Method and device for high-temperature rapid fermentation on agricultural waste to produce organic fertilizer

An agricultural waste, high-temperature rapid technology, applied in the preparation of organic fertilizers, organic fertilizers, fertilization devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

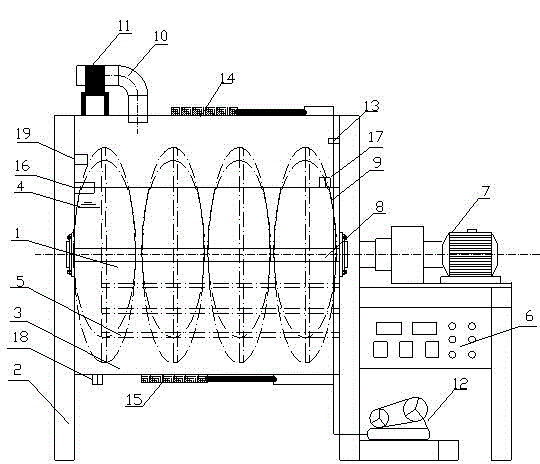

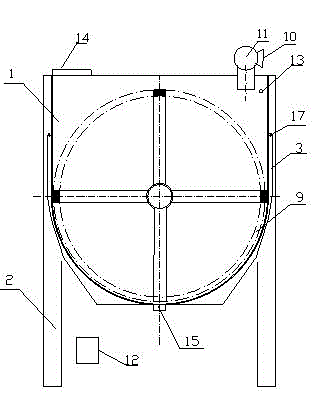

[0044] Method and device for producing organic fertilizer by high-temperature rapid fermentation of agricultural waste

[0045] A device for producing organic fertilizer by high-temperature rapid fermentation of agricultural waste, which is composed of a material storage system, a heating system, a stirring system, a dehumidification and biological deodorization system, an oxygenation system, a feeding and discharging system, and an electrical automatic control system. The material storage system is a stainless steel U-shaped fermentation box 1 placed on the overall frame 2; the heating system is composed of a heating and insulating jacket 3, a heat transfer oil 4 and an electric heating tube 5, and the heating and insulating jacket 3 is located in the U-shaped The outer wall of the fermentation box 1, the heat transfer oil 4 and the electric heating tube 5 are located in the jacket 3, and are provided with a heat transfer oil inlet 17 and a heat transfer oil discharge port 18,...

Embodiment 2

[0047] A method for producing organic fertilizer using a high-temperature rapid fermentation of agricultural waste to produce organic fertilizer, which is characterized in that the moisture content of the mixture of livestock manure and straw agricultural waste is required to be ≤ 60%, and the C / N ratio is between 20-30 , the bacteria agent used is thermophilic complex microbial flora, the mixed bacteria contained in the complex flora include Brevibacillus borstelensis, Bacillus sp., Geobacillus sp. , extreme thermophile (Calditerricola yamamurae) and Saccharomyces.Cerevisiae (Saccharomyces.Cerevisiae), the highest thermophile temperature is > 80 ℃, and can produce stable, decomposed and harmless organic fertilizer products through high-temperature fermentation within 9 hours;

[0048] The detailed steps are as follows:

[0049] (1) When using a high-temperature rapid fermentation device, first mix livestock and poultry manure, straw, organic domestic waste, agricultural waste...

Embodiment 3

[0054] A method for producing organic fertilizer using a high-temperature rapid fermentation of agricultural waste to produce organic fertilizer, which is characterized in that the moisture content of the mixture of livestock manure and straw agricultural waste is required to be ≤ 60%, and the C / N ratio is between 20-30 , the bacteria agent used is thermophilic complex microbial flora, the mixed bacteria contained in the complex flora include Brevibacillus borstelensis, Bacillus sp., Geobacillus sp. , extreme thermophile (Calditerricola yamamurae) and Saccharomyces.Cerevisiae (Saccharomyces.Cerevisiae), the highest thermophilic temperature> 80 ℃, and can produce stable, decomposed and harmless organic fertilizer products through high-temperature fermentation within 9 hours;

[0055] The detailed steps are as follows:

[0056] (1) When using a high-temperature rapid fermentation device, first mix livestock and poultry manure, straw, organic domestic waste, agricultural waste an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com