System for recycling waste heat produced by methyl-diethanolamine (MDEA) decarburization process by using ultra high temperature heat pump

A warm and ultra-high technology, applied in the direction of heat pump, through absorption, lighting and heating equipment, etc., can solve the problems of waste of resources, large consumption of primary energy MDEA solution, low-grade waste heat can not be used, etc., to reduce use and improve energy Utilization rate, the effect of reducing the emission of a large amount of harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

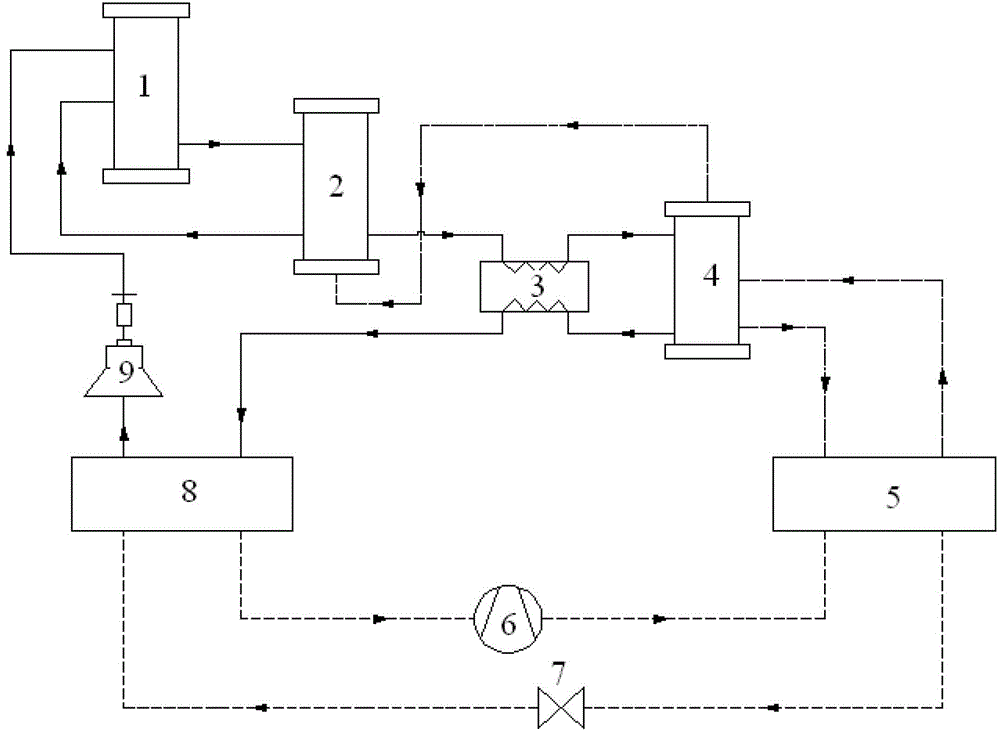

[0018] The system and device for recovering and utilizing the waste heat of the MDEA decarbonization process by the ultra-high temperature heat pump were used in the MDEA decarbonization process of an enterprise in Gansu for an example analysis, combined with the system flow figure 1 Express.

[0019] In this example, the lean liquid (105° C.) regenerated in the regeneration tower 4 enters the solution heat exchanger 3 to release part of the heat, and the temperature drops to 80° C. The lean liquid at 80°C enters the evaporator 8, the temperature of the lean liquid in the evaporator 8 drops to 60°C, and then the lean liquid returns to the inlet of the lean liquid pump 9, and enters the absorption tower 1 to absorb the CO in the process gas 2 , the poor solution becomes the rich solution. The rich liquid enters the steam and CO in the flash column 2 and regeneration column 4 2 The mixed gas is contacted in countercurrent to absorb heat, and part of the CO is desorbed through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com