Thermal concentration system for dilute brine based on hydrogen chloride synthesis

A hydrogen chloride and light salt water technology, applied in the field of light salt water thermal concentration system, can solve the problems of lack of market competitiveness and high cost, and achieve the effects of simplifying equipment investment, reducing consumption and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

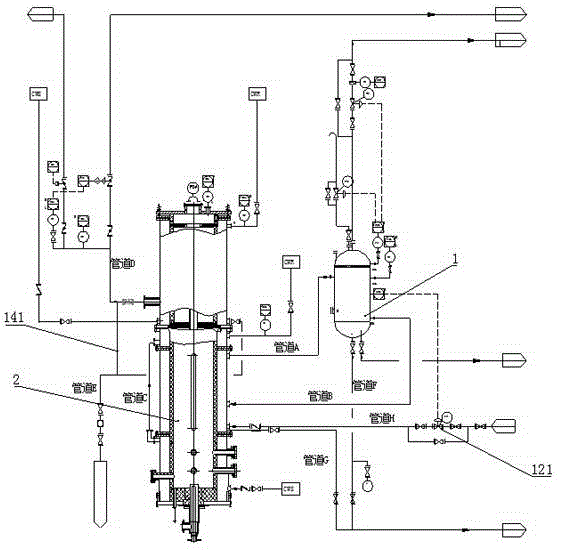

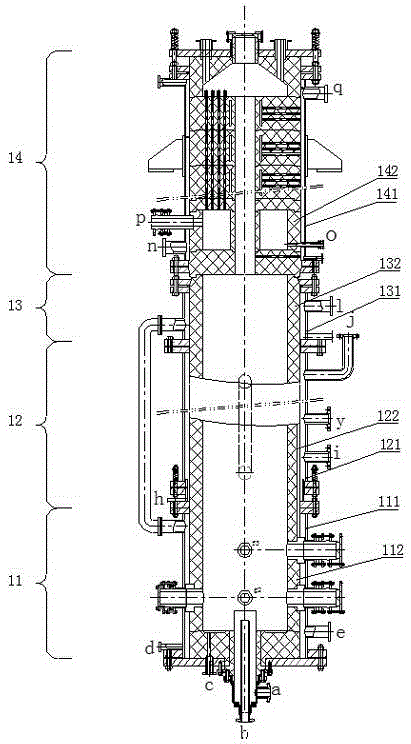

[0022] Such as figure 1 shown , including hydrogen chloride synthesis light brine concentration furnace 1 and light brine concentration flash tank 2, hydrogen chloride synthesis light brine concentration furnace 1 is sequentially divided into hydrogen chloride synthesis section and hydrogen chloride cooling section from bottom to top, the hydrogen chloride synthesis section has a The hydrogen chloride synthesis section heats the light brine circulation heating jacket layer located in the high temperature part of the hydrogen chloride synthesis section. The light brine circulation heating jacket layer has a light brine wet steam outlet j in the upper part, a light brine reflux inlet y and at least one light brine in the lower part complement import i;

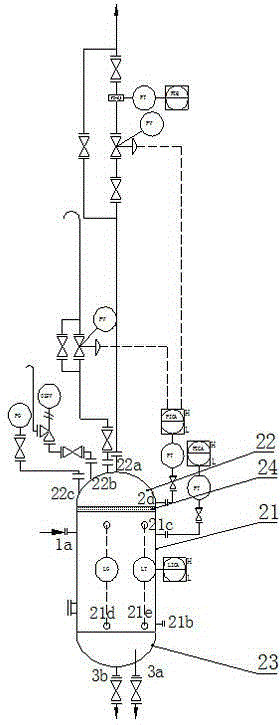

[0023] The tank top center of the flash tank 2 for concentration of light brine has a steam outlet 22a, and the side wall of the tank has a light brine wet steam inlet 21a on the upper part of the side wall and a light brine r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com