Organic fertilizer fermentation production line

An organic fertilizer and production line technology, applied in the direction of organic fertilizer, organic fertilizer equipment, organic fertilizer preparation, etc., can solve the problems of unscientific mechanical transmission, complex structure, low efficiency, etc., achieve fermentation and automatic output, scientific and reasonable design , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in combination with specific embodiments.

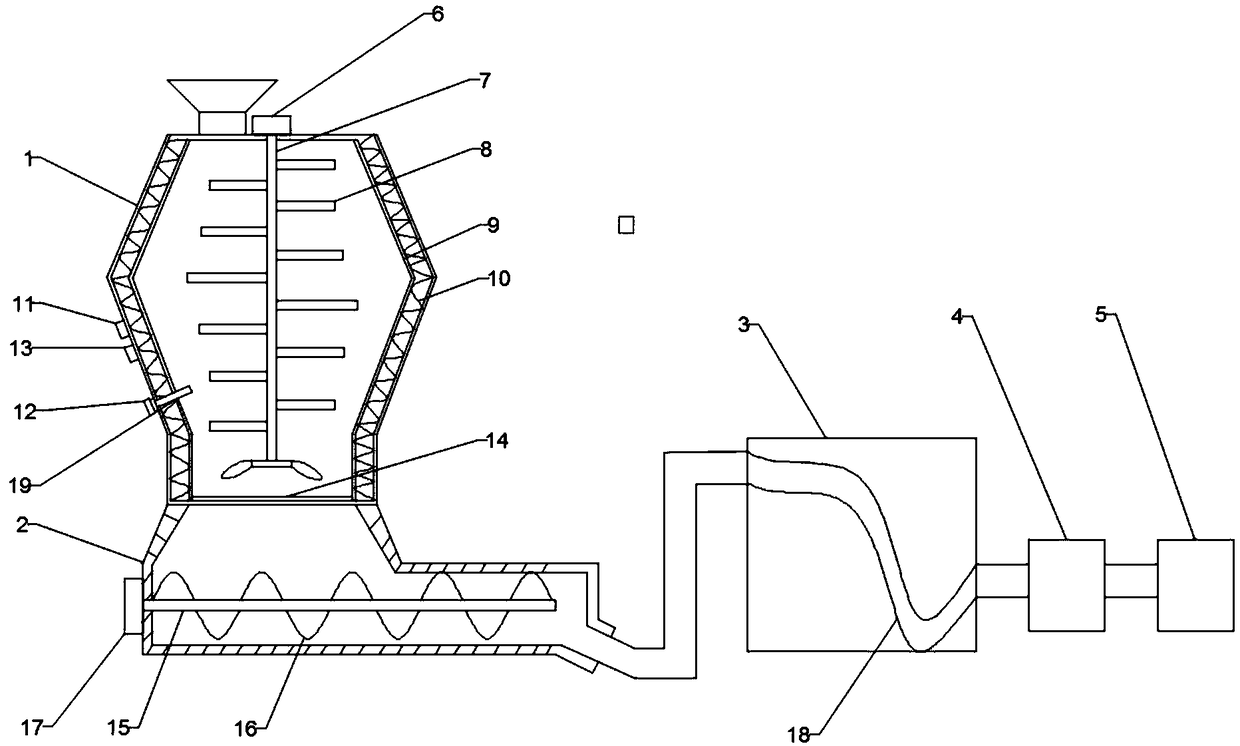

[0014] The structure of an organic fertilizer fermentation production line is as follows: figure 1 As shown, it includes a fermenter 1, a discharge cylinder 2, and a dryer 3, a screening machine 4, and a granulator 5 that are connected end to end through pipelines and the discharge port of the discharge cylinder 2. It is characterized in that the fermenter 1 The top is provided with a feed inlet and a motor 6, and the stirring shaft 7 connected to the motor 6 extends into the fermenter 1, and the part of the stirring shaft 7 located in the fermenter 1 is evenly spaced from top to bottom Several stirring paddles 8 are provided, the lower end of the stirring shaft 7 is close to the bottom wall of the fermentor 1, the outer wall of the fermentor 1 is provided with a water jacket 9, and an electric heating wire 10 is arranged in the water jacket 9, and the fermenter 1 The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com