Forming device for machining complex variable section small-scale tubes and forming method

A forming device and variable cross-section technology, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to realize the installation of designed coils, difficult density control, and inability to apply variable cross-section small-size tube forming work, etc. Achieve the effect of simple shape, lower manufacturing cost, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

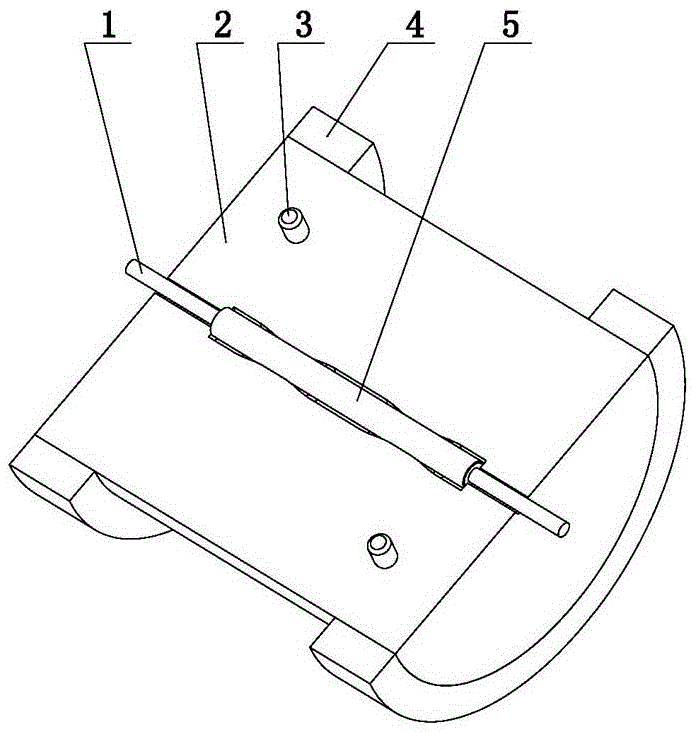

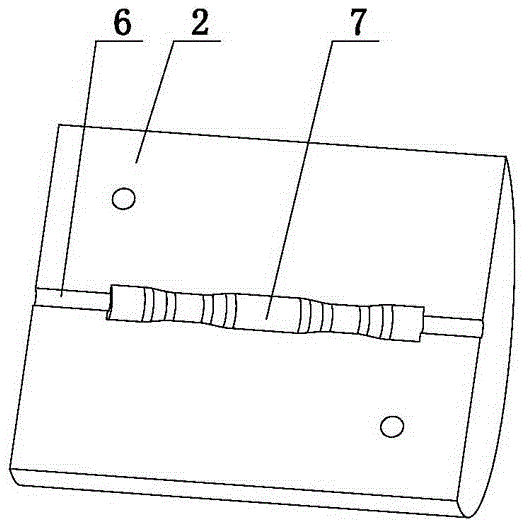

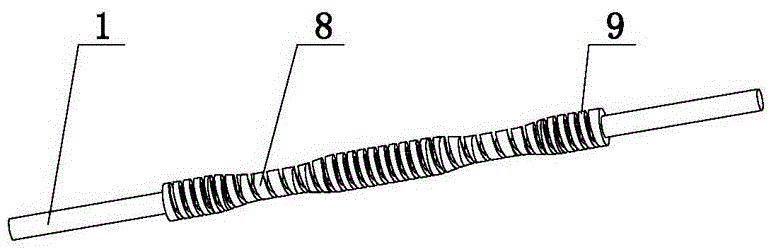

[0035] Embodiment: Add pins in a non-magnetic half-mold 2, close the other half-mold 2, and then put the aluminum alloy tube blank 5, so that the aluminum alloy tube blank 5 is placed in the model groove 7 in the two half-molds 2 Inside, the magnetic coil 9 is put into the middle of the hollow tube blank 5, the two ends of the magnetic coil 9 metal pipe 1 are placed on the positioning grooves 6 in the two halves of the mold 2, and the magnetic coil 9 two ends are respectively connected to two stages of power supply. Then put the two locking collars 4 on the outside of the forming die, and clamp them in a stepped manner to fix them. Connect the magnetic coil 9 into the electromagnetic forming machine, start the power supply and charge the high voltage capacitor first, after the charging capacitor is fully charged, check the wiring of the main circuit, and after confirming that it is correct, start the instantaneous discharge button to complete the instantaneous discharge. Under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com