High-efficiency tail flue gas energy utilization and treatment system of oxygen-enriched combustion boiler

An oxygen-enriched combustion and treatment system technology, which is applied in the direction of combustion product treatment, combustion air/fuel supply, combustion equipment, etc., can solve the problems of increasing desulfurization water consumption, etc., to improve energy utilization, reduce volume, and avoid low temperature The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

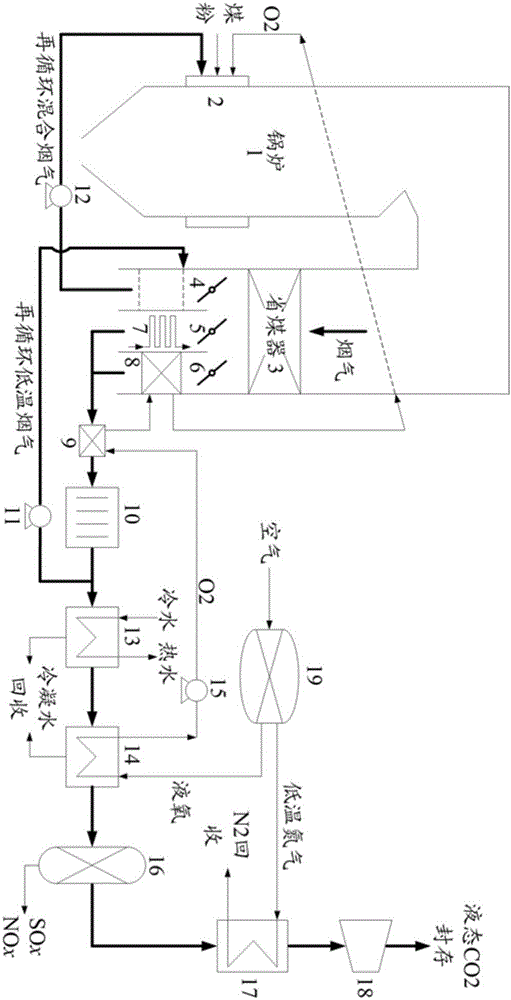

[0031] The embodiment of the present invention provides a high-efficiency exhaust gas energy utilization and treatment system at the tail of the oxygen-enriched combustion boiler, which realizes the integration of the air separator system of the oxygen-enriched combustion boiler with the flue gas recirculation system and the exhaust gas energy recovery and treatment system at the tail. Coupling, divide the boiler tail flue into three parallel flues, adjust the recirculation flue gas volume and temperature, and improve the adaptability of the system to coal types; recover the waste heat of the flue gas through the low-pressure economizer; adjust the oxygen temperature at the outlet of the air preheater ; The three parallel flues are coupled with each other to increase the adjustment margin of the flue gas temperature. The recirculated flue gas mixed with high-temperature flue gas and recirculated low-temperature flue gas is used as the primary air to avoid the phenomenon that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com