Combined memorial archway

A kind of archway and joint surface technology, applied in the direction of metal rolling, metal rolling racks, manufacturing tools, etc., can solve the problems of manufacturers increasing investment, restricting the development of rolling equipment, processing technology, tooling transportation and installation difficulties, etc., to achieve The effect of convenient transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] The present invention provides a combined archway, and the combined archway 100 is formed by plugging and connecting components.

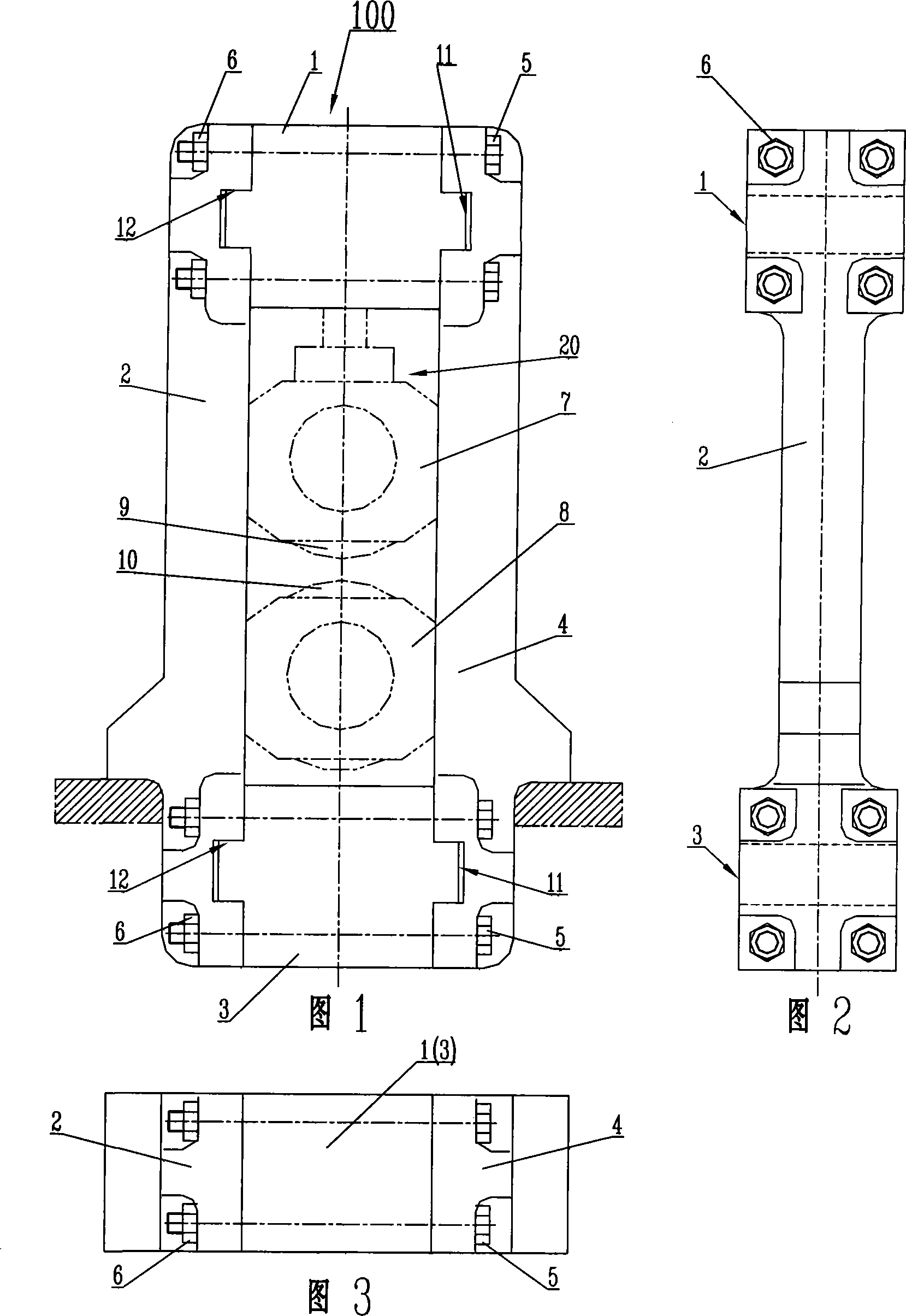

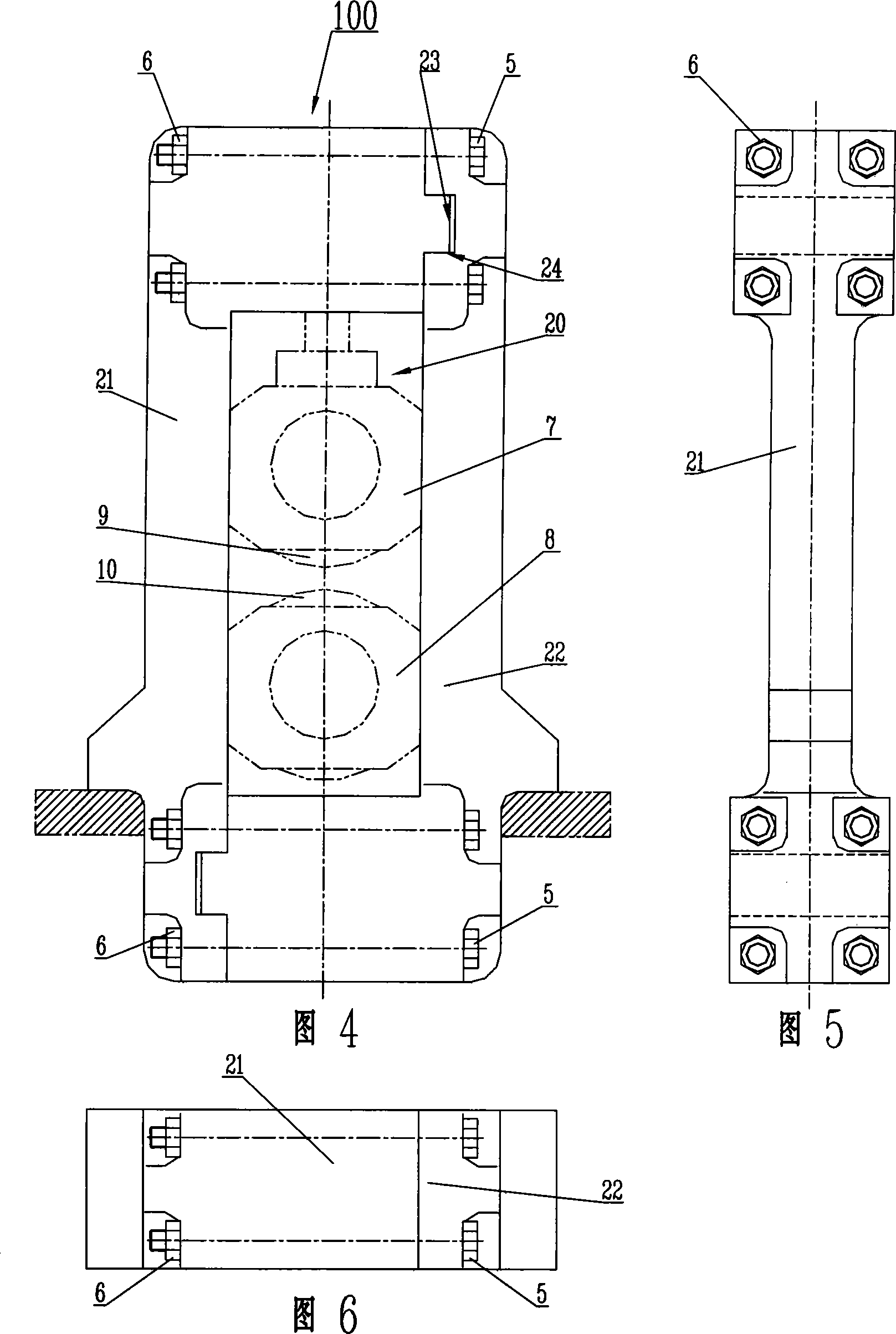

[0021] As shown in Fig. 1 to Fig. 3, be the 1st embodiment of the present invention, the 1st embodiment is described below:

[0022] The combined archway 100 of the present invention is composed of 4 components, and the components include: an upper beam 1, a lower beam 3, a left column 2, and a right column 4; wherein the upper beam 1 and the lower beam 3 are respectively combined on the left column 2 and The upper and lower ends between the right columns 4; the above-mentioned upper beam 1, lower beam 3, left column 2, and right column 4 are combined to form a closed through hole 20 in the middle. Upper bearing seat 7 and lower bearing seat 8 are installed in this through hole, and the two ends of upper roller 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com