Production system for conducting comprehensive treatment and utilization on waste straw and livestock feces

A comprehensive treatment and waste straw technology, applied in water/sewage treatment, biological sludge treatment, water/sewage multi-stage treatment, etc., can solve the problem of unreasonable utilization of straw biomass waste resources and unsuitable treatment methods for ecological environmental protection To improve the quality of agricultural products, enhance drought resistance and lodging resistance, and increase production significantly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the present invention will be further described below in conjunction with specific examples.

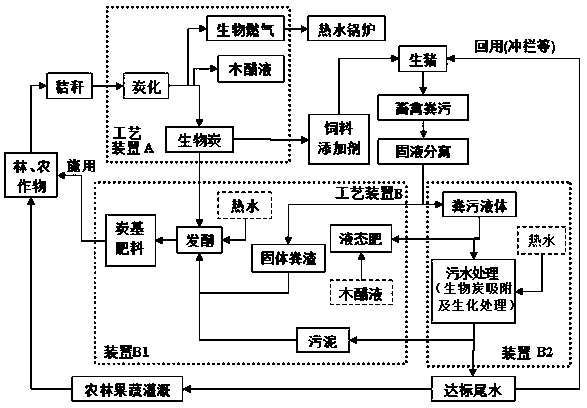

[0030] see figure 1 , The invention provides a production system for comprehensive treatment and utilization of waste straw and livestock and poultry manure. The system includes waste biomass straw treatment and livestock and poultry manure treatment devices and their combined comprehensive utilization production; figure 1 The waste biomass straw treatment device in China is represented by process device A, and the livestock and poultry manure treatment device is represented by process device B; including B1: solid manure fertilization device and B2: sewage biochemical treatment device.

[0031]The waste biomass straw treatment device A includes a carbonization furnace, a cyclone separator, a washing tower, a condenser, a coke remover, etc. The waste biomass straw treatment device treats agricultural and forestry waste stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com