Hydraulic sleeper replacement machine and hydraulic sleeper replacement method

A replacement method and machine replacement technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of lack of small mechanized equipment, achieve the effect of ensuring mobility and flexibility, improving operation efficiency, and preventing UMC accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

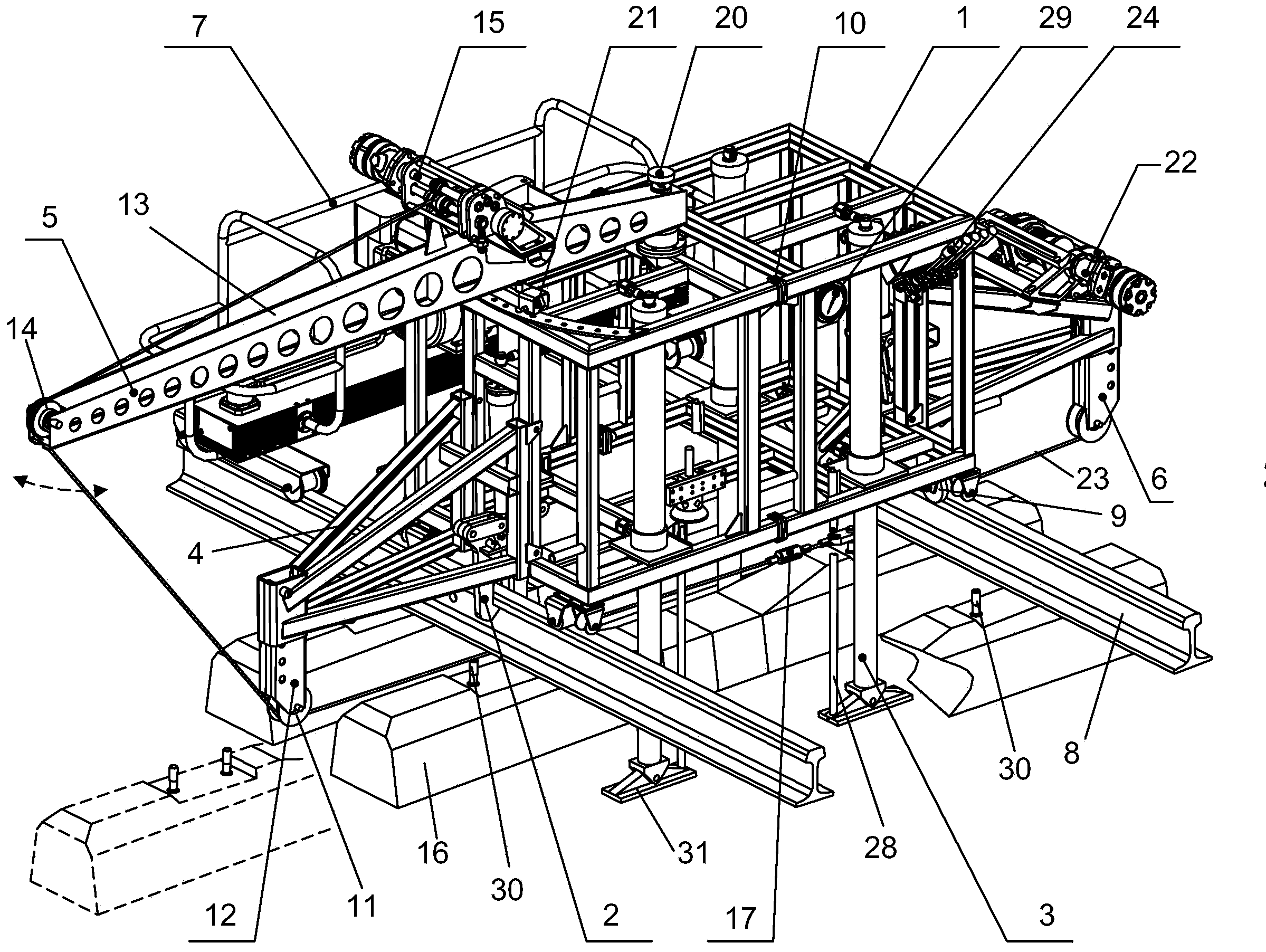

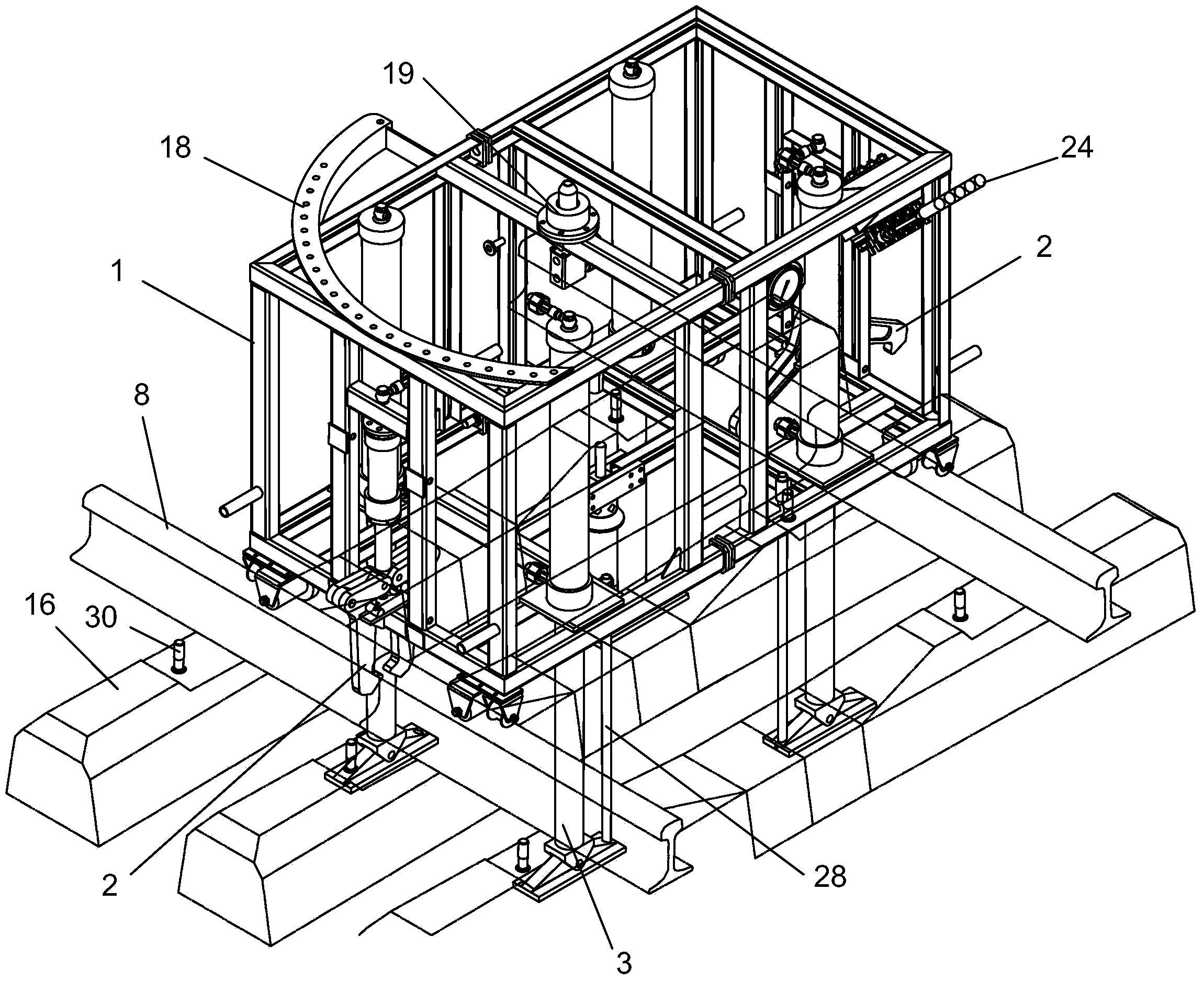

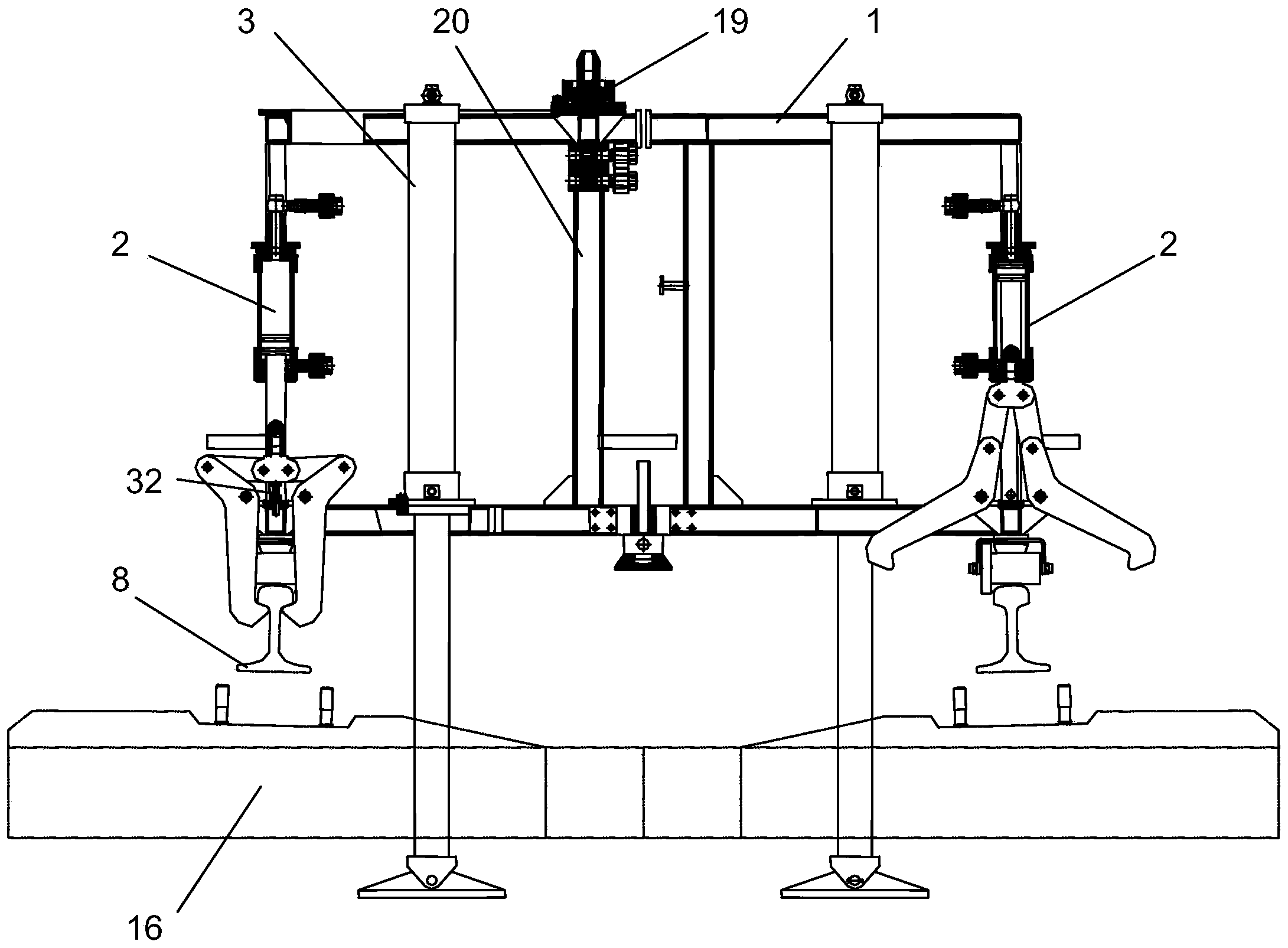

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0044] see Figure 1~3 As shown in the figure, the hydraulic sleeper replacement machine of the present invention mainly includes the main frame 1, the lifting claw 2, the lifting cylinder 3, the unpowered pulley support 4, the hydraulic crane 5, the powered pulley support 6, the hydraulic pump station 7 and other components, in:

[0045] The main frame 1 is a frame structure, on which one or more pairs of lifting claws 2 and several pairs of lifting cylinders 3 ( figure 1 , figure 2 The track claws 2 shown in the figure are a pair of track oil cylinders and 3 are two pairs), wheels 9 walking on rails 8 are arranged at the bottom of the main frame 1, and an insulating assembly 10 is also provided on the main frame 1.

[0046] The unpowered pulley support 4 is located at one end of the main frame 1 and is in the shape of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com