Fertilizer system that uses solar energy to dry manure

A technology of solar drying and solar energy, applied in the field of solar energy application, can solve the problems of excessive heavy metals, heavy metal pollution, waste of resources, etc., and achieve the effects of high energy utilization rate, waste reduction, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

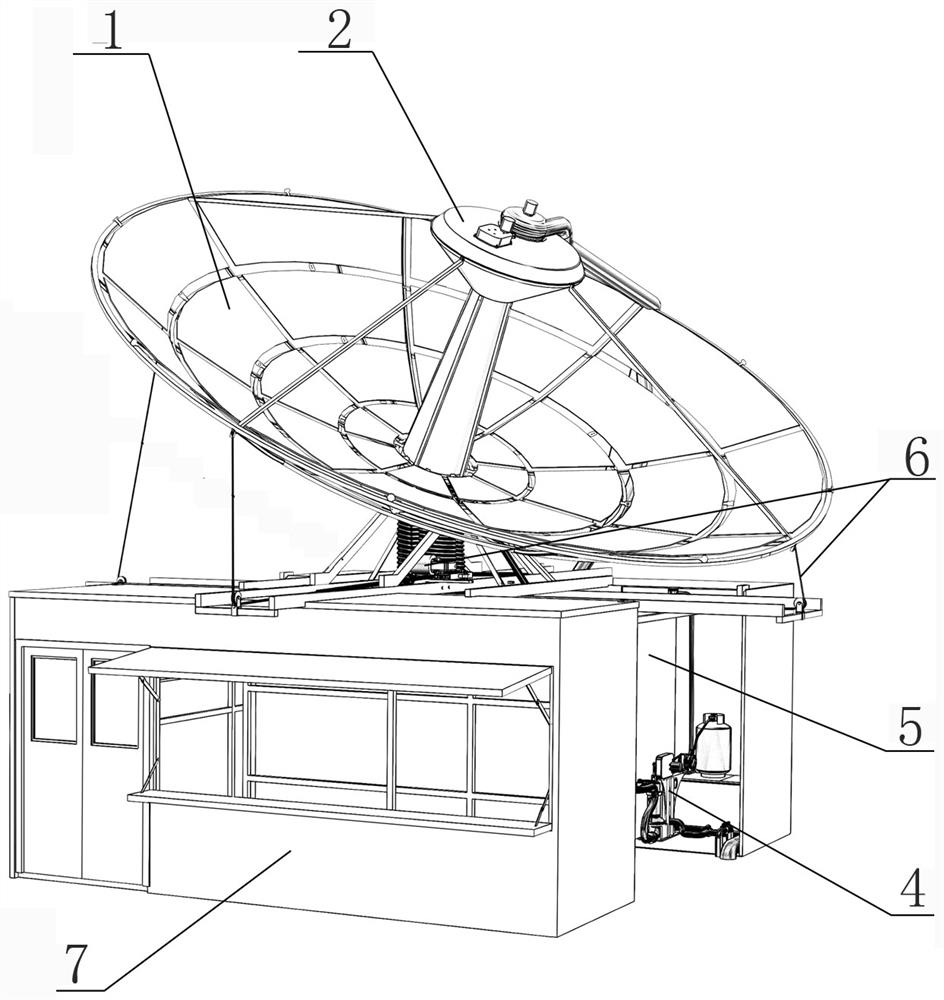

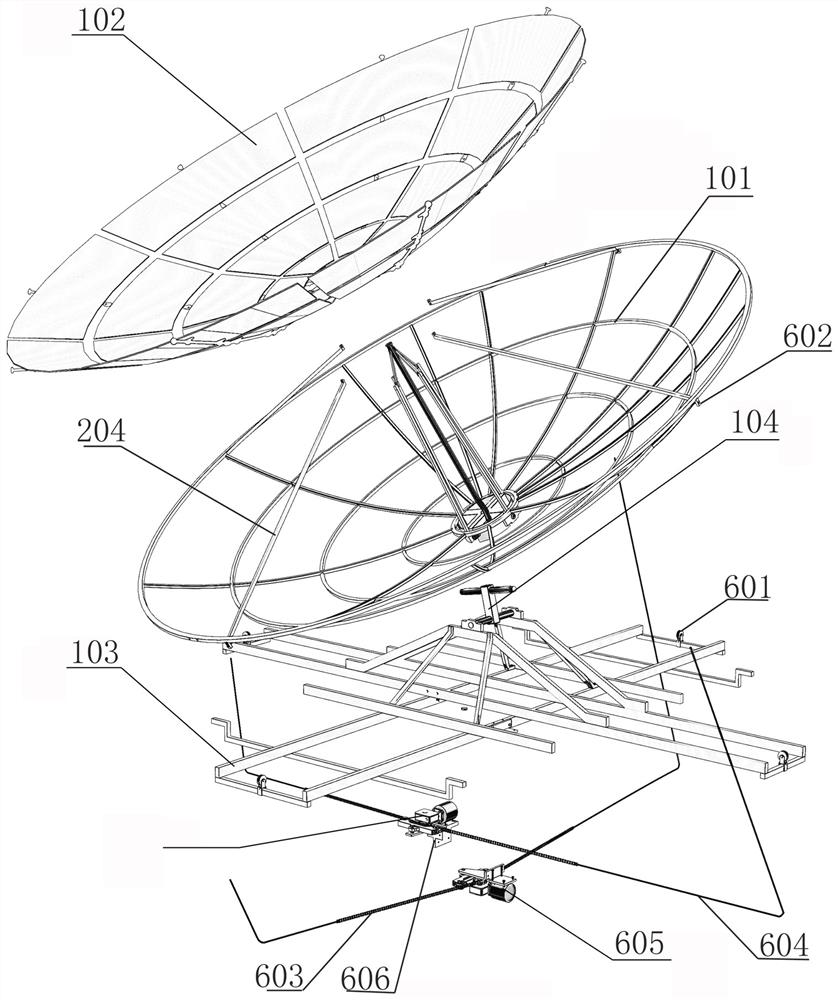

[0027] Embodiment one: see Figure 1-Figure 5 , a fertilizer making system using solar energy to dry feces, comprising a spherical reflective focusing solar device 1, a conical inner-rotating dryer 2 arranged in the middle of the spherical reflective focusing solar device 1, a dry material storage tank 3 and a grouting control system 4 The spherical reflective focusing solar device 1 includes a solar reflector support 101 in a spherical structure, a spherical solar reflector 102 arranged on the solar reflector support 101 for matching, and a support frame 103 arranged at the bottom of the solar reflector support 101 , the support frame 103 and the solar reflector support 101 are connected and supported by a universal joint bracket 104 , and a dual-axis clock type sun tracking control device 6 is also arranged on the support frame 103 .

[0028] The two-axis clock type sun tracking control device 6 includes four guide wheels 601 respectively arranged in four directions of east,...

Embodiment 2

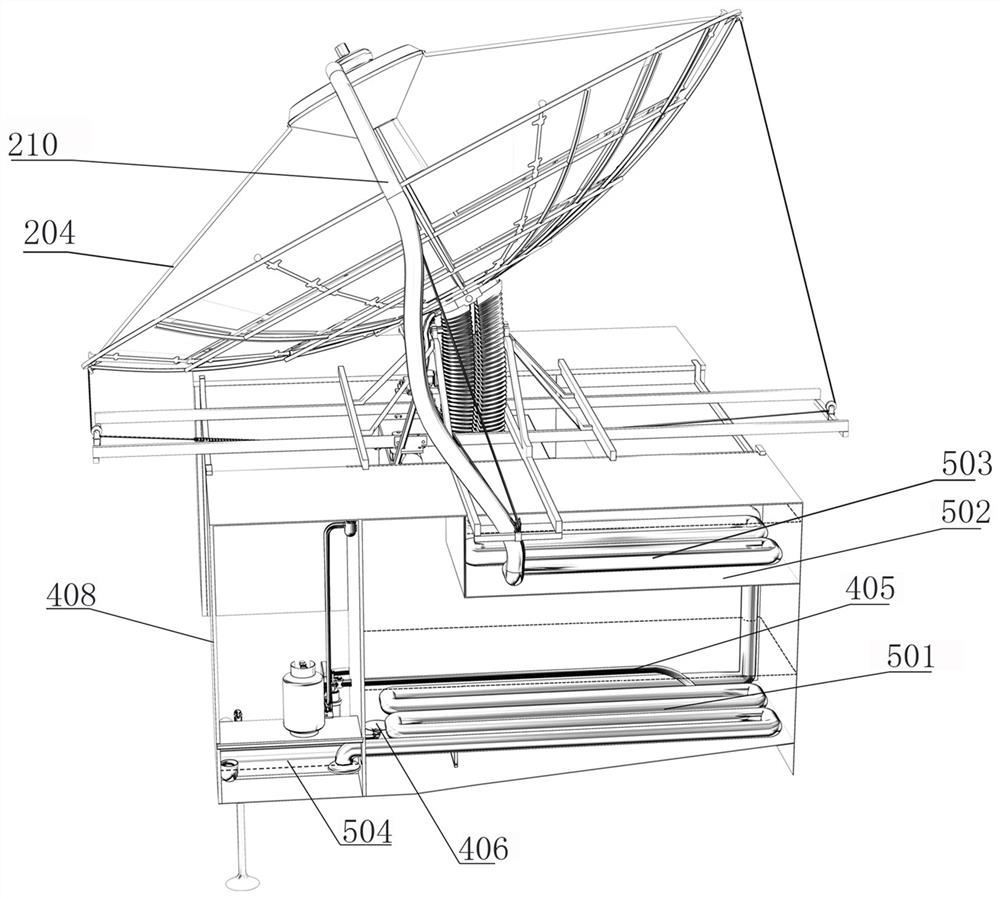

[0030] Embodiment two: see Figure 1-Figure 5 The structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that: during the drying process, a large amount of hot steam will be generated, and if the feces are directly processed without fermentation Drying wastes a lot of biogas resources. Therefore, in order to be able to use the biogas resources and solar energy in the feces more reasonably, a powerful exhaust fan 209 and an exhaust hose 210 are communicated on the upper cover of the dryer, and a sealed fermentation cooling chamber 5 for fermenting the feces is provided. , before the feces are dried, the feces fermentation should be carried out in the sealed fermentation cooling chamber 5, and the collection of biogas. The bottom of the sealed fermentation cooling chamber 5 is laid with a feces fermentation heat exchange pipe 501, and the feces fermentation heat exchange pipe 501 is connected to th...

Embodiment 3

[0034] Embodiment three: see Figure 1-Figure 5 , the structure of this embodiment is basically the same as that of Embodiment 2, and the similarities will not be repeated. The difference is that a water tank 502 is provided on the sealed fermentation cooling chamber 5, and a water tank 502 is also provided in the water tank 502. The water tank heat exchange pipe 503, the exhaust hose 210, the water tank heat exchange pipe 503, and the excrement fermentation heat exchange pipe 501 are connected in sequence, so that the high-temperature waste gas produced by drying the feces can be fully utilized to convert the energy in the high-temperature waste gas For high temperature domestic water.

[0035] Embodiment three: see Figure 1-Figure 6 , the structure of this embodiment is basically the same as the above-mentioned embodiment, and the similarities will not be repeated. The difference is that the fertilizer making system also includes a function expansion chamber 7 for supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com