Hydrothermal Carbonization Coupled Double Flash-Organic Rankine Cycle Power Generation System and Power Generation Method

A technology of hydrothermal carbonization and Rankine cycle, applied in chemical instruments and methods, flash evaporation, separation methods, etc., can solve problems such as inability to generate high-grade energy, poor heat and mass transfer performance, and high viscosity of feed materials, and achieve The effect of improving energy quality, reducing moisture content, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

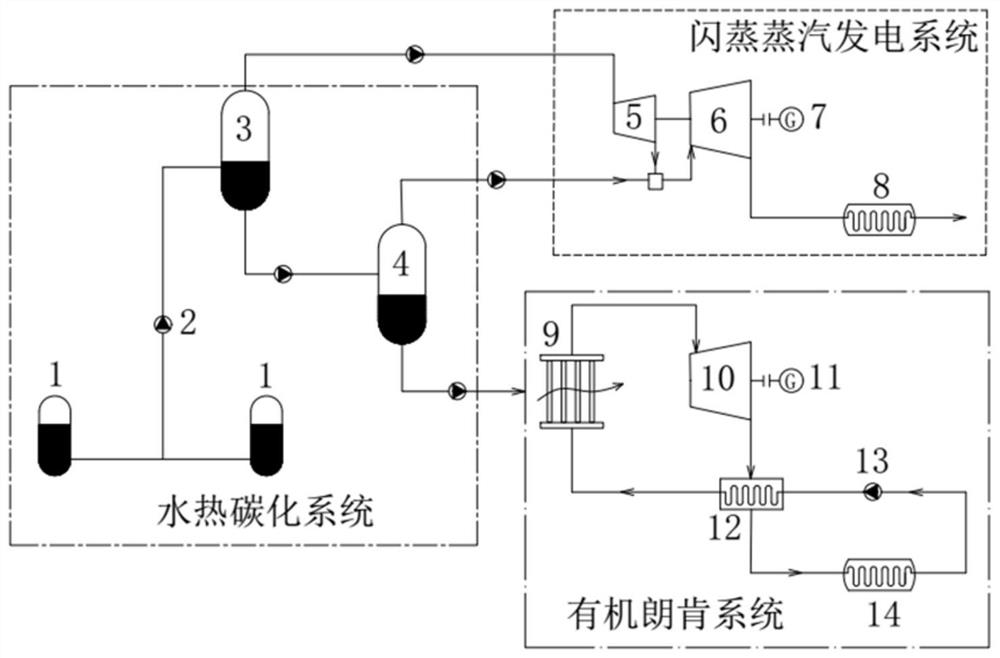

[0027] Such as figure 1 As shown, this embodiment provides a hydrothermal carbonization coupled double flash-organic Rankine cycle power generation system, including a hydrothermal carbonization system, a flash steam power generation system and an organic Rankine cycle system, wherein the hydrothermal carbonization system includes a reaction Kettle 1, slurry pump 2, primary flash tank 3 and secondary flash tank 4, the flash steam power generation system includes primary turbine 5, secondary turbine 6, first generator 7 and first Condenser 8; Organic Rankine cycle system includes evaporator 9, turbine 10, second generator 11, internal regenerator 12, working medium pump 13 and second condenser 14;

[0028] Reactor 1 is connected to primary flash tank 3 through slurry pump 2, the concentrated slurry outlet of primary flash tank 3 is connected to secondary flash tank 4, and the steam outlet of primary flash tank 3 is connected to primary The turbine 5, the steam outlet of the se...

Embodiment 2

[0033] This embodiment provides a hydrothermal carbonization coupled double-flash-organic Rankine cycle power generation method, taking municipal solid waste as a raw material for hydrothermal carbonization as an example, including the following steps:

[0034] (1) Hydrothermal carbonization process: Municipal solid waste is mixed with the condensed water after the flash steam has done work to make feed material with a moisture content of 83.3%, pumped into the reactor, and preheated by the previous batch of carbonized gas production. The feeding temperature is 45°C, the hydrothermal carbonization temperature is 270°C, and the reaction time is 2h.

[0035] (2) Flash process: After carbonization, the slurry product is pumped into the primary flash tank at 14.4t / h, the primary flash steam enters the primary turbine, and the wet steam after work is mixed with the secondary flash steam into the The coaxial two-stage turbine works; the primary flash temperature is 174°C, the steam ...

Embodiment 3

[0038] This embodiment provides a hydrothermal carbonization coupled double flash-organic Rankine cycle power generation method, taking corn stalks as a raw material for hydrothermal carbonization as an example, including the following steps:

[0039](1) Hydrothermal carbonization process: corn stalks are mixed with the condensed water after the flash steam has done work to make a feed material with a moisture content of 90%, which is pumped into the reactor and preheated by the previous batch of carbonization to produce gas. The material temperature is 38°C, the hydrothermal carbonization temperature is 200°C, and the reaction time is 1h.

[0040] (2) Flash process: After carbonization, the slurry product is pumped into the primary flash tank at 14.4t / h, the primary flash steam enters the primary turbine, and the wet steam after work is mixed with the secondary flash steam into the The coaxial two-stage turbine works; the primary flash temperature is 135°C, the steam mass flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com