Circulating fluidized bed domestic waste incineration power generation boiler

A domestic waste incineration and circulating fluidized bed technology, which is applied to steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of large-area coking, low combustion efficiency, corrosion, etc., and reduce corrosion and replacement. Good thermal area and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

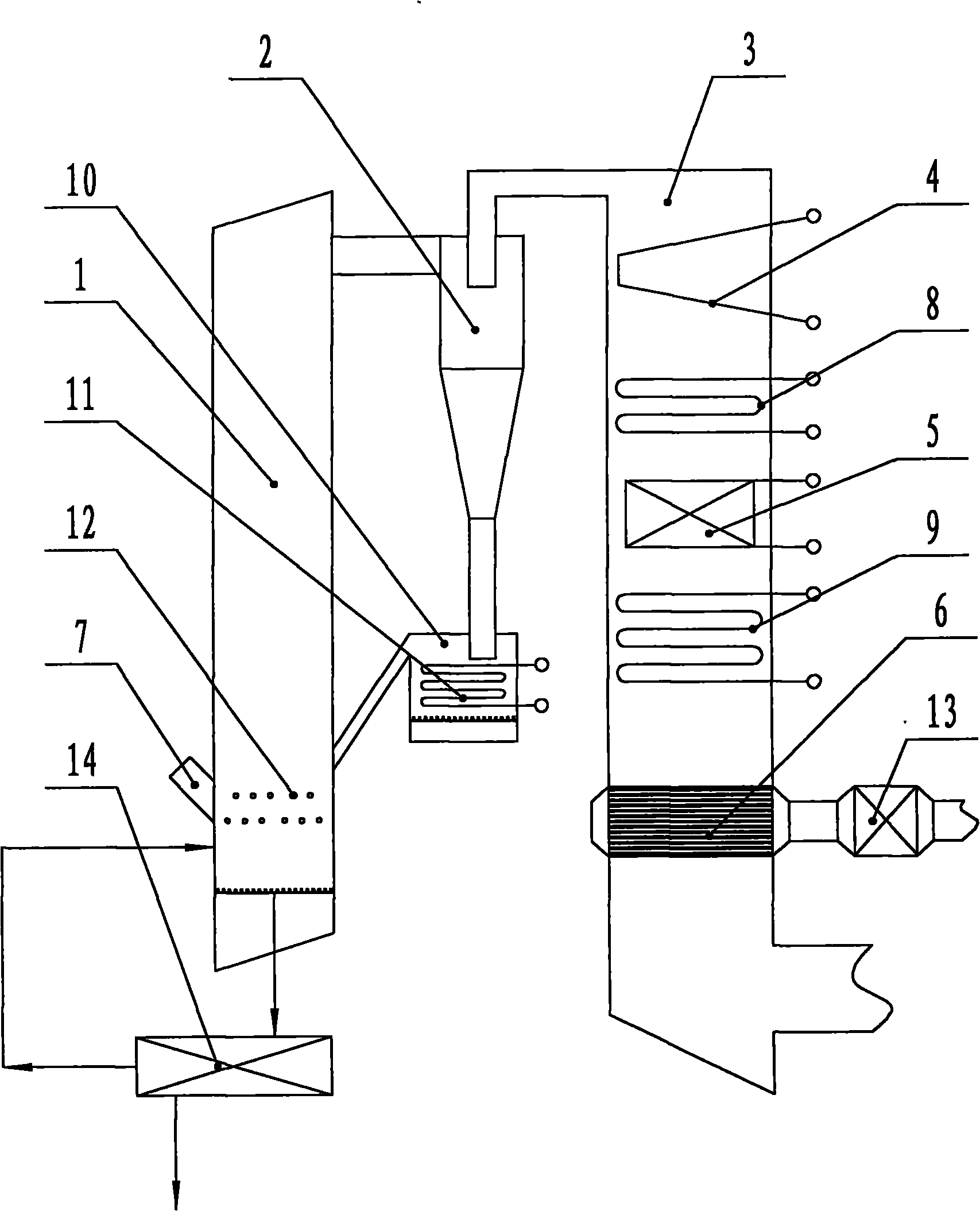

[0020]Circulating fluidized bed domestic waste incineration power generation boiler, including sequentially connected furnace 1, cyclone separator 2 and tail shaft flue 3, the tail shaft flue 3 is equipped with a convective evaporation heating surface 4, an economizer, and a low-temperature superheater 5 and an air preheater 6, the lower part of the side wall of the furnace 1 is provided with a domestic waste feed port 7, the economizer includes an upper-level economizer 8 and a lower-level economizer 9, and a connection with the cyclone separator 2 and the lower part of the furnace 1 is provided. The fluidized return feeder 10 connected to the two and the high temperature superheater 11 is arranged in the fluidized return feeder 10, and a number of secondary air nozzles 12 are provided on the side wall of the furnace 1 around the domestic waste feed port 7, and the convective evaporation The heating surface 4, the upper-level economizer 8, the low-temperature superheater 5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com