Brayton-steam Rankine-organic Rankine combined cycle power generation device

A combined cycle power generation and Rankine cycle technology, applied in steam engine installations, gas turbine installations, steam applications, etc., can solve problems such as organic working fluid explosion, heat exchanger leakage, etc., and achieve high-efficiency recovery, power consumption reduction, and power saving effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

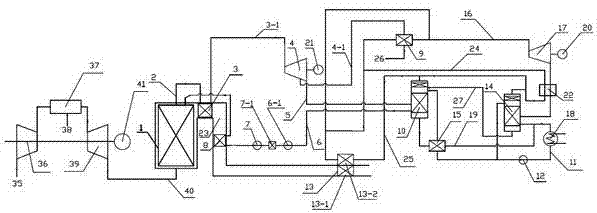

[0039] like figure 1 Shown, a kind of Britton-steam Rankine-organic Rankine combined cycle power generation device, this device comprises Bretton cycle, steam Rankine cycle, organic Rankine cycle system, specific examples are as follows:

[0040] The air 35 is sent to the combustion equipment 37 through the compressor 36, and is fully combusted with the incoming fuel 38, and the generated high-temperature flue gas enters the gas turbine 39, drives the gas turbine generator 41 to generate electricity, and completes the Breton cycle of the gas turbine unit.

[0041] The high-temperature flue gas 40 discharged from the gas turbine 39 is used as the heat source of the steam Rankine cycle system. The high-temperature flue gas 40 is discharged after being lowered in temperature by the waste heat boiler body 1 , the superheater 2 , the feedwater heater 8 and the heat exchanger 13 .

[0042] The steam Rankine cycle refers to the saturated steam 2 coming out of the waste heat boiler b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com