Method for installing explosion-proof plate on matched piece, namely flap of heavy-duty tyre

A technology for explosion-proof discs and accessories, applied in tire parts, tire inflation valves, vehicle parts, etc., can solve the problems of difficult assembly, inflexible operation, low operation efficiency, etc., and achieve low operating costs and operability. good, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

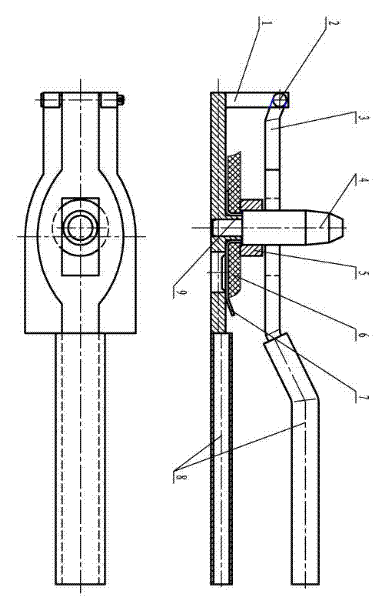

[0011] The step that the inventive method implements operation is:

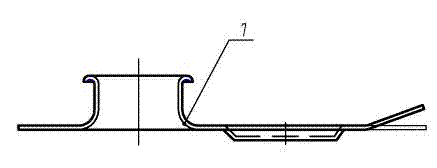

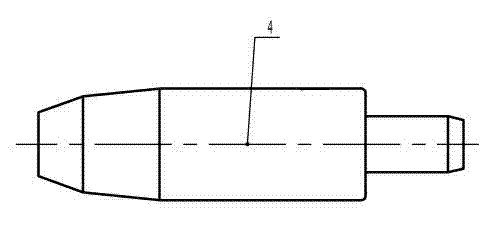

[0012] 1. In Figure 5 In the embodiment, the tooling can be directly placed on the ground or other planes during operation, such as Figure 4 The shown support frame (1) supports the entire tooling, hold the handle (8) of the gland frame (3), pull up the gland frame (3) of the press-fitting mechanism, and place a piece to be assembled such as figure 2 The explosion-proof disk (7) shown is installed on the support (9). Note that the explosion-proof disk (7) has direction and position requirements. Its protrusion direction is consistent with the direction of the groove of the on, plug in as image 3 With the support shaft (4) shown, complete the preparation for operation.

[0013] 2. In Figure 5 In the embodiment, a pad (6) to be assembled is placed on the end of the support shaft (4) through the hole, and the pad (6) at the hole is generally flattened, and the inner circle of the pad (6) faces Down, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com