Coke boiler

A boiler and coke technology, which is applied to steam boilers, firebox-type steam boilers, and treatment of combustion products. It can solve the problems of high manufacturing cost and large size, and achieve the effect of compact structure, beautiful appearance and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

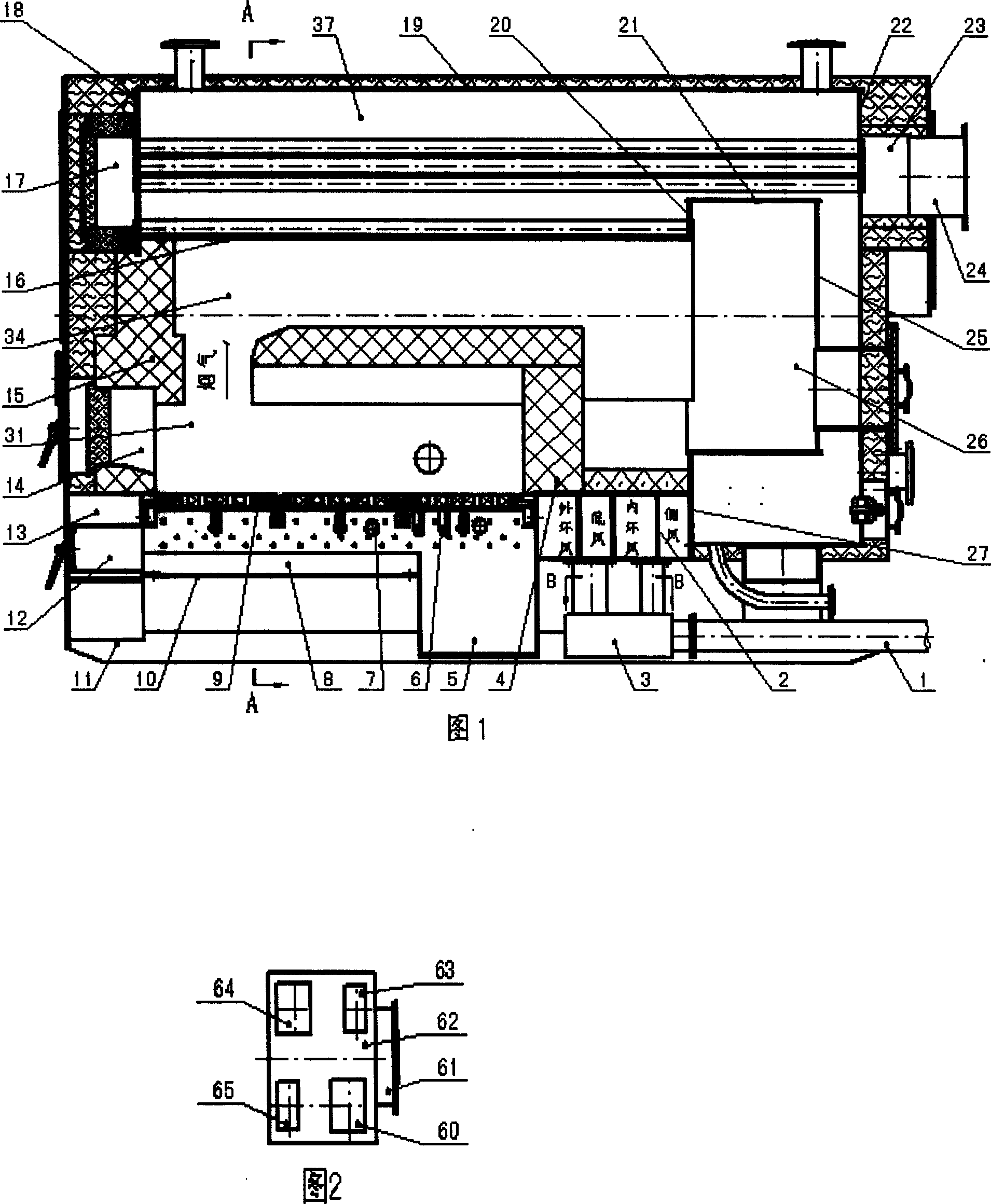

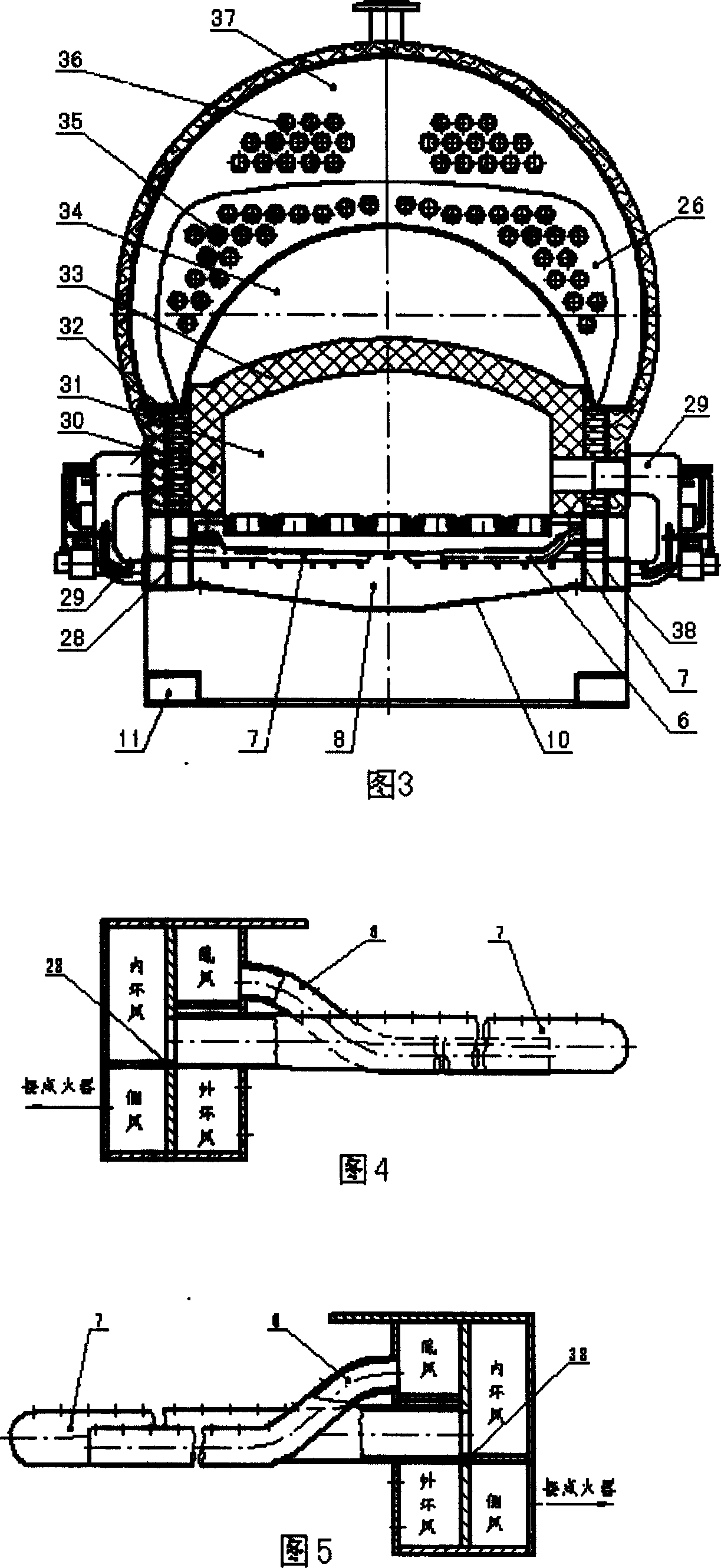

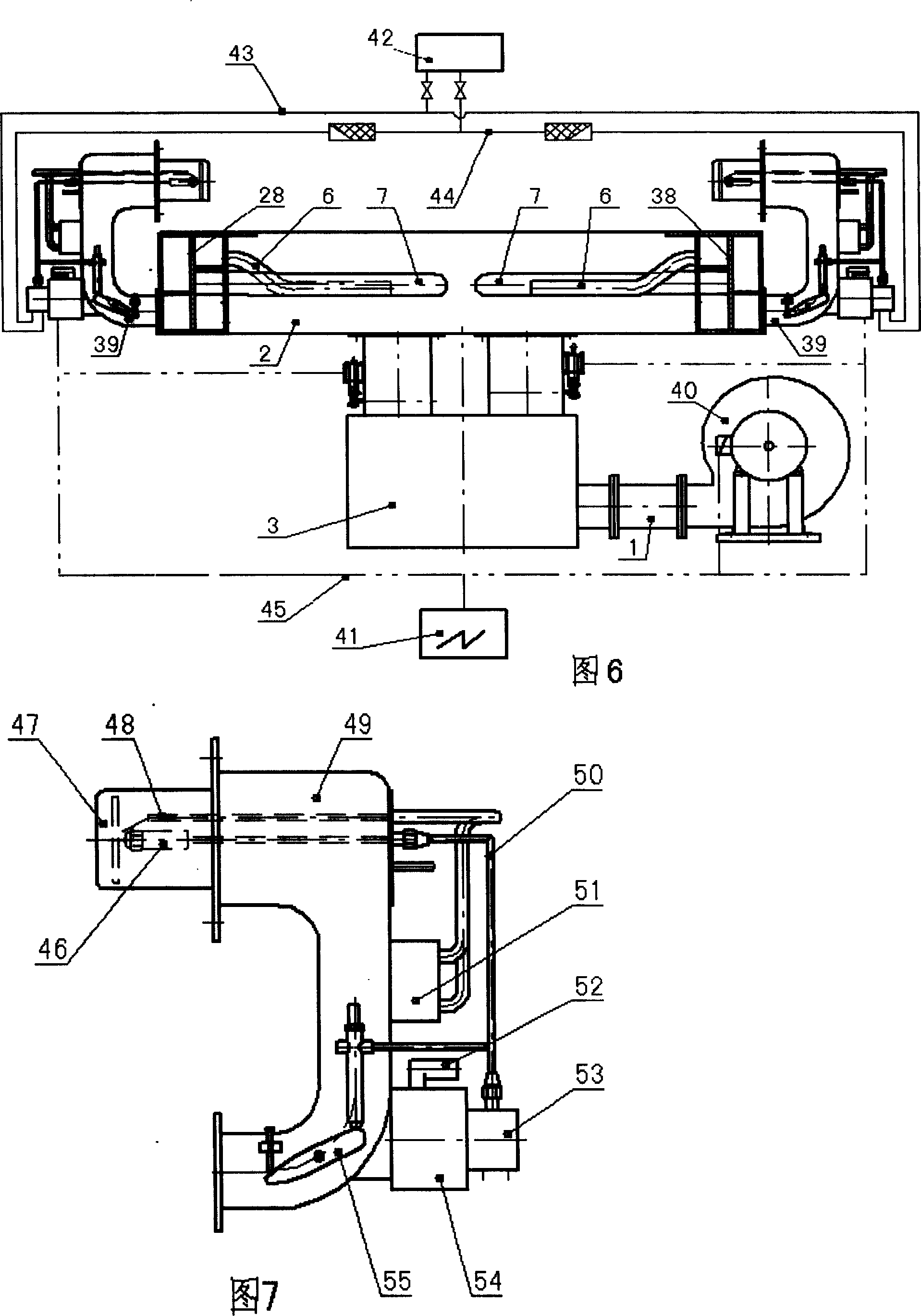

[0028] The present invention will be further described below in conjunction with accompanying drawing.

[0029] As shown in Fig. 1,2,3, the present invention is made of components such as blast pipe 1, air distribution device 3, combustion equipment 11, combustion chamber 31, ember chamber 34, boiler body 37, automatic ignition system 29. The air distribution device 3 is made up of an air inlet nozzle 61, an air collecting box 62 and an air distribution pipe base. The sub-air pipe seat is made up of side air pipe seat 63, bottom air pipe seat 65, inner ring air pipe seat 60 and outer ring air pipe seat 64, and the air door automatic opening and closing device is all provided in each pipe seat. Combustion equipment 11 is composed of air duct, ash bin 5, air bin 8, fire grate 9 and so on. The air duct surrounds the air storehouse 8 and consists of a front air duct 13, a rear air duct 2, a left air duct 28, and a right air duct 38. The rear air passage 2 is divided into four pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com