Printing method of colorful gradient print product

A printing method and printing technology, applied in dyeing, textiles and papermaking, etc., can solve problems such as color breaks, moiré, uneven transition colors, etc., and achieve the effect of full color and uniform transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

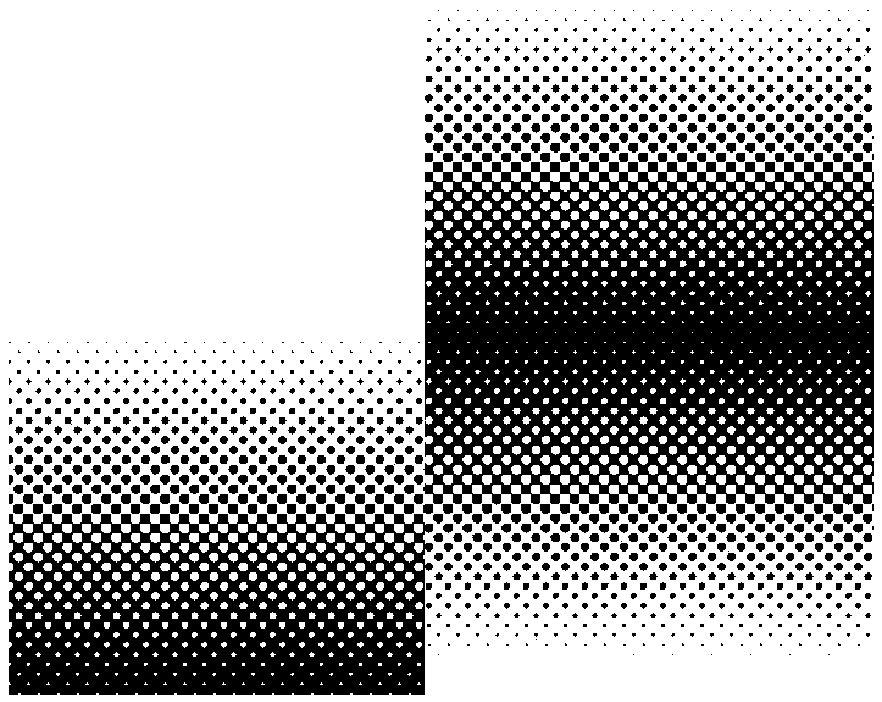

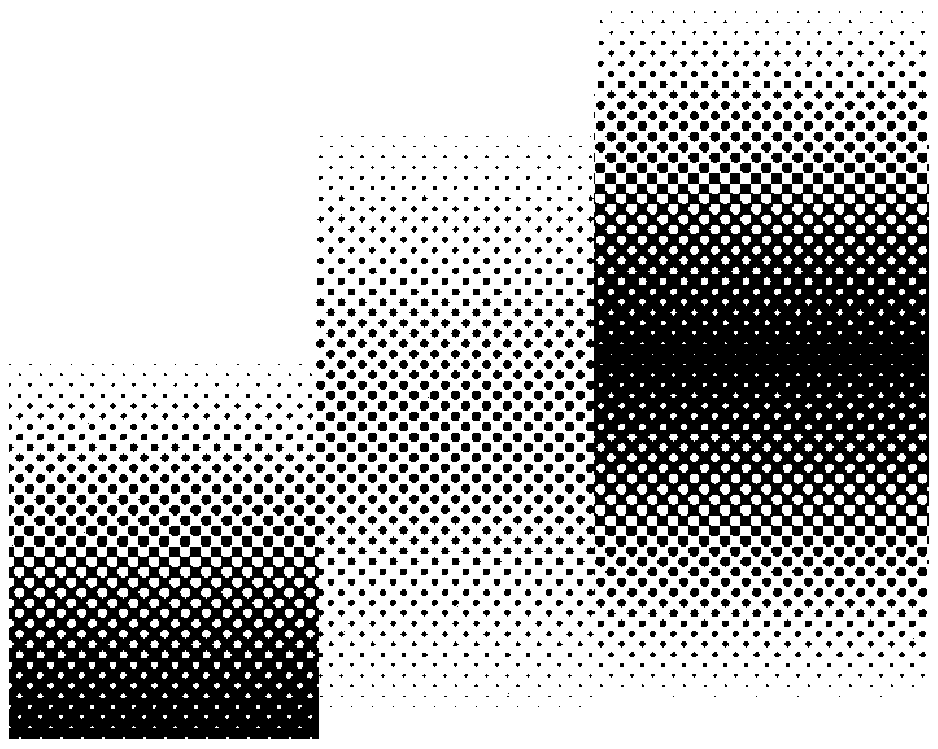

Image

Examples

Embodiment 1

[0035] The print of the colorful gradient print bath towel:

[0036] Material: 100% cotton.

[0037] Gram weight: 400g / m 2

[0038] Process flow: color separation, plate making, printing, drying, steaming, washing, sewing.

[0039] Color separation: draw moiré for the color that needs to be gradient, each color gradually transitions from dark to light, and the color density gradually weakens from 100% to 0%; two adjacent color moirés overlap each other by 30%, forming Superimposed moiré; lower the concentration in the middle of the superimposed moiré to 38%; each color transitions to the adjacent color and stops at 1 / 2 to form the bottom layer of the transition layer; then from the middle of the superimposed moiré to Two intermediate colors are used at both ends to make a layer of weak transition, superimposed on the bottom layer of the transition layer, and the width stops from the middle of the superimposed cloud pattern to 2 / 3 of the two ends; the color of the intermedia...

Embodiment 2

[0047] The print of the colorful gradient print bath towel:

[0048] Material: 100% cotton.

[0049] Gram weight: 380g / m 2

[0050] Process flow: color separation, plate making, printing, drying, steaming, washing, sewing.

[0051] Color separation: draw moiré for the color that needs to be gradient, each color gradually transitions from dark to light, and the color density gradually weakens from 100% to 0%; two adjacent color moirés overlap each other by 35%, forming Superimpose moiré; lower the concentration in the middle of the superimposed moiré to 40%; each color transitions to the adjacent color and stops at 1 / 2, forming the bottom layer of the transition layer; then from the middle of the superimposed moiré to Two intermediate colors are used at both ends to make a layer of weak transition, superimposed on the bottom layer of the transition layer, and the width stops from the middle of the superimposed cloud pattern to 3 / 5 of the two ends; the color of the intermedia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com