Crane winding device with steel wire rope straining mechanism

A technology of tensioning mechanism and hoisting device, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of reducing the service life of steel wire rope, skipping or slipping wire rope arrangement, loose and disordered, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

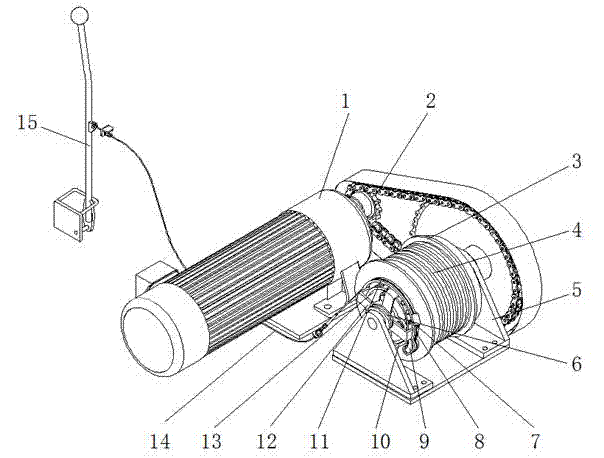

[0010] Such as figure 1 As shown, the hoisting device of the crane with the steel wire rope tensioning mechanism of the present invention comprises a reel part, a motor 1 and a deceleration system 2, in the reel part, the steel wire rope 4 is wound on the reel 3 through one end of the pulley block, and the other end is connected to the suspension hook, and the reel The drum 3 is supported by the bearing housing 5, and the motor 1, the reduction system 2 and the transmission shaft of the reel 3 are connected in sequence. A one-way bearing is installed in the reel 3 , the inner ring of the one-way bearing cooperates with the transmission shaft, and the outer ring cooperates with the reel 3 . A wire rope tensioning mechanism is installed on one side of the reel 3. The wire rope tensioning mechanism is composed of a ratchet 13, a pawl 9, a bracket 12 and a limit block 10. The ratchet 13 is connected to the end cover of the reel 3 by bolts. The outer periphery of the ratchet 13 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com