Tooling device and method for measuring casting thickness

A tooling and thickness measurement technology, applied in measuring devices, instruments, using wave/particle radiation, etc., can solve the problems of inaccurate measurement of hollow blades, and achieve the effects of simple and convenient card installation, short detection period, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

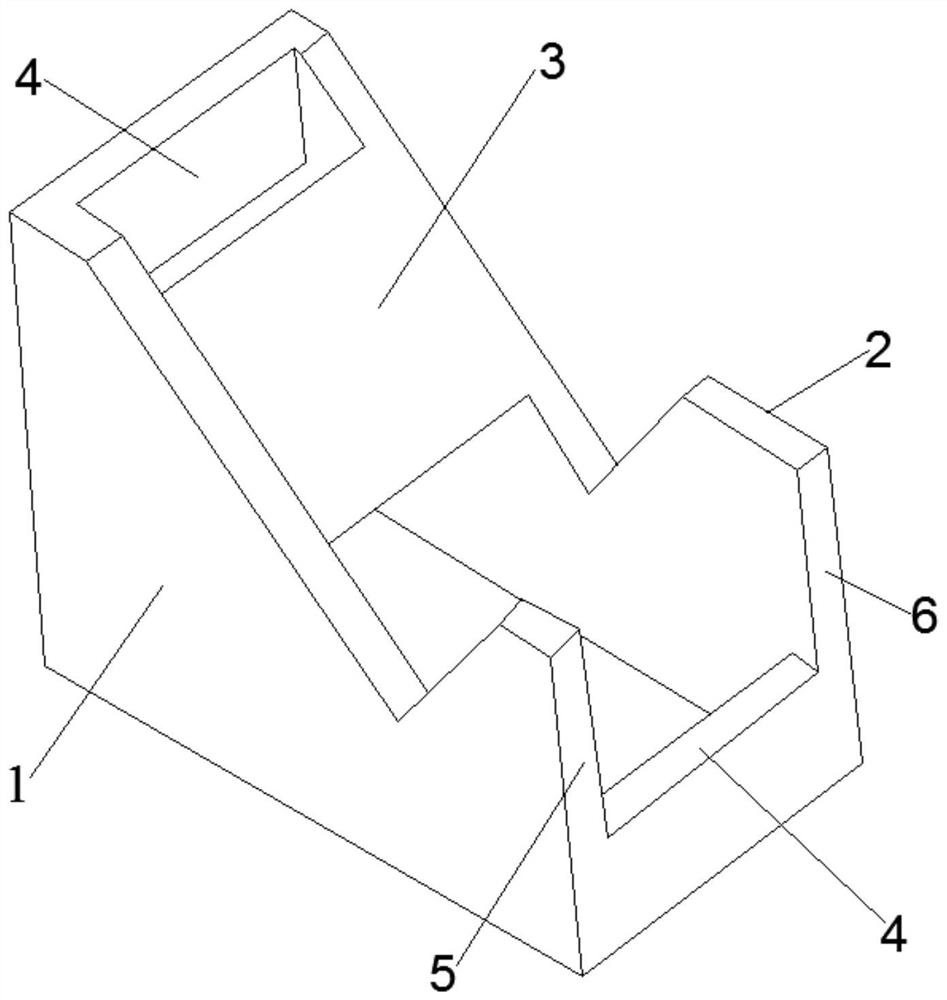

[0047] Example 1: Detection of the wall thickness of the inlet R of a high-pressure turbine blade of a certain machine

[0048] The blade body size of the hollow blade to be tested is less than 50mm, so only the tooling device for measuring the thickness of the casting is used. The selected size of the tooling device is:

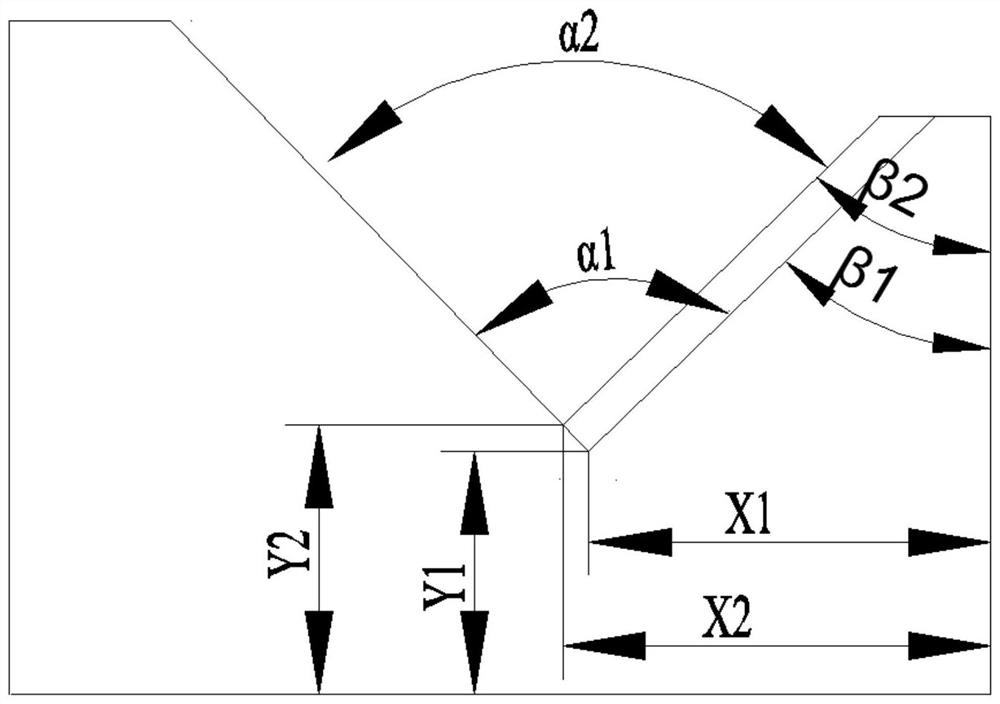

[0049] Tenon root placement plate: α1=90°, β1=46°, X1=16mm, Y1=13mm, H1=28.5mm;

[0050] Edge plate placement plate: α2=90°, β2=46°, X2=18.5mm, Y2=17mm, H2=35.5mm;

[0051] Mortise and tenon backing plate: length 25mm, width 20mm;

[0052] Reinforced tooling plate: length 25mm, width 10mm;

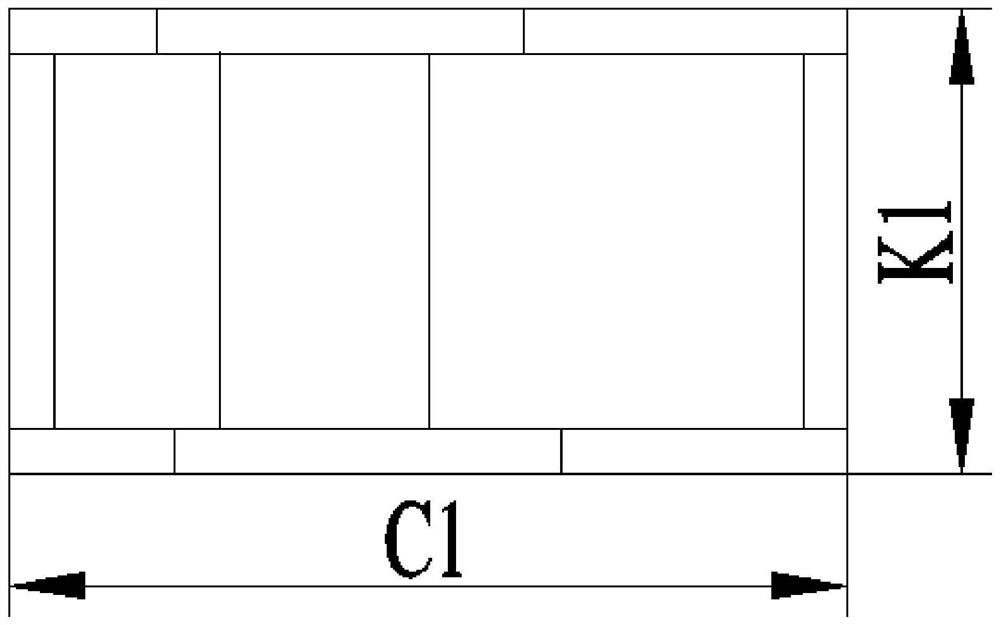

[0053] The wall thickness of tenon root placement board, edge board placement board, tenon root support board and reinforced tooling board is 3mm, C1=50mm, K1=31mm.

[0054] Make a thickness measuring tooling device according to the above dimensions, place the hollow blade on the tooling device, put the placed hollow blade and the tooling device into the CR testing eq...

Embodiment 2

[0055] Example 2: Detection of the wall thickness of the inlet R of the working blade of a high-pressure turbine of a certain machine

[0056] The blade body size of the hollow blade to be tested is about 126mm, and the casting thickness measuring tooling device and auxiliary tooling parts are used for detection. The dimensions of the tooling device and auxiliary tooling parts are as follows:

[0057] Tenon root placement plate: α1=80°, β1=60°, X1=20mm, Y1=20mm, H1=35mm;

[0058] Edge plate placement plate: α2=75°, β2=50°, X2=30mm, Y2=5mm, H2=35mm;

[0059] Mortise and tenon backing plate: length 80mm, width 50mm;

[0060] Reinforced tooling plate: length 50mm, width 10mm;

[0061] The wall thickness of tenon root placement board, edge board placement board, tenon root support board and reinforced tooling board is 3mm, C1=86mm, K1=56mm;

[0062] Auxiliary tooling parts: L1=6mm, length 30mm, width 20mm.

[0063] Make the tooling device and auxiliary tooling parts according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com