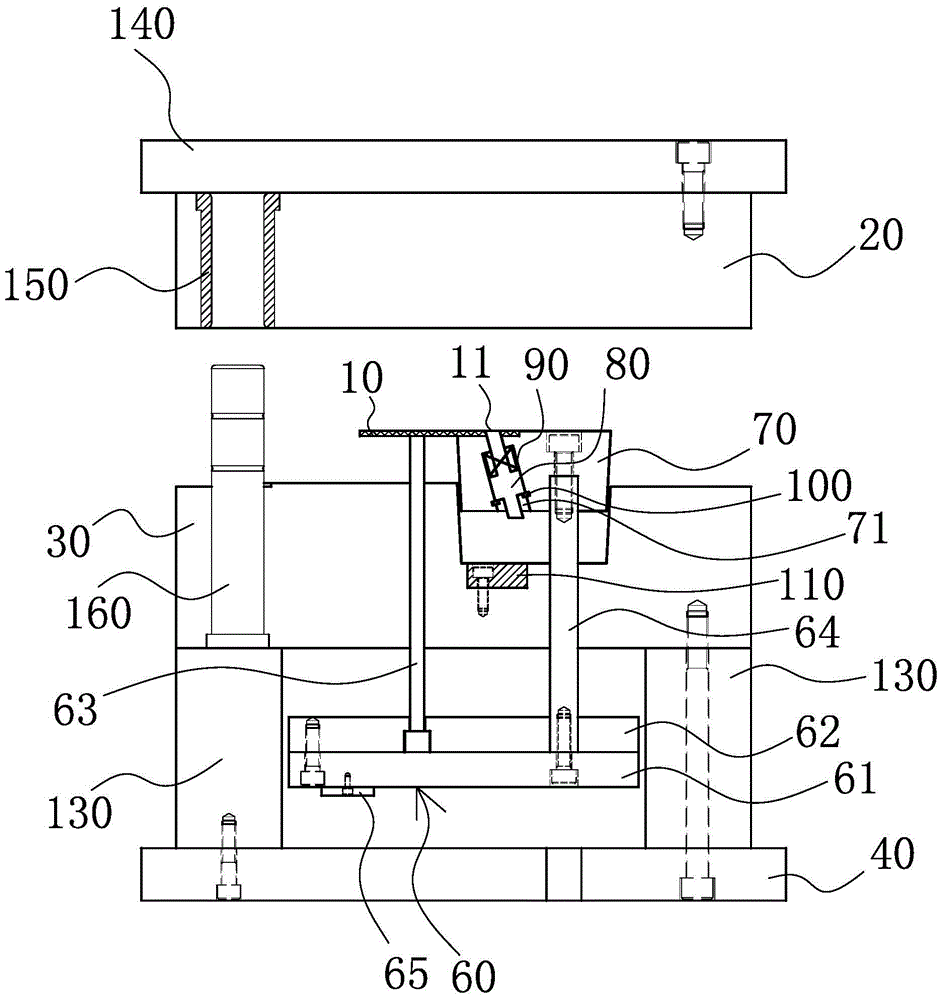

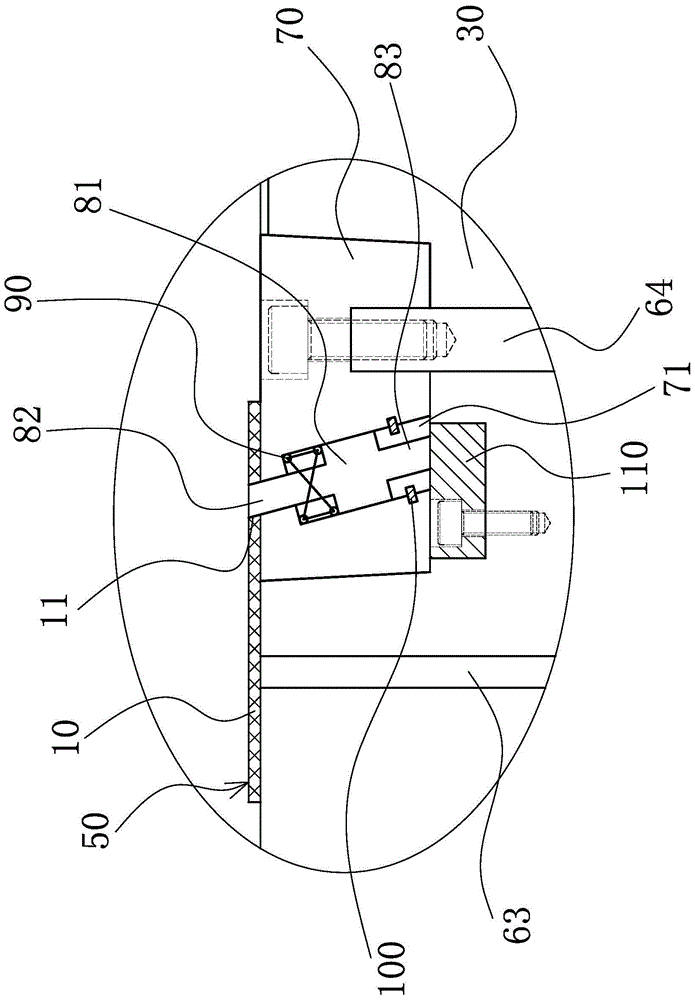

An injection mold for processing products with oblique holes

The invention provides an injection mold for processing a product with an oblique hole, and belongs to the technical field of molds. The injection mold comprises a fixed mold middle plate, a movable mold middle plate and a movable mold seat plate, wherein an injection molding cavity for forming a product with an oblique hole is formed by buckling the fixed mold middle plate and the movable mold middle plate; a pushing assembly is movably mounted between the movable mold middle plate and the movable mold seat plate; a straight ejection block connected with the pushing assembly is embedded into the movable mold middle plate; a mounting slot is formed in the straight ejection block, and an inclined core pulling needle is mounted in the mounting slot; a resetting piece sleeving the core pulling needle is also mounted in the mounting slot; during mold assembling, one end of the core pulling needle penetrates through the straight ejection block and is inserted into the oblique hole of the product, and the other end of the core pulling needle is pressed against the movable mold middle plate; during mold opening, the pushing assembly upwards ejects the product and simultaneously drives the straight ejection block to move upwards; at the moment, the resetting piece works and drives the core pulling needle to be separated from the oblique hole of the product. The injection mold has the advantages of simple structure, high working efficiency and convenience in maintenance.

Owner:NINGBO SOUTH MOLD & PLASTIC

Automobile engine muffler gas leak detection tool and method thereof

ActiveCN109506851BEasy toolingSimple structureMeasurement of fluid loss/gain rateInjection airAir tightness

The invention discloses a test tool for air leakage of a silencer of an automobile engine and a method of the test tool. The test tool comprises a vertical air impermeability detection cylinder, a liquid injection and pumping unit, a pressure boost air injection unit and a tested silencer body; the tested silencer body is detachably installed in the air impermeability detection cylinder, and the pressure boost air outlet end of the pressure boost air injection unit is communicated with the air inlet end of the air impermeability detection cylinder through an air injection pipe; the liquid injection and pumping unit is communicated with the lower end of a liquid cavity in the air impermeability detection cylinder through a liquid communication pipe. The test tool is simple in structure, andthe outer wall of an air discharging cylinder and the inner wall of the wall body of an inner annular column are converted into sealing fit without air leakage from conveniently-detached clearance fit. The test tool is beneficial to a tool of the tested silencer and also helps to improve the sleeving sealing performance in the detection process.

Owner:宁波远亚车辆检测有限公司

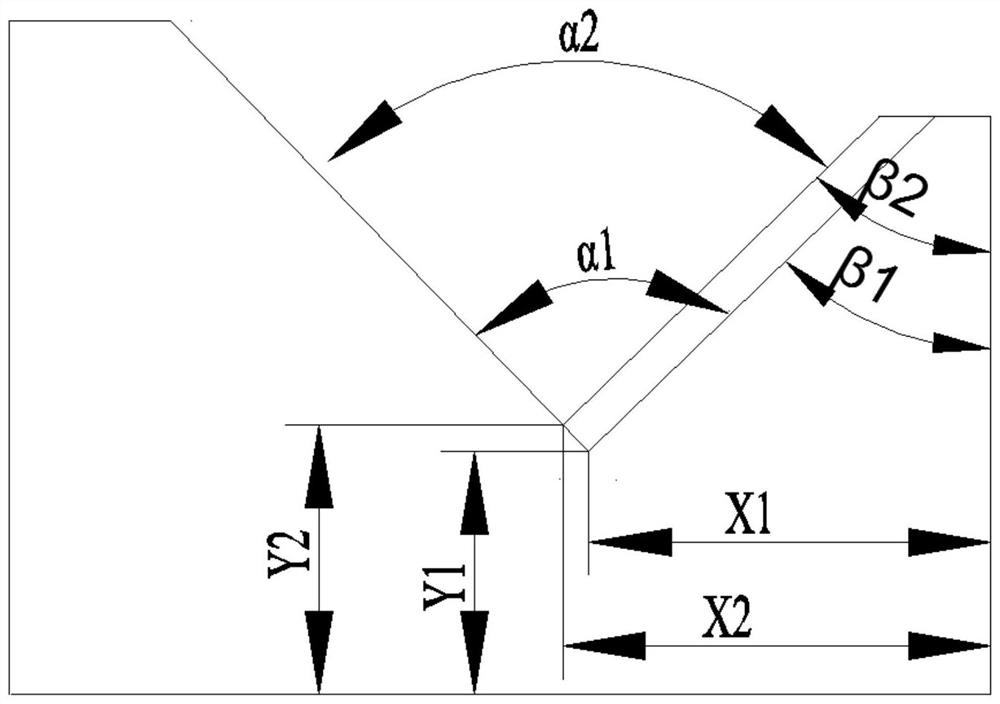

Tooling device and method for measuring casting thickness

ActiveCN111750809BAccurate wall thicknessSimple structureUsing wave/particle radiation meansStructural engineeringMechanical engineering

The invention discloses a tooling device for measuring the thickness of a casting and a method thereof. The degree is equal to the included angle between the end face of the tenon root inlet side and the end face of the tenon root on the back side of the blade; The included angle between the reference side, the first reference side and the V-shaped opening of the tenon root is β1, and the opening degree of the V-shaped opening of the tenon root is α1, and the β1 is equal to the angle between the end face of the tenon root inlet side and the vertical CR ray Angle, the structure of the edge plate placement plate is the same as that of the tenon root placement plate, wherein the angle between the second reference edge and the V-shaped opening of the edge plate is β2, and the opening degree of the V-shaped opening of the edge plate is α2, and the β2 is equal to The angle between the end surface 13 of the inlet side of the edge plate and the vertical CR ray, after the hollow blade is placed in the present invention, the plane where the R part of the hollow blade inlet side is located is perpendicular to the detection ray, and the detection ray can detect the vertical distance of the R component , making the measured wall thickness of the R part more accurate.

Owner:AECC AVIATION POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com