A pre-tightening clamping device

A clamping device and pre-tightening technology, which is applied in the field of pre-tightening clamping devices, can solve problems such as high cost and complex structure, and achieve the effect of reducing operating torque and simple and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

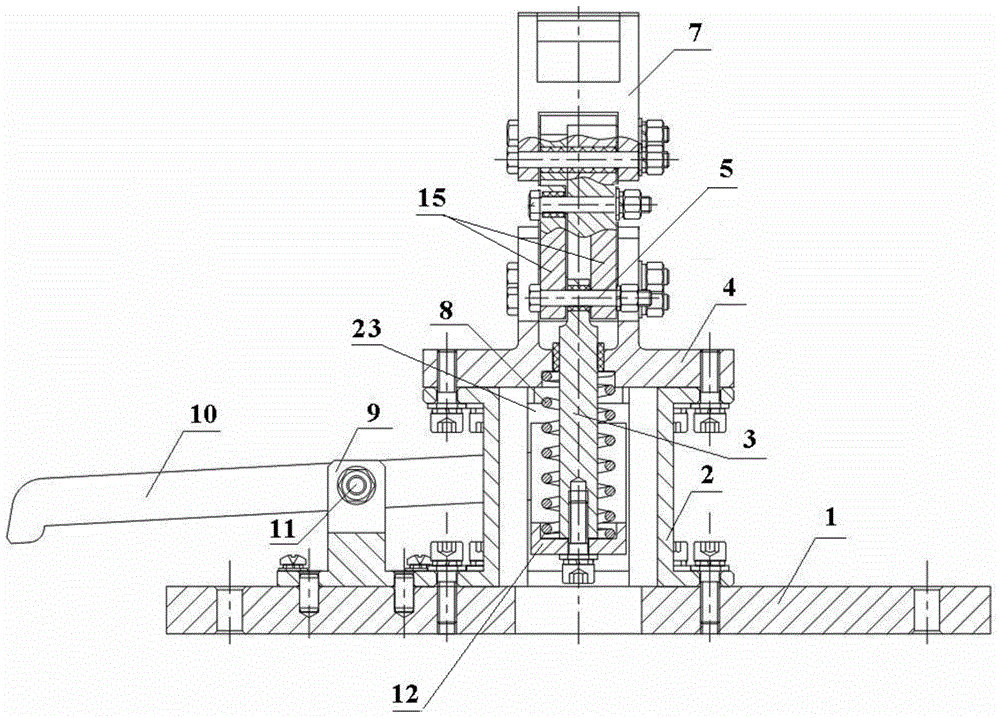

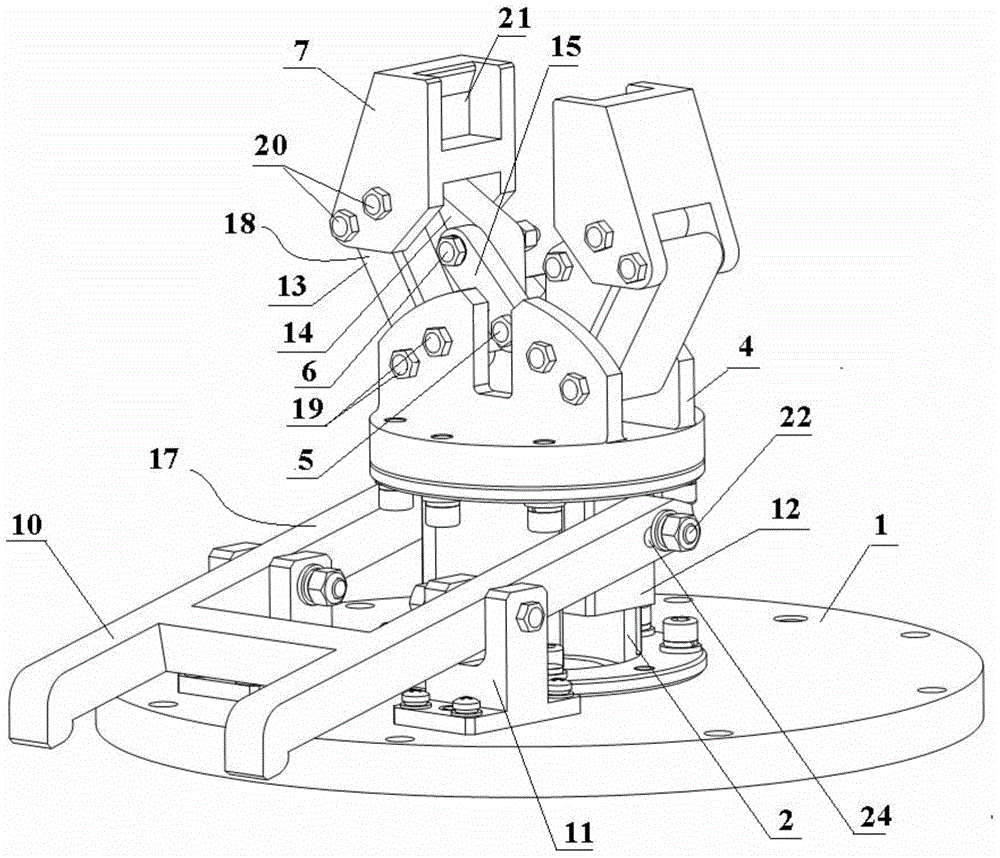

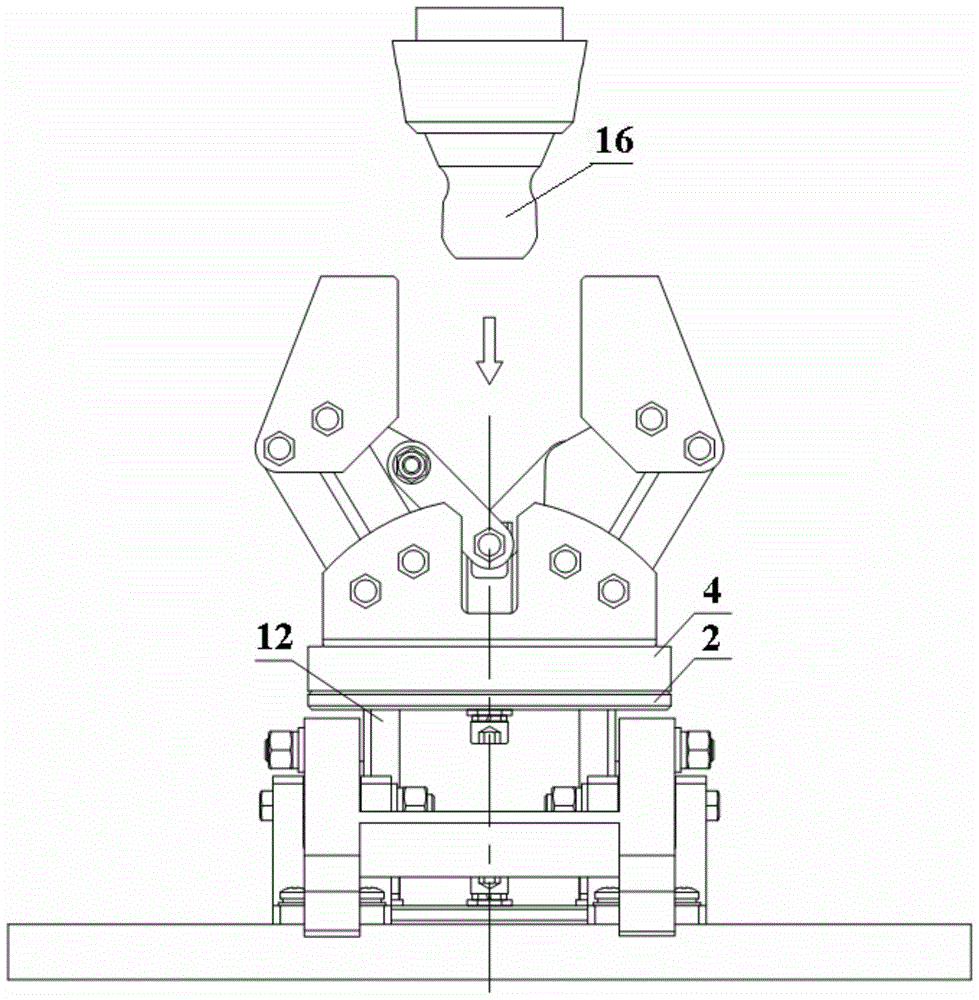

[0023] Such as Figure 1~2 As shown, the present invention includes a base 1, a support member 2, a sliding rod 3, a bearing 4, a pincer finger 7, a slider guide mechanism 17, a drive link 15 and a parallel rod mechanism 18, wherein the slider guide mechanism 17 includes a shift fork 10 and a slider 12, the shift fork 10 is fixed on the base 1 through two shift fork supports 9, the shift fork 10 is an "H" type structure, including side bars on both sides and a crossbeam in the middle, and the middle parts of the side bars on both sides of the shift fork 10 are hinged to the two shift fork supports 9 through the shift fork rotating shaft 11 respectively. The slider 12 is arranged in the support member 2 and moves up and down along the support member 2. The support member 2 is in the shape of a sleeve with flanges at both ends, and the support member 2 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com