A method for coupling extraction and fermentation to separate lactic acid in fermentation broth

A fermented liquid and extraction technology, applied in the field of bioengineering, can solve the problems of high cost, difficulty in removing bacteria, protein and glucose, and low efficiency, and achieve the effect of cheap source, reduced energy consumption, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] 2. Preparation of lactic acid fermentation broth

[0036] (1) Inoculate Lactobacillus rhamnosus into the seed medium, and cultivate at 37°C and 200rpm shaker for 24h;

[0037] (2) insert the bacterial culture liquid of step (1) into the fermentation medium at the inoculum size of 10% (v / v), and carry out fermentation, the stirring speed is 250r / min, the fermentation temperature is 37 ° C, and the fermentation process does not Aeration, using 5mol / L NaOH solution to control the pH value to 5.5, and fermenting for 28h to obtain lactic acid fermentation broth, the concentration of lactic acid in the fermentation broth is 76.95g / L, and the residual glucose concentration is 12g / L.

[0038] Pretreatment of lactic acid fermentation liquid: The lactic acid fermentation liquid obtained in the above 2 contains bacterial cells, and can be pretreated by flocculation, filtration, microfiltration or centrifugation to remove the bacterial cells to obtain lactic acid fermentation clear...

Embodiment 1

[0060] Embodiment 1 The influence of different organic solvents (extracting agents) on the separation effect of lactic acid in fermentation broth

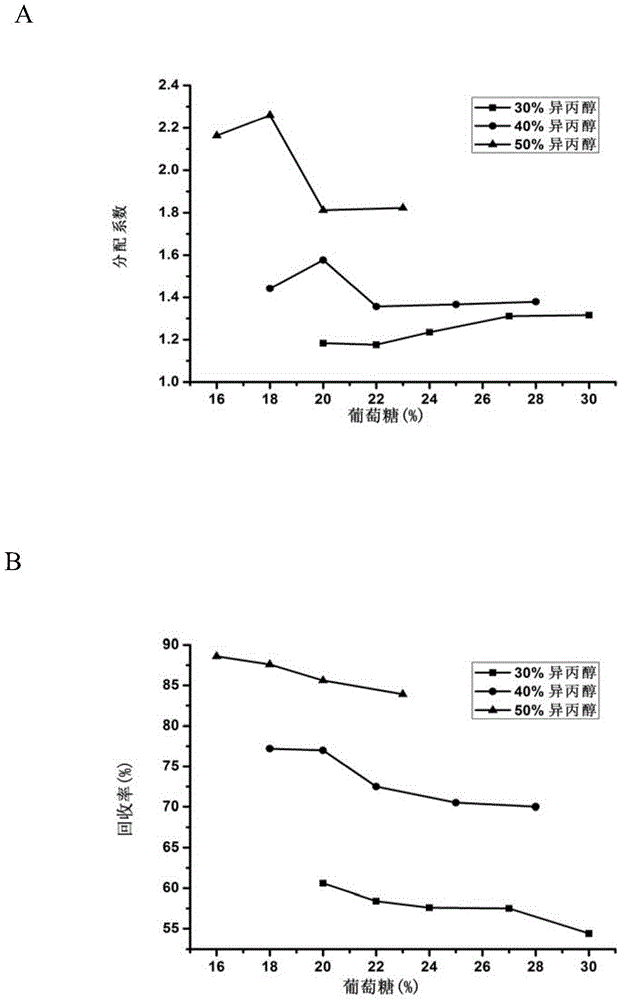

[0061] Lactic acid was isolated from the lactic acid simulant as described in 3 above. Among them, the concentration of lactic acid in the lactic acid simulation solution was 150 g / L, and the pH was 5.5. Glucose is added to the lactic acid simulation solution and completely dissolved to obtain a sugar-containing mixed solution. Add different organic solvents (organic solvent types, as shown in Table 1) to the sugar-containing mixed solution, mix, adjust the pH of the mixed solution to 3.5, stand at room temperature to obtain two layers of water phase (lower phase) and organic phase (upper phase) In the extraction system with the coexistence of liquid phases, samples were taken to measure the concentration of lactic acid in the upper and lower phases, and the partition coefficient (K) and recovery rate (Y) of lactic acid were calcu...

Embodiment 2

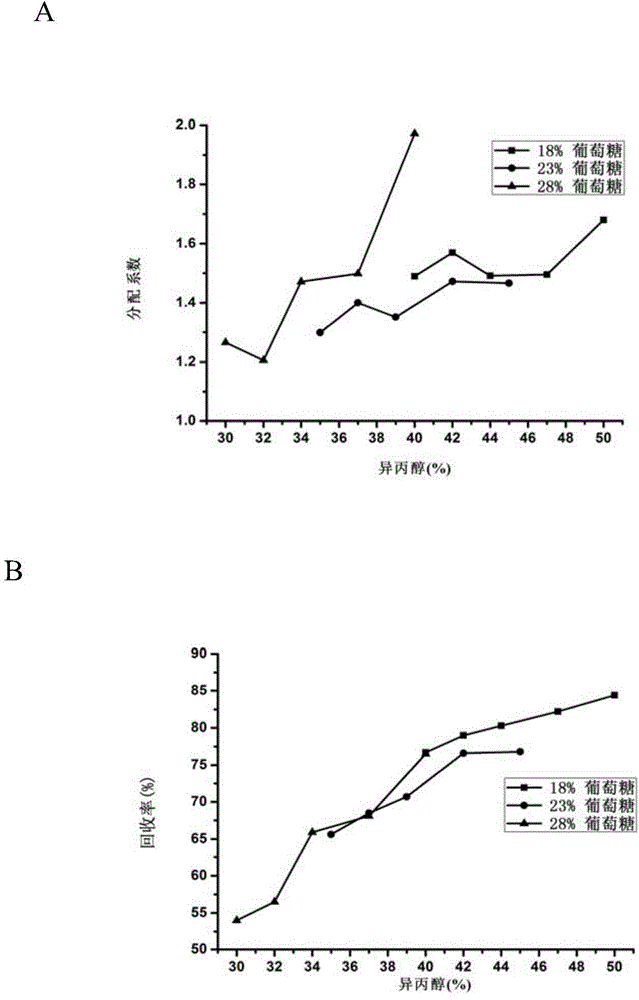

[0066] Embodiment 2 The influence of different sugars on the separation effect of lactic acid in fermentation broth

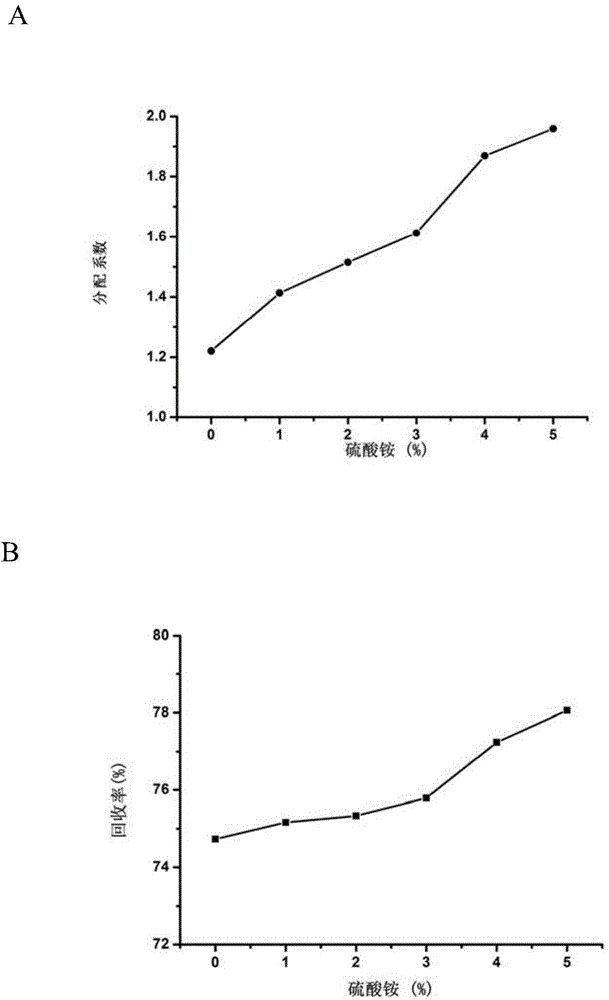

[0067] Lactic acid was isolated from the lactic acid simulant as described in 3 above. Among them, the concentration of lactic acid in the lactic acid simulation solution was 150 g / L, and the pH was 5.5. Different kinds of sugars (types of sugars, as shown in Table 2) were added to the lactic acid simulant solution and completely dissolved to obtain a sugar-containing mixed solution. Add isopropanol to the sugar-containing mixed solution, mix, adjust the pH of the mixed solution to 3.5, and stand at room temperature to obtain an extraction system in which two liquid phases coexist in an aqueous phase (lower phase) and an organic phase (upper phase). The concentration of lactic acid in the phase and the lower phase, the partition coefficient (K) and the recovery rate (Y) of lactic acid were calculated, and the results are shown in Table 2. The mass percentages...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com