Mounting method of aircraft conduit bracket

A conduit bracket and aircraft technology, applied in the field of aviation assembly, can solve problems such as low installation efficiency, high labor intensity, and uncoordinated assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] This part is the embodiment of the present invention, which is used to explain and illustrate the technical solution of the present invention.

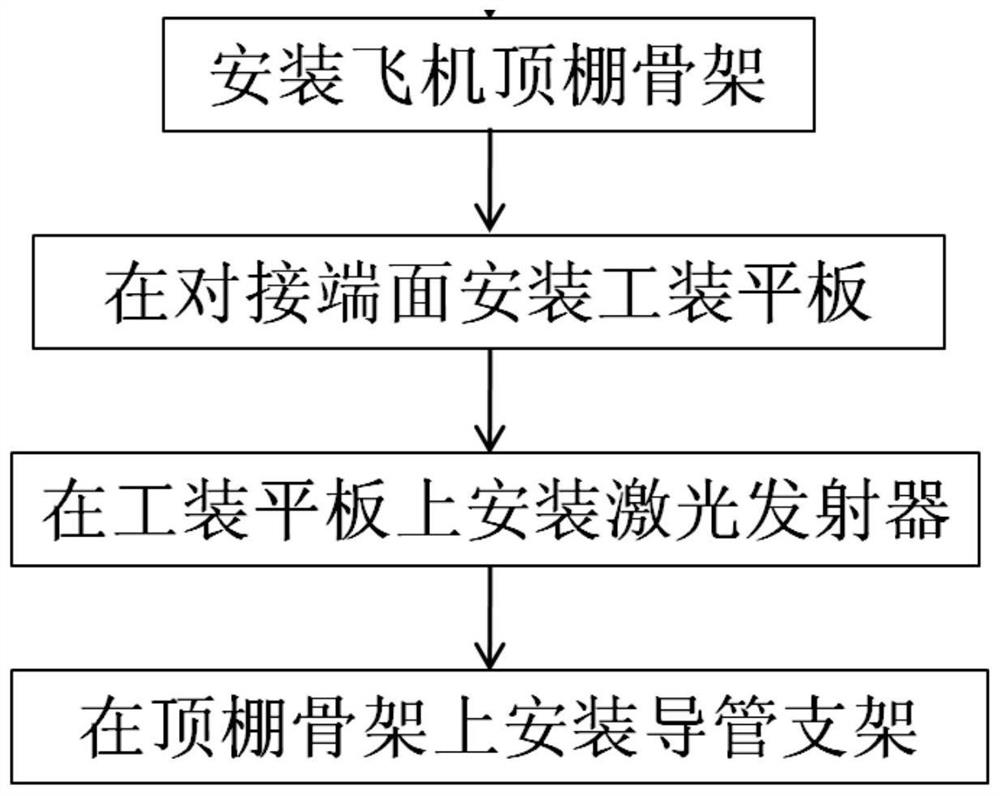

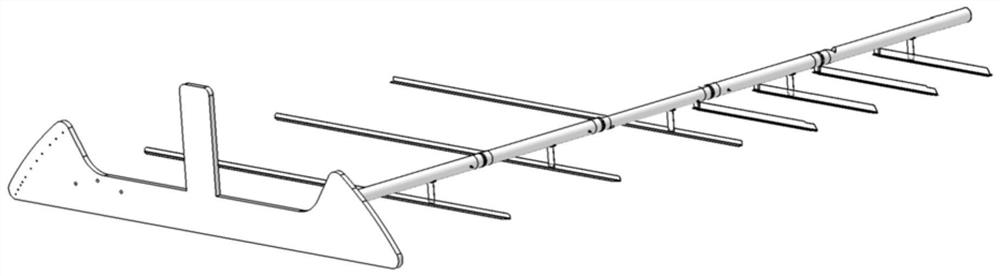

[0029] figure 1 The schematic flow chart of the installation method of the aircraft duct support provided by the present invention, as figure 1 shown, including:

[0030] Step 1, install the aircraft roof skeleton on the aircraft middle part and the aircraft tail part respectively;

[0031] Step 2. Set tooling plates at the joints of the middle part of the aircraft and the tail part of the aircraft respectively. The tooling plate is parallel to the plane where the docking holes of the middle part of the aircraft and the tail part of the aircraft are located. The mounting holes for the laser pointer are arranged on the tooling plate ;

[0032] Step 3. Insert the laser transmitter into the mounting hole on the tooling plate, turn on the laser transmitter, and the laser light emitted by the laser transmitter is perpendicular to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com