Method for overheating steam of cooler waste heat boiler and device used in same

A waste heat boiler and cooling machine technology, applied in the direction of steam superheating, steam generation, furnace, etc., can solve the problems of low quality, shorten the operation period, pipe perforation, etc. The effect of avoiding low temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

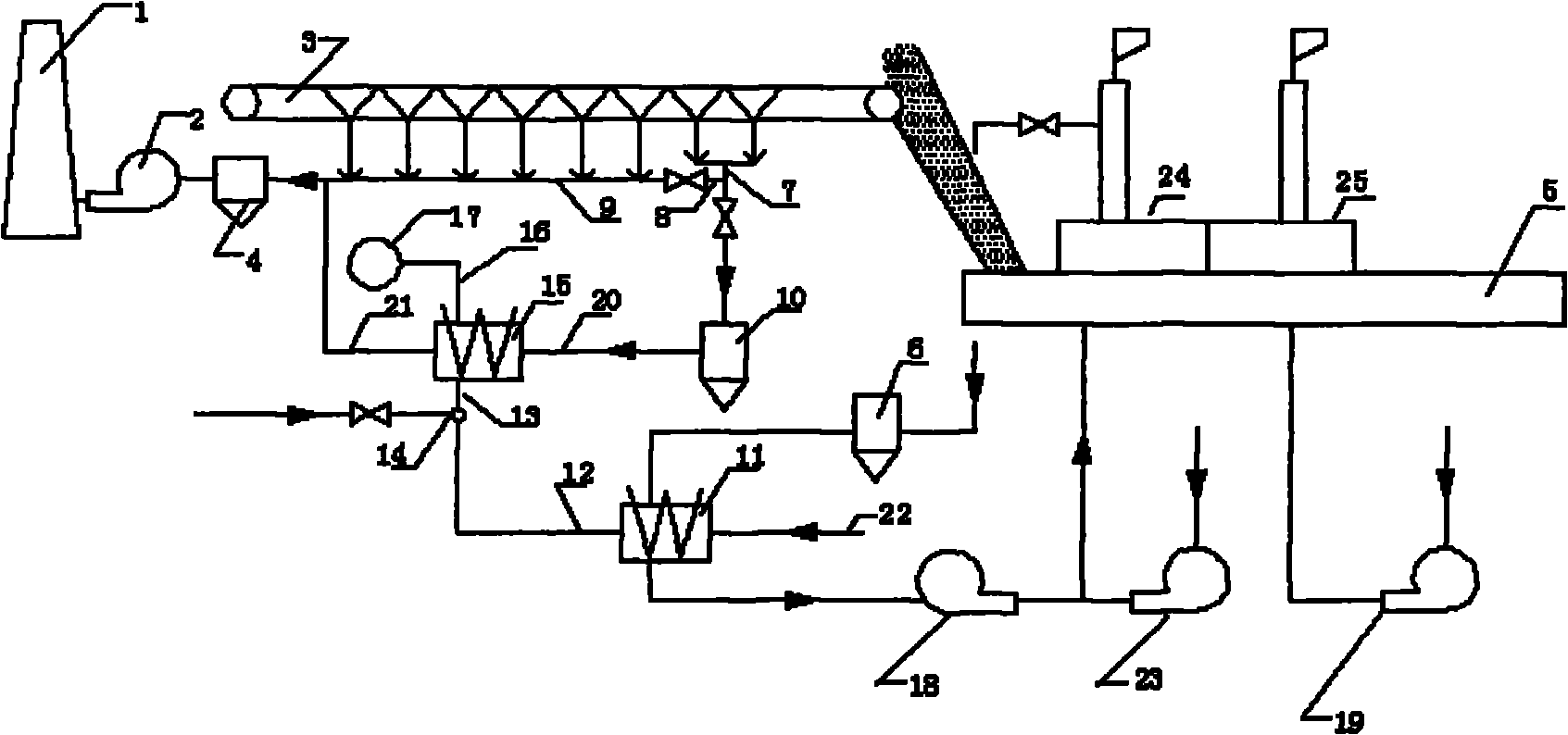

[0041] A device used in a method for superheating steam from a cooler waste heat boiler such as figure 1 shown.

[0042] A device used in the method of superheating steam from a cooler waste heat boiler, including a chimney 1, a spindle fan 2, a sintering machine 3, a sintering flue gas outlet 7, a large flue dust collector 4, a cooler 5, and a cooler dust collector 6 , sintering flue gas outlet bypass valve 8, sintering machine flue 9, sintering flue gas dust collector 10, cooling machine waste heat boiler 11, water spray desuperheater 14, sintering flue gas heat exchanger 15, heat user 17, circulation Fan 18, blower 19, spare fan 23;

[0043] The sintering flue gas heat exchanger 15 is provided with a flue gas inlet 20, a flue gas outlet 21, a steam inlet 13, and a steam outlet 16;

[0044] The flue gas outlet of the cooler waste heat boiler 11 is connected to the inlet of the circulating fan 18, and the outlet of the circulating fan 18 and the outlet of the standby fan 23...

Embodiment 2

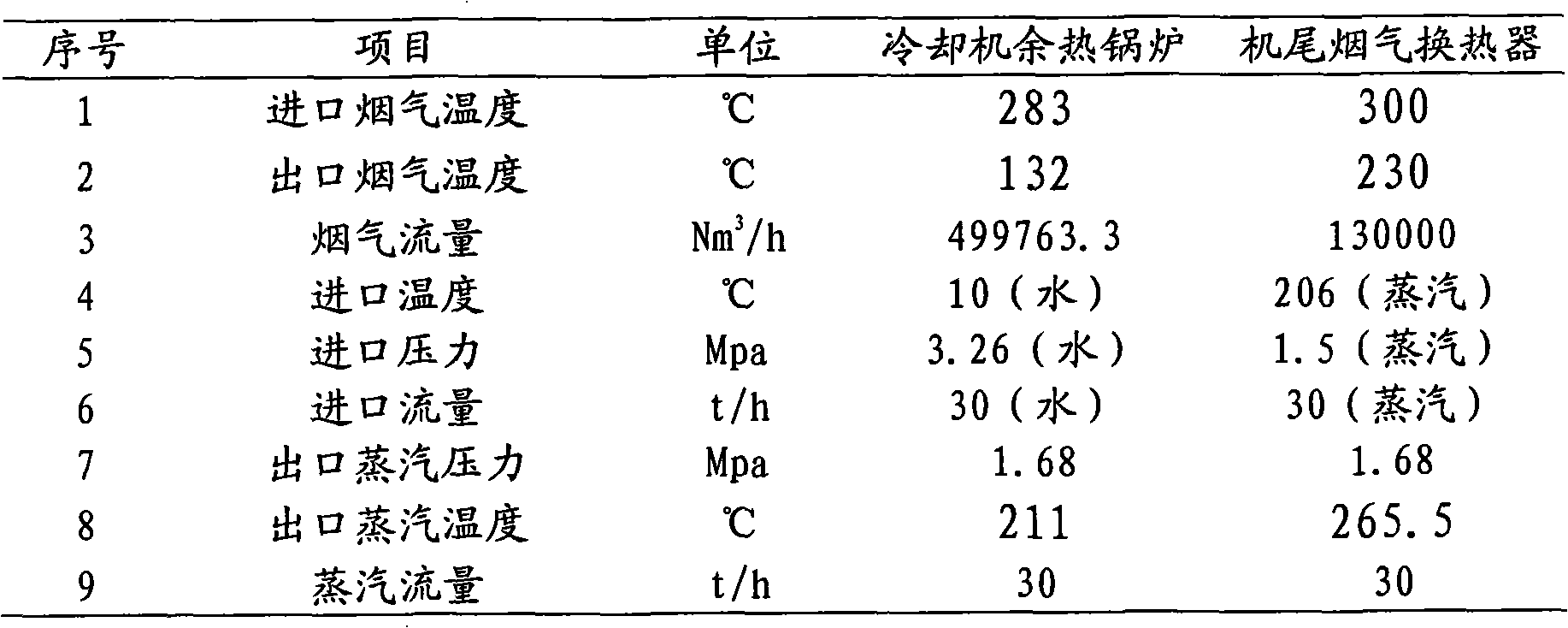

[0052] Taking the 1# sintering machine of Baosteel Stainless Steel Division as an example, the cooling waste heat boiler + tail heat exchanger of the present invention is used, that is, a method for superheating the waste heat boiler steam of the cooling machine, including the following two steps:

[0053] (1) Preparation of waste heat boiler steam for cooler

[0054] The flue gas with an outlet temperature of 132°C from the waste heat boiler 11 of the cooling machine enters the circulating fan 18, and then the flue gas enters the high temperature section 24 of the cooler 5 to cool the sintered ore at a temperature of 600-800°C, and the outlet temperature of the cooler 5 reaches 283°C The flue gas enters the cooler dust collector 6 for dust removal, and then enters the cooler waste heat boiler 11 to heat the chemical desalinated water added through the chemical desalinated water inlet 22 to become steam at a temperature of 211°C;

[0055] The flue gas discharged from the waste...

Embodiment 1

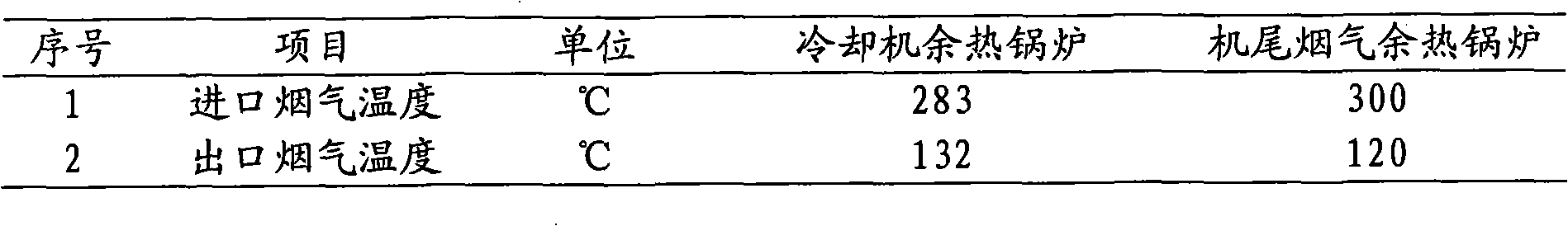

[0064] The traditional way (individually cooling waste heat boiler+tail waste heat boiler) is written as an embodiment contrasted with the present invention, and the results are shown in Table 2.

[0065] Table 2 compares the traditional way (separately cooling waste heat boiler + tail waste heat boiler)

[0066]

[0067]

[0068] From Example 2 and Comparative Example 1, it can be seen that the traditional single cooling waste heat boiler and the tail waste heat boiler produce a total of nearly 32.75t / h of steam, the steam parameters are 1.68Mpa, and the temperature is 226°C. However, the cooling waste heat boiler and tail heat exchanger of the present invention can generate nearly 30t / h of steam, and the steam parameters are pressure 1.5Mpa and temperature 265.5°C. Therefore, compared with the traditional method, the steam production is slightly reduced, but the temperature is increased compared with the traditional method, and the quality of the steam is improved, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com