Rotor blade for a thermal rotary machine and method for producing such a rotor blade

A technology for rotor blades and rotating machines, applied in the direction of supporting elements of blades, machines/engines, mechanical equipment, etc., can solve problems such as expensive inspection or maintenance work, consumption, power limitations of rotating machines, etc., to achieve stress resistance, Effect of high wall thickness characteristics and centrifugal stress reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

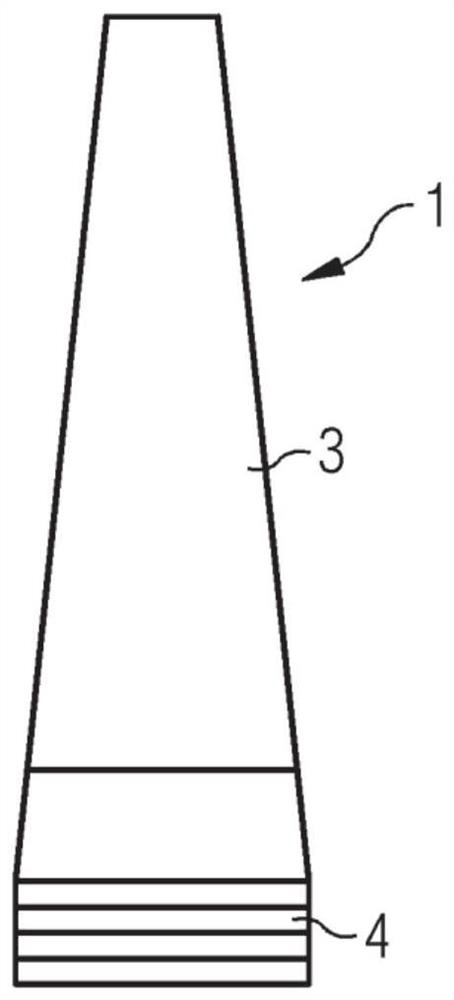

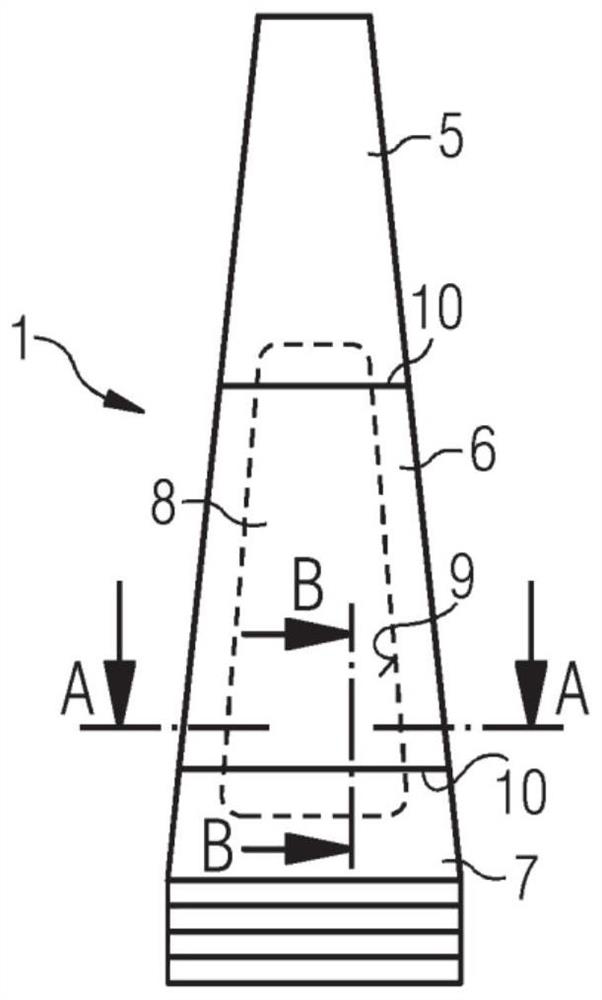

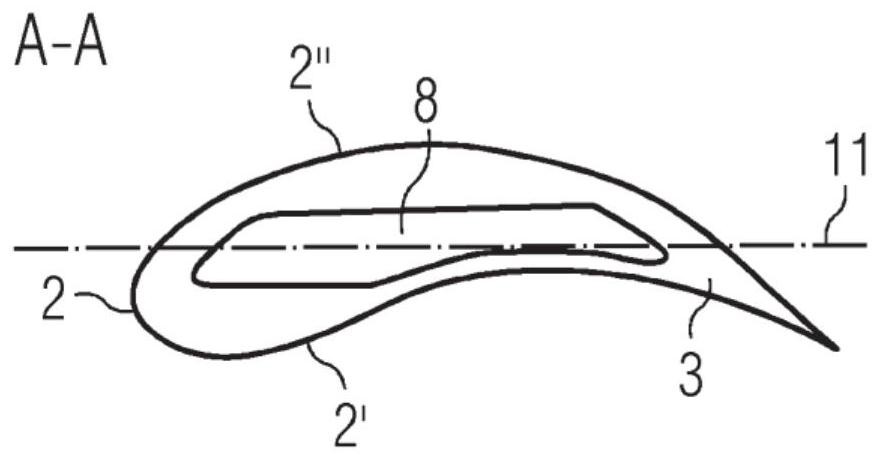

[0033] figure 1A rotor blade 1 according to the prior art is shown. The rotor blade is here produced in one piece, for example from a forging or a semi-finished product. The rotor blade 1 comprises an airfoil region 3 formed in the form of a flow profile 2 and a root region 4 formed for fastening the rotor blade 1 to the rotor. Due to the solid, one-piece construction of the rotor blade 1 , high centrifugal stresses act during operation of the hot rotating machine. Particularly at large blade lengths and / or high rotational speeds, rotor blades can only be produced from high-strength and thus expensive materials or eventually no longer can be produced at all. The most stressed regions of the rotor blade 1 are here the blade root region 4 and the transition into the airfoil region 3 . The airfoil region 3 itself is also subjected to high stresses in the wide part of its extension. The stress on the blade root and airfoil acts as a combination of LCF and HCF stresses generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com