Sewage energy and biogas energy combined heat pump heating system

A technology for heating systems and sewage pumps, applied in heating systems, hot water central heating systems, heat pumps, etc., can solve the problems of heat pump popularization restrictions, insignificant energy-saving effects, and failure to meet user requirements, etc., to improve comprehensive Effects of utilization rate, temperature increase, and power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

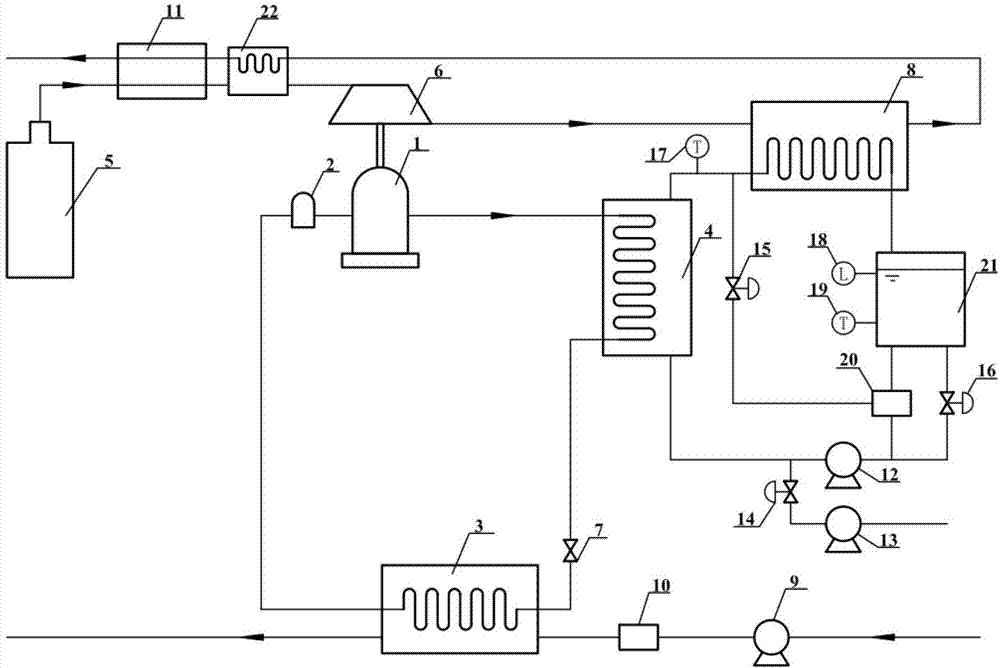

[0022] combine figure 1 , the present invention includes: compressor 1, gas-liquid separator 2, sewage evaporator 3, condenser 4, biogas tank 5, biogas engine 6, throttling device 7, water / waste gas heat exchanger 8, sewage pump 9, sewage Filter 10, desulfurization device 11, heating circulation pump 12, circulating water supply pump 13, first solenoid valve 14, second solenoid valve 15, third solenoid valve 16, first temperature sensor 17, second temperature sensor 18, liquid Bit meter 19, user 20, hot water storage tank 21, preheater 22; sewage evaporator 3 and condenser 4 are water heat exchangers; compressor 1, sewage evaporator 3, condenser 4, gas-liquid separator 2. The throttling device 7 is connected through refrigerant pipelines to form a vapor compression heating circuit; the sewage pump 9 is connected to the sewage filter 10, the sewage filter 10 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com