Still kettle system for producing ardealite steam-pressing bricks

An autoclave and autoclaved brick technology is applied in the field of energy saving and environmental protection in the production of building materials, which can solve the problems of poor water resistance and acid corrosion resistance, low added value, large shrinkage rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

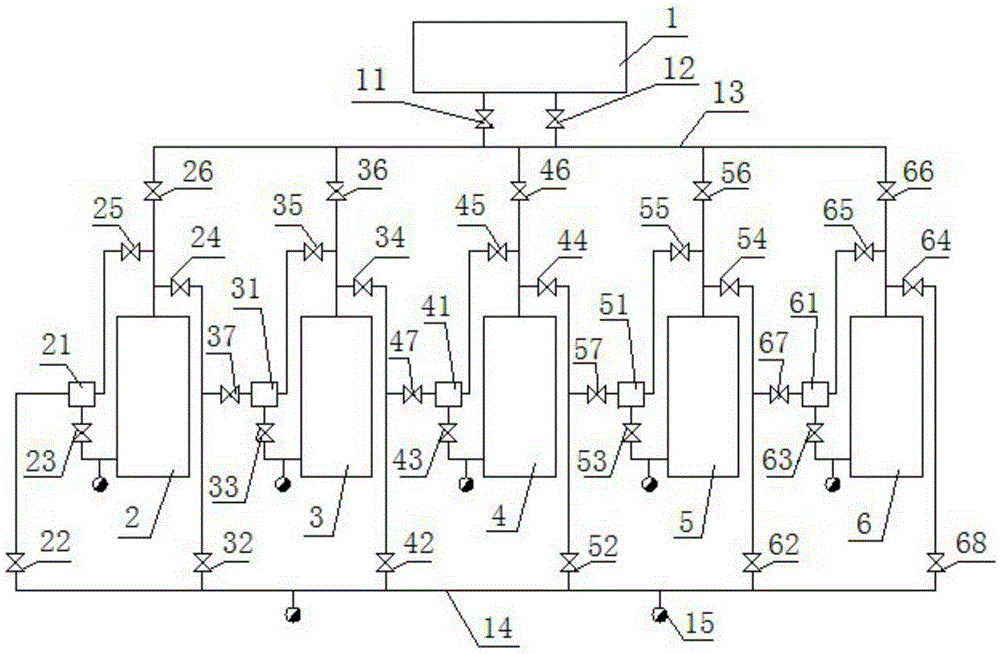

[0019] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0020] Such as figure 1 As shown, a kind of autoclave system for producing phosphogypsum autoclaved bricks according to the present invention includes heat total steam source header 1, autoclave A2, autoclave B3, autoclave C4, autoclave Kettle D5, autoclave E6, steam source distribution pipe 13, exhaust steam distribution pipe 14, steam extraction pipe A21, steam extraction pipe B31, steam extraction pipe C41, steam extraction pipe D51 and steam The extraction pipe E61, the total steam source header 1 is connected to the steam source distribution pipe 13 through the steam source main valve A11 and the steam source main valve B12 respectively; the autoclave A2, autoclave B3, and autoclave C4 The inlets of , autoclave D5 and autoclave E6 are respectively connected with steam source distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com