Automatic flipping device for car cup box

An automatic flipping and cup box technology, which is applied to the special position of the vehicle, vehicle parts, transportation and packaging, etc., can solve problems such as complex structure, and achieve the effect of simple technical solution, saving tooling cost, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

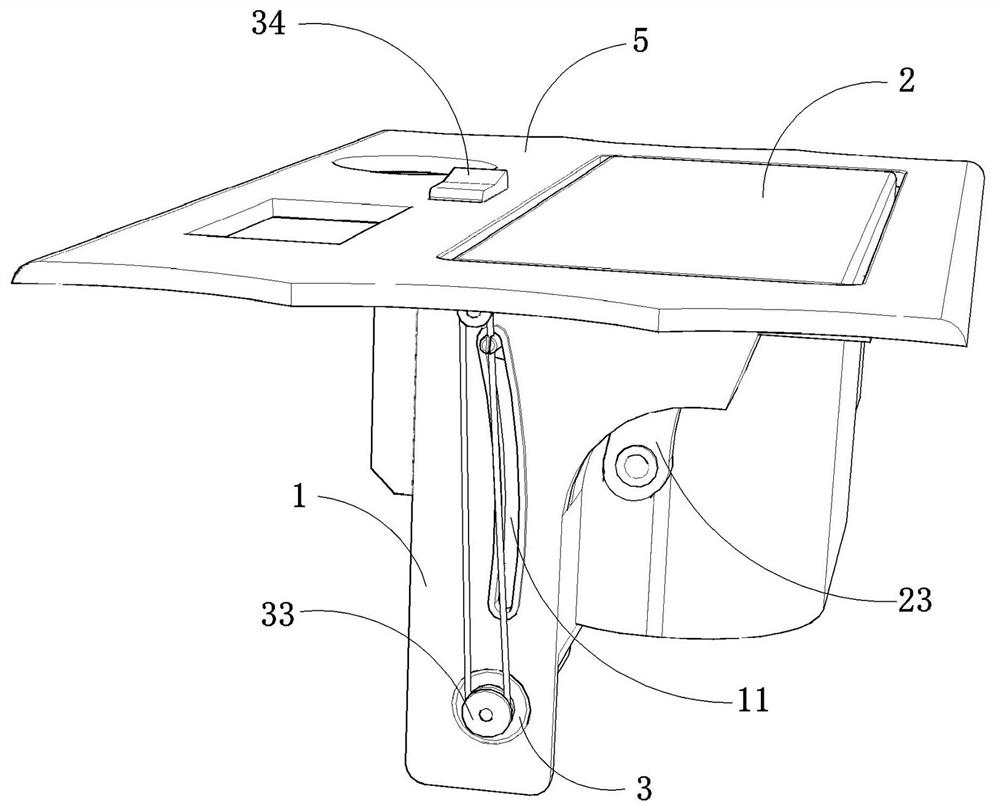

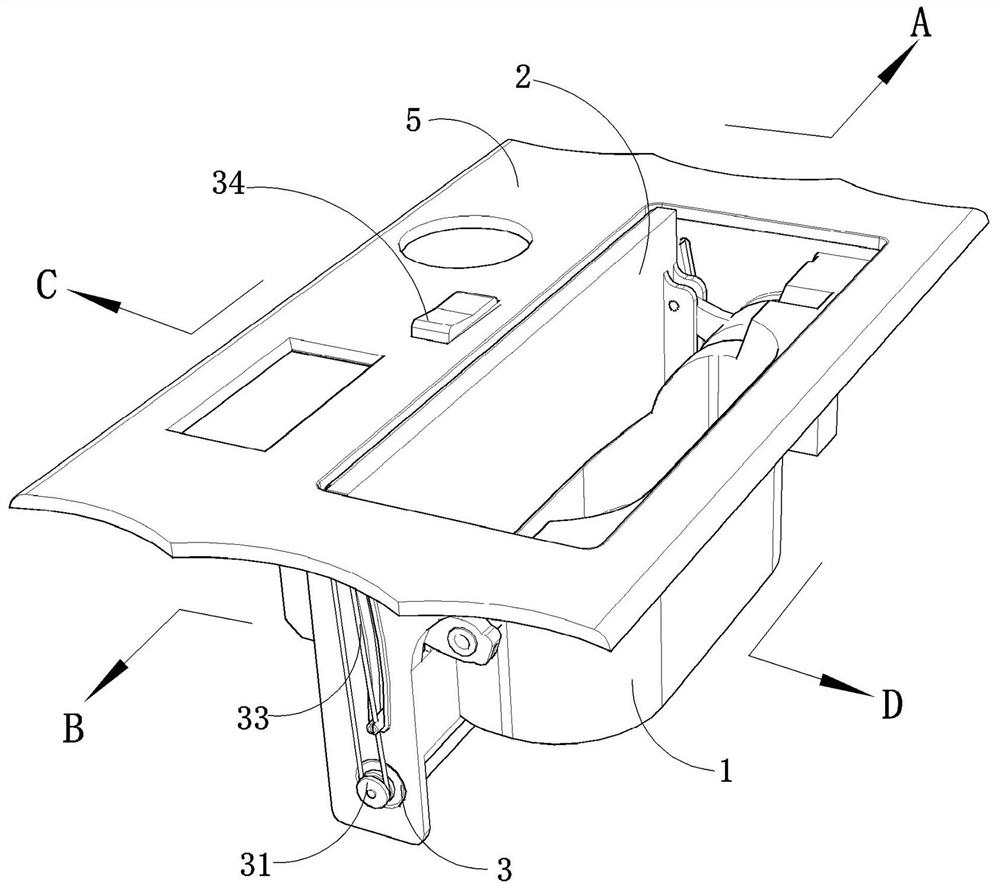

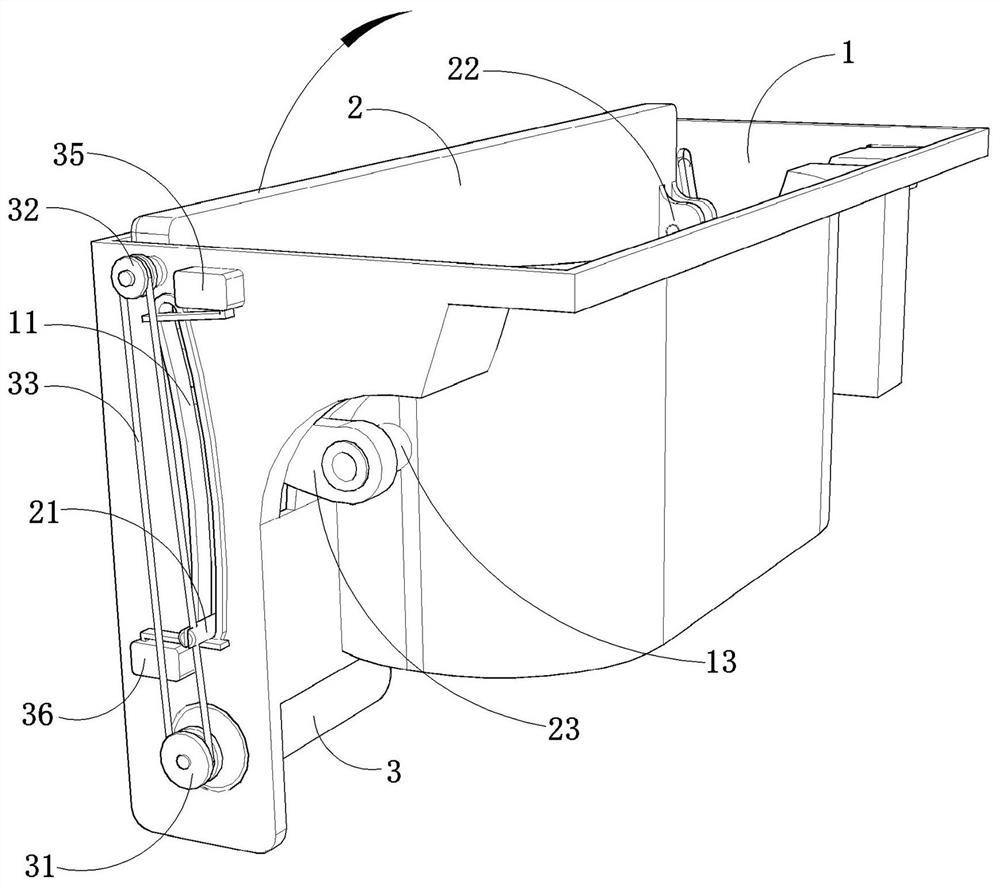

[0039] As shown in the figure: A is the front, B is the back, C is the left, and D is the right;

[0040] 1. Box frame, 2. Cover plate, 3. Power mechanism, 5. Panel;

[0041] 11. Limit chute, 12. Cover plate groove, 13. Connection base, 15. Guide wheel shaft seat, 16. Power installation hole;

[0042] 21. Traction sliding shaft, 22. Fixed shaft joint, 23. Swivel arm, 25. Traction sliding shaft hole, 26. Limit clip, 27. Card slot, 28. Index card slot;

[0043] 31. index sheave, 32. guide sheave, 33. traction belt, 34. reverse switch, 35. first travel switch, 36. second travel switch, 37. upper travel switch, 38. lower travel switch.

[0044] like figure 1 Shown in -10: automatic flipping device for cup boxes for vehicles, including box frame 1, cover plate 2 and power mechanism 3, the upper side of box body frame 1 is provided with cover pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com