Catalytic conversion method for high sulfur wax oil

A catalytic conversion method and catalytic cracking technology, applied in the field of catalytic conversion of integrated processes, can solve the problems of reduced processing efficiency, difficulty in meeting environmental protection requirements, and difficulty in maintaining balanced operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

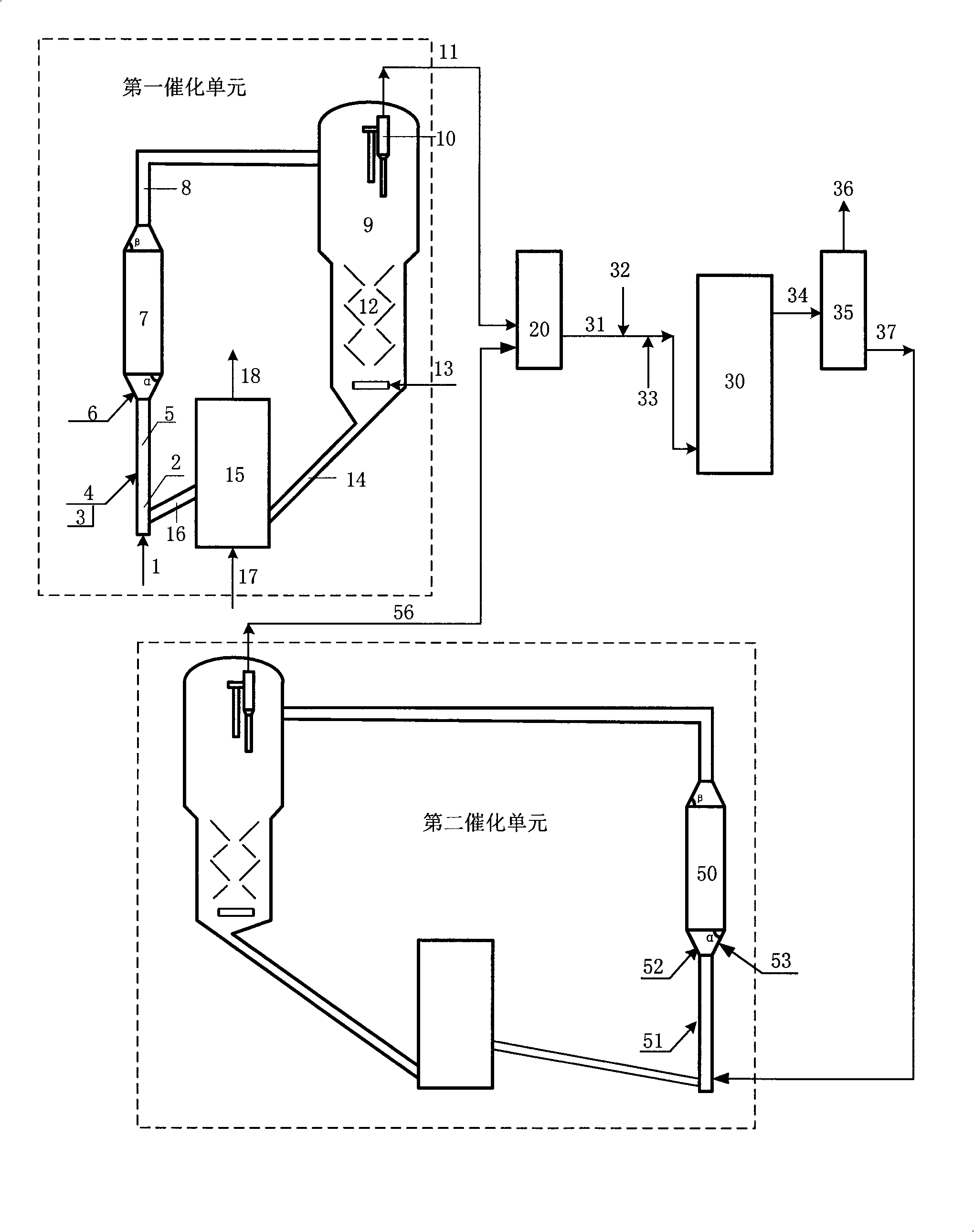

[0069] This example illustrates the product distribution and product properties of raw material A after being treated by a medium-sized catalytic cracking unit and a medium-sized hydrotreating unit using the method provided by the present invention. Both the first catalytic unit and the second catalytic unit use medium-sized catalytic cracking units with the same structure, but the operating conditions of the two catalytic units are different.

[0070] The medium-sized catalytic cracking unit adopts a variable-diameter riser reactor. The total height of the pre-lift section, the first reaction zone, the second reaction zone and the outlet zone of the reactor is 15 meters, the diameter of the pre-lift section is 0.025 meters, and its height is 1.5 meters; the diameter of the first reaction zone is 0.025 meters, and its height It is 4 meters; the diameter of the second reaction zone is 0.1 meters, and its height is 6.5 meters; the diameter of the outlet zone is 0.025 meters, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com