Injection molded doll head, its mfg. method and mould

A head and toy technology, applied in the field of doll heads and molds, can solve the problems of unfavorable environment and harmful health of PVC materials, and achieve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Referring to the accompanying drawings, preferred embodiments of the present invention will be described in detail below. The directional terms: front, back, left, right, top, bottom, height, width, etc. are referred to from the perspective that a doll's head would have in a conventional vertical position, and are used herein to identify and describe the invention Different features of these preferred embodiments. However, these directional terms are not intended to limit the invention in any way.

[0024] Also, what is described herein is a preferred embodiment of a doll's head. However, the term is not meant to be limited to any particular type of doll head, nor is it limited to human characteristics. As used in this specification, the term "doll head" may be the head of any toy, figurine, memorabilia, animate robot, and representation of a human being, a living or extinct animal, or even an unknown Heads of analogues of sources such as aliens, etc.

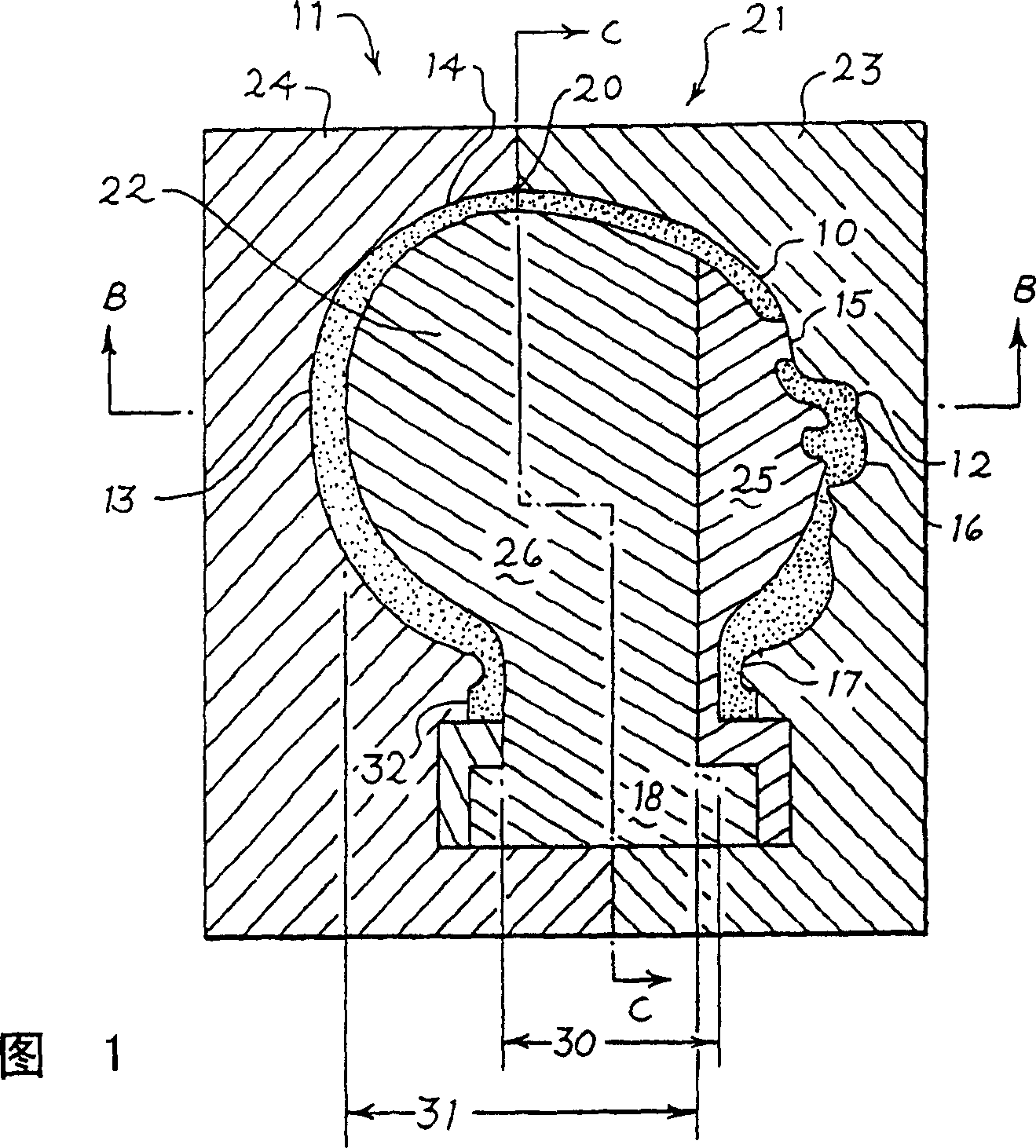

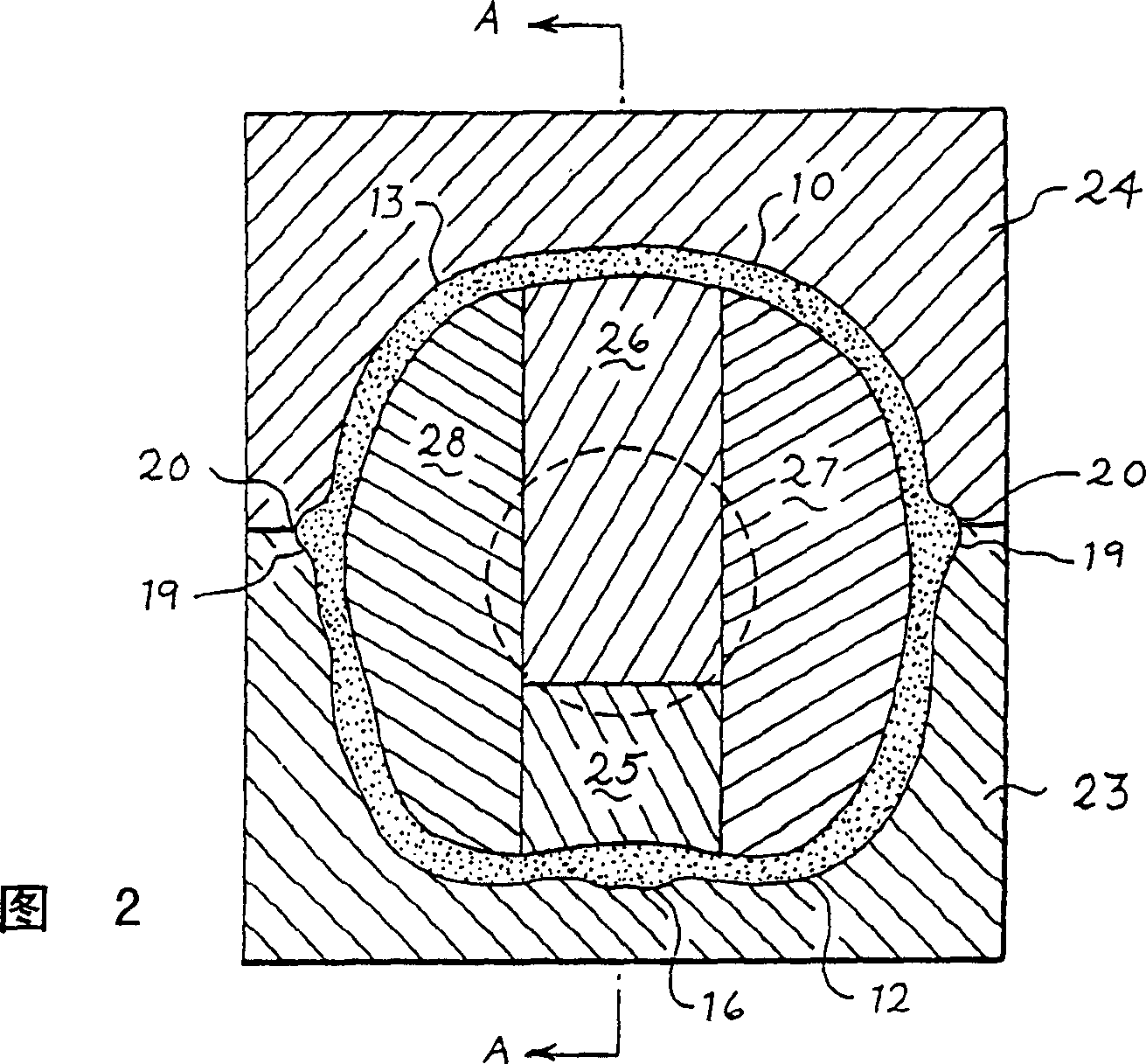

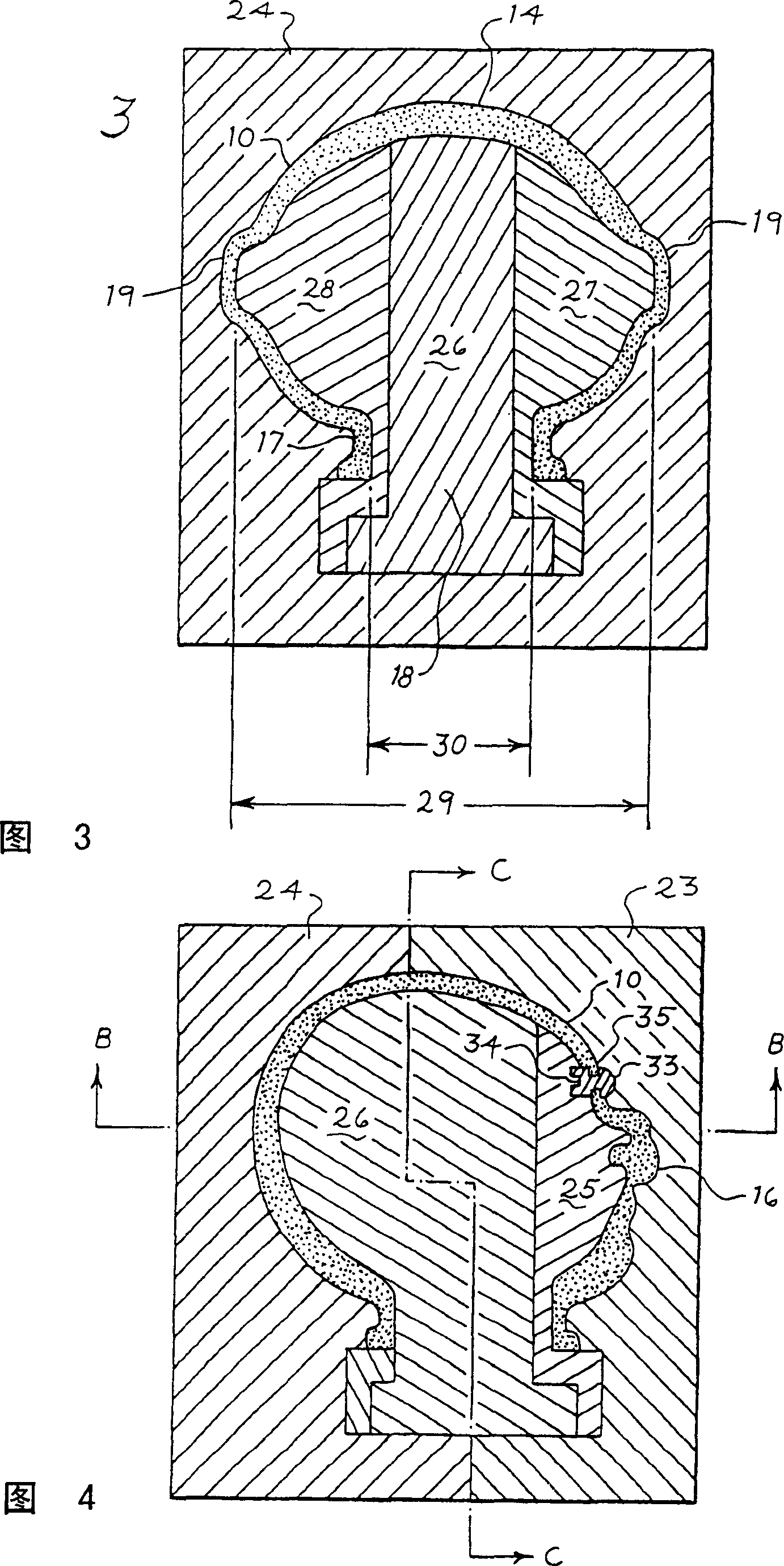

[0025] Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com