A quick installation method for vehicle glass

An installation method, vehicle glass technology, applied in the surface pretreatment bonding method, bonding method, non-polymer adhesive additives, etc., can solve the problems of lack of elasticity, delay in the installation of vehicle glass, and one-component polyurethane sealing Solve problems such as incomplete curing of glue, achieve the effect of ensuring fast installation, improving amine activity and curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for quickly installing vehicle glass in this embodiment includes the following steps:

[0034] Step 1, base surface treatment: evenly apply the base surface treatment agent on the glued part of the vehicle and / or glass;

[0035] Step 2, gluing and assembling: applying heat-curing one-component polyurethane sealant to the position of the adhesive glass of the vehicle, and then gluing and assembling the vehicle and the glass;

[0036] Step 3, infrared radiation curing: using infrared radiation equipment to cure the heat-cured one-component polyurethane sealant between the vehicle and the glass, so as to complete the installation process between the vehicle and the glass.

[0037] Wherein, in the first step, the coating width of the surface treatment agent is 2.5-3 cm.

[0038] Wherein, in the step 1, the surface treatment agent is one or more of cleaning agent, activator and primer.

[0039] Wherein, in the second step, the application thickness of the heat-cur...

Embodiment 2

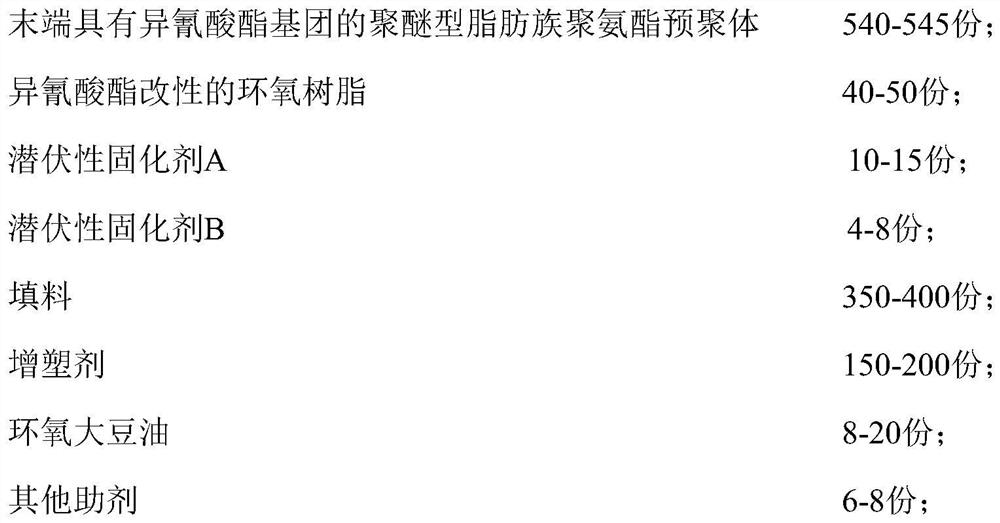

[0053] The heat-cured one-component polyurethane sealant of this embodiment and its preparation method are basically the same as in Example 1, the difference being that the heat-cured one-component polyurethane sealant of this embodiment includes the following raw material components in parts by weight:

[0054]

Embodiment 3

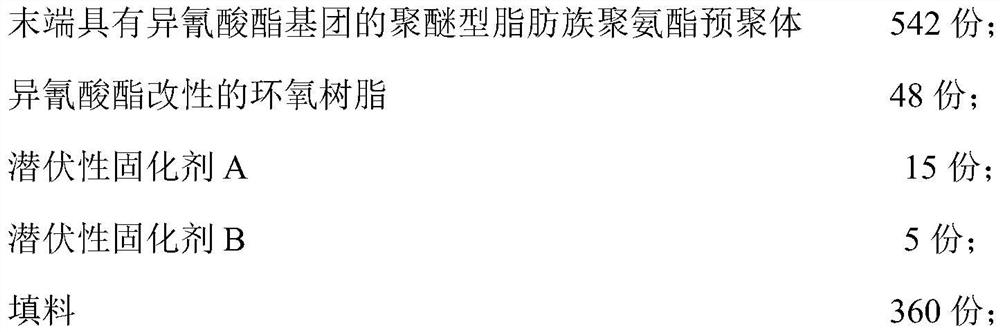

[0056] The heat-cured one-component polyurethane sealant of this embodiment and its preparation method are basically the same as in Example 1, the difference being that the heat-cured one-component polyurethane sealant of this embodiment includes the following raw material components in parts by weight:

[0057]

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com