Steel wire rope winding device

A hoisting device and wire rope technology, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of excessive deflection angle of wire rope, affecting the normal use of pillow changing machine, and the failure of real synchronization between drum and rope guide wheel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

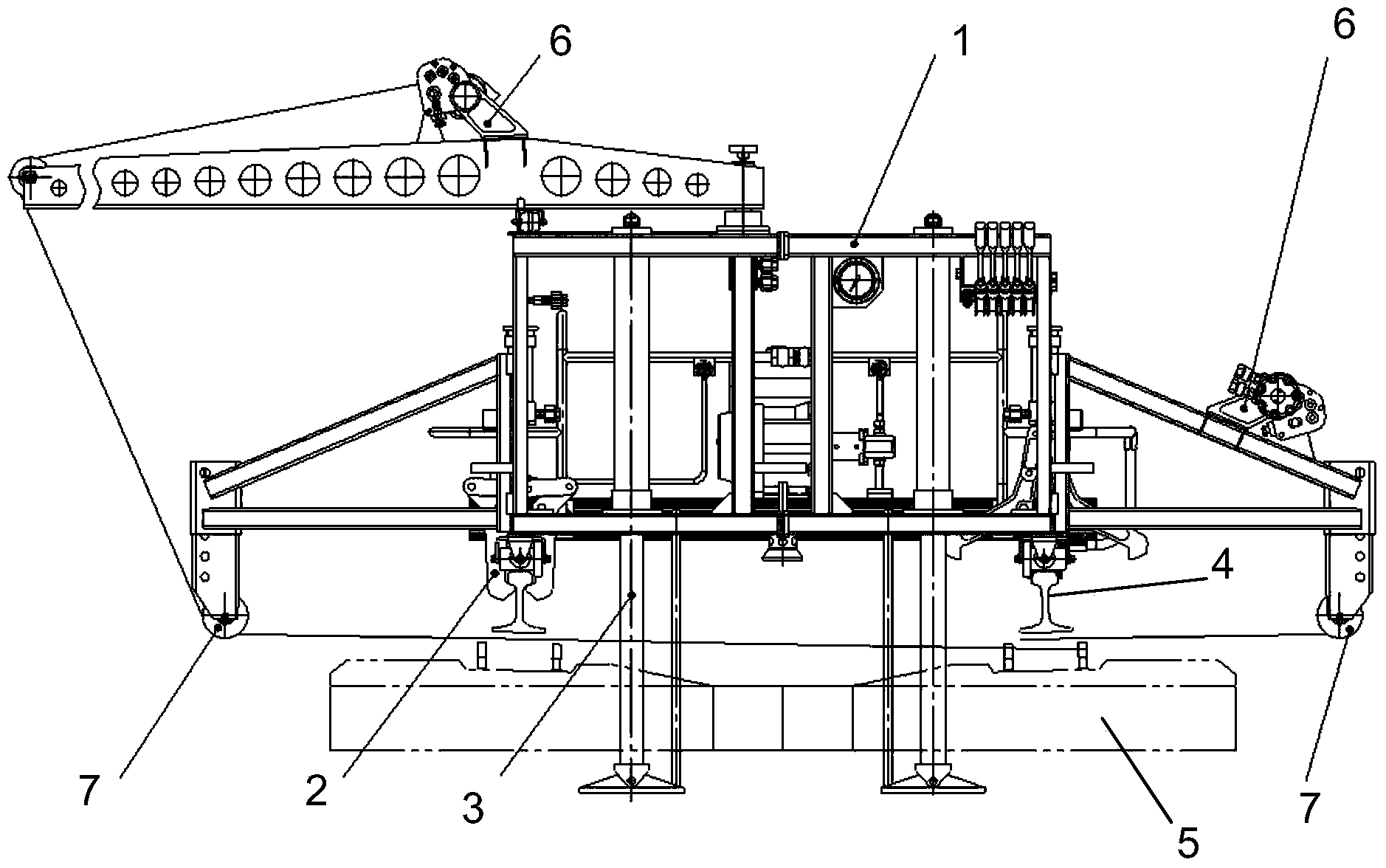

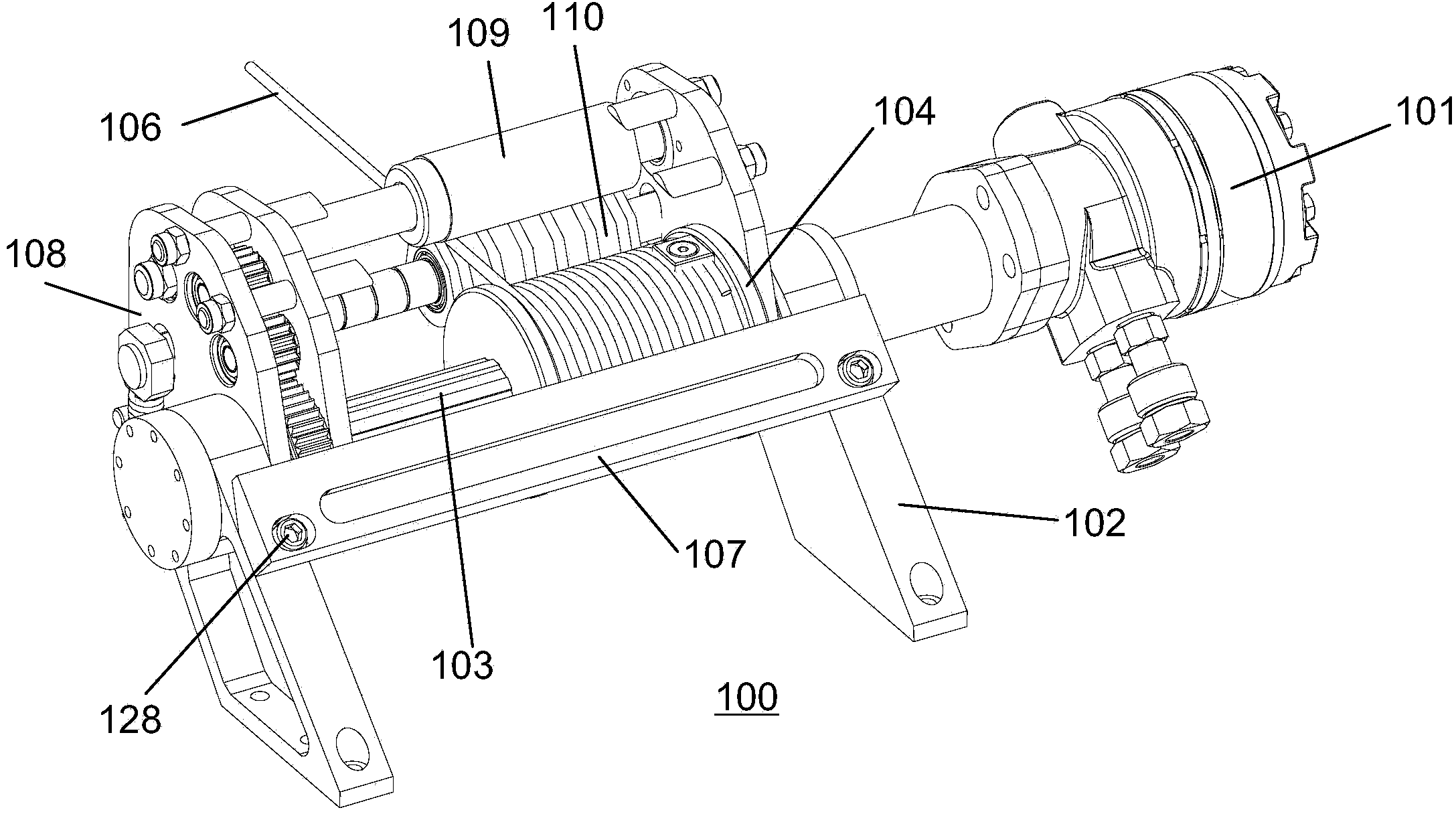

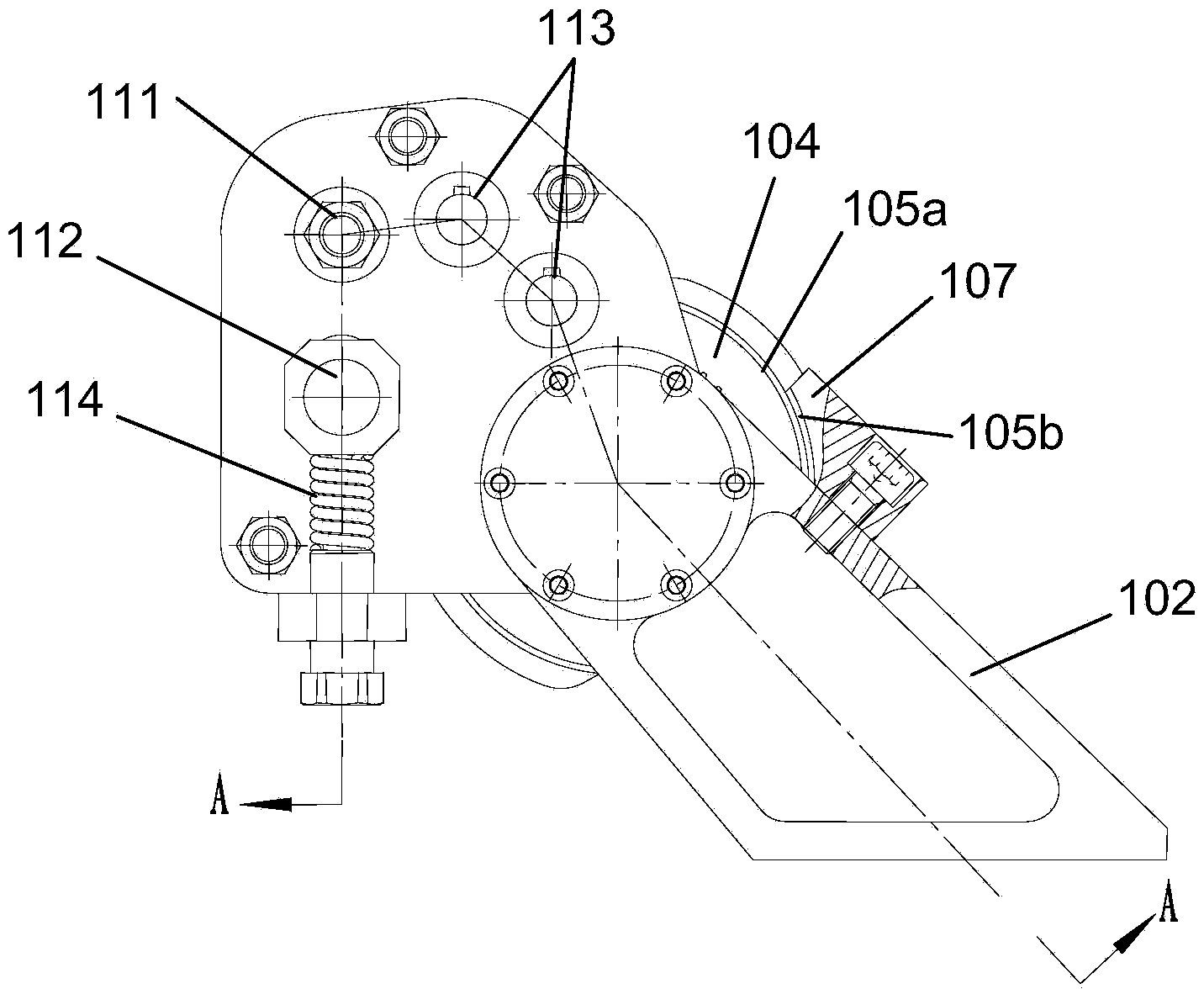

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] see Figure 2-6 As shown in the figure, the wire rope hoisting device 100 of the present invention is the same as the prior art in that it also includes a power component 101, a fixed frame 102, a spline shaft 103 arranged on the fixed frame 102 and connected to the power component 101, and a movable sleeve. The wire rope reel 104 on the spline shaft 103, the power part 101 can use a hydraulic motor or other power device to drive the spline shaft 103 to rotate, and the fixed frame 102 is provided with a pair of self-aligning bearings 105 to install the spline shaft 103 , the wire rope reel 104 is used to wind the wire rope 106 , and through the self-aligning bearing 105 , the non-concentric error of the bearing hole of the fixing frame 102 caused by manufacturing can be eliminated. Different from the prior art, the wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com