Rubber ring film winding system

A technology of wrapping film and aprons, which is applied in the direction of external support, packaging, and packaging material feeding devices, etc., which can solve the problems of low work efficiency, time-consuming, labor-intensive, and heavy labor, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

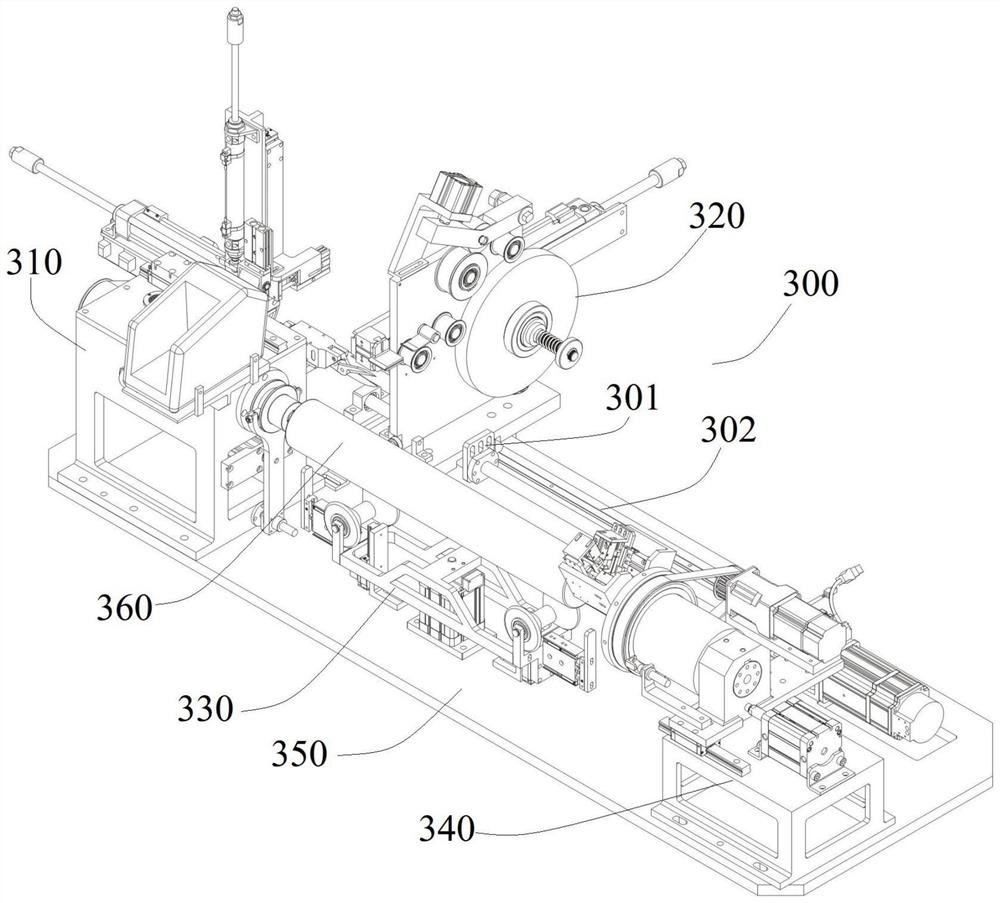

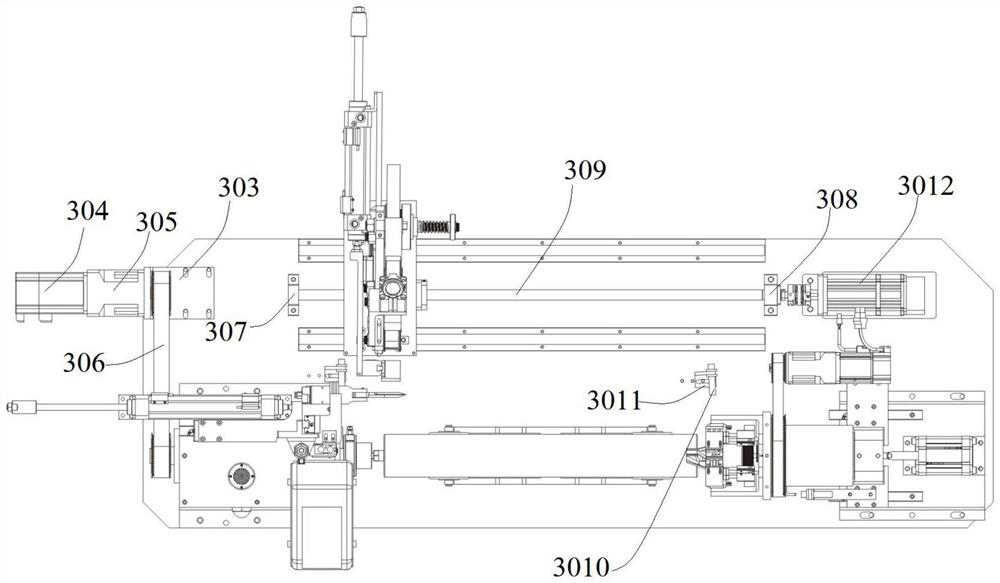

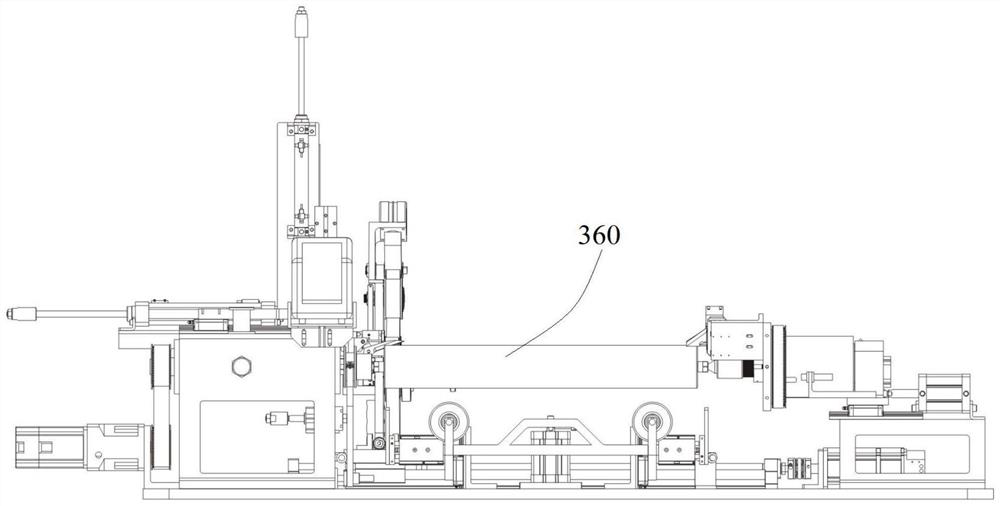

[0070] Such as Figure 1-28 As shown, the present embodiment provides an apron wrapping system, including a main workbench 370, on which several apron wrappers 300 are evenly distributed; in the present embodiment, the main workbench 370 is a circle Shaped workbench, on which a plurality of apron wrapping machines 300 are evenly distributed in a circle, which can wrap a plurality of aprons 360 to be processed at the same time, improving the working efficiency of wrapping.

[0071] In this embodiment, the apron winding machine 300 mainly includes:

[0072] Lifting device 330, the lifting device 330 can carry the apron 360 to be processed, and drive the apron 360 to be processed up and down, the apron 360 to be processed is set on the mandrel, and the mandrel can be installed on the lifting device 330;

[0073] The back seat box device 340, the back seat box device 340 is located at one end of the lifting device 330, the back seat box device 340 can fix one end of the mandrel, ...

Embodiment 2

[0114] This embodiment is an improvement made on the basis of Embodiment 1, and its improvements are as follows:

[0115] In this embodiment, a tape machine 311 is also installed on the spindle housing 221, and a tape pressing wheel device is also installed on the spindle housing 221, and the tape pressing wheel device can press the tape on the end of the apron 360 to be processed. , to fix the membrane;

[0116] The tape pressing wheel device includes front and rear drive cylinders 3111, up and down drive cylinders 3114 and left and right drive cylinders 315, front and rear drive cylinders 3111 are installed on the main shaft casing 221, and are arranged parallel to the main shaft 2217; front and rear drive cylinders 3111 are equipped with up and down drive cylinders Support, the upper and lower driving cylinders 3114 are vertically arranged on the upper and lower driving cylinder brackets, the left and right driving cylinder brackets are installed on the upper and lower driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com