Multi-working-medium backheating type Rankine cycle system

A technology of Rankine cycle and circulation system, applied in the field of multi-working fluid regenerative Rankine cycle system, can solve the problems of air leakage, air short circuit, wear and so on, reduce the resistance loss along the way, increase the average heating temperature, reduce engineering The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

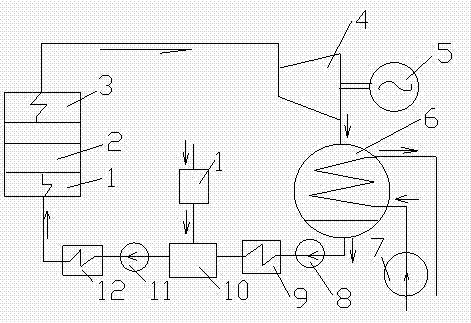

Image

Examples

Embodiment 1

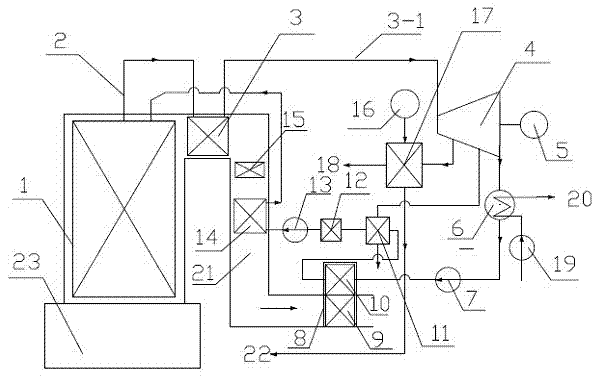

[0055] like figure 2 As shown, a multi-working medium regenerative Rankine cycle system, the system includes a boiler body heating surface 1, combustion equipment 23, flue 21 and auxiliary equipment, the flue 21 is provided with a superheater 3, a feed water heater 14 , a phase-change heat exchanger 8, a steam turbine 4, a generator 5, a condenser 6, a condensate pump 7, a phase-change heat exchanger 8, a low-pressure heater 11, a deaerator 12, a feed water pump 13 are arranged outside the flue, and Supercharger 16, heterogeneous substance regenerator 17. Wherein the phase change heat exchanger 8 includes an evaporator 9 and a condenser 10. The phase change working medium is water, which absorbs the heat of the flue gas in the evaporator 9, evaporates to generate steam, and the steam enters the condenser 10 to condense to form a saturated liquid and then Returning to the evaporator, absorbing the heat of the flue gas to generate steam, thus forming a phase change working med...

Embodiment 2

[0063] The air blown out by the supercharger 16 (ie blower) is preheated by the condenser 10 of the phase change heat exchanger 8, and sent to the heterogeneous regenerator 17 for further heating before being sent to the boiler combustion equipment. The condensed water pressurized by the condensed water pump is sent to the low-pressure heater 11, heated by steam extraction by the steam turbine, and then sent to the deaerator. All the other are similar to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com