Air pre-heater system preventing low-temperature corrosion and air pre-heating method

An air preheater and air preheating technology, applied in combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve problems such as vacuum damage in the pipe, damage to the air preheater, and inability to transfer latent heat of steam. Achieve the effect of prolonging service life, preventing low temperature corrosion and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

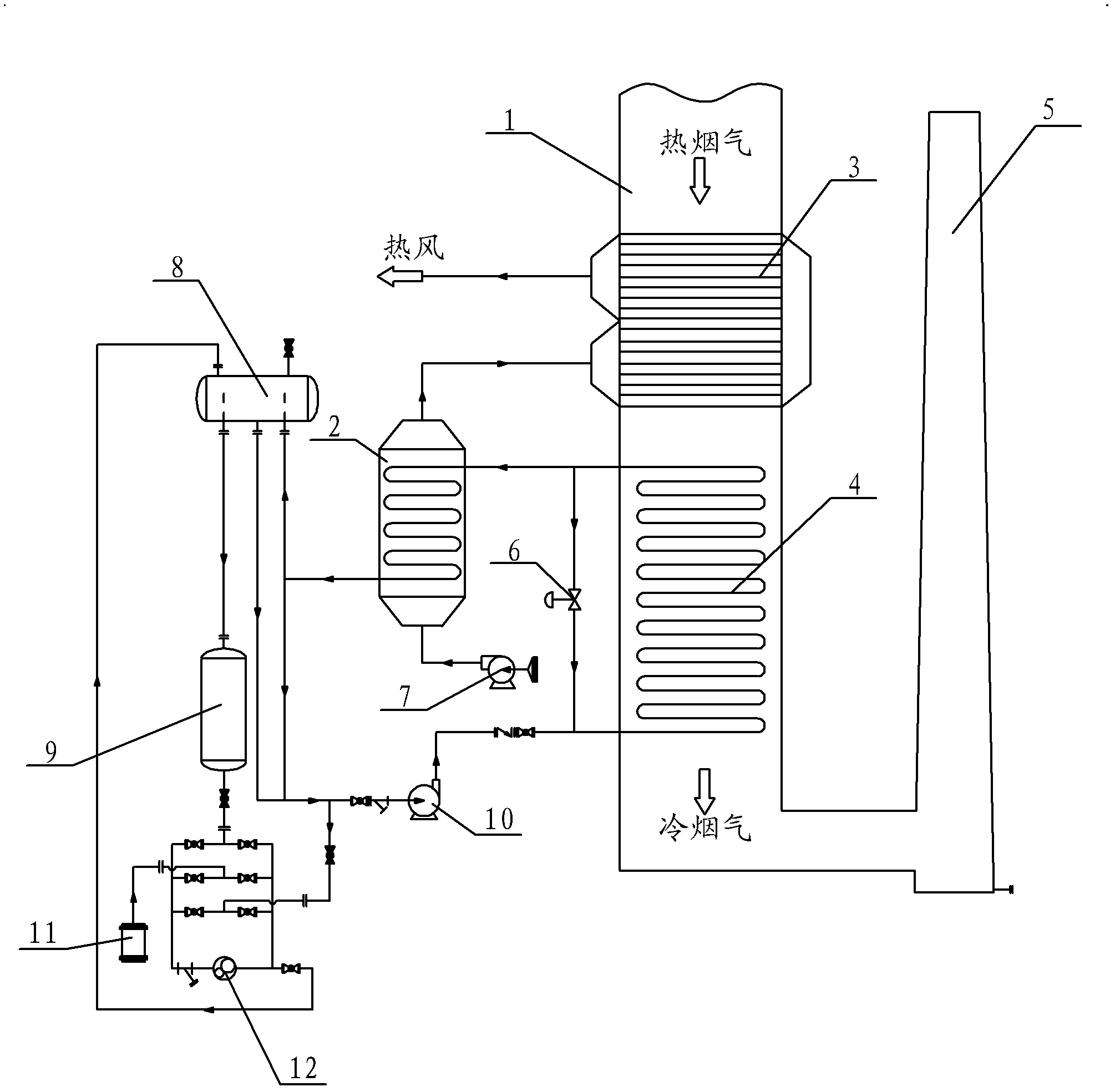

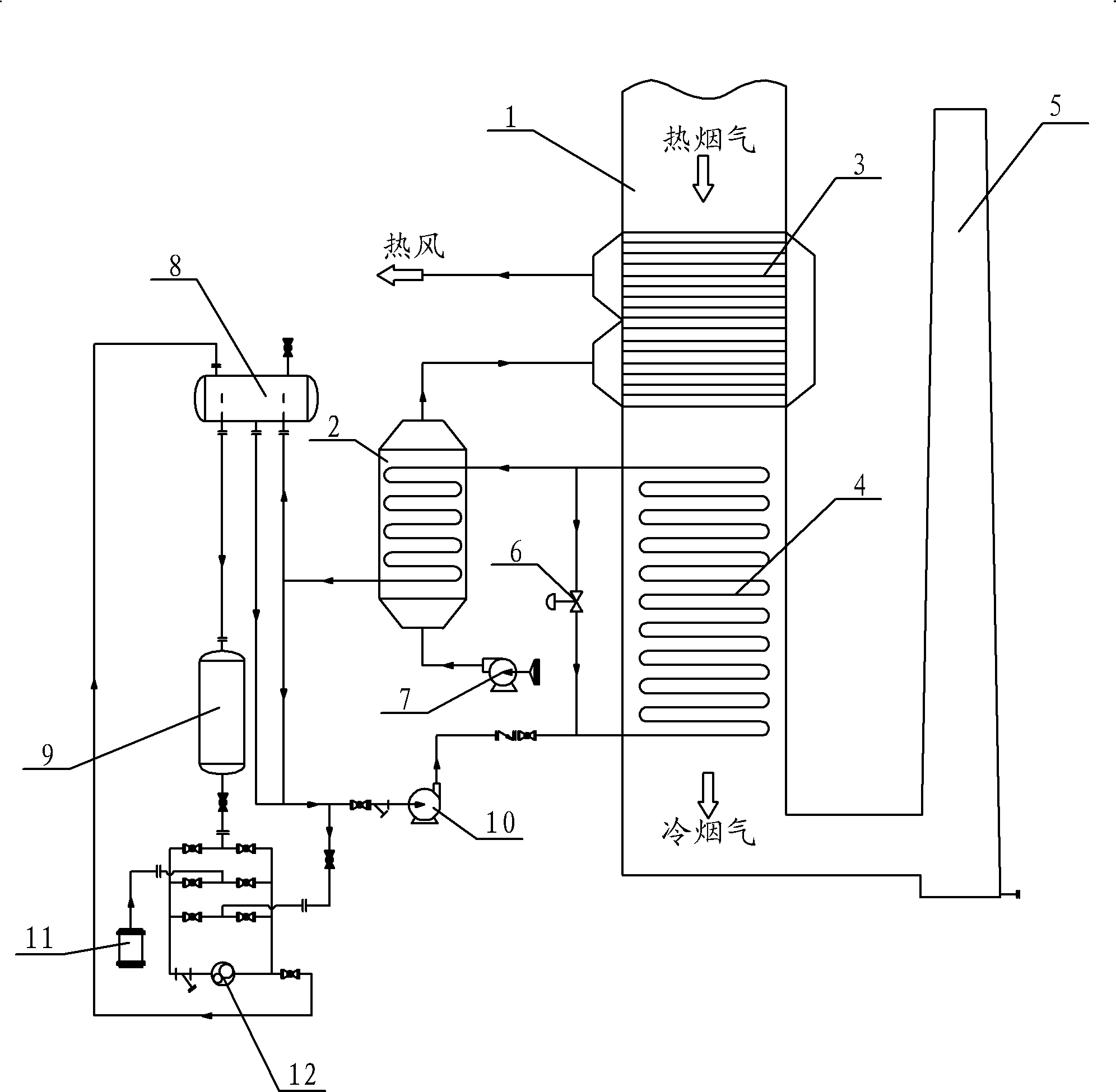

[0041] Such as figure 1 As shown, a low-temperature corrosion-resistant air preheater system according to the present invention includes a heat exchange system and a heat medium system;

[0042] The heat exchange system includes flue gas-air heat exchanger 3, flue gas-heat medium heat exchanger 4, heat medium-air heat exchanger 2, flue gas-air heat exchanger 3, flue gas-heat medium heat exchanger 4 Installed in the flue 1 of the heating furnace, and arranged in sequence along the flue gas flow direction, the heat medium-air heat exchanger 2 is arranged outside the flue 1 of the heating furnace;

[0043] The inlet of the flue gas-heat medium heat exchanger 4 is connected to the output end of the centrifugal pump 10, the outlet of the flue gas-heat medium heat exchanger 4 is connected to the heat medium inlet of the heat medium-air heat exchanger 2, and the heat medium-air heat exchanger The heat medium outlet of 2 is connected to the input end of the centrifugal pump 10;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com