Patents

Literature

41results about How to "High drive reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

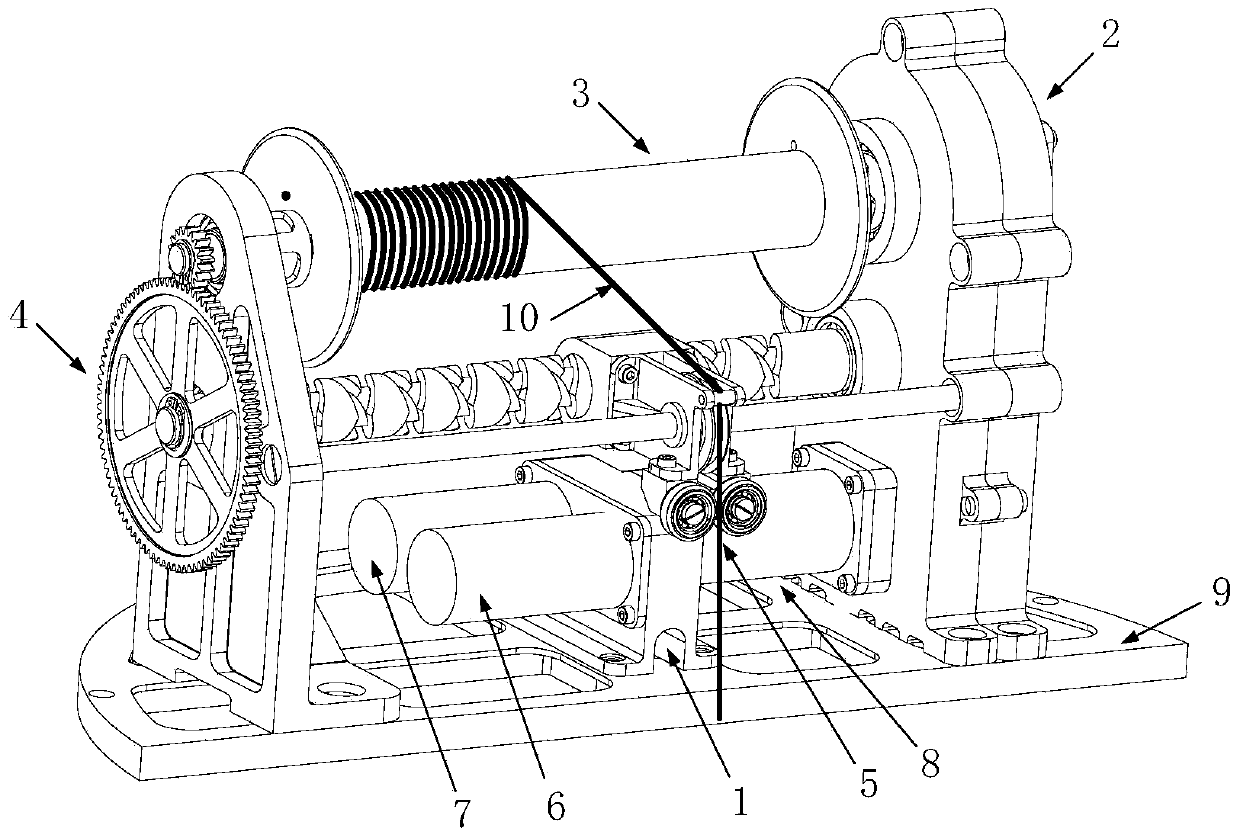

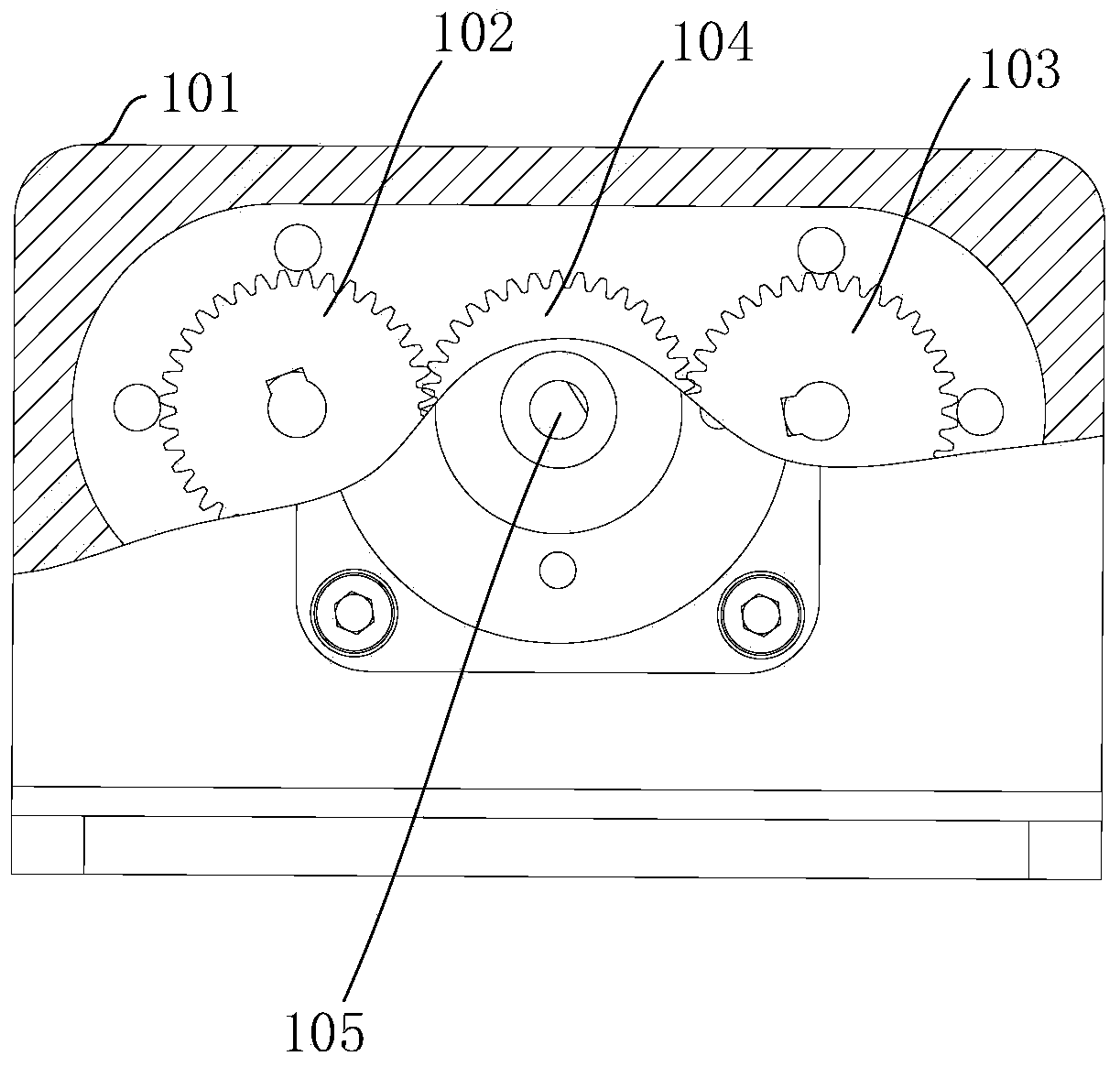

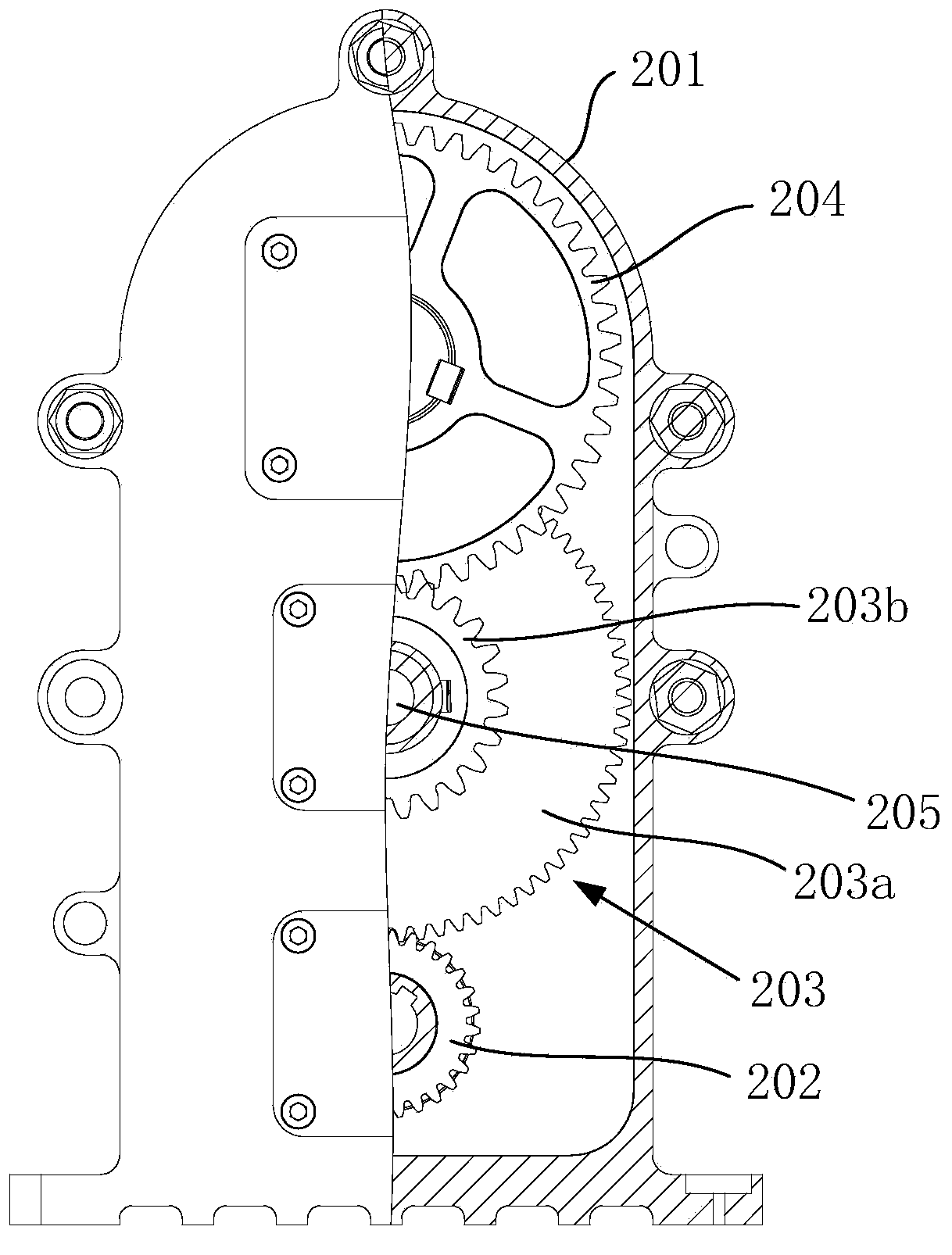

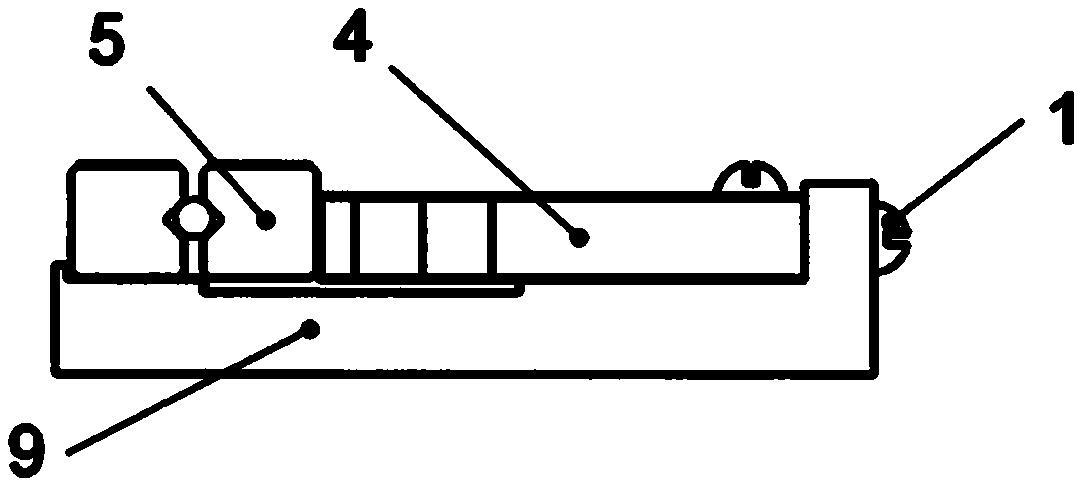

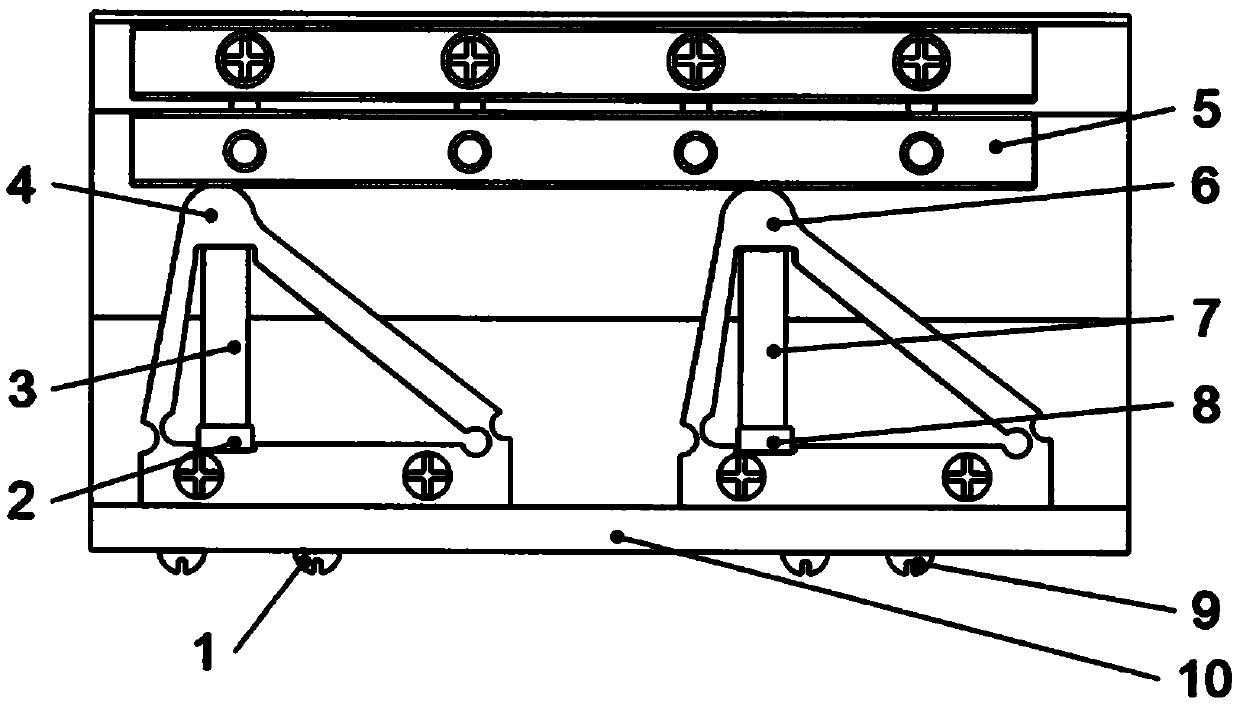

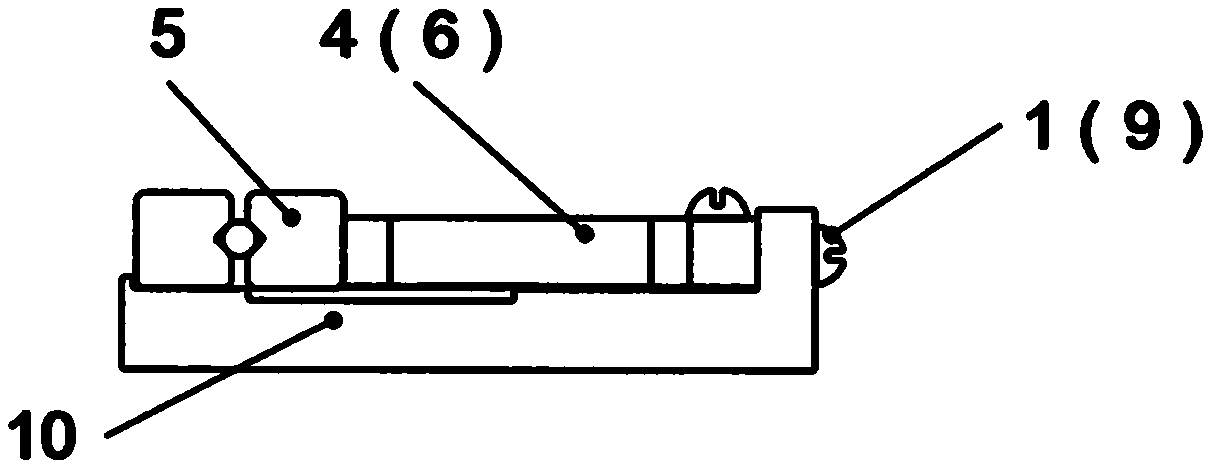

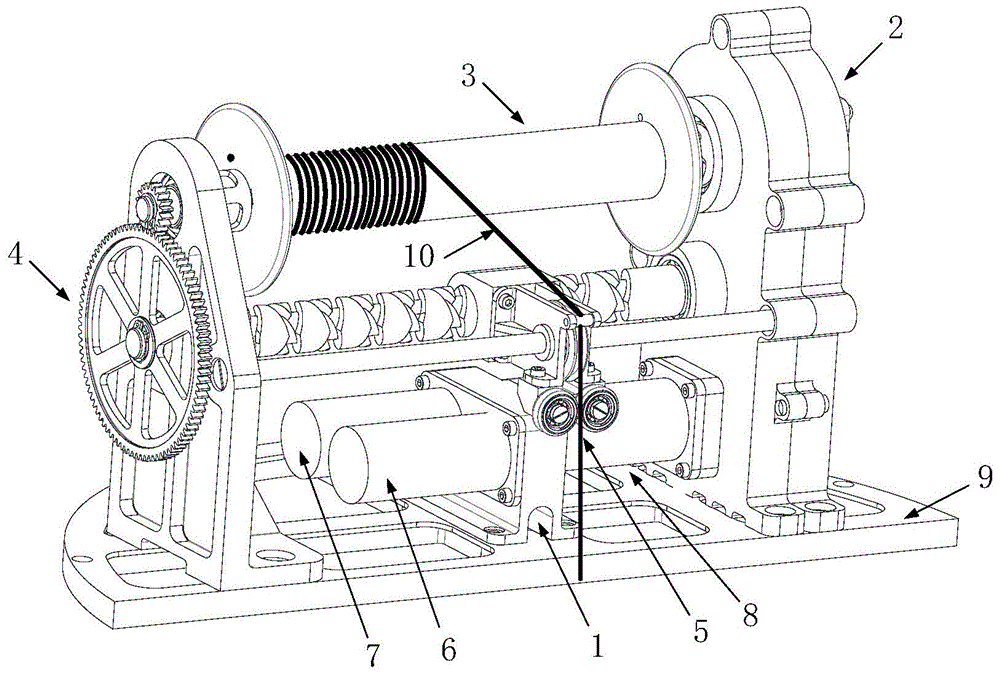

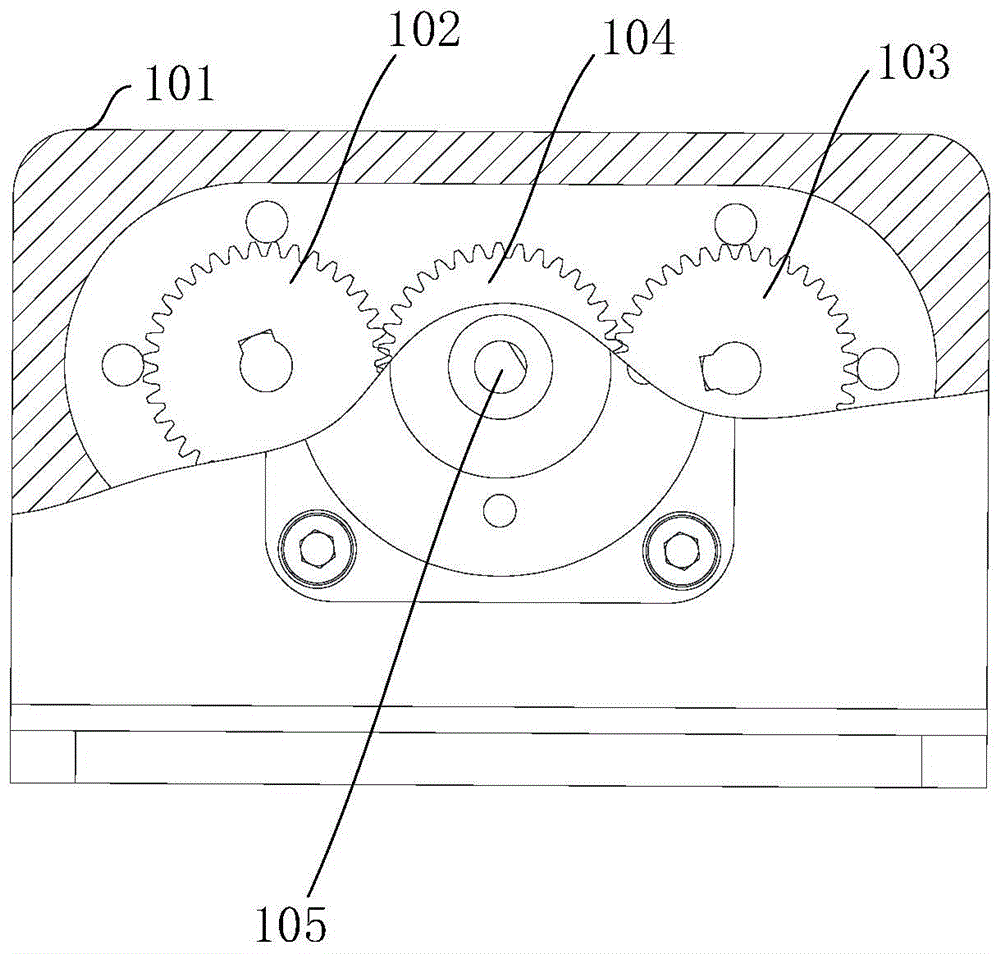

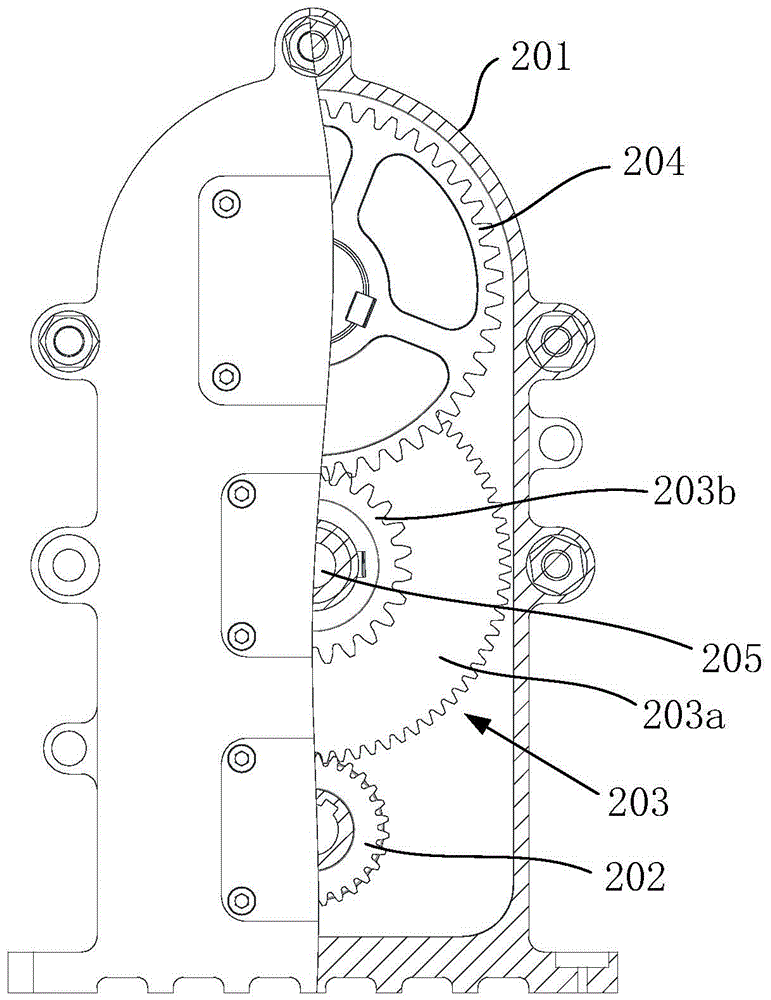

Rope drive device with reciprocating wire arrangement function

ActiveCN104192637AWith reciprocating cable functionWinding orderlyFilament handlingReciprocating motionGear wheel

The invention discloses a rope drive device with a reciprocating wire arrangement function. The rope drive device comprises a backup motor gearbox, a rope roller reducer, a winding roller, a reciprocating screw mechanism and an arrangement guide wheel set. A driving motor is connected with an output shaft of a backup motor and an input shaft of a planetary reducer through the backup motor gearbox, so that both the driving motor and the backup motor can drive the motor gearbox to move. The rope roller reducer transmits rotation of an output shaft of the planetary reducer to the winding roller according to a specified speed ratio, and a large torque is obtained. The winding roller is mounted at an output shaft of the rope roller reducer; a drive rope is wound on and unwound from the winding roller. A reciprocating screw of the reciprocating screw mechanism is connected with the winding roller through a gear and drives a nut slider mounted on the reciprocating screw, to reciprocate. The arrangement guide wheel set is fixedly connected with the screw slider and reciprocates with the screw slider to guide the drive rope being tightly wound on the winding roller in a reciprocating manner. The rope drive device allows winding and unwinding of the rope and allows the rope to be regularly and tightly wound.

Owner:BEIHANG UNIV

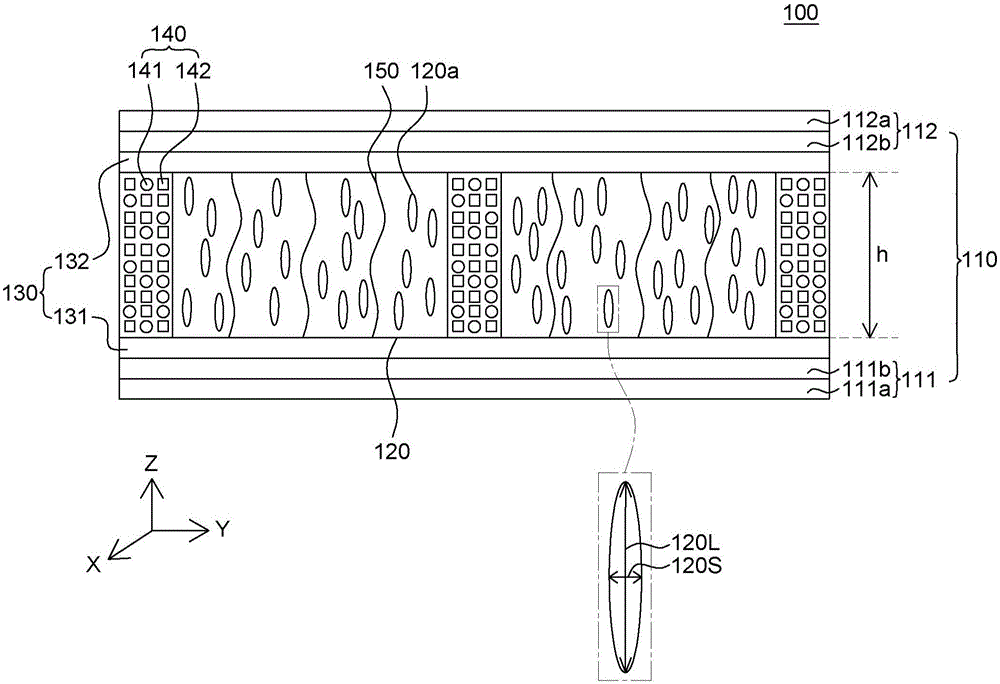

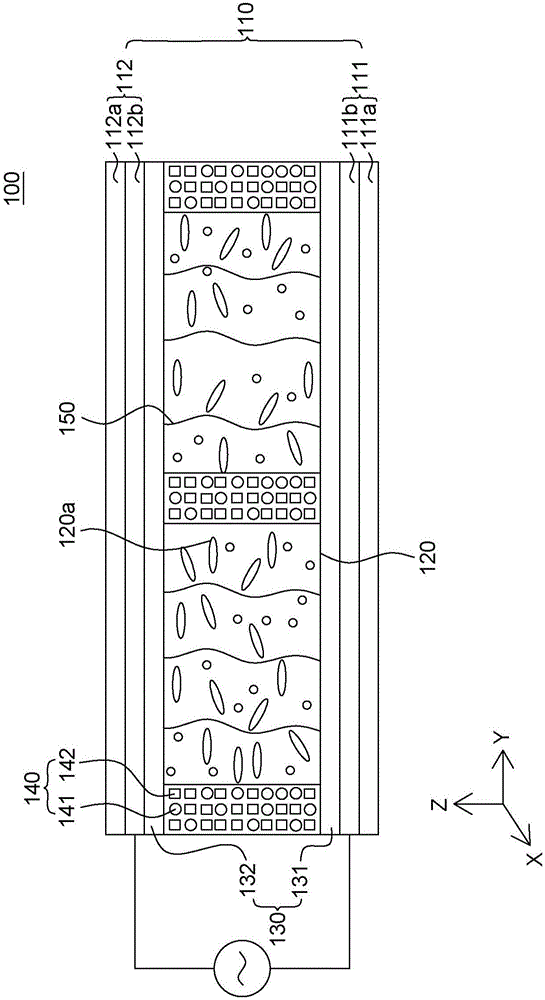

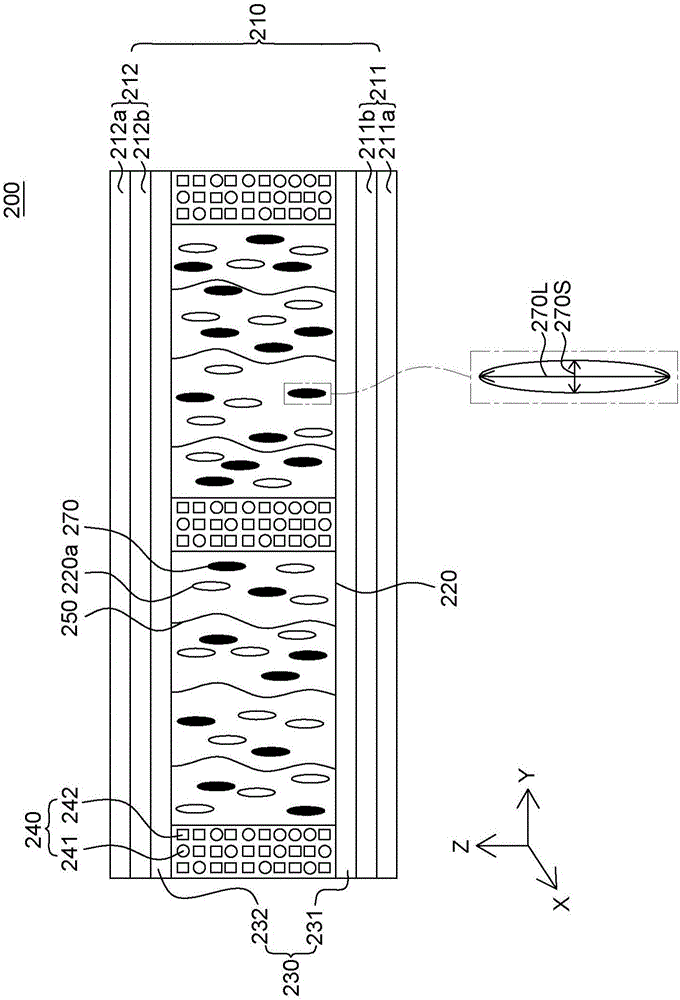

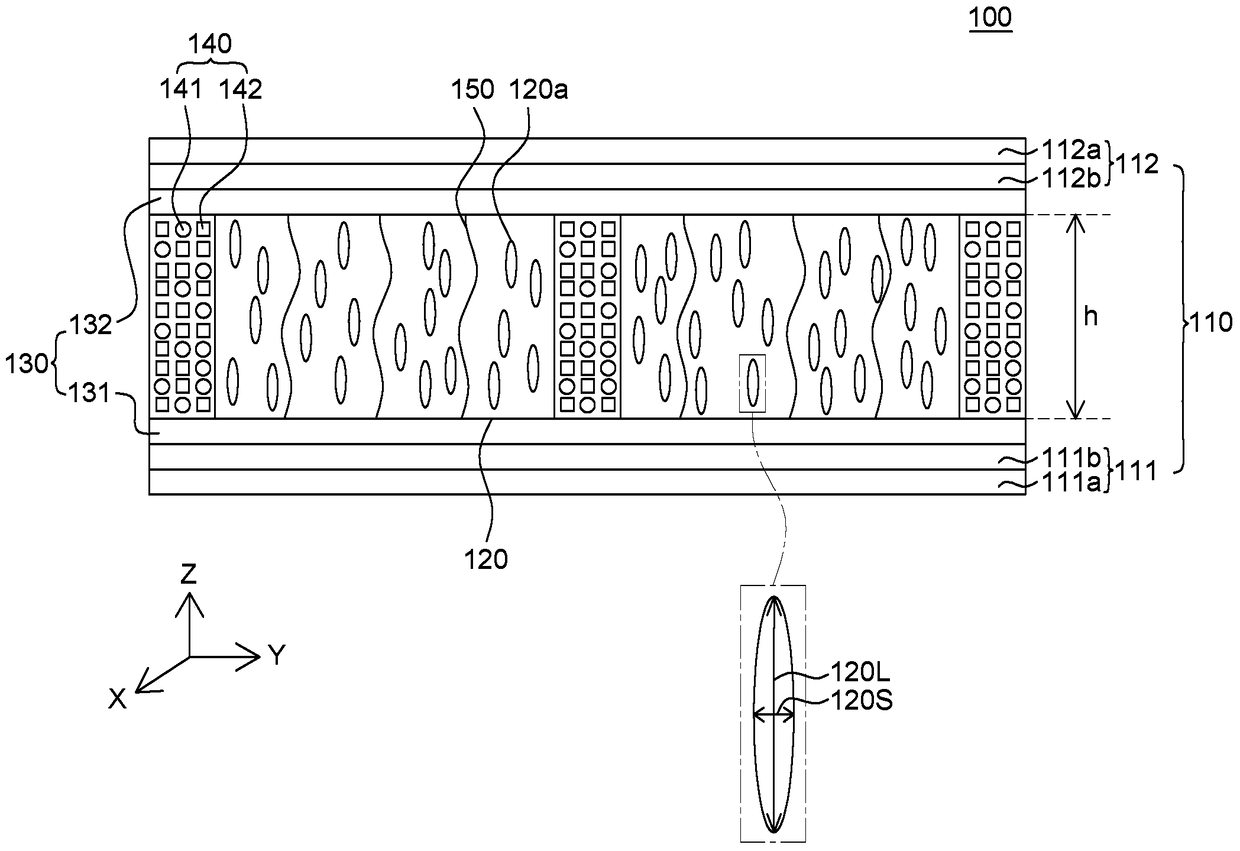

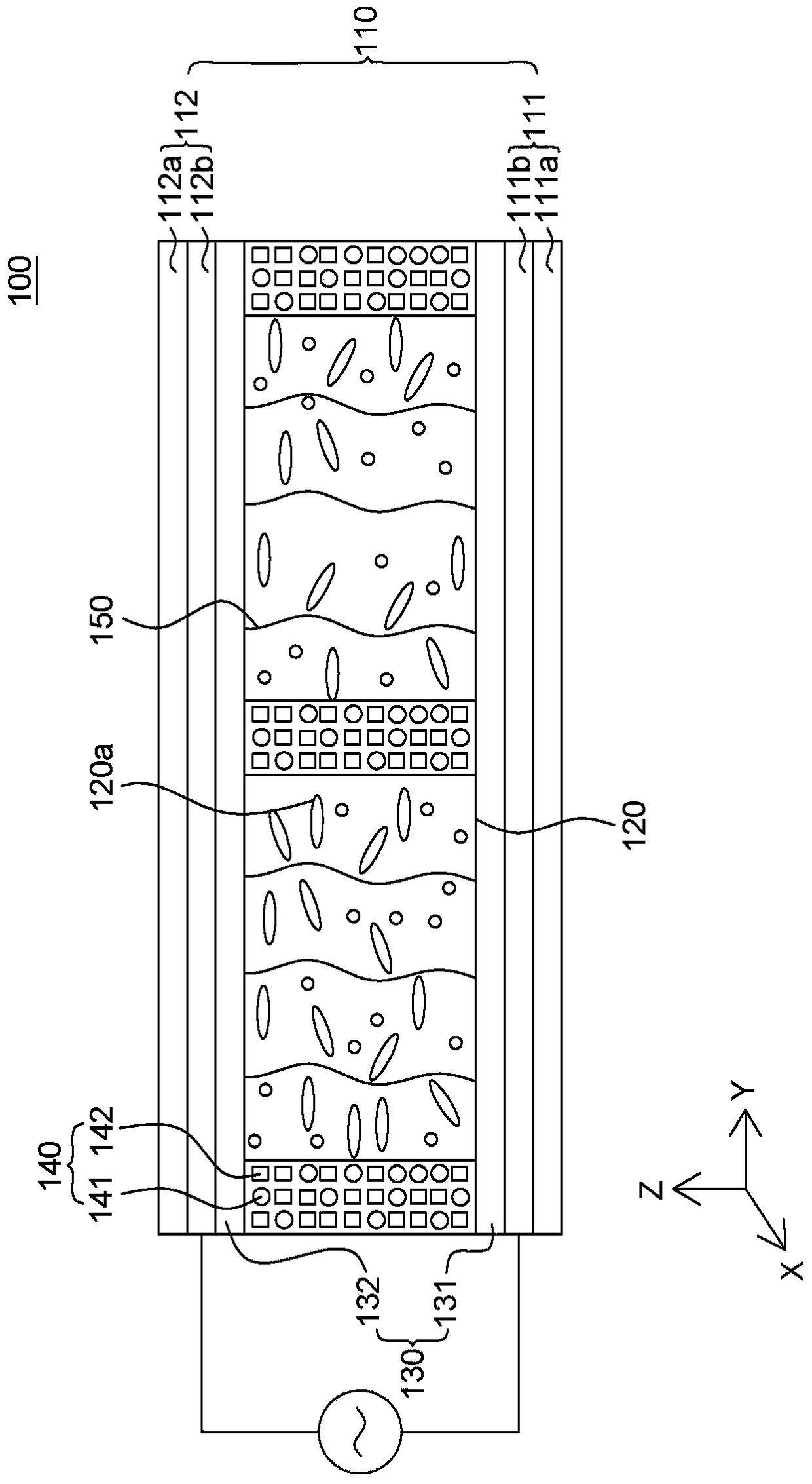

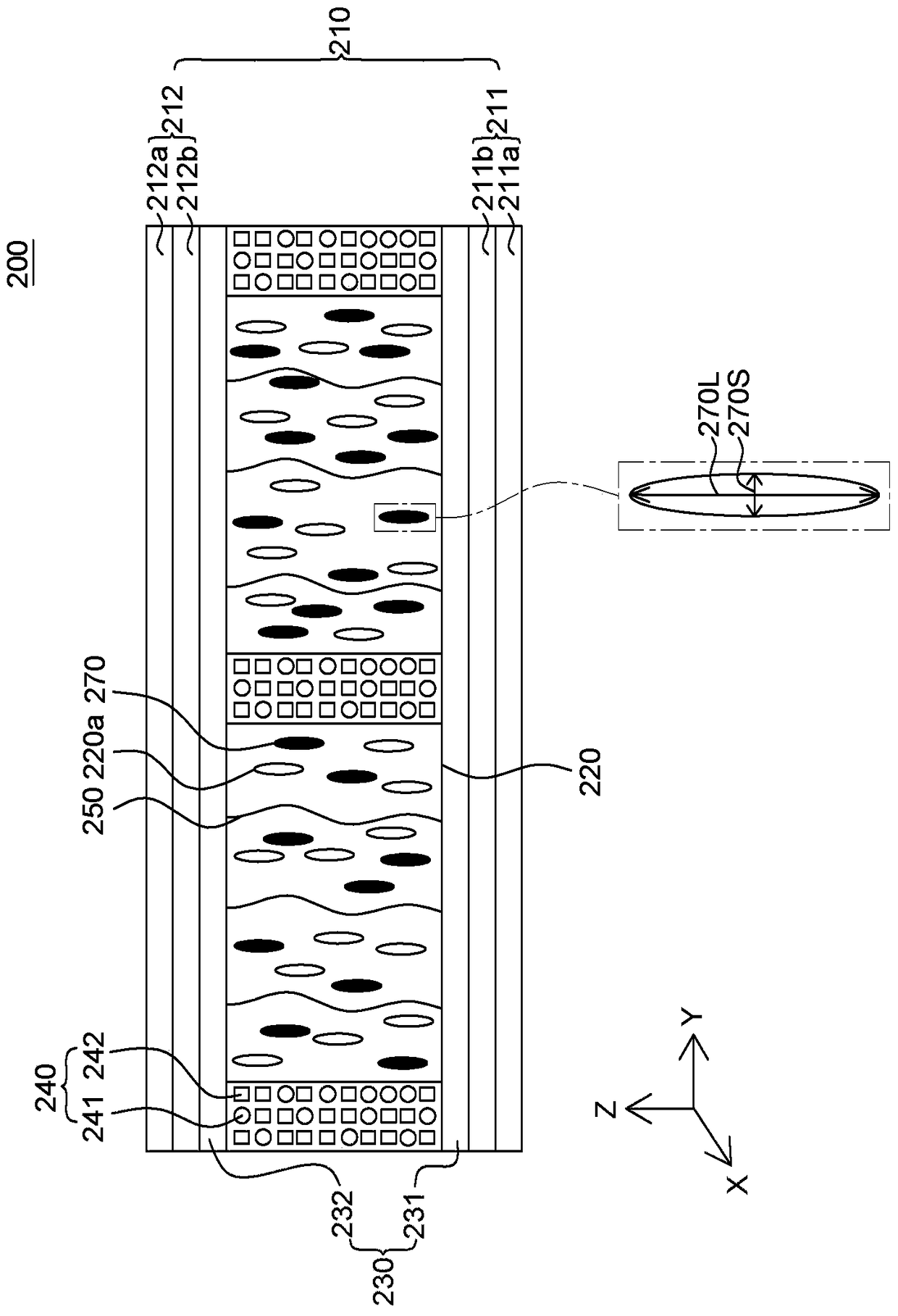

Light controlling apparatus and method of fabricating same

Provided are a light controlling apparatus and a method of fabricating the same. The light controlling apparatus comprises: a first electrode unit and a second electrode unit facing each other; a liquid crystal unit between the first electrode unit and the second electrode unit, the liquid crystal unit including: a liquid crystal; a network having a first polymer polymerized from a first monomer having a similar shape as the liquid crystal and a second polymer polymerized from a second monomer having a shape different from the first monomer; and a wall having the first polymer and the second polymer.

Owner:LG DISPLAY CO LTD

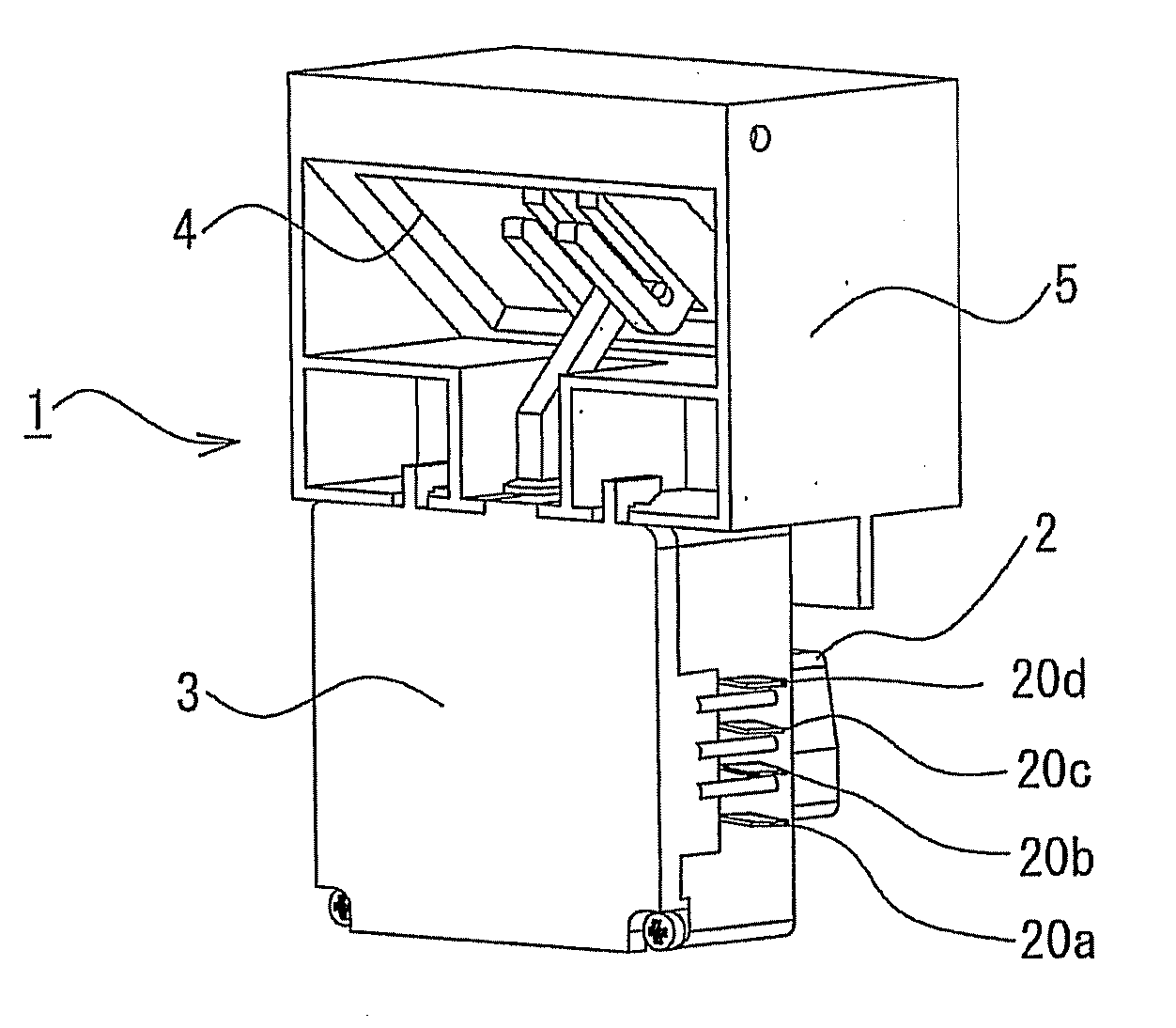

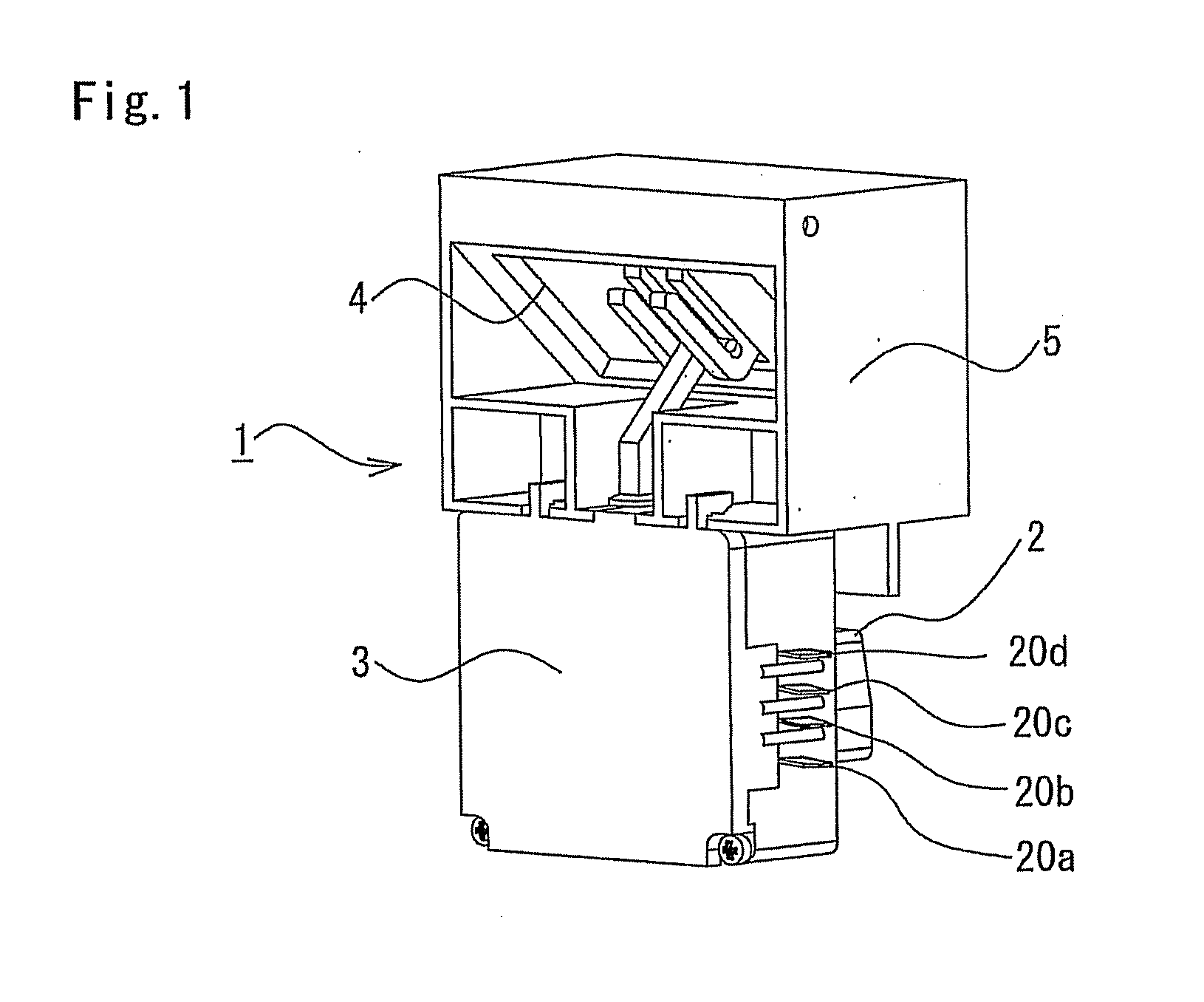

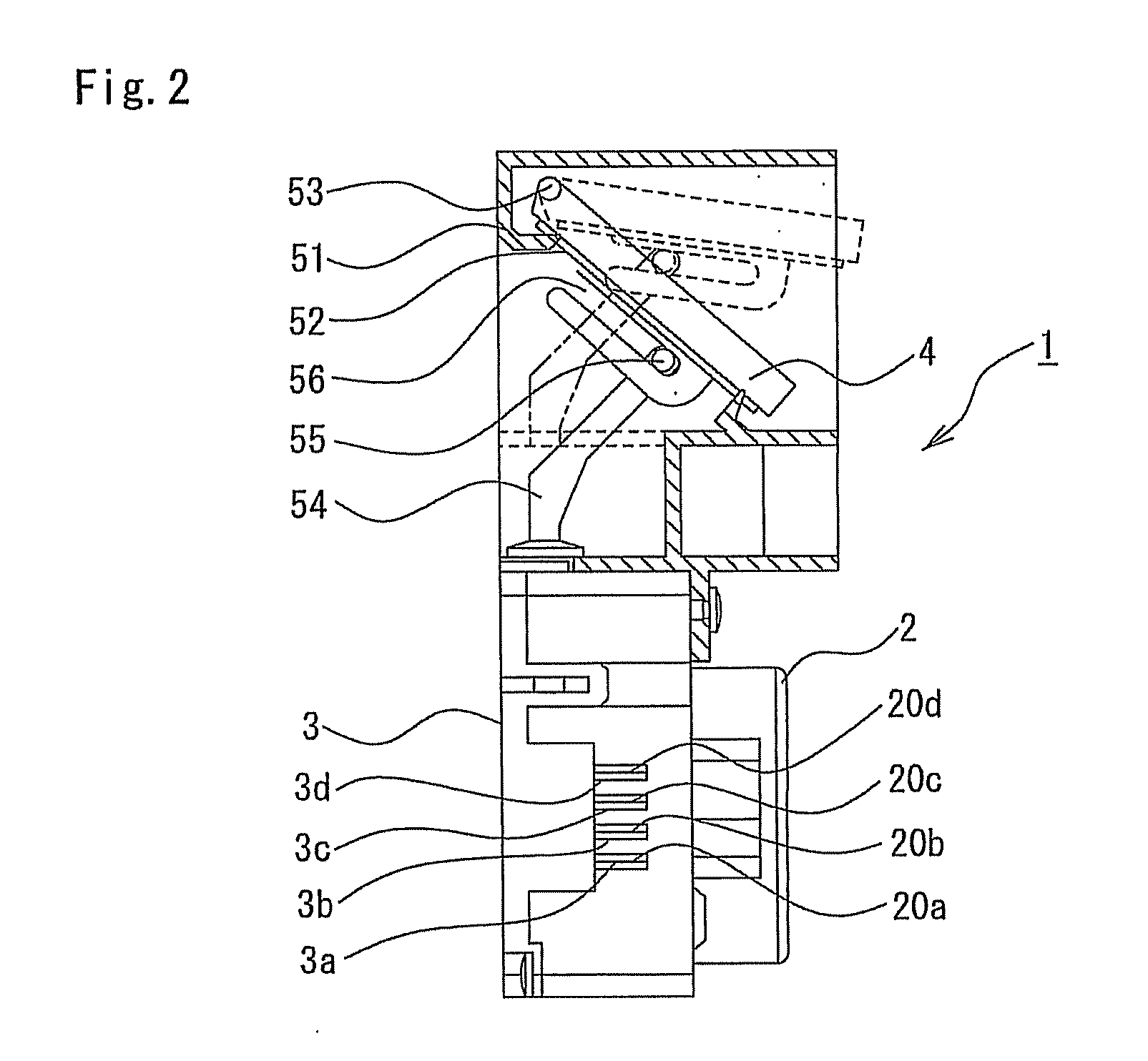

Motor actuator

ActiveUS20080048512A1Easy to modifyHigh drive reliabilityLighting and heating apparatusSpace heating and ventilation detailsEngineeringActuator

A motor actuator may include a motor, a cam driven by the motor, switch contact pieces operated by the cam, a housing case which accommodates at least the cam, the switch contact pieces, and connection terminals attached to the housing case for connecting an external power supply to the motor. The cam is formed with a step part for operating the switch contact pieces and the switch contact pieces are structured as a position sensor. The connection terminals may include a first switch terminal, a second switch terminal, a first motor terminal, and a second motor terminal. The housing case is formed with at least three cut-out portions so that the first switch terminal, the first motor terminal and the second switch terminal are disposed in this order.

Owner:SANKYO SEIKI MFG CO LTD

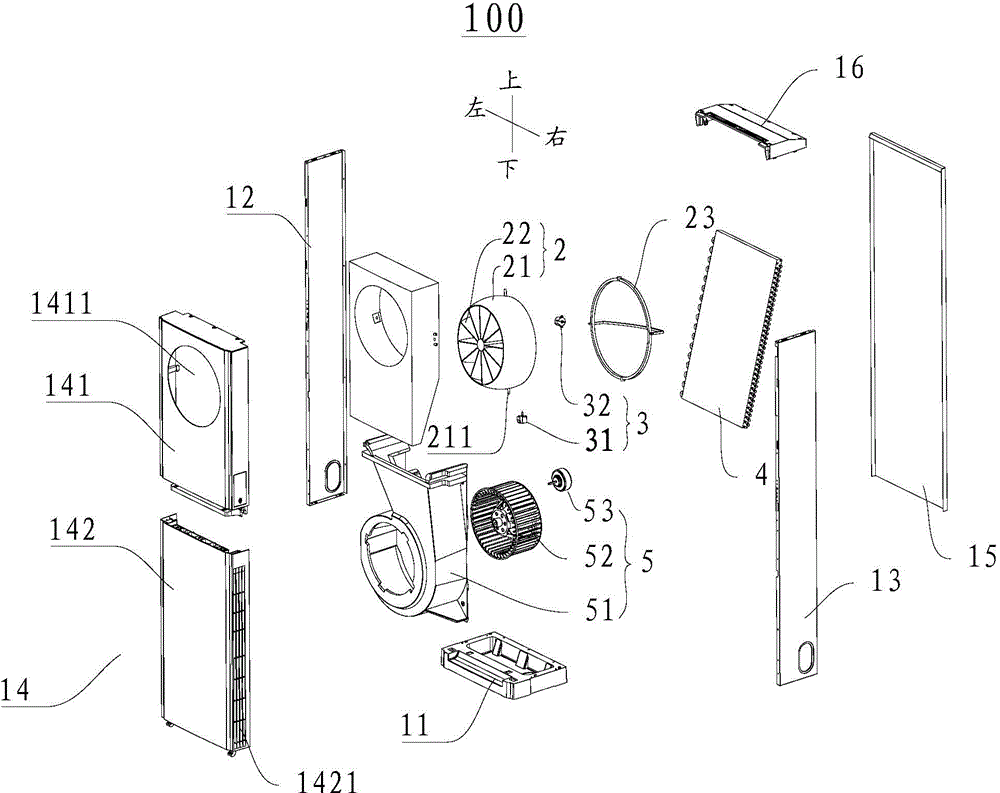

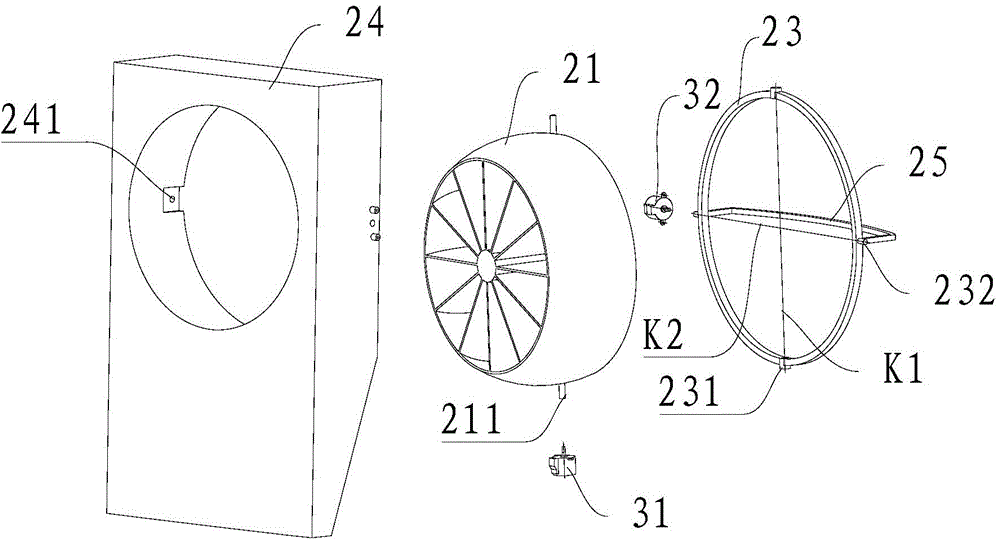

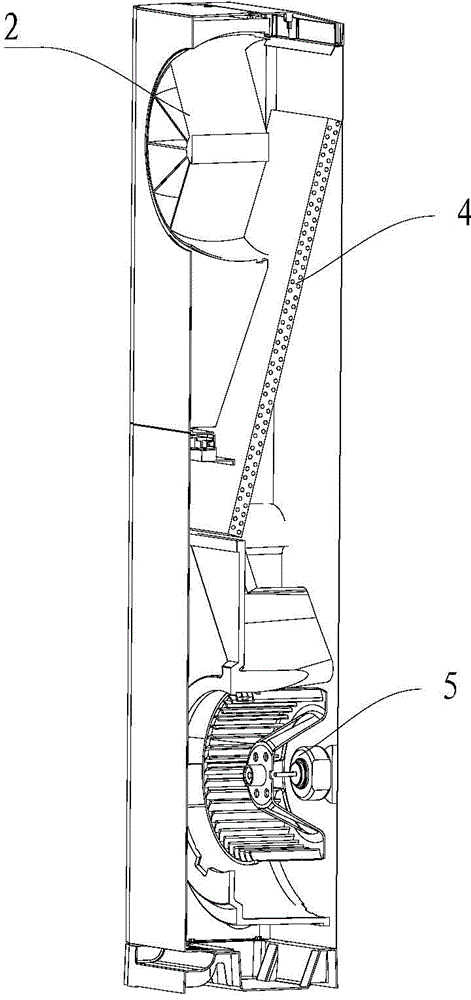

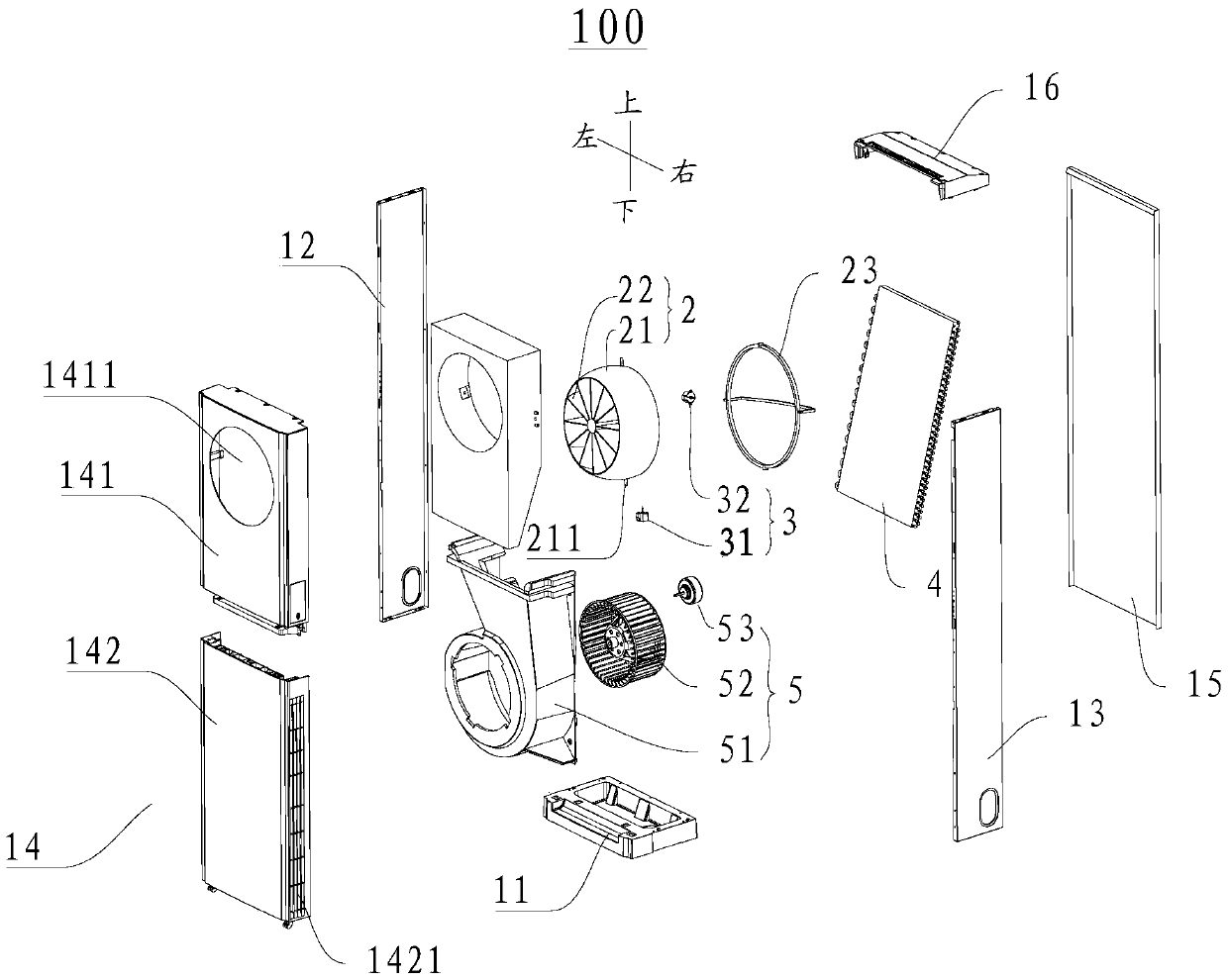

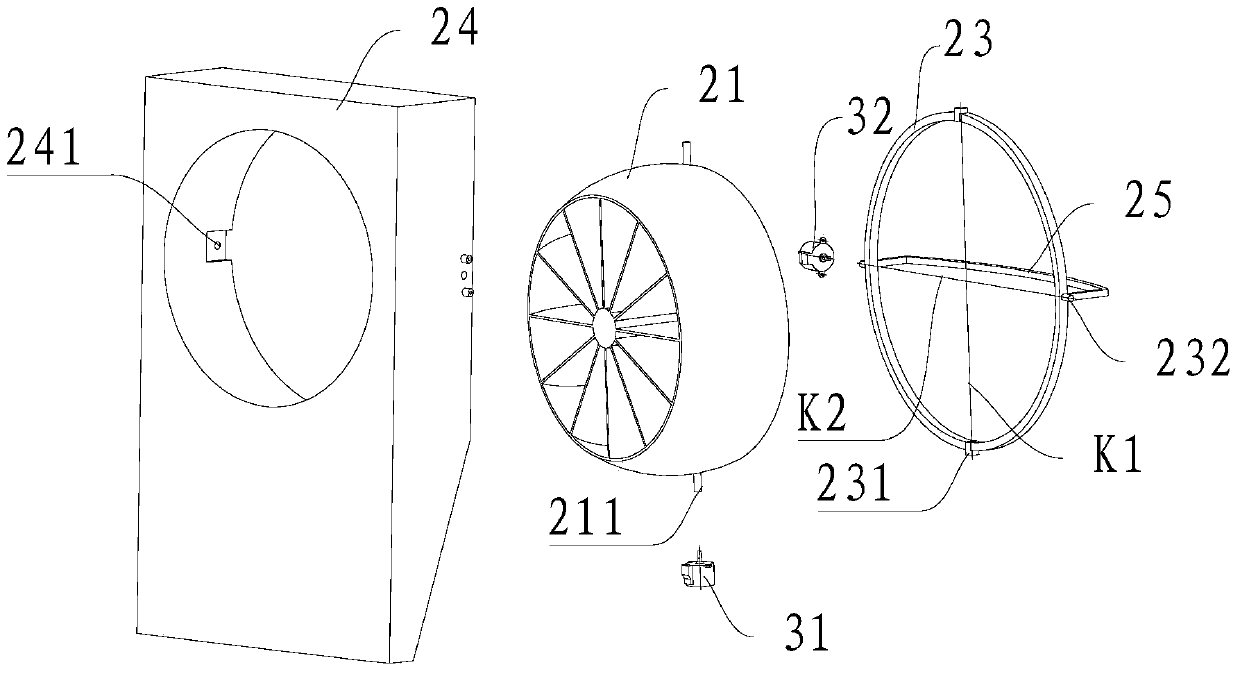

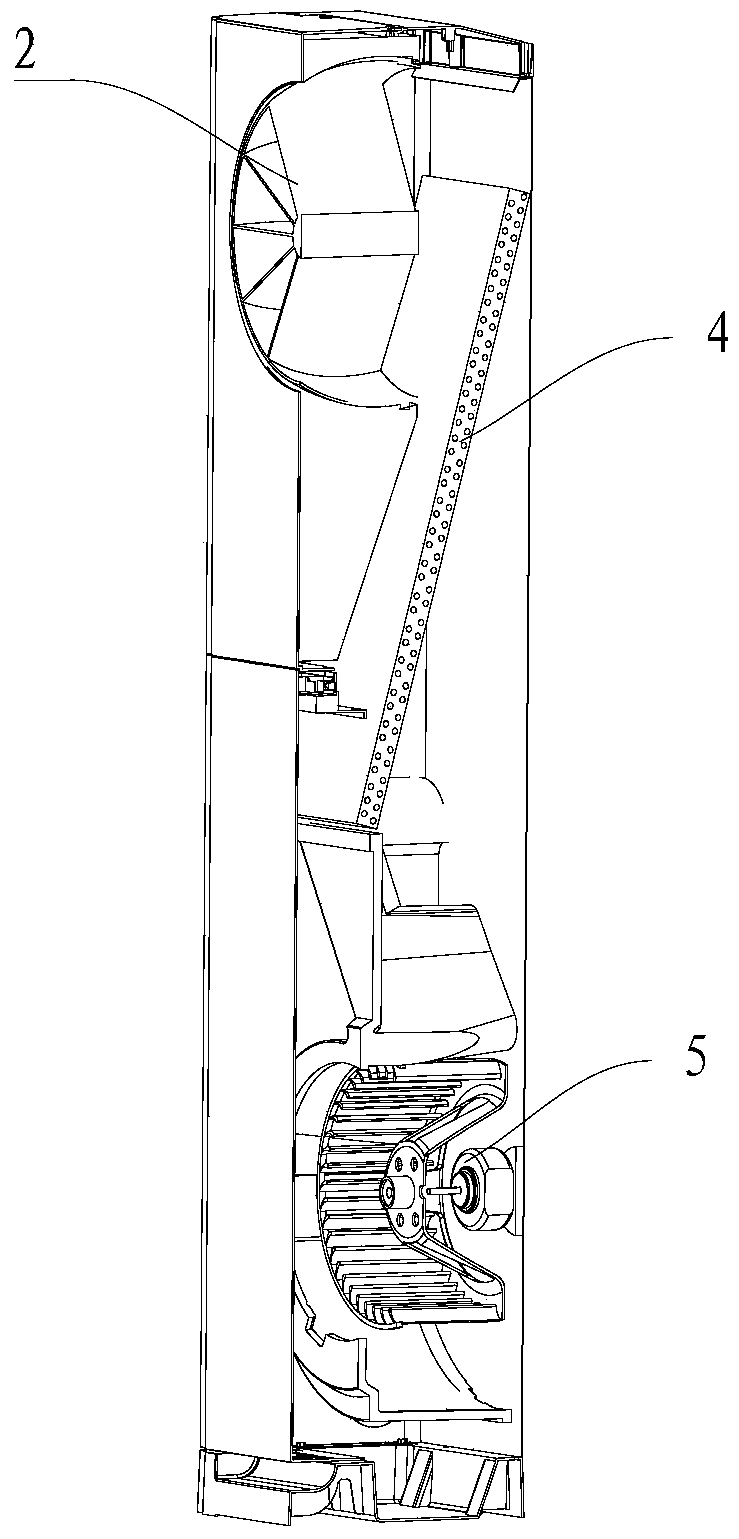

Air conditioning indoor unit and air conditioner with air conditioning indoor unit

ActiveCN104676745AExpand the range of air supplyImprove comfortLighting and heating apparatusHeating and ventilation casings/coversAir conditioningEnergy consumption

The invention discloses an air conditioning indoor unit and an air conditioner with an air conditioning indoor unit. The air conditioning indoor unit comprises a shell body, which is provided with an air supply opening and an air returning opening; an air guide ring, which is arranged at the air supply opening for adjusting the air supply direction; a driving component, which is connected with the air guide ring, and drives the air guide ring to crossly sway and / or vertically sway; an indoor heat exchanger, which is arranged in the shell body; a blower component, which is arranged in the shell body. The air conditioning indoor unit can greatly increase the air supply scale thereof by arranging the air guide ring which can sway along cross and vertical directions, and air flow can be blown to any zone in front of the shell body, and thereby the dead corner of the air supply in the room is effectively solved, the comfort level of the air conditioning indoor unit is added, time from the indoor temperature to the preset temperature is shortened, and energy consumption of the air conditioning indoor unit is reduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

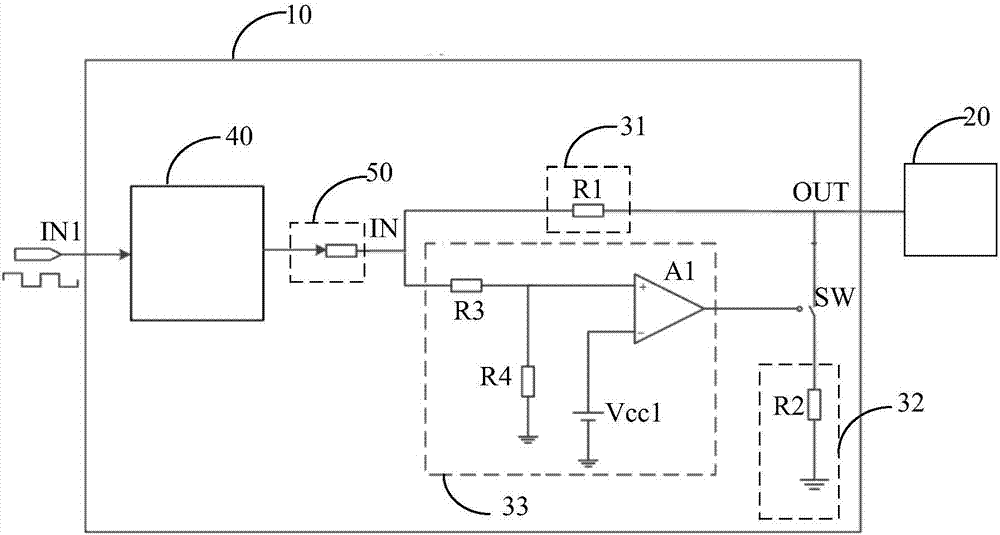

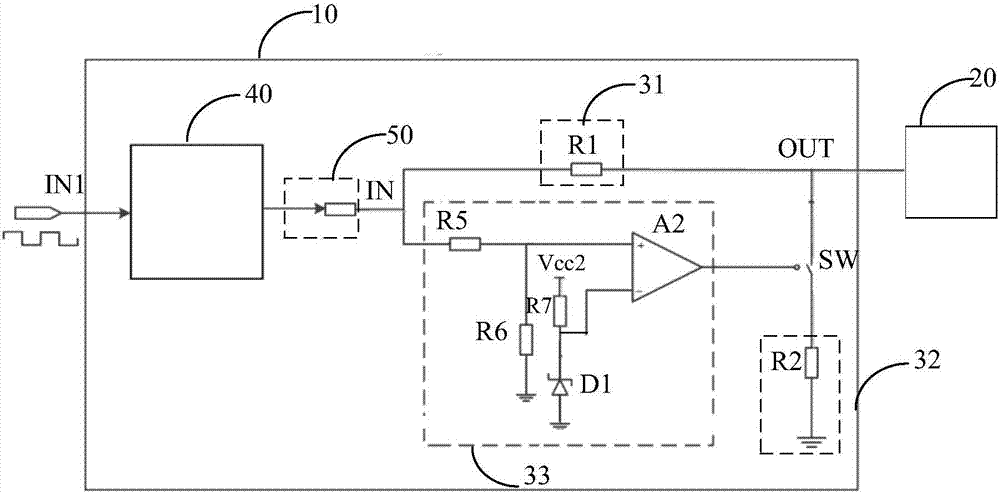

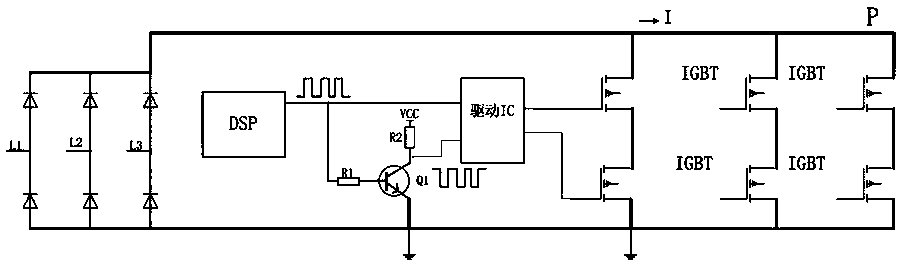

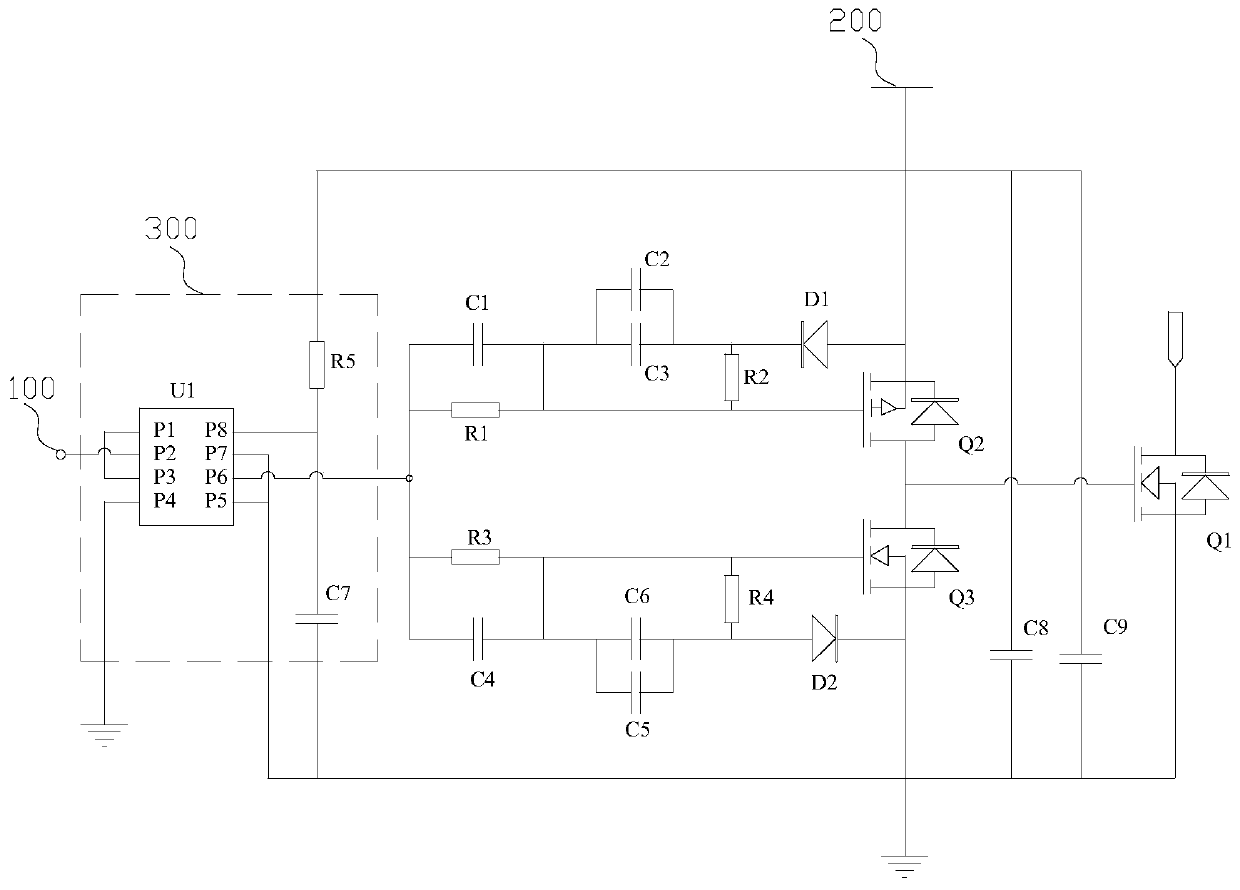

Drive protection circuit for power switch transistor, integrated circuit, IPM module and air conditioner

InactiveCN107453739AReduce overvoltage failure at the controlled endHigh drive reliabilityTransistorElectronic switchingVoltage rangeIntegrated circuit

The invention discloses a drive protection circuit for a power switch transistor, an integrated circuit, an IPM module and an air conditioner. The drive protection circuit for the power switch transistor comprises a signal input end, a first protection circuit, a signal output end, a voltage division circuit, a switch and a gating control circuit. The gating control circuit is used for controlling the switch to be switched on / switched off when it is detected that a voltage of a drive signal input by the signal input end is greater than a preset voltage value, thereby reducing the voltage of the drive signal output by the signal output through the voltage division circuit. According to the drive protection circuit of the power switch transistor, a mode of actively controlling a drive voltage is employed; and a first protection circuit is flexibly controlled to be connected with / separated away from the signal output end, so the drive signal output to a controlled end of the power switch transistor does not exceed an allowed drive voltage circuit; and the drive reliability for a wide band gap material power switch transistor is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

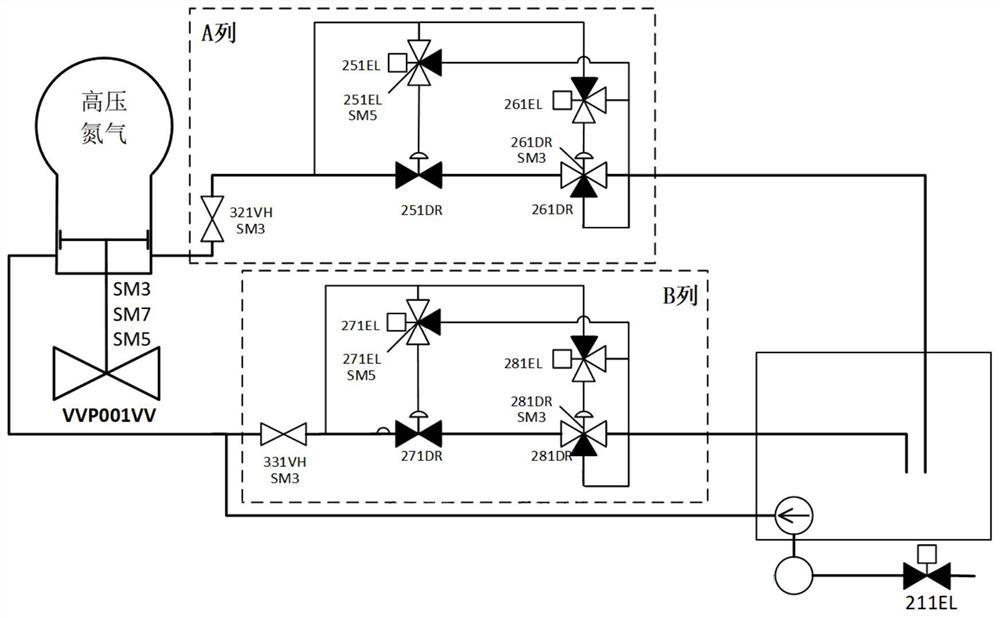

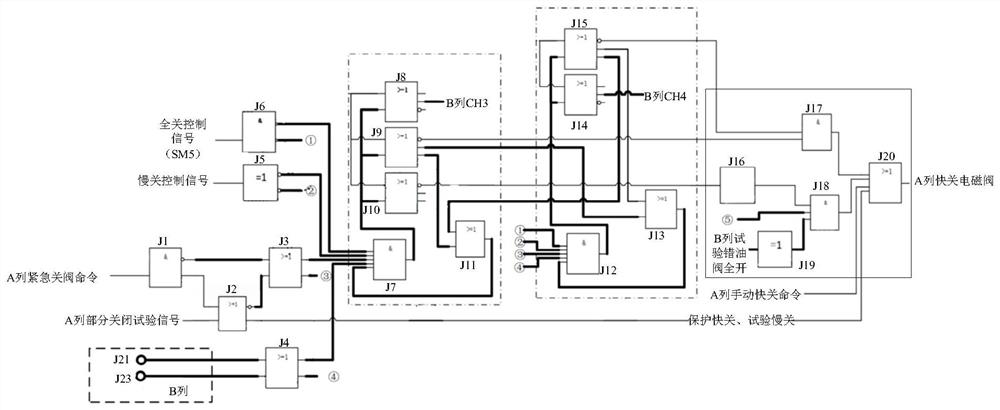

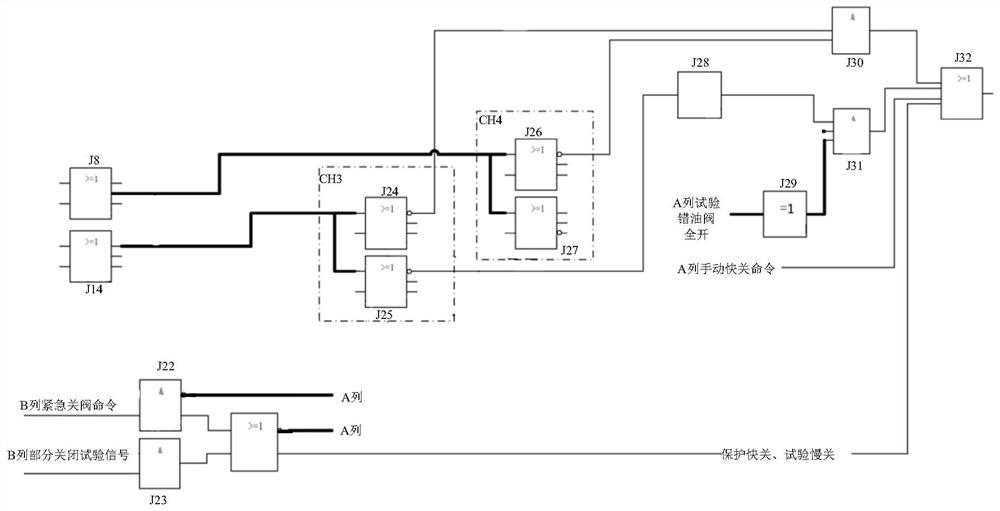

Nuclear power plant quick-closing electromagnetic valve control circuit and main steam system

ActiveCN111816505AAvoid shutdown failureHigh drive reliabilityOperating means/releasing devices for valvesSafety arrangmentsNuclear plantIsolation valve

The invention belongs to the technical field of nuclear power station main steam systems, and provides a nuclear power plant quick-closing electromagnetic valve control circuit and a main steam system. The nuclear power plant quick-closing electromagnetic valve control circuit comprises a first electromagnetic valve control circuit and a second electromagnetic valve control circuit which are in redundant design, wherein the first electromagnetic valve control circuit comprises a first relay, a second relay, a third relay, a first self-holding loop, a second self-holding loop and a first quick-closing relay circuit; the first relay and the second relay are changed into normally open contacts which are connected in series to control the third relay, namely a conduction relay; and normally open contacts sent to the self-holding loops by the third relay are changed into normally closed contacts. According to the nuclear power plant quick-closing electromagnetic valve control circuit, the same logic function as the original design is achieved, the third relay is changed from a normally-excited state to a normally-demagnetized state in the power operation period, the fault that a main steam isolation valve is closed due to excitation of A-column quick-closing electromagnetic valves caused by a single fault of the third relay can be effectively avoided, and the driving reliability ofthe main steam isolation valve is improved.

Owner:LINGDONG NUCLEAR POWER +5

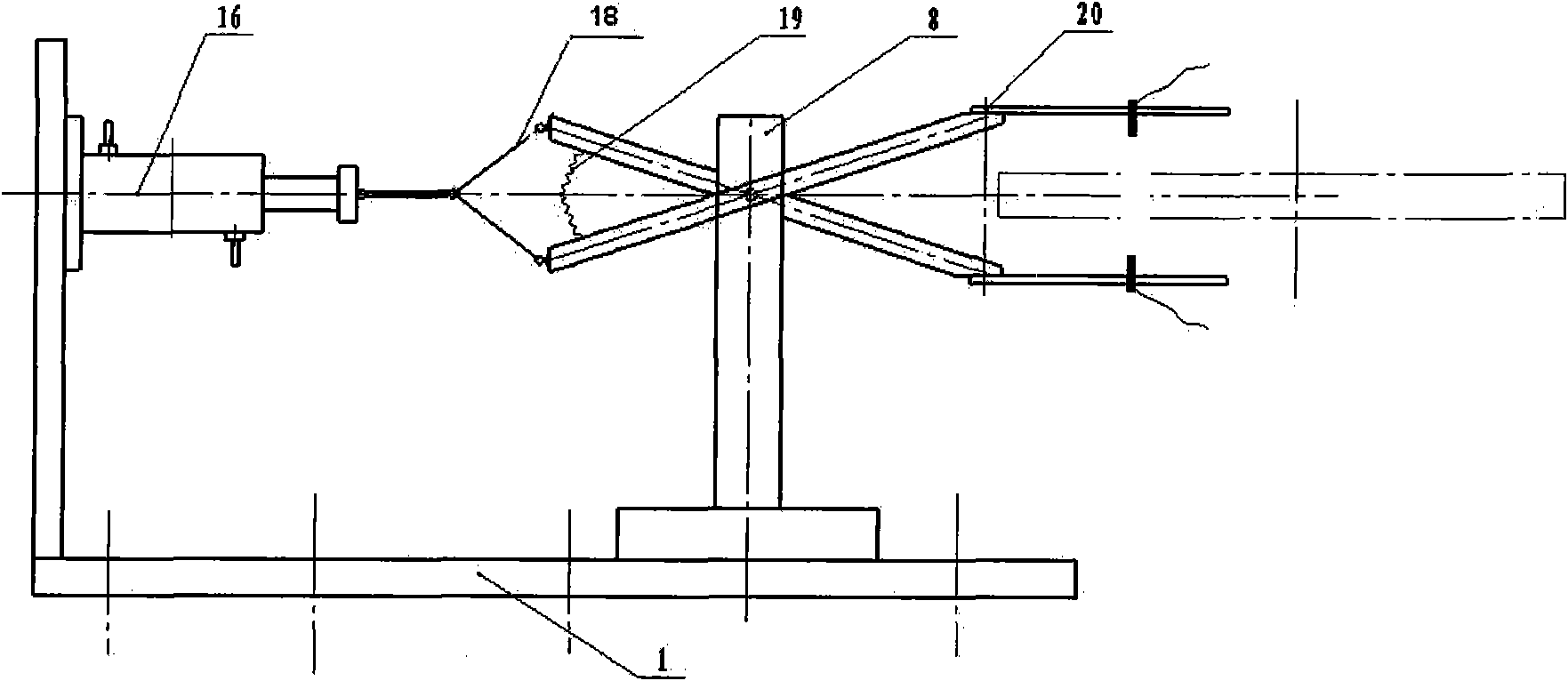

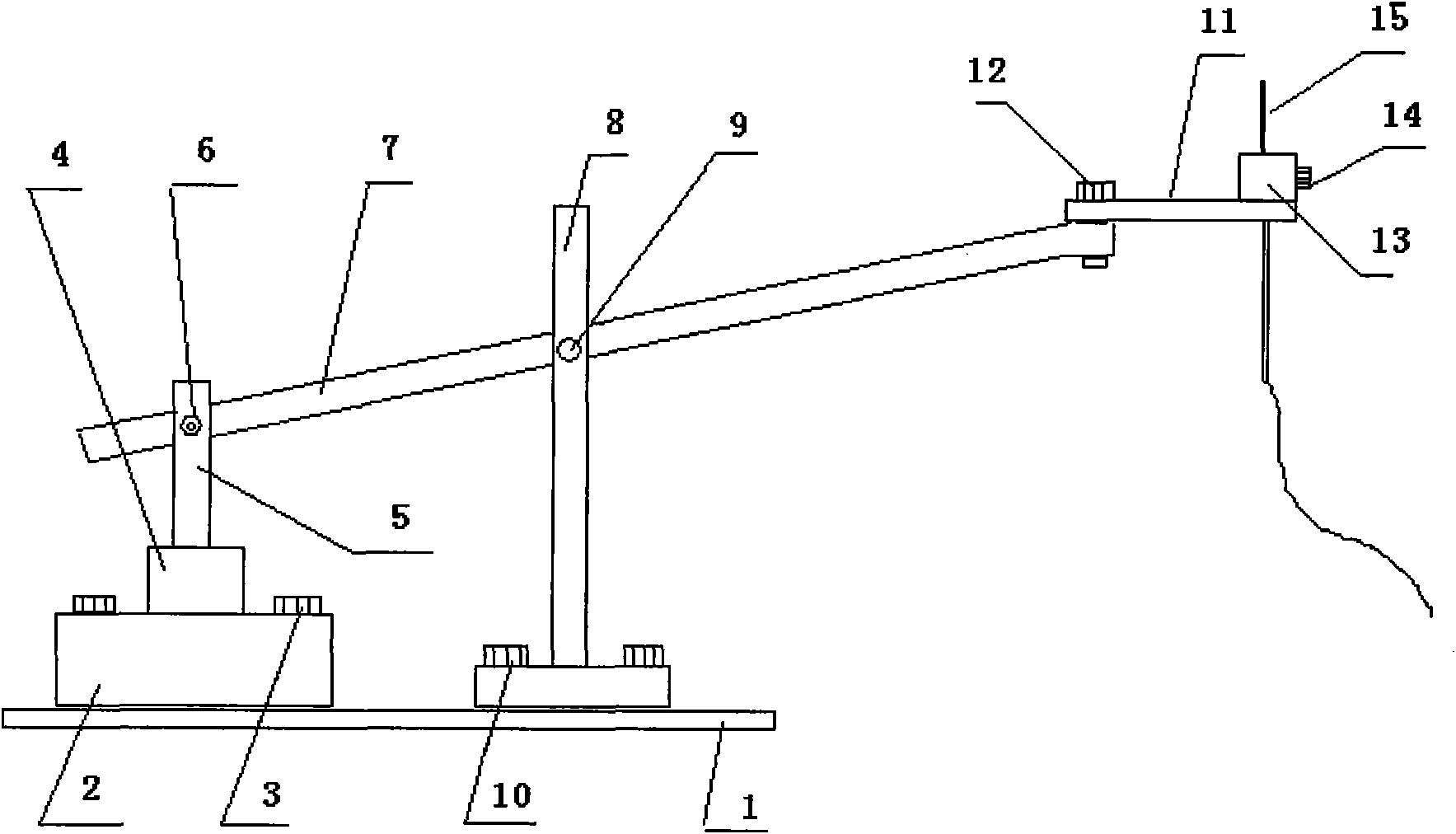

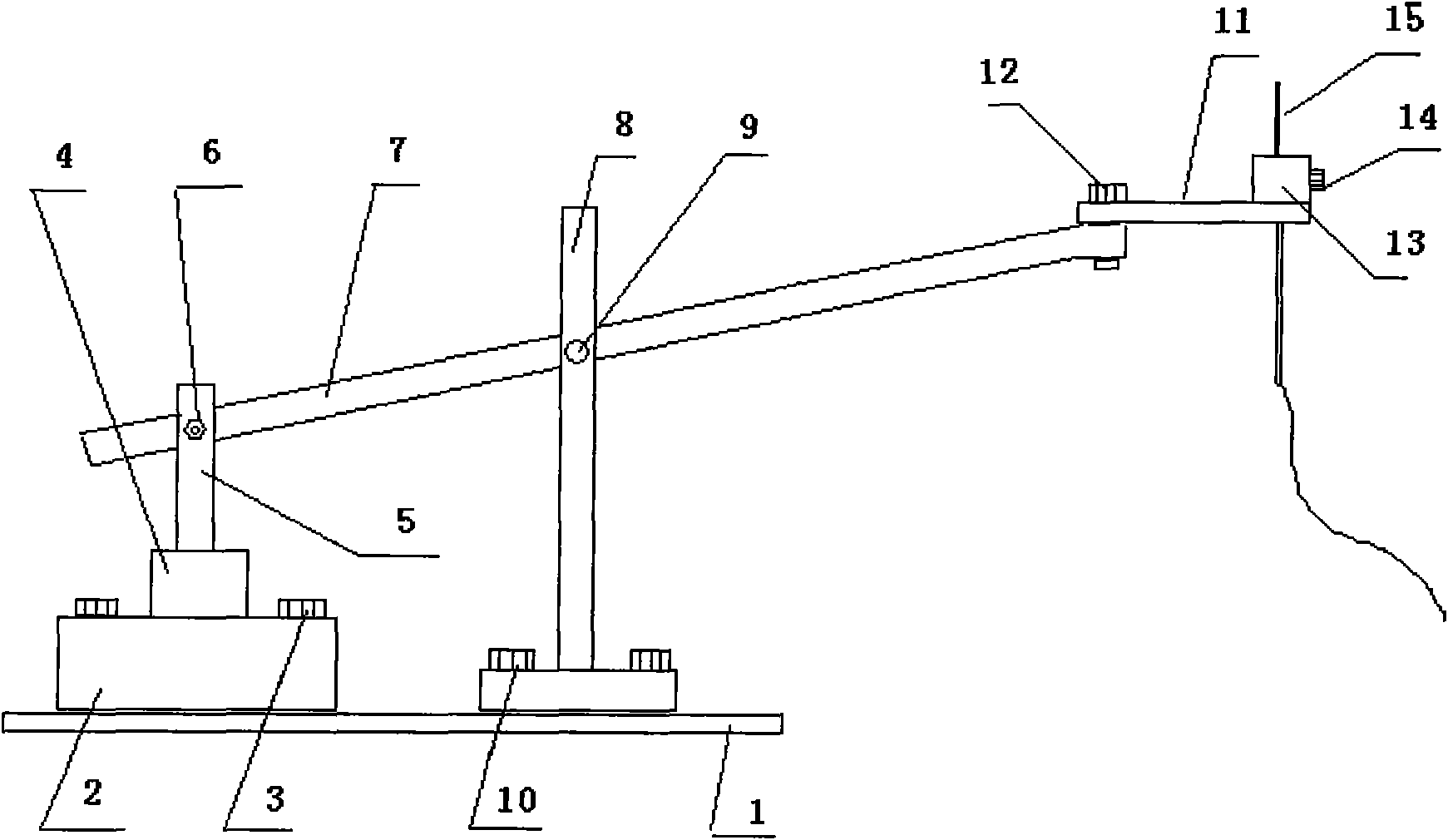

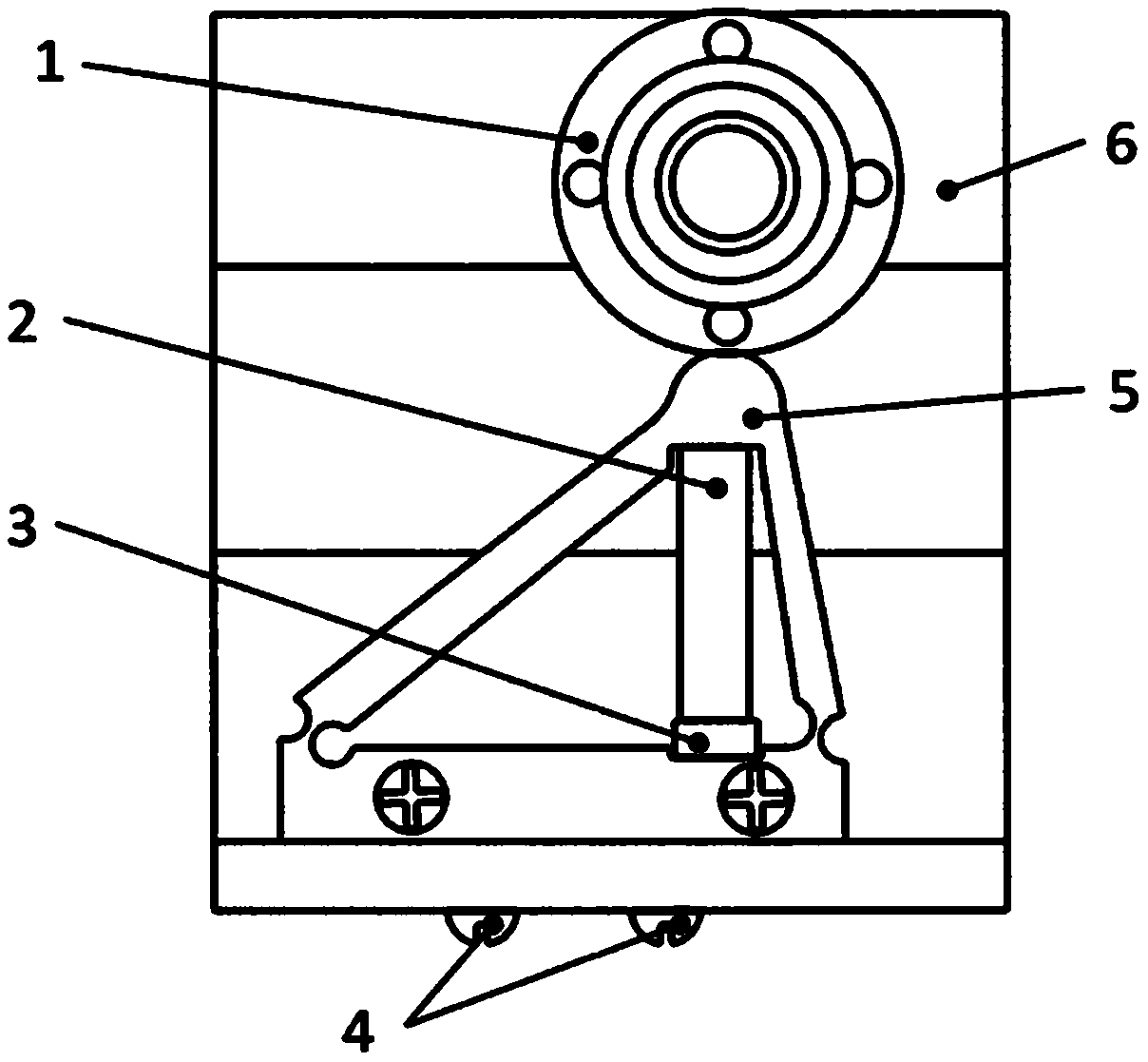

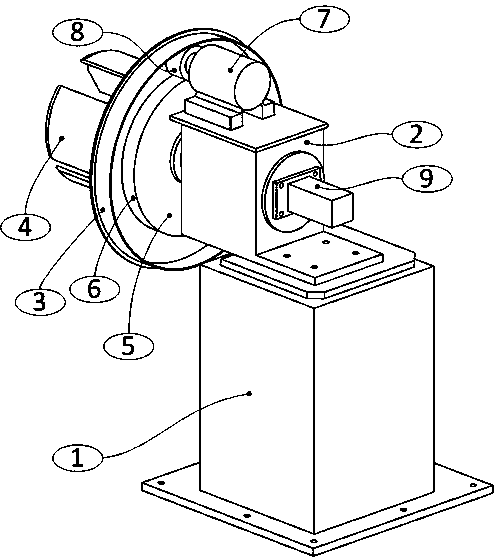

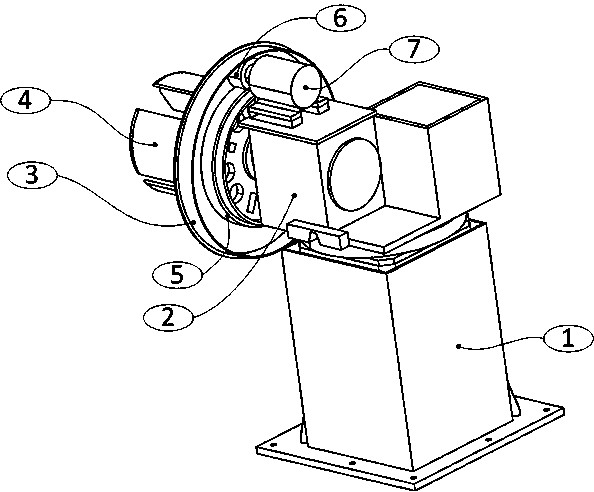

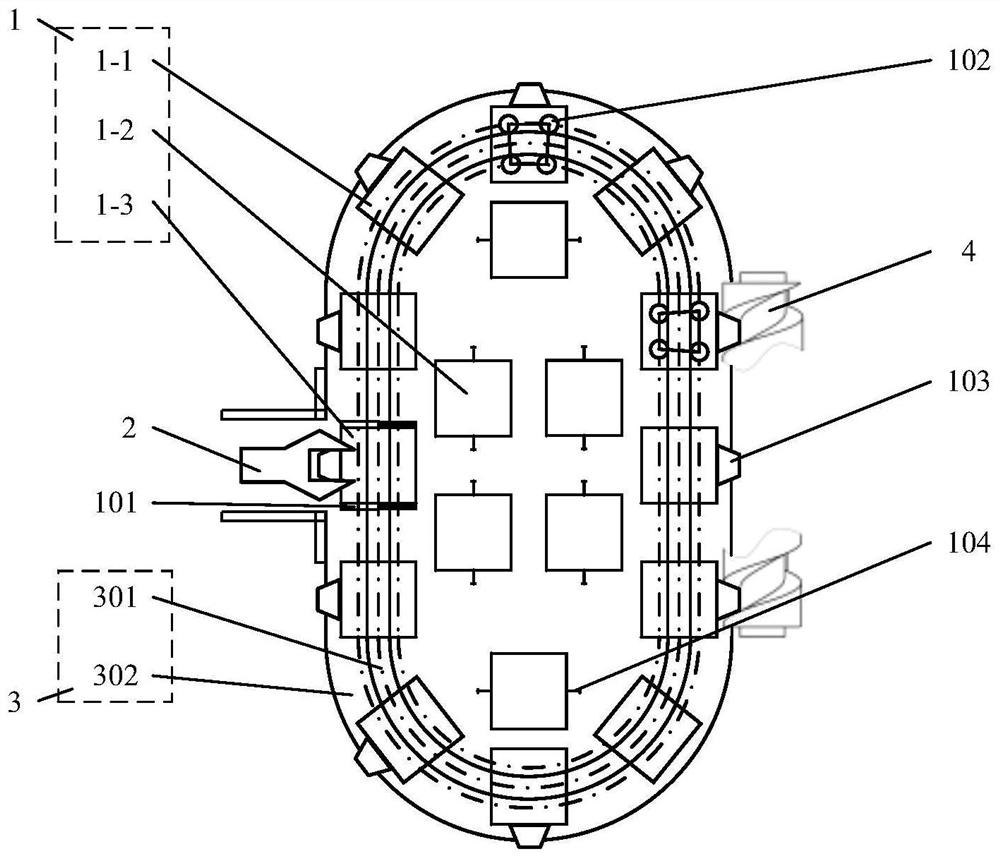

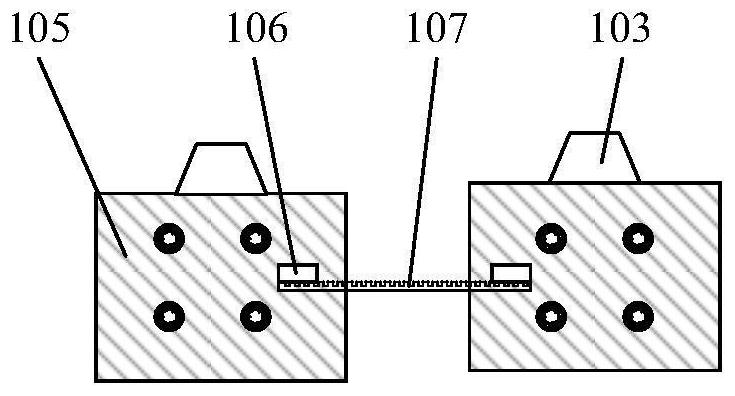

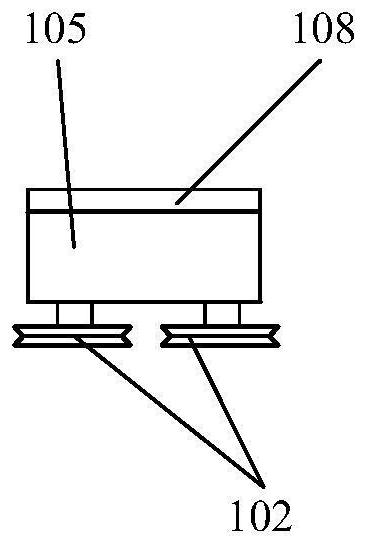

Rotatory test temperature measuring equipment of aircraft engine rotor part

ActiveCN101915622AMeet the needs of temperature measurementEasy to adjustThermometer detailsThermometers using electric/magnetic elementsAviationEngine testing

The invention belongs to an aircraft engine testing technology and relates to an improvement of rotatory test temperature measuring equipment of an aircraft engine rotor part. The temperature measuring equipment comprises a baseplate (1), a lever bracket (8) and a thermocouple assembly, and is characterized by being provided with a single-arm lever mechanism formed by an electromagnet driving mechanism, a connecting bar hinge shaft (6), a lever (7), a thermocouple assembly mounting plate (11) and a connecting screw (12), wherein the electromagnet driving mechanism comprises an electromagnet mounting base (2), an electromagnet (4) and a connecting bar (5). The temperature measuring equipment has high driving reliability, and can meet the need for measuring the temperature of a rotor assembly with larger axial dimension. The installation position of the temperature measuring equipment can be adjusted freely according to the testing needs.

Owner:AECC AVIATION POWER CO LTD

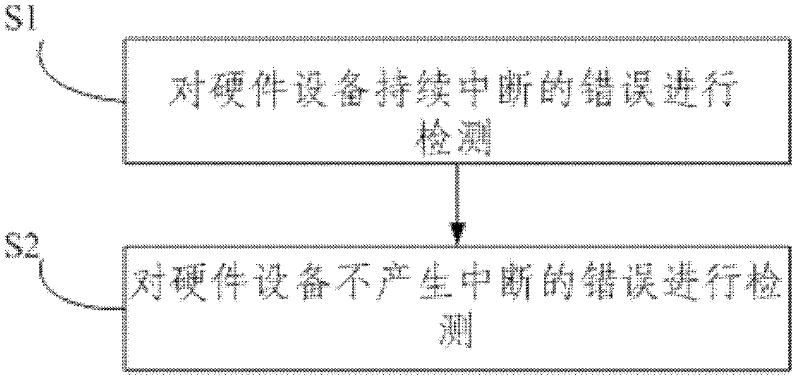

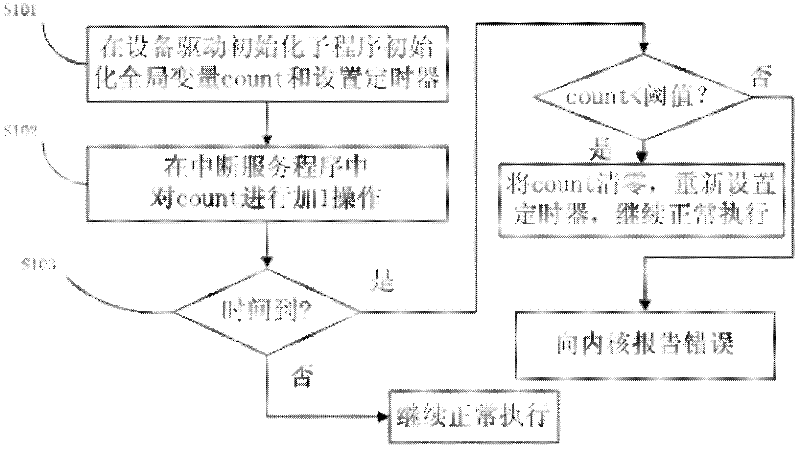

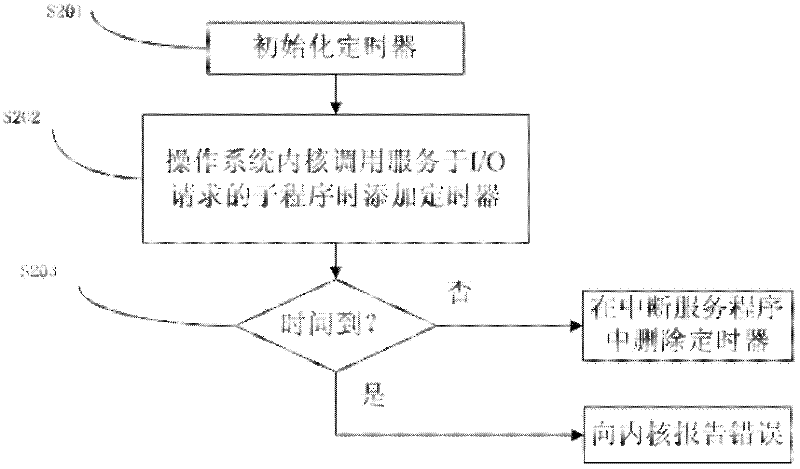

Hardware equipment error detection method

ActiveCN102521089AHigh drive reliabilityDetecting faulty computer hardwareReal-time computingComputer hardware

Owner:TSINGHUA UNIV

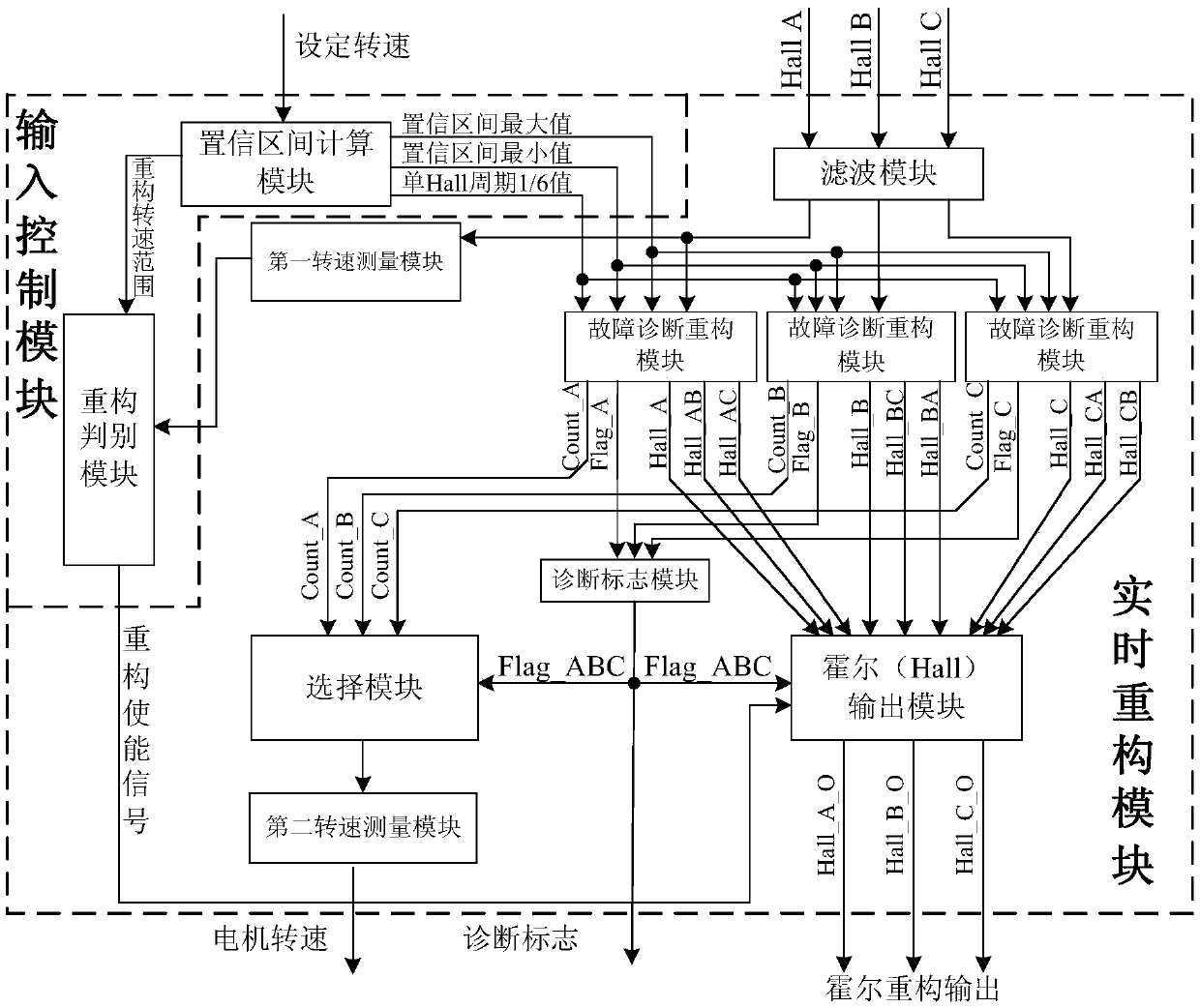

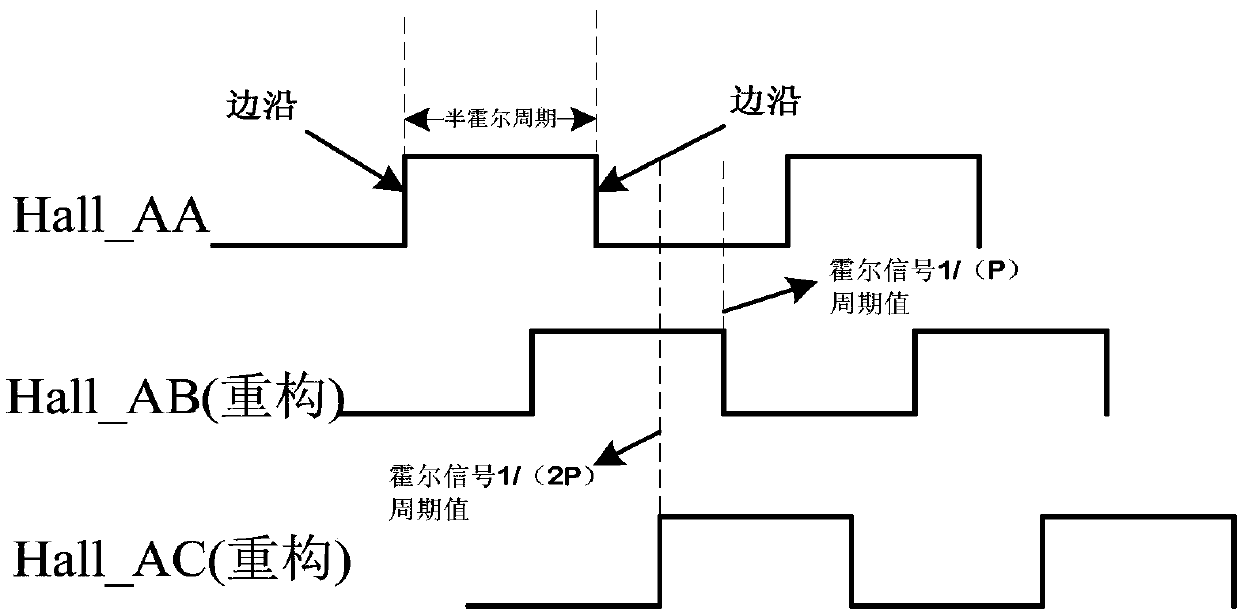

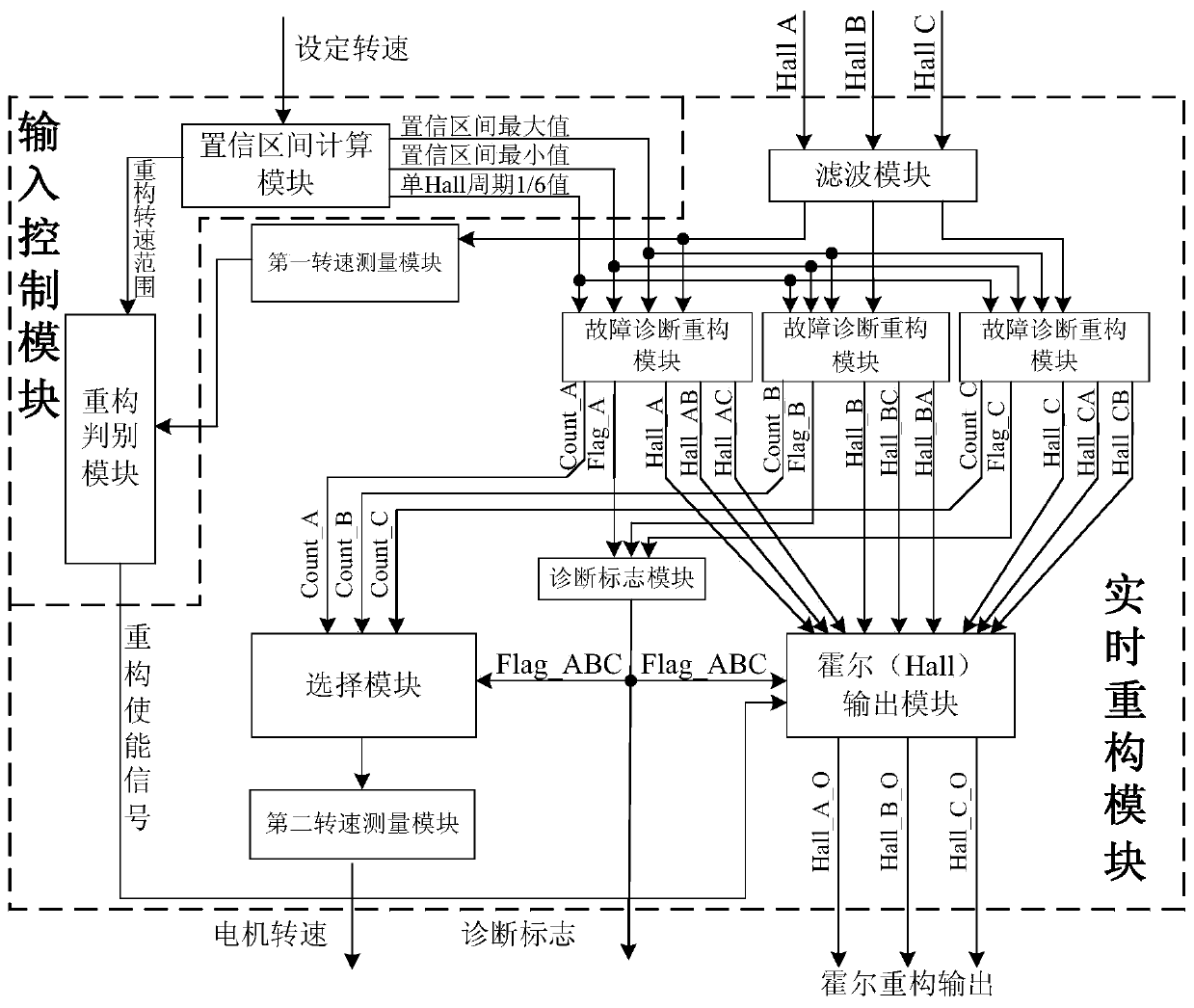

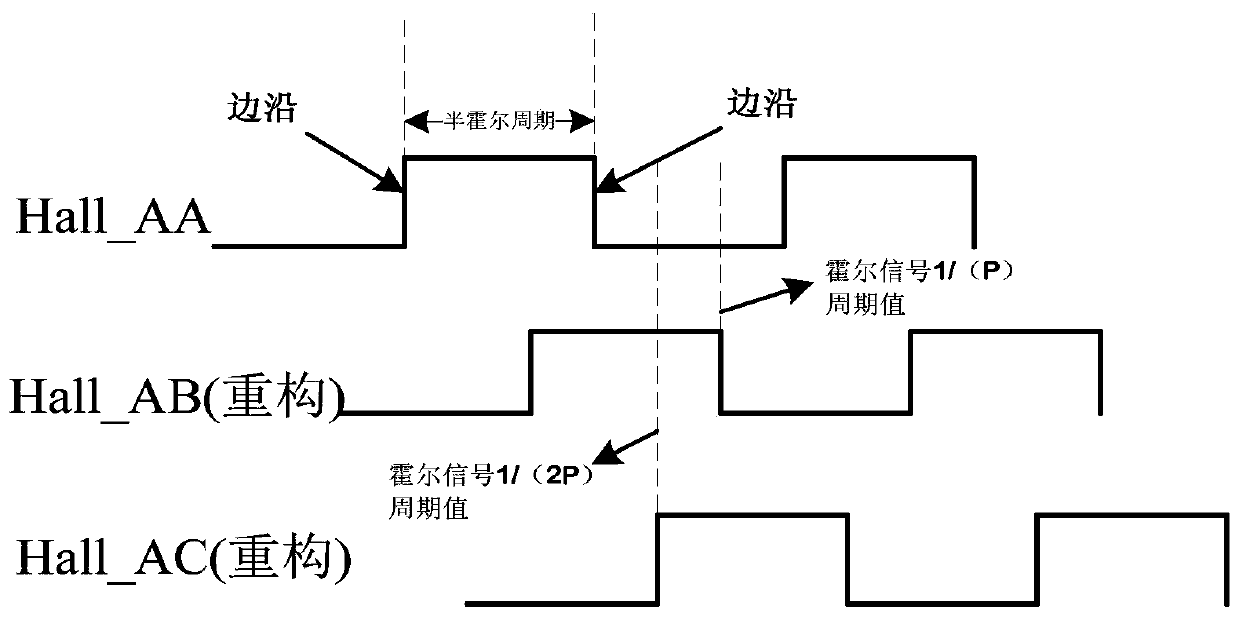

Real-time fault identification and reconstruction system and method for hall sensor of brushless direct current motor

ActiveCN109687809AHigh drive reliabilityNo overcurrent phenomenonElectric motor controlElectronic commutatorsElectric machineEngineering

The invention relates to a real-time fault identification and reconstruction system and method for a hall sensor of a brushless direct current motor, in particular to a real-time fault identification,reconstruction and protection method for a hall signal of the brushless direct current motor. The real-time fault identification and reconstruction system and method for the hall sensor of the brushless direct current motor are suitable for various brushless direct current motors of high-speed (high speed means the running state of the brushless direct current motor after starting) running. According to the method, in the running state of the brushless direct current motor, faults of the hall sensor of the brushless direct current motor can be recognized in real time, and hall signal reconstruction can be completed. It is only required that one phase of the hall signal of the brushless direct current motor is correct, other hall signals can be reconstructed, and normal work of the high-speed motor is ensured; when all hall signals are subjected to faults, it can be ensured that the overcurrent phenomenon cannot occur on the motor, and motor safety is ensured. Compared with a traditional control method for the brushless direct current motor, the method can greatly improve the driving reliability of the brushless direct current motor.

Owner:BEIJING INST OF CONTROL ENG

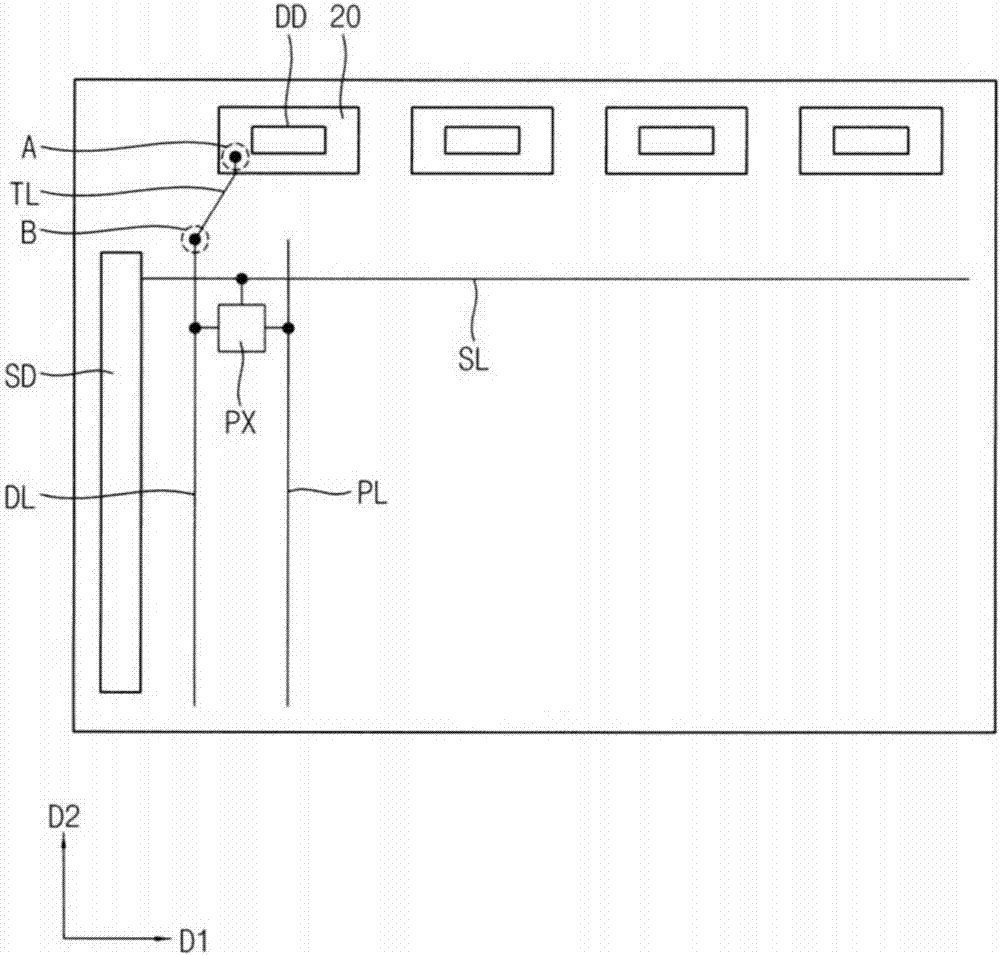

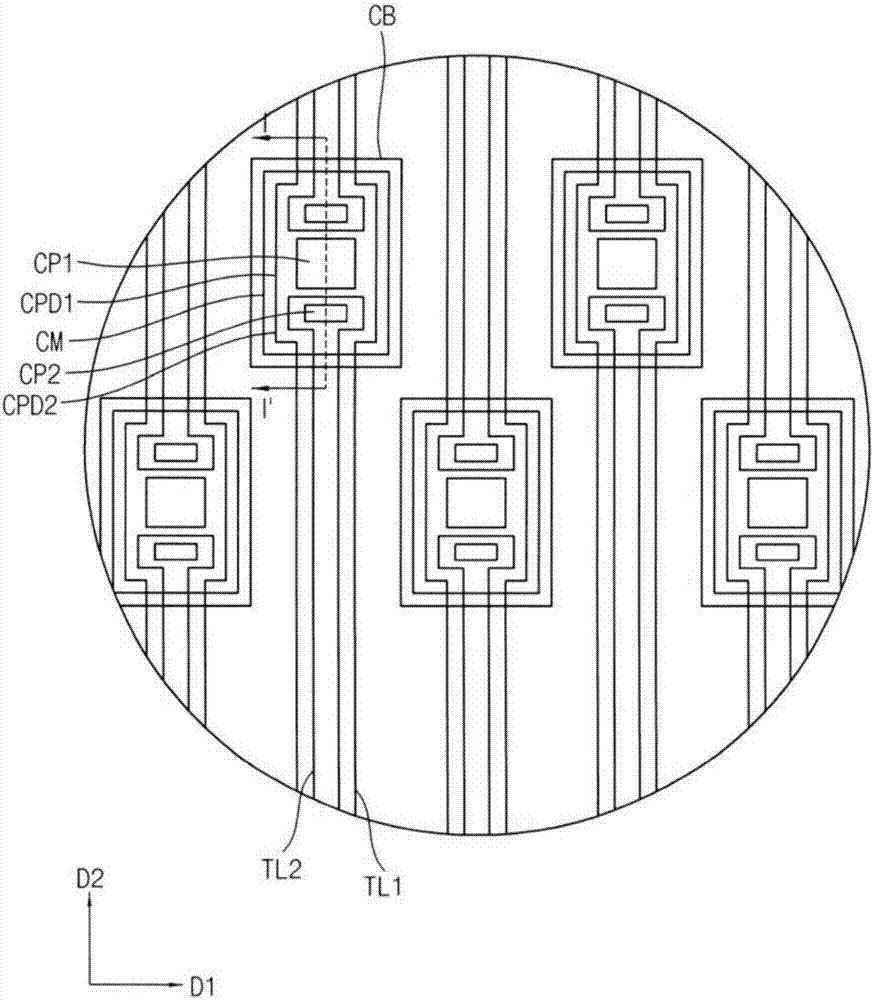

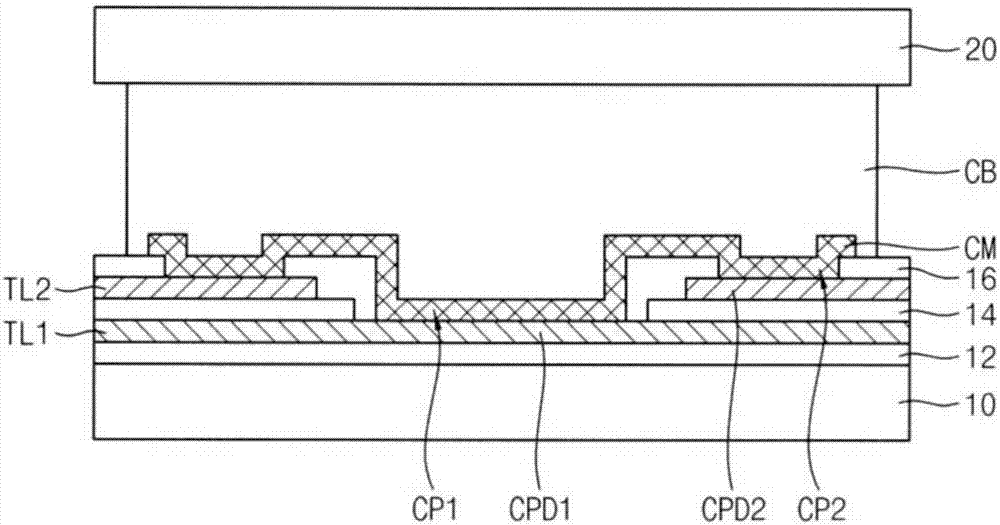

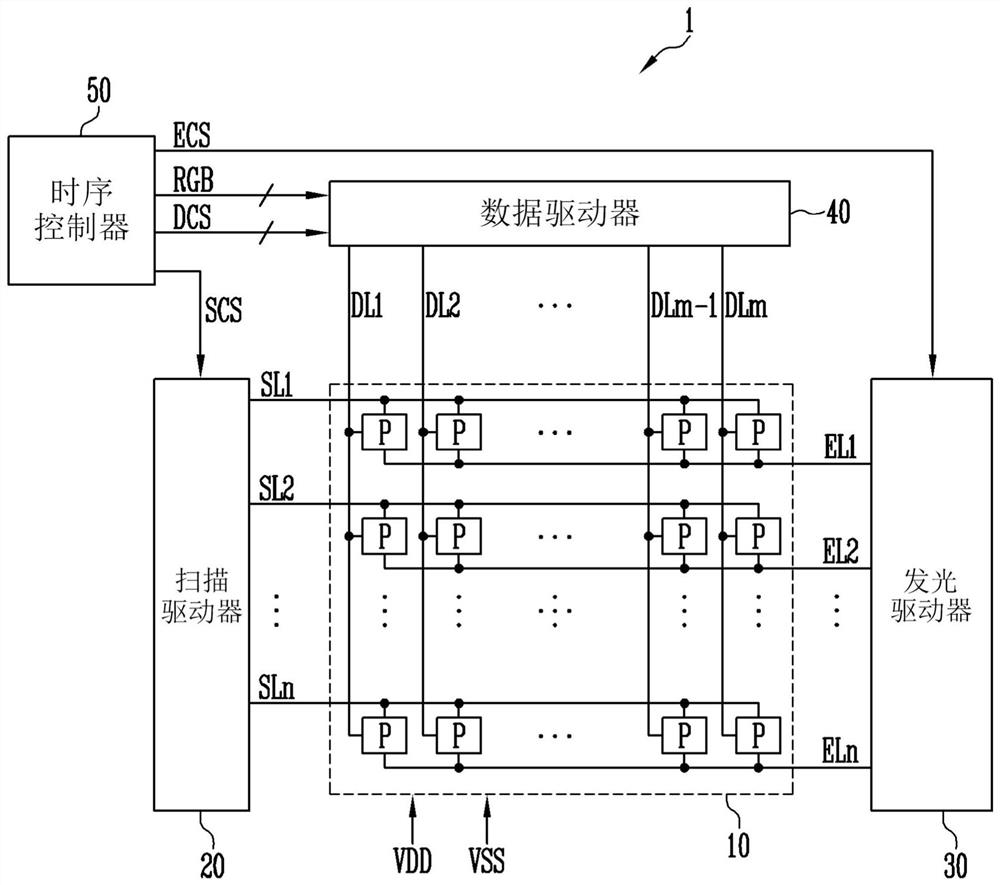

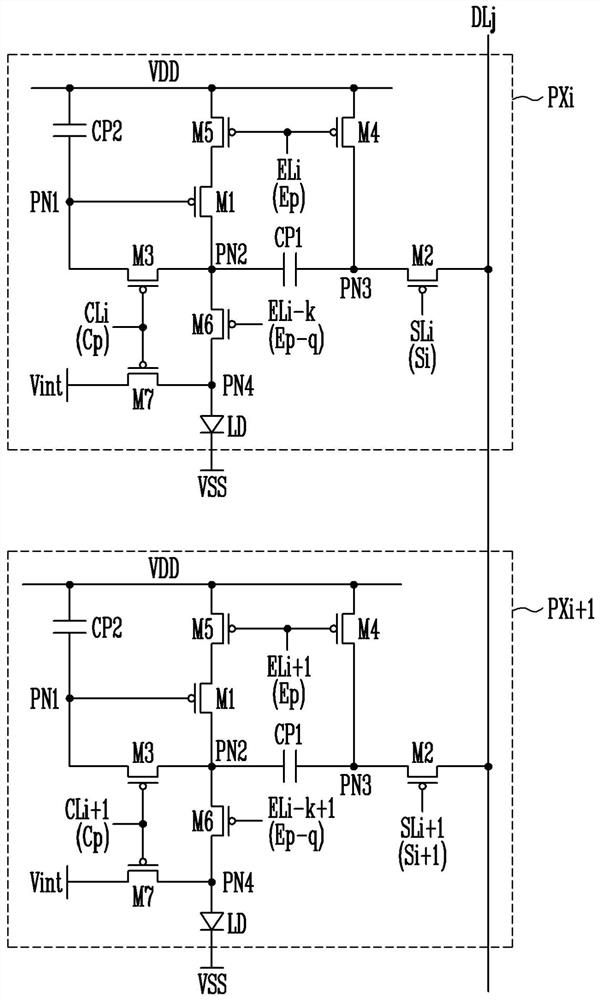

Display device

ActiveCN107342293AHigh drive reliabilityImprove display qualityStatic indicating devicesSolid-state devicesDisplay devicePixel array

Owner:SAMSUNG DISPLAY CO LTD

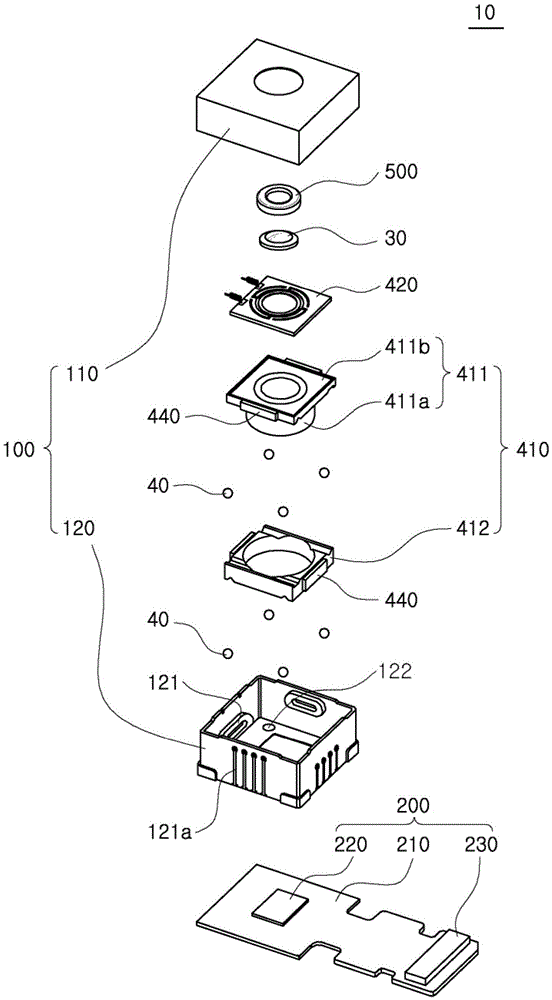

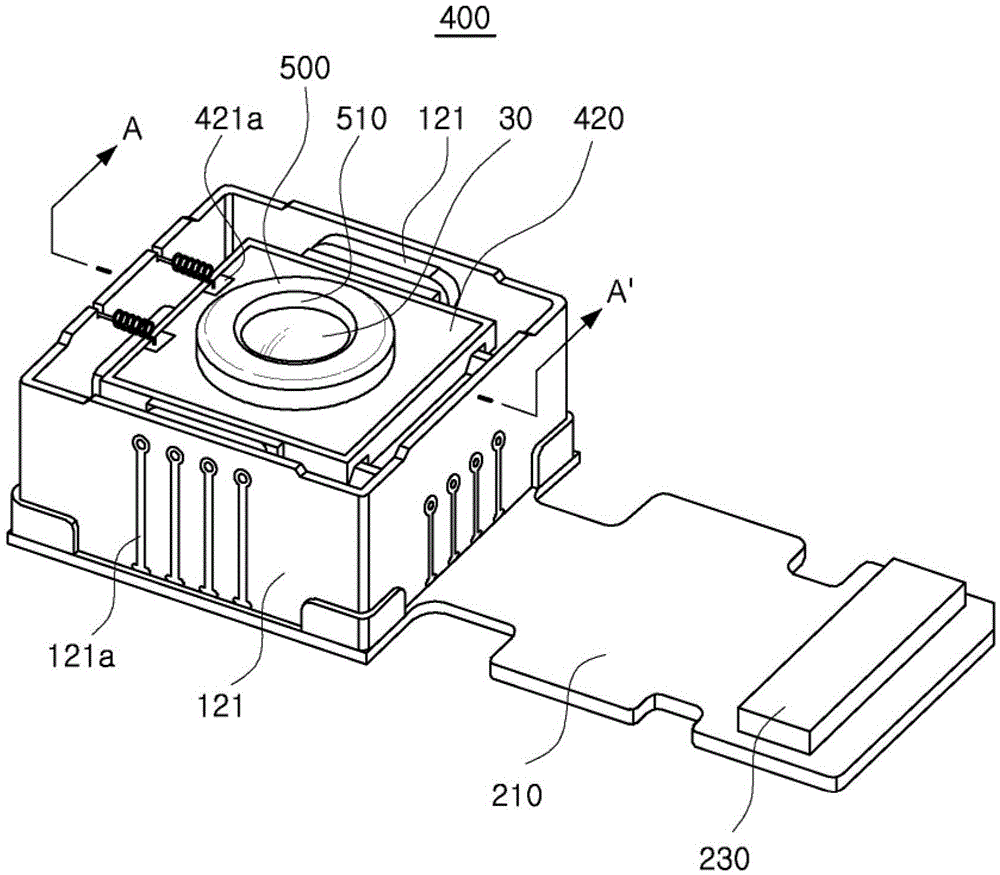

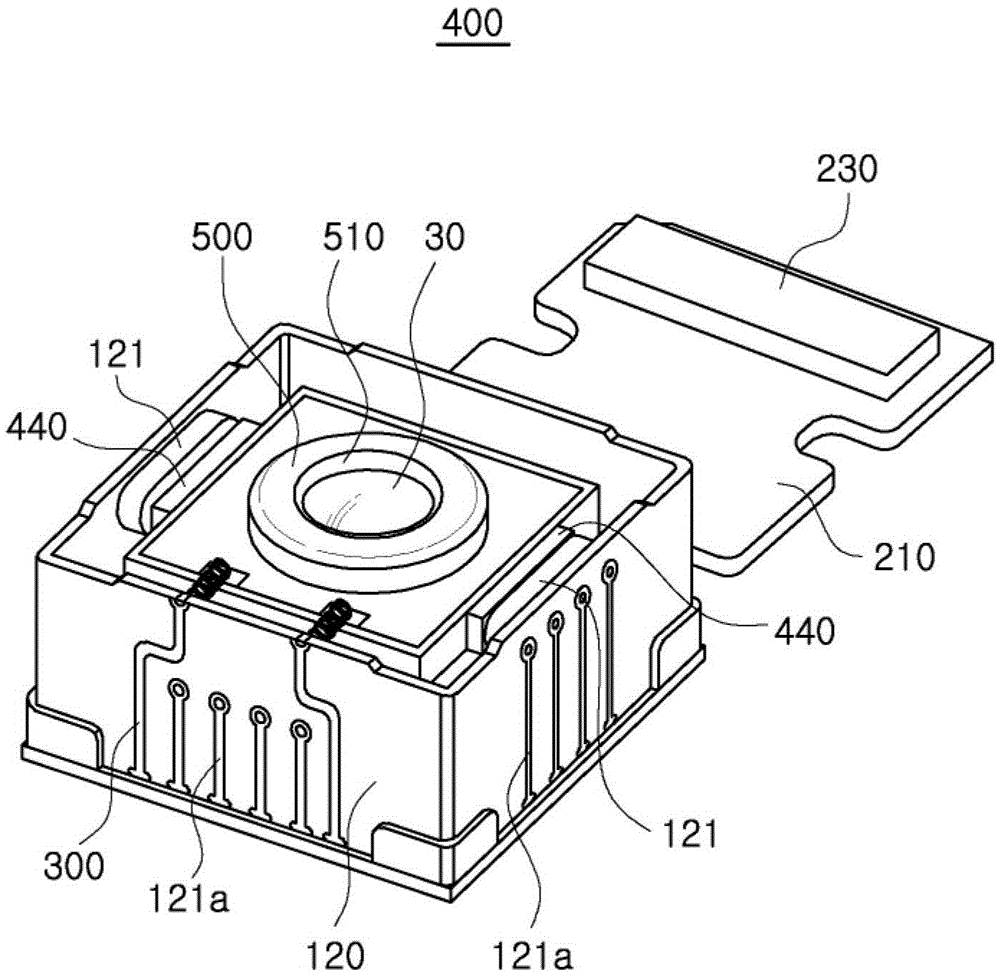

Lens module and camera module including the same

The present invention provides a lens module and camera module including the same. The lens module comprises: a lens barrel with a fixed lens; a driving unit arranged in the lens barrel and supporting the mobile lens in the separation mode in the optical axial direction of the mobile lens and the fixed lens; and a pressure member combined to the driving unit to allow the driving unit to deform in the mode of mobile lens moves along the optical axial direction.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

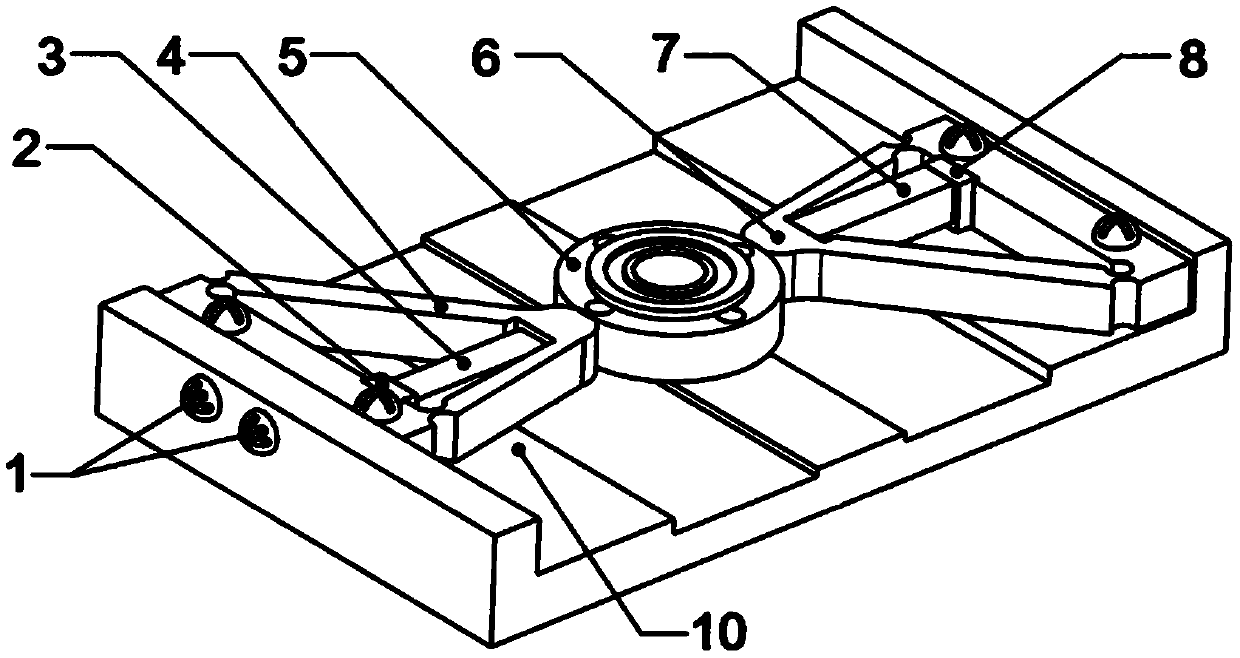

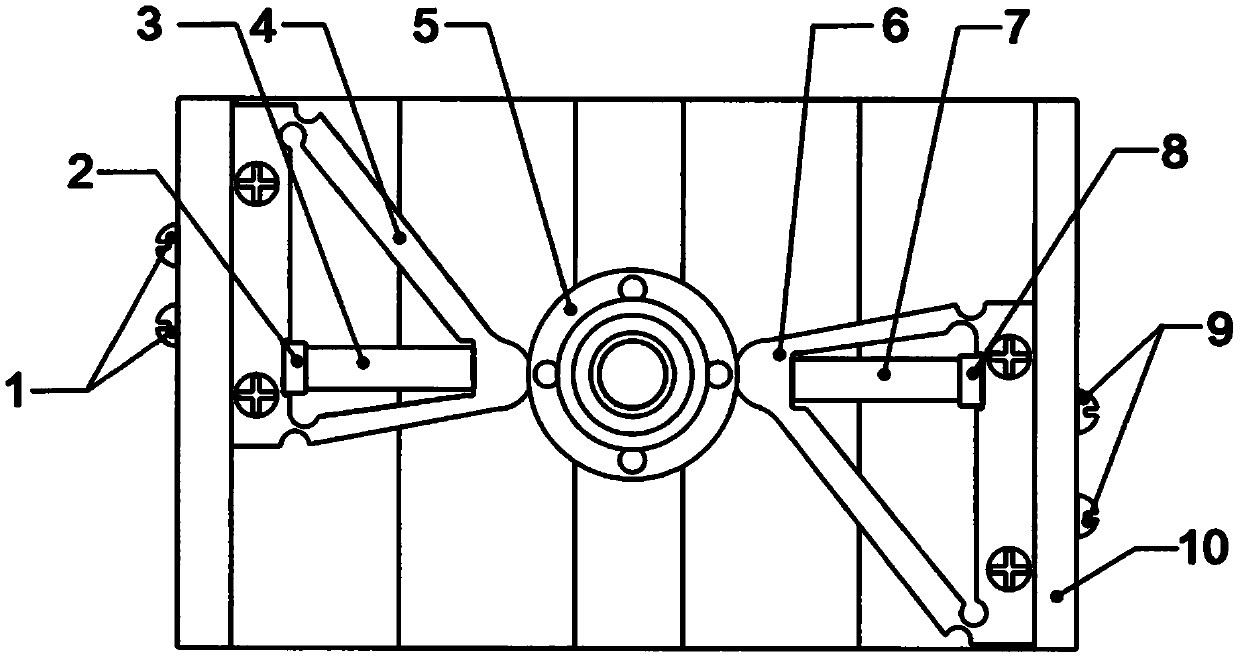

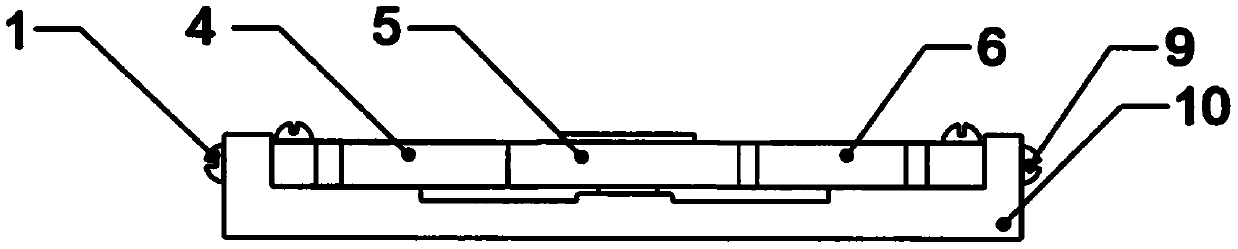

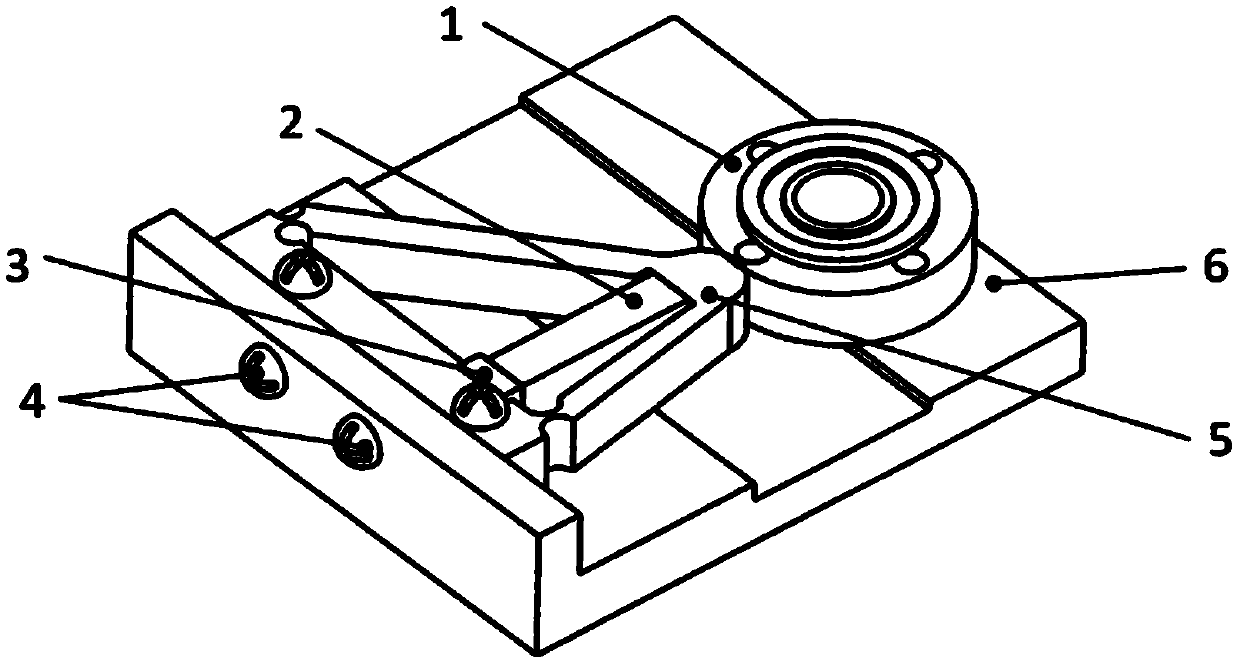

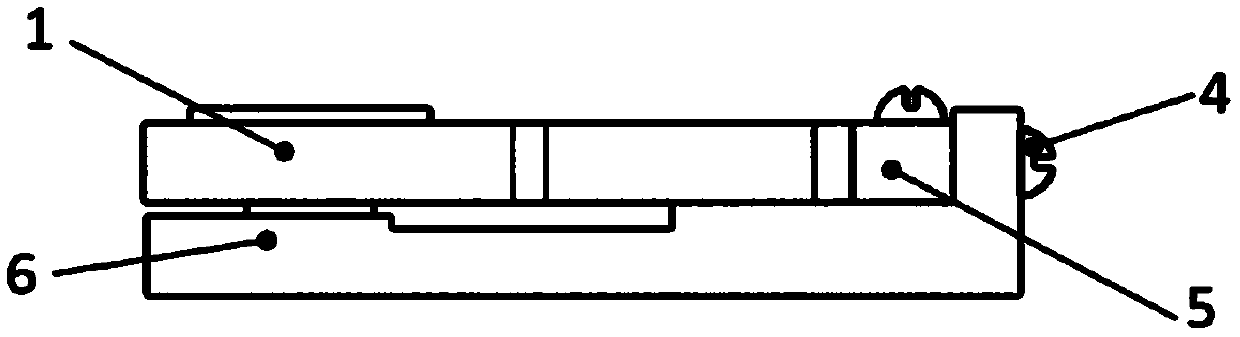

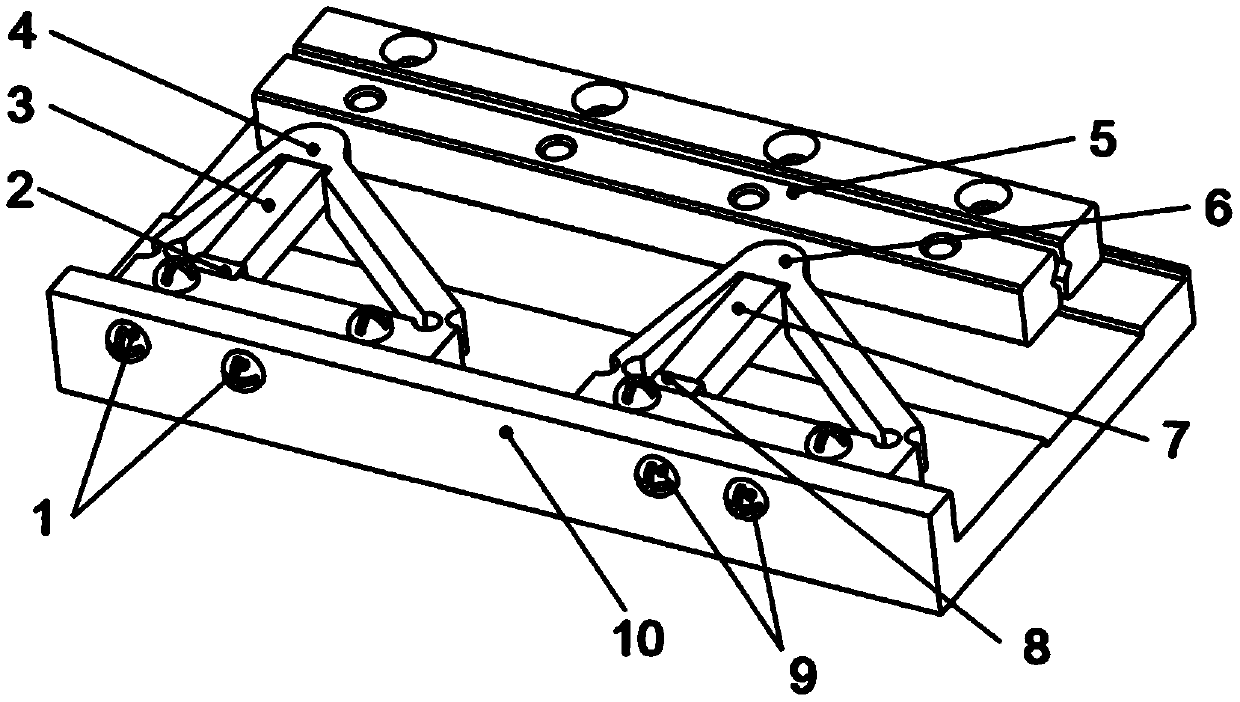

Novel efficient piezoelectric rotation precision driving platform based on asymmetric triangular arc type flexible hinge mechanism

ActiveCN110912448AGood stiffness output performanceSmooth and efficient movementPiezoelectric/electrostriction/magnetostriction machinesIntegrated circuit manufacturingMicro-operation

The invention relates to a novel efficient piezoelectric rotation precision driving platform based on an asymmetric triangular arc type flexible hinge mechanism. The novel efficient piezoelectric rotation precision driving platform is composed of two sets of piezoelectric stacks, two sets of asymmetric triangular arc type flexible hinge mechanisms, a rotor, a pre-tightening screw, a pre-tighteningwedge block and a base. Each piezoelectric stack can be extended and recovered under the driving of a voltage signal; the two groups of asymmetric triangular arc type flexible hinge mechanisms can realize parasitic inertial motion; the pre-tightening screw and the pre-tightening wedge block adjust the initial pre-tightening force between the asymmetric triangular arc type flexible hinge mechanismand the rotor. The base plays a role in supporting. According to the invention, the two piezoelectric stacks are alternately driven under the control of a voltage time sequence, so that the rotor rollback phenomenon can be eliminated, and the output performance of the platform is improved. The platform can drive the rotor to achieve efficient rotary motion, and can be applied to the technical fields of precision and ultra-precision machining, micro electro mechanical systems, micro operation robots, large-scale integrated circuit manufacturing and biology.

Owner:ZHEJIANG NORMAL UNIVERSITY

Rotary piezoelectric driving device based on asymmetric triangular hinge mechanism

PendingCN110855181AGood stiffness output performanceIncrease output loadPiezoelectric/electrostriction/magnetostriction machinesIntegrated circuit manufacturingMicro-operation

The invention relates to a rotary piezoelectric driving device based on an asymmetric triangular hinge mechanism. The device consists of a piezoelectric stack, the asymmetric triangular hinge mechanism, a rotor, a pre-tightening screw, a pre-tightening wedge and a base. The piezoelectric stack can be elongated and recovered under the drive of a voltage signal. The asymmetric triangular hinge mechanism can realize parasitic inertia motion. The pre-tightening screw and the pre-tightening wedge adjust the initial pre-tightening force between the asymmetric triangular hinge mechanism and the rotor. The base acts as a support. The main output direction of the piezoelectric stack is on a straight line with the rotation center of the rotor so that the rigidity of the main output direction of thepiezoelectric stack can be fully utilized. The asymmetric triangular hinge mechanism has a simple structure and good stiffness output performance and can bear high load and greatly improves the outputload of the driving device and can realize the rotating stepping movement of the rotor. The device can be applied to the fields of precision ultra-precision machining, micro-electromechanical systems, micro-operation robots, large-scale integrated circuit manufacturing and biotechnology.

Owner:ZHEJIANG NORMAL UNIVERSITY

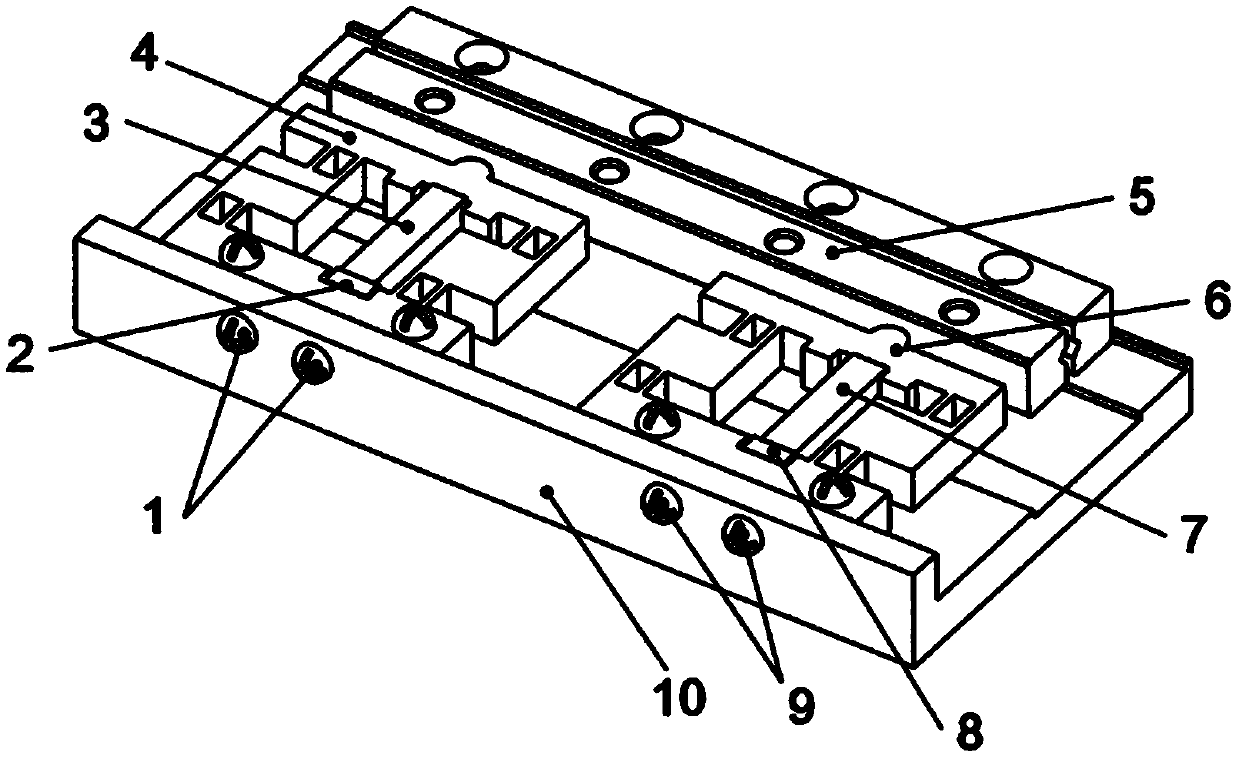

Novel bionic creeping type piezoelectric precision driving device based on parasitic inertia principle

ActiveCN110768571AEliminate backlashRealize linear motionPiezoelectric/electrostriction/magnetostriction machinesLinear motionIntegrated circuit manufacturing

The invention relates to a novel bionic creeping type piezoelectric precision driving device based on a parasitic inertia principle. The device comprises piezoelectric stacks, an asymmetric thin-walltype flexible hinge mechanism, a rotor, a pre-tightening screw, a pre-tightening wedge block and a base; the piezoelectric stacks can be stretched and recovered under the drive of a voltage signal; the asymmetric thin-wall flexible hinge mechanism can realize parasitic inertial motion; the pre-tightening screw adjusts the initial pre-tightening force between the asymmetric thin-wall flexible hingemechanism and the rotor; and the base plays a supporting role. The two piezoelectric stacks alternately provide drive under the time sequence control of voltage, so that the asymmetric thin-wall flexible hinge mechanism performs bionic crawling motion, the output load is increased, the backspacing phenomenon of the rotor in the motion period is eliminated, the output performance of the device isimproved, and the efficient linear motion of the rotor is realized. The platform can be applied to the fields of precision ultra-precision machining, micro electro mechanical systems, micro operationrobots, large-scale integrated circuit manufacturing and biotechnology.

Owner:ZHEJIANG NORMAL UNIVERSITY

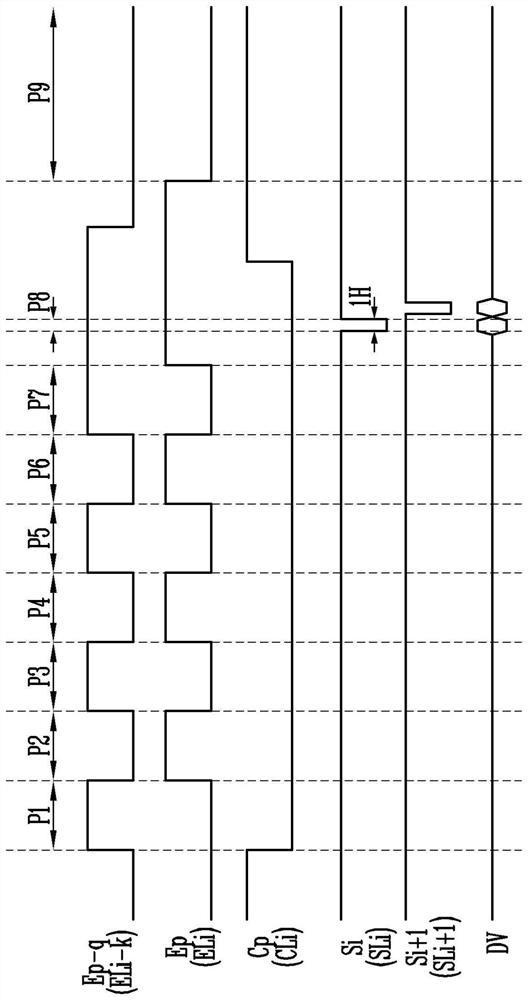

Light emission driver and display device having same

PendingCN112542131ASlow down timeHigh drive reliabilityStatic indicating devicesControl signalDisplay device

The present invention provides a light emission driver and a display device having the same. The light emission driver includes a plurality of stages outputs a light emission control signal. Each of the stages includes an input circuit controlling voltages of a first node and a second node, an output circuit supplying a voltage of first power or a second power to an output terminal, a first signalprocessor controlling a voltage of a fourth node based on a signal supplied to a third input terminal and a voltage of a fifth node, a second signal processor controlling the voltage of the fourth node in response to the voltage of a third node, a first stabilizer limiting voltage drops of the first node and the second node, and a second stabilizer controlling an electrical connection between thethird node and the first node in response to the voltage of the fourth node.

Owner:SAMSUNG DISPLAY CO LTD

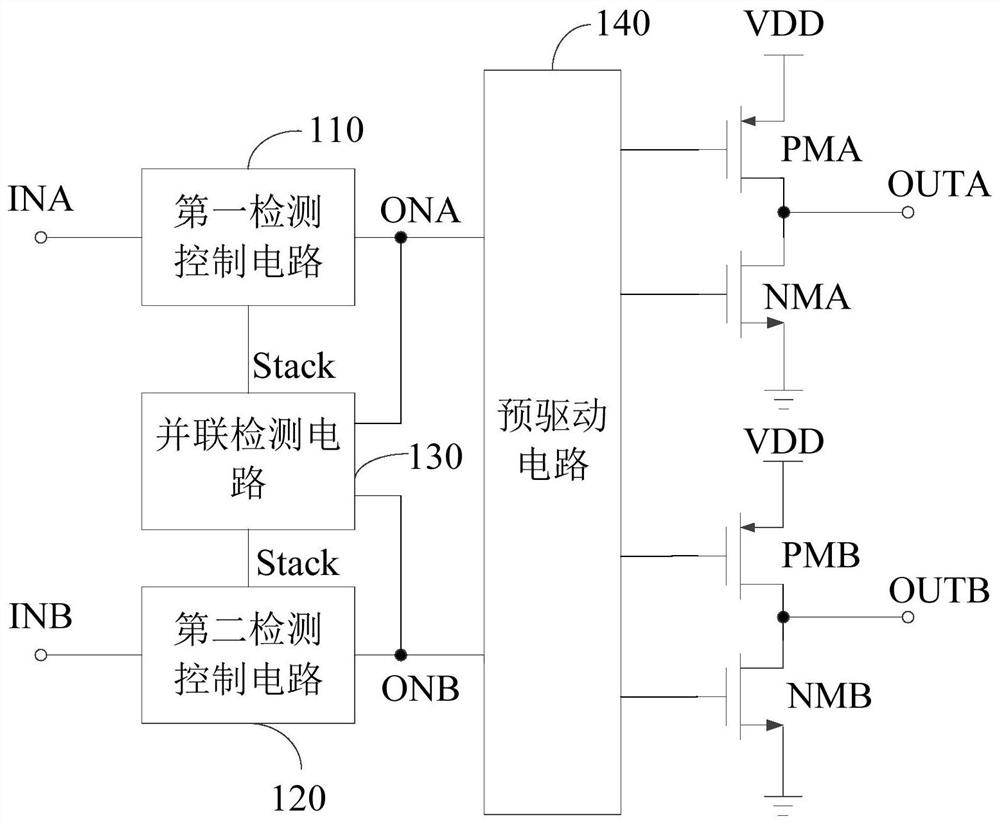

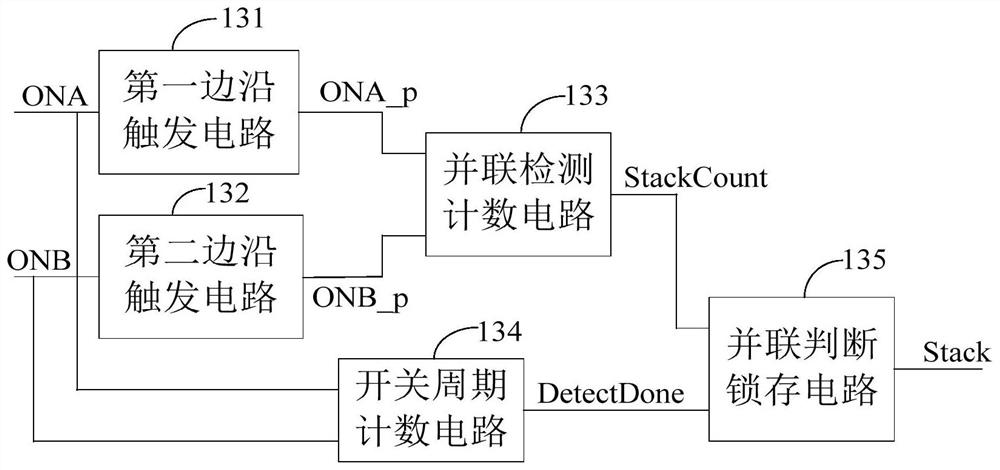

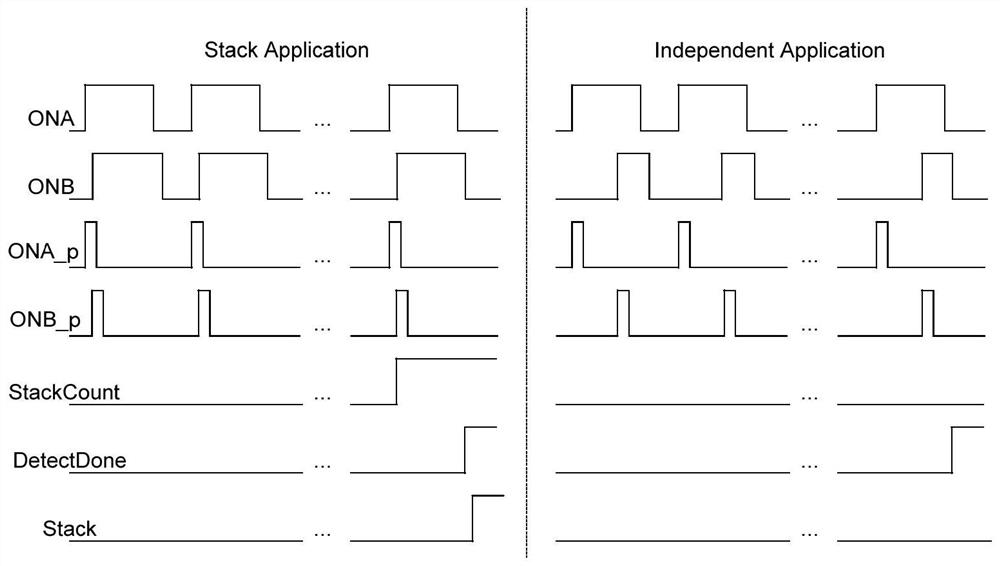

Dual-channel gate drive circuit and dual-channel gate drive chip

PendingCN113972815AExtended dead timeAvoid straight up and downPower conversion systemsHemt circuitsEngineering

The invention is suitable for the technical field of switch driving, and particularly relates to a dual-channel gate driving circuit and a dual-channel gate driving chip. The dual-channel gate drive circuit comprises a first detection control circuit, a second detection control circuit, a parallel detection circuit, a pre-drive circuit, a first pull-up bridge arm, a first pull-down bridge arm, a second pull-up bridge arm and a second pull-down bridge arm, the parallel detection circuit detects whether PWM signals output by the first detection control circuit and the second detection control circuit are overlapped or not, and when the signals are detected to be overlapped, it is indicated that the current dual-channel gate drive circuit is applied in a dual-channel parallel mode. The parallel detection circuit respectively controls the first detection control circuit and the second detection control circuit to increase the dead time with the preset size, so that up-and-down straight-through of double channels of the double-channel gate drive circuit is avoided, and the drive reliability is improved.

Owner:茂睿芯(深圳)科技有限公司

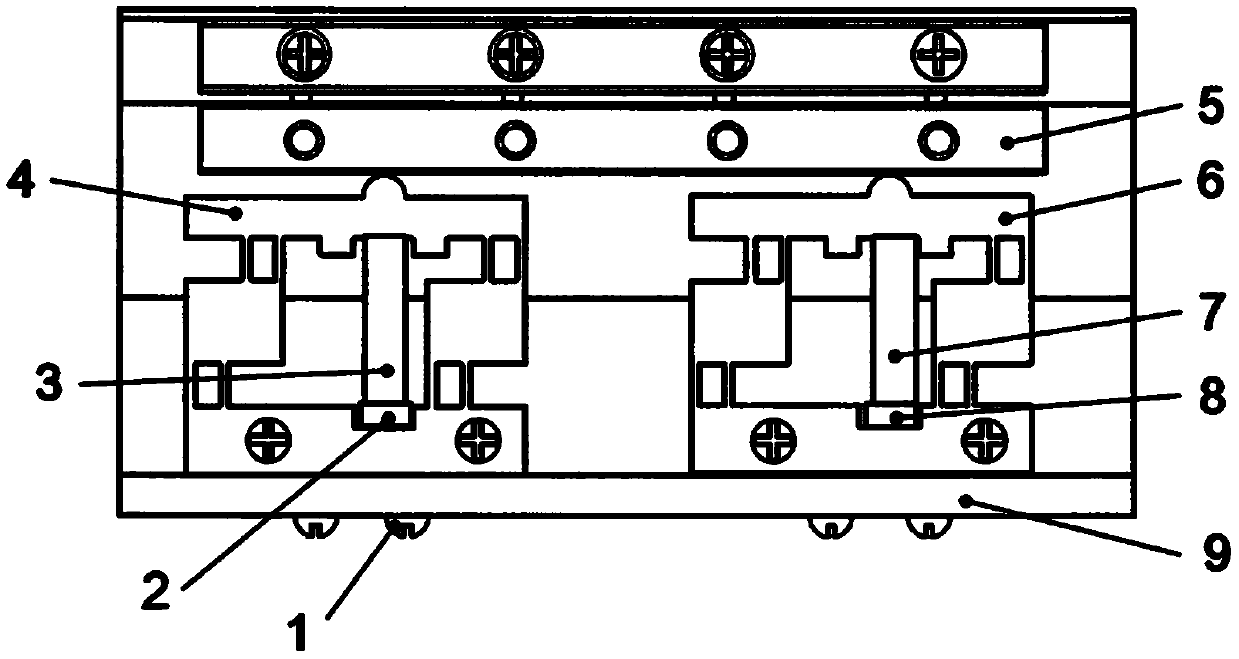

Damping type uncoiler

The invention discloses a damping type uncoiler. The damping type uncoiler comprises a supporting base, a bearing supporting base is arranged on the supporting base, an uncoiler head is fixed to the bearing supporting base through a rotating bearing supporting system, an expanding type clamping jaw system is arranged on the uncoiler head, a driving plate is arranged on the back face of the uncoiler head, the driving plate and the uncoiler head are tightly connected and rotate synchronously, the driving plate is provided with a driving surface, the driving surface is a steel round surface, a driving motor is arranged on the bearing supporting base, a driving head is arranged on an output shaft of the driving motor, the driving head matches with the driving surface, the driving head is a rubber cylindrical head, is tightly pressed on the driving surface and drives the driving plate to rotate through friction force, and then the whole uncoiler head is driven to rotate. The damping type uncoiler is simple in structure, capable of providing driving force and damping force at the same time and good in using effect.

Owner:丁伟峰

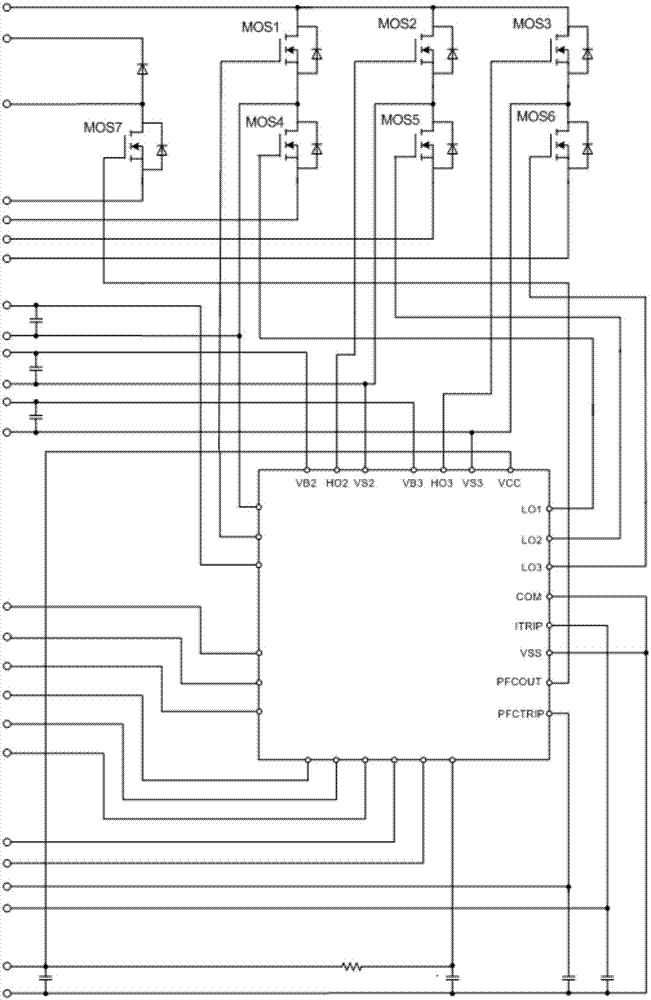

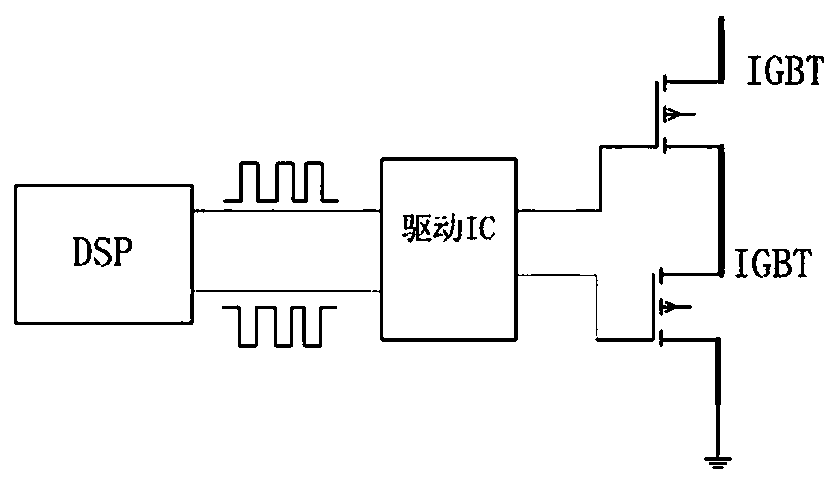

PWM wave adaptive generating circuit, an inverting circuit and air conditioner

InactiveCN110299831AReduce difficultyAvoid damageAc-dc conversionComputer moduleSoftware development

The invention discloses a PWM wave adaptive generating circuit, which includes a PWM wave generating module and a driving module connected with the output end of the PWM wave generating module. A phase reversing module is arranged between the output end of the PWM wave generating module and the driving module, so that the driving module can obtain two opposite PWM waves. The driving module drivesa post-stage power switch according to the two opposite PWM waves. Through a simple hardware circuit, self-adaptive on-off control of IGBT is realized, the difficulty of software development is reduced, the damage of the driving board caused by direct connection of the upper and lower bridges of IGBT is prevented, and the driving reliability is improved. At the same time, the PWM wave adaptive generating circuit has the advantages of simple structure, fewer devices, low cost and high reliability.

Owner:GREE ELECTRIC APPLIANCES INC

A brushless DC motor hall sensor real-time fault identification and reconstruction system and method

ActiveCN109687809BHigh drive reliabilityNo overcurrent phenomenonElectric motor controlElectronic commutatorsDC - Direct currentElectric machine

The invention relates to a real-time fault identification and reconstruction system and method for a hall sensor of a brushless direct current motor, in particular to a real-time fault identification,reconstruction and protection method for a hall signal of the brushless direct current motor. The real-time fault identification and reconstruction system and method for the hall sensor of the brushless direct current motor are suitable for various brushless direct current motors of high-speed (high speed means the running state of the brushless direct current motor after starting) running. According to the method, in the running state of the brushless direct current motor, faults of the hall sensor of the brushless direct current motor can be recognized in real time, and hall signal reconstruction can be completed. It is only required that one phase of the hall signal of the brushless direct current motor is correct, other hall signals can be reconstructed, and normal work of the high-speed motor is ensured; when all hall signals are subjected to faults, it can be ensured that the overcurrent phenomenon cannot occur on the motor, and motor safety is ensured. Compared with a traditional control method for the brushless direct current motor, the method can greatly improve the driving reliability of the brushless direct current motor.

Owner:BEIJING INST OF CONTROL ENG

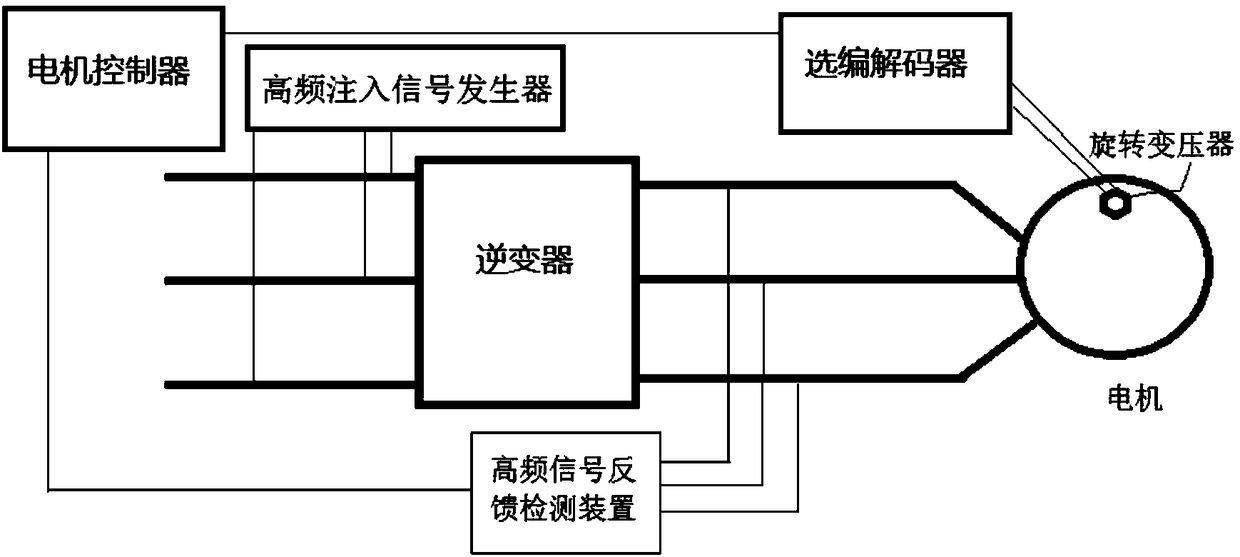

Cross detection system and method of motor rotor position

PendingCN108173471AImprove reliabilityHigh drive reliabilityMotor parameters estimation/adaptationElectric vehicleStator

The invention discloses a cross detection system of motor rotor position. The cross detection system of motor rotor position is characterized in that a power supply input terminal of a motor is connected with a power supply through an inverter; the motor includes a support, a rotor and a stator; a motor controller controls the output parameters of the motor; a rotary transformer is fixed on the motor; the rotary transformer outputs an induction signal to a selection decoder; the selection decoder outputs a rotor position signal to the motor controller; a high frequency injection signal-generator respectively sends a signal to each phase of the input terminal of the inverter; a high frequency signal feedback detector is connected with each phase of the output terminal of the inverter, and separates a feedback signal from an injection signal; and the high frequency signal feedback detector outputs the rotor position signal to the motor controller. The cross detection system of motor rotor position has the advantages of being able to improve the motor driving reliability by performing cross detection on double path of rotor positions, and providing a fault driving mode so as to avoidthe situation that the electric vehicle needs a trailer because the rotary transformer fails.

Owner:江西精骏电控技术有限公司

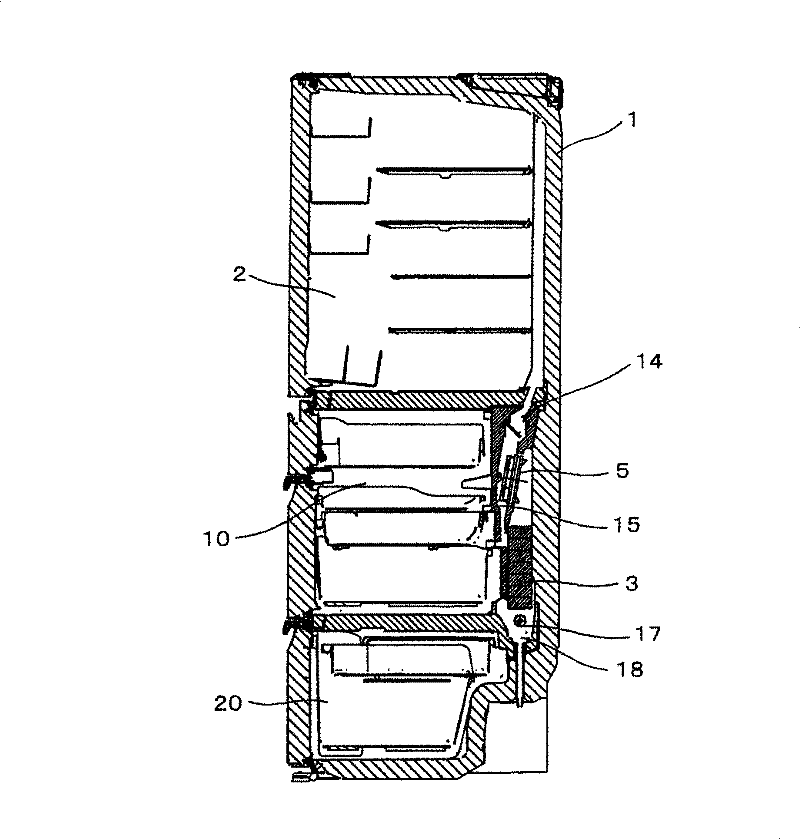

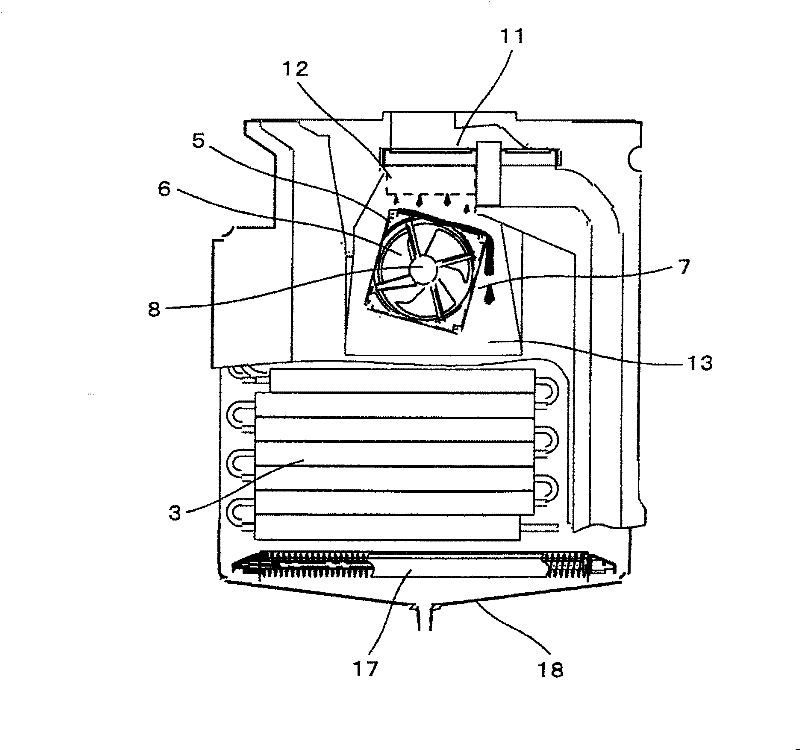

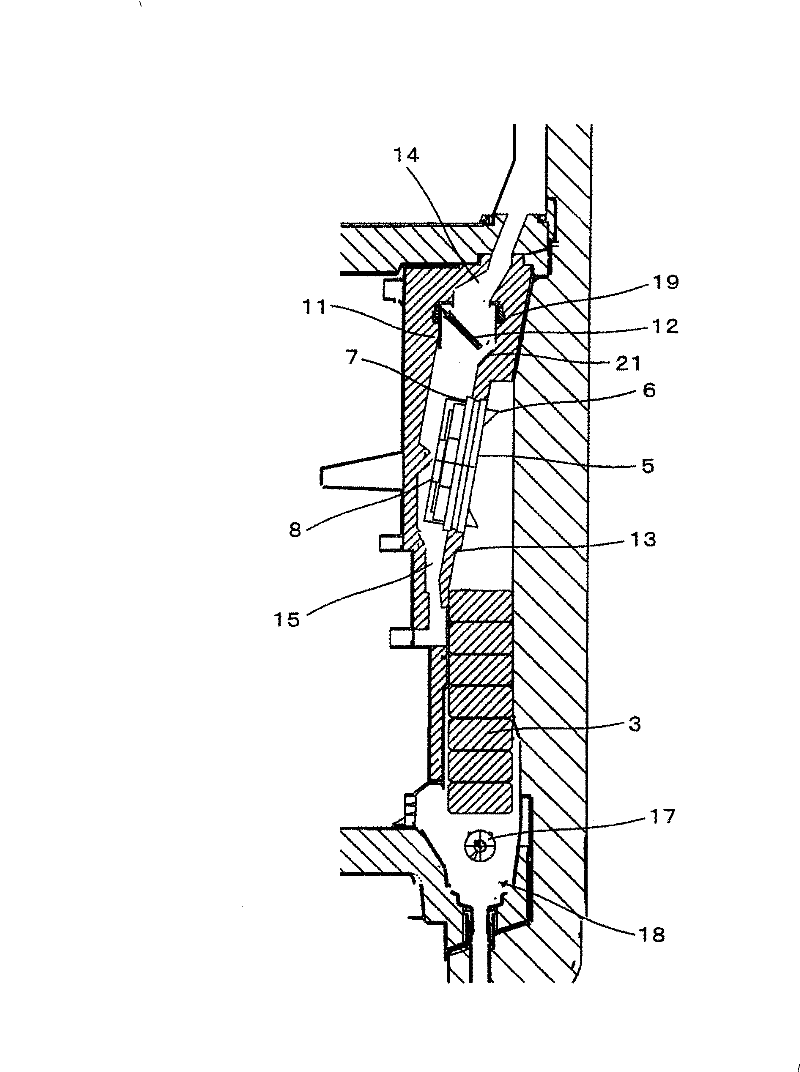

Electrical refrigerator

ActiveCN101382372BHigh drive reliabilityLighting and heating apparatusDomestic refrigeratorsCold airIcebox

The invention provides a refrigerator improving reliability of driving of a blower. The refrigerator has a refrigeration compartment provided in an upper part of a refrigerator body, a freezing compartment provided below the refrigeration compartment, the blower blowing cold air into an interior, a cold air duct provided behind the freezing compartment and installed with the blower, and a damper provided above the blower and adjusting supply of the cold air blown by the blower into the interior. The damper has a flapper rotatably in the up and down direction provided and driven in the cold air duct to control passage of the cold air in the cold air duct. The blower is provided with a fan, and a fan case provided around the fan, a top face of the fan case is provided such that it is slanted in right and left directions as seen from the front of the refrigerator body, the cold air duct has a slanting part above the fan, and the flapper rotates such that an end of the flapper is positioned above the slanting part.

Owner:HITACHI GLOBAL LIFE SOLUTIONS INC

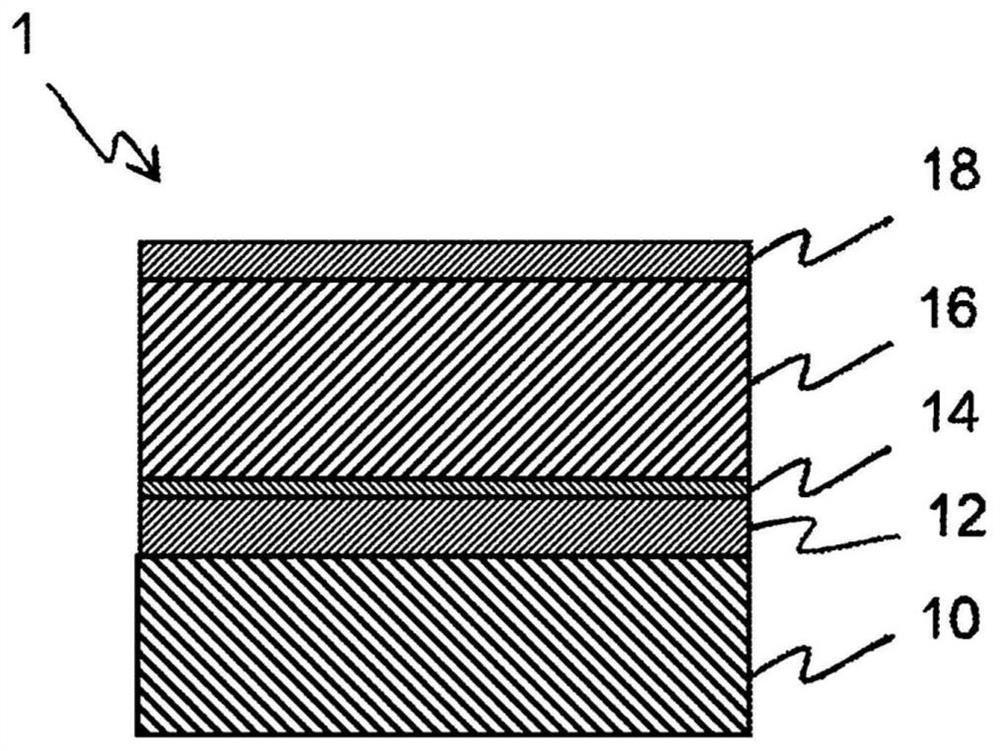

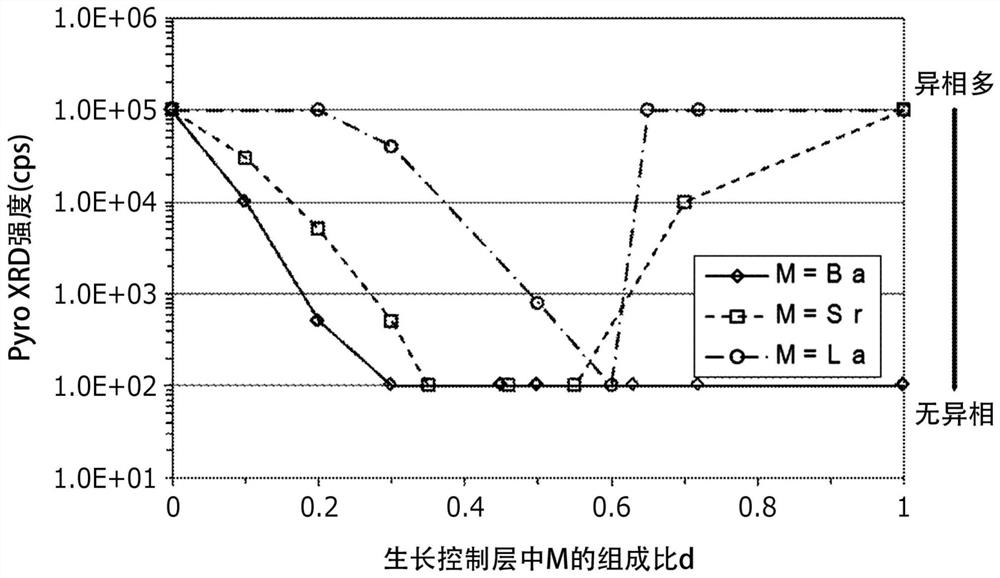

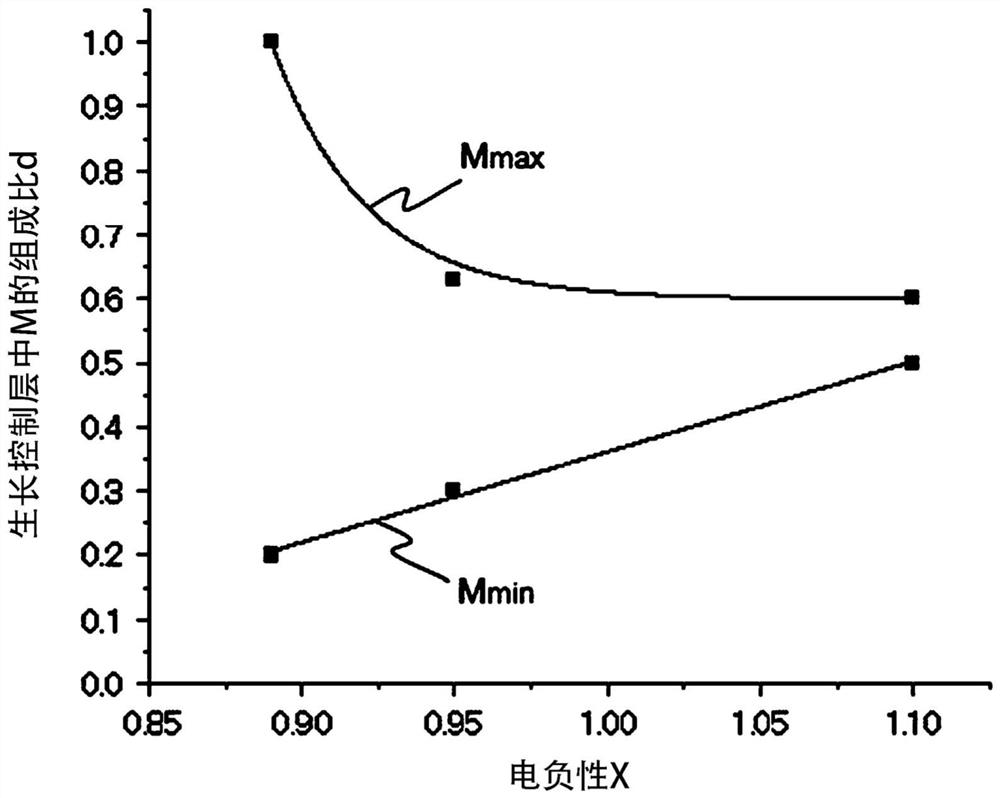

Piezoelectric element

PendingCN113966552AHigh drive reliabilityVacuum evaporation coatingSputtering coatingGrowth controlElectronegativity

The present invention provides a piezoelectric element which comprises a piezoelectric layer constituted of a Pb-containing perovskite type oxide and which exhibits high driving reliability even in a warm environment. This piezoelectric element comprises, in the given order on a substrate, the following: a lower electrode layer; a growth control layer; a piezoelectric layer which contains a perovskite type oxide containing lead as a primary A-site component; and an upper electrode layer. The growth control layer contains a metal oxide represented by MdN1-dOe. M comprises one or more metal elements able to be substituted at A-sites in the perovskite type oxide. If X denotes the electronegativity of M, 1.41X-1.05 <= d <= A1.exp(-X / t1)+y0, where A1=1.68x1012, t1=0.0306, and y0=0.59958. The perovskite type oxide is represented by (Pba1 alpha a2)(Zrb1Tib2 beta b3)Oc, and 0.5 < a1 / (b1+b2+b3) < 1.07.

Owner:FUJIFILM CORP

Uncoiler for cross cut shear

The invention discloses an uncoiler for a cross cut shear. The uncoiler comprises a support base, the support base is provided with a rotating seat, and an uncoiler head is fixed to the rotating seatthrough a rotating bearing supporting system; the uncoiler head is provided with an opened clamping jaw system; and a driving disc is arranged on the back of the uncoiler head, a driving device is arranged on the upper part of the rotating seat, the driving device is provided with a driving head, the driving head is matched with the driving disc, and the driving head is mounted on a driving motor.The uncoiler head is driven from a large circular surface through the driving head, on the one hand, speed reduction is achieved, so that driving is smoother, on the other hand, through a speed reduction device, driving torque is reduced, and driving reliability is improved.

Owner:丁伟峰

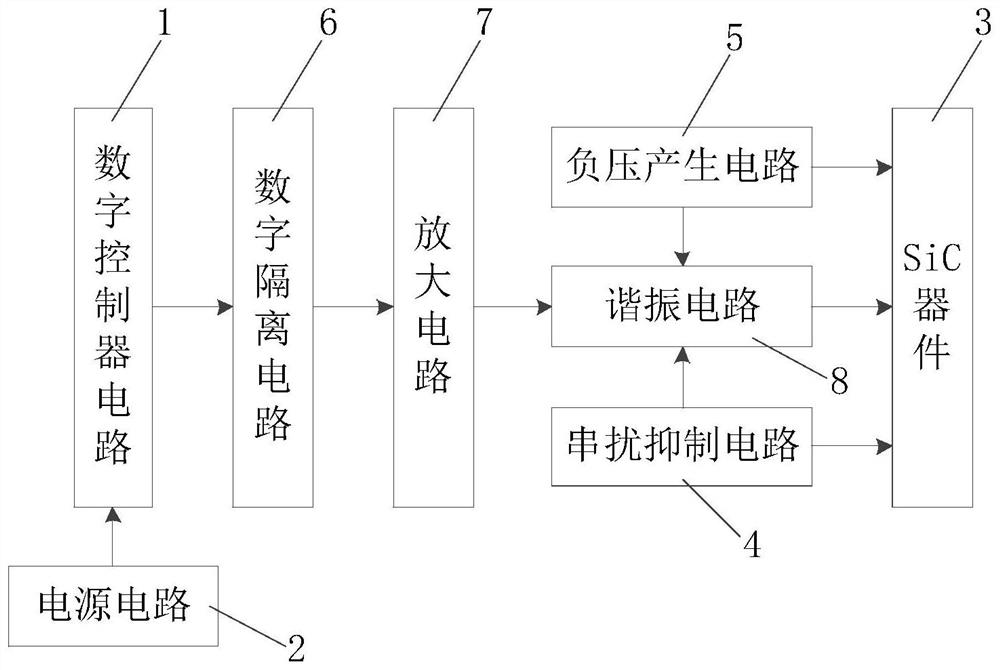

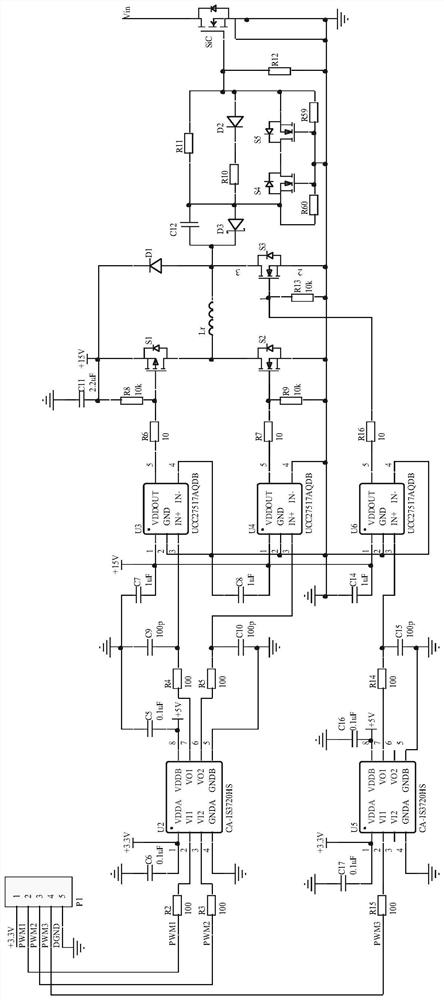

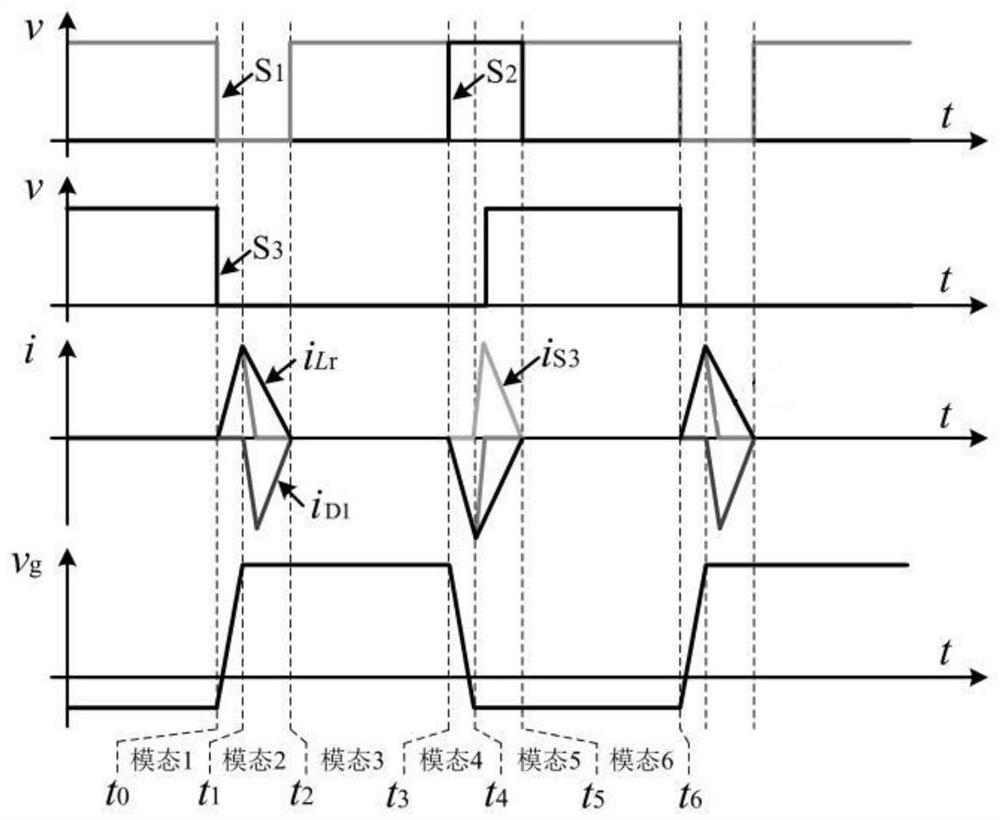

Resonant gate driving circuit with crosstalk suppression and driving method thereof

PendingCN113965055ASimple structureReasonable designEfficient power electronics conversionPower conversion systemsCapacitanceHemt circuits

The invention discloses a resonance gate driving circuit with crosstalk suppression and a driving method thereof. The driving circuit comprises a digital controller circuit, a power supply circuit for supplying power to each electric circuit in the driving circuit, a crosstalk suppression circuit for suppressing bridge arm crosstalk of a SiC device, and a negative voltage generation circuit for providing negative voltage required when the SiC device is turned off, wherein the digital controller circuit generates pulse width modulation waves meeting the time sequence of the driving circuit, the signal output end of the digital controller circuit is connected with a digital isolation circuit, the signal output end of the digital isolation circuit is connected with an amplification circuit, and a resonance circuit used for charging and discharging the gate capacitor of the SiC device is connected between the amplification circuit and the SiC device. According to the invention, the resonance gate driving circuitis reasonable in design, convenient to implement, capable of being effectively applied to high-frequency driving of the SiC device, capable of effectively reducing power loss and effectively inhibiting bridge arm crosstalk by combining the driving method of resonance driving and crosstalk inhibition, high in driving reliability, remarkable in effect and convenient to popularize.

Owner:XIAN UNIV OF SCI & TECH

Crawling piezoelectric precision driving device based on asymmetric triangular flexible hinge mechanism

ActiveCN110855179ARealize bionic crawling linear driveEliminate backlashPiezoelectric/electrostriction/magnetostriction machinesSequence controlMicro-operation

The invention relates to a crawling piezoelectric precision driving device based on an asymmetric triangular flexible hinge mechanism. The device consists of two groups of piezoelectric stacks, two groups of asymmetric triangular flexible hinge mechanisms, a mover, a pre-tightening screw, a pre-tightening wedge and a base. The two groups of piezoelectric stacks can be elongated and recovered underthe driving of voltage signals. The two groups of asymmetric triangular flexible hinge mechanisms can realize parasitic inertial motion. The pre-tightening screw and the pre-tightening wedge adjust the initial pre-tightening force between the asymmetric triangular flexure hinge mechanism and the mover. The base acts as a support. The two piezoelectric stacks alternately drive under the voltage sequence control so that the asymmetric triangular flexible hinge mechanisms perform bionic crawling movement, thus increasing the output load, eliminating the backward phenomenon of the mover in the movement period, improving the output performance of the device and realizing the linear movement of the mover. The device can be applied to the fields of ultra-precision machining, micro-electromechanical systems, micro-operation robots and biotechnology.

Owner:ZHEJIANG NORMAL UNIVERSITY

Light control device and manufacturing method thereof

ActiveCN105652505BReduce energy consumptionEasy to scatterNon-linear opticsPolymer networkEngineering

Owner:LG DISPLAY CO LTD

Three-dimensional circulating conveying line type dense container system

PendingCN114516510AMeet shipping requirementsThe driving process is simple and reliableStorage devicesControl engineeringProcess engineering

The invention provides a three-dimensional circulating conveying line type dense container system, and belongs to the technical field of space intelligent storage. The problems that an existing container system is low in volume loading rate, large in working space requirement, complex in driving process and low in working efficiency are solved. The system comprises a material conversion mechanism, the material conversion mechanism comprises a loading platform, a mechanical claw mechanism, a material circulation track system and a driving screw mechanism, and the loading platform comprises a plurality of movable loading platforms, a plurality of fixed loading platforms and a no-load platform. The multiple movable loading platforms and the no-load platform are evenly distributed on the outer ring of the material circulation track system, the multiple fixed loading platforms are evenly distributed on the inner ring of the material circulation track system, the driving screw mechanism is installed on one side of the material circulation track system, and the mechanical claw mechanism is installed on the other side of the material circulation track system. And the driving screw mechanism is in driving connection with the movable loading platform and the no-load platform. The system is mainly used for space intelligent storage.

Owner:HARBIN INST OF TECH

A rope driving device with the function of reciprocating wire arrangement

ActiveCN104192637BWith reciprocating cable functionWinding orderlyFilament handlingReciprocating motionGear wheel

The invention discloses a rope drive device with a reciprocating wire arrangement function. The rope drive device comprises a backup motor gearbox, a rope roller reducer, a winding roller, a reciprocating screw mechanism and an arrangement guide wheel set. A driving motor is connected with an output shaft of a backup motor and an input shaft of a planetary reducer through the backup motor gearbox, so that both the driving motor and the backup motor can drive the motor gearbox to move. The rope roller reducer transmits rotation of an output shaft of the planetary reducer to the winding roller according to a specified speed ratio, and a large torque is obtained. The winding roller is mounted at an output shaft of the rope roller reducer; a drive rope is wound on and unwound from the winding roller. A reciprocating screw of the reciprocating screw mechanism is connected with the winding roller through a gear and drives a nut slider mounted on the reciprocating screw, to reciprocate. The arrangement guide wheel set is fixedly connected with the screw slider and reciprocates with the screw slider to guide the drive rope being tightly wound on the winding roller in a reciprocating manner. The rope drive device allows winding and unwinding of the rope and allows the rope to be regularly and tightly wound.

Owner:BEIHANG UNIV

Air-conditioning indoor unit and air conditioner having the air-conditioning indoor unit

ActiveCN104676745BExpand the range of air supplyImprove air supply efficiencyLighting and heating apparatusHeating and ventilation casings/coversAir conditioningEnergy consumption

The invention discloses an air conditioning indoor unit and an air conditioner with an air conditioning indoor unit. The air conditioning indoor unit comprises a shell body, which is provided with an air supply opening and an air returning opening; an air guide ring, which is arranged at the air supply opening for adjusting the air supply direction; a driving component, which is connected with the air guide ring, and drives the air guide ring to crossly sway and / or vertically sway; an indoor heat exchanger, which is arranged in the shell body; a blower component, which is arranged in the shell body. The air conditioning indoor unit can greatly increase the air supply scale thereof by arranging the air guide ring which can sway along cross and vertical directions, and air flow can be blown to any zone in front of the shell body, and thereby the dead corner of the air supply in the room is effectively solved, the comfort level of the air conditioning indoor unit is added, time from the indoor temperature to the preset temperature is shortened, and energy consumption of the air conditioning indoor unit is reduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

A drive circuit for a mos tube

Owner:SICHUAN SHENGHUA POWER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com