Brayton-cascade steam Rankine combined cycle power generation system

A Rankine cycle and steam technology, which is applied in the field of Breton-cascade steam Rankine combined cycle power generation units, can solve the problems of difficult organization of heat balance, low quality of waste heat, difficulty in recycling, etc., and achieves reduction in size and ratio. The effect of reducing the capacitance and improving the thermal efficiency of the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

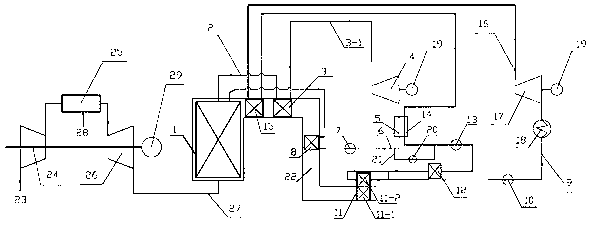

[0039] Such as figure 1 As shown, a Bretton-cascade steam Rankine combined cycle heat and power cogeneration device includes a Bretton cycle, a steam Rankine cycle at the high pressure end, and a steam Rankine cycle at the low pressure end:

[0040] The air 23 is sent to the combustion equipment 25 through the compressor 24, fully combusted with the incoming fuel 28, and the generated high-temperature flue gas enters the gas turbine 26, drives the gas turbine generator 29 to generate electricity, and completes the gas turbine unit Breton cycle.

[0041] The steam Rankine cycle at the high-pressure end refers to the saturated steam 2 coming out of the waste heat boiler body 1, passing through the high-pressure superheater 3 to form a high-pressure superheated steam 3-1, and sending it to the high-pressure steam turbine 4 to drive a generator to generate electricity; the high-pressure steam turbine 4 comes out The exhausted steam is condensed into condensed water 6 in the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com