Low-pressure expanded economizer system

A low-pressure economizer and heat exchanger technology, applied in heating systems, hot water central heating systems, heating methods, etc., can solve high investment costs, complex structure and control, dry heating of flue gas heating network heaters, etc. problems, achieve the effect of less system investment, improve energy conversion efficiency, and reduce exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

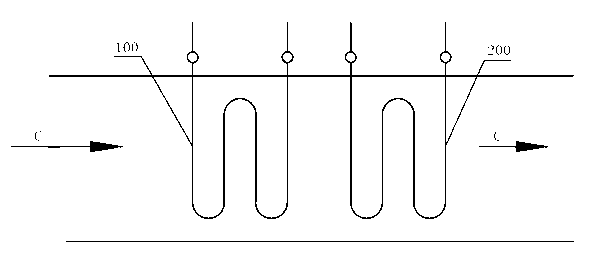

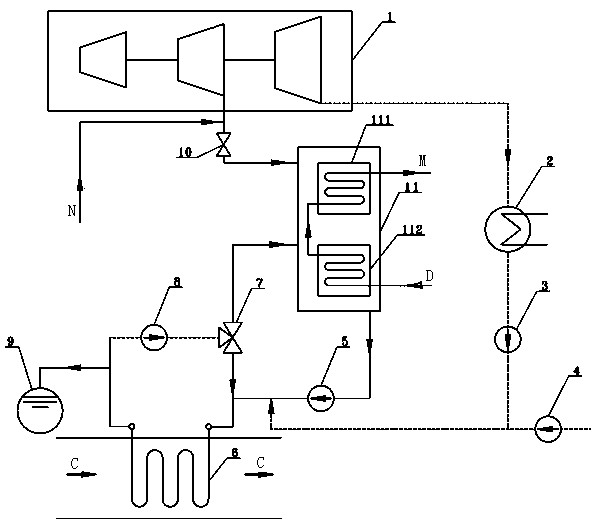

[0033] like figure 2 An expanded low-pressure economizer system as shown, mainly includes a steam turbine 1, a condenser 2, a condensate pump 3, a make-up pump 4, a drain pump 5, an expanded low-pressure economizer 6, a three-way valve 7, and a recirculation pump 8 , low pressure steam drum 9, shut-off valve 10, heat exchanger 11. The heat exchanger 11 includes a high temperature section 111 of the heat exchanger and a low temperature section 112 of the heat exchanger, and the high temperature section 111 of the heat exchanger and the low temperature section 112 of the heat exchanger communicate with each other.

[0034] In the heating season, in order to meet the user's maximum heat supply requirements, on the one hand, all or part of the medium-pressure steam from the steam turbine 1 is extracted and mixed with the low-pressure superheated steam N from the waste heat boiler. After mixing, it enters the heat exchanger 11 through the shut-off valve 10. On the shell side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com