Turbine-boiler gathered heat energy circulating residual heat reuse system

A thermal energy and collection technology, applied in the directions of preheating, mechanical equipment, steam engine devices, etc., can solve problems such as unfavorable water saving and increase desulfurization water consumption, and achieve the effect of reducing desulfurization water consumption, improving dust collector efficiency and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

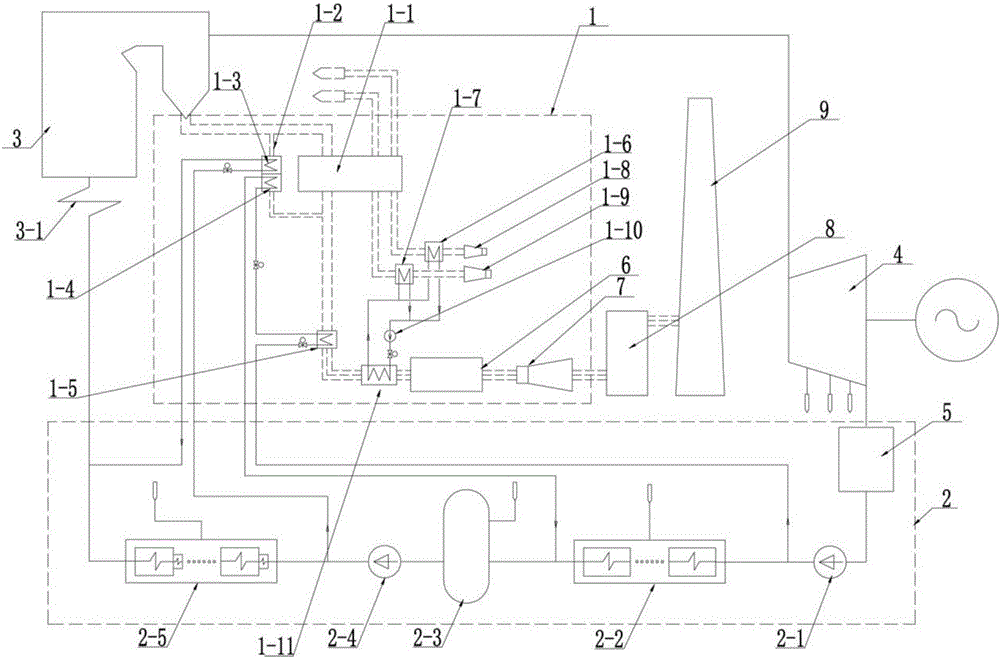

[0029] Such as figure 1 As shown in the figure, a waste heat recovery system for integrated heat energy circulation of a machine furnace includes a boiler 3, a heat energy integrated flue gas system 1 at the tail of the boiler side, a steam turbine and a combined heat exchange water supply system 2 on the steam turbine side, and an economizer 3 is installed on the boiler -1; the front side of the heat energy collection flue gas system at the tail of the boiler side is connected to the boiler, and the rear side is connected to the original flue, desulfurization absorption tower 8, clean flue and chimney 9 in sequence, and the steam turbine side is combined for heat exchange The front side of the water supply system is connected to the condenser 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com