Cross detection system and method of motor rotor position

A motor rotor and cross detection technology, which is applied in the estimation/correction of motor parameters, etc., can solve problems such as runaway time, high amplitude of injected signals, loss, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

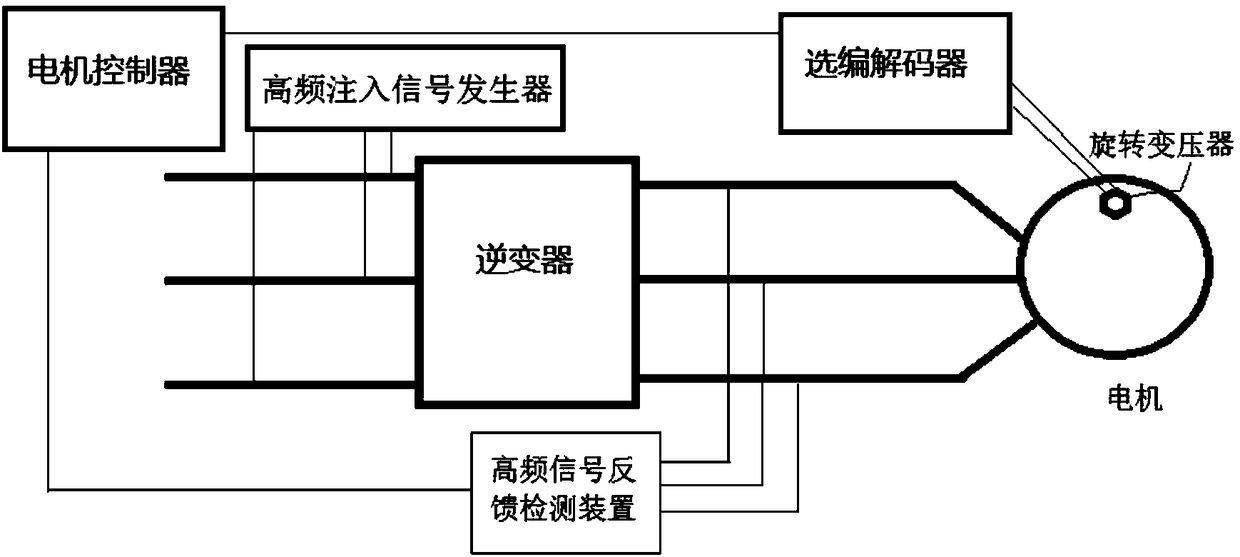

[0022] Such as figure 1 The cross-detection system for the rotor position of the motor shown includes a motor, a resolver, a codec, a motor controller, a high-frequency signal generator, an inverter, a wiring harness, and a high-frequency signal feedback detection device.

[0023] The motor is a permanent magnet drive motor, mainly composed of a base, a rotor and a stator.

[0024] A resolver is an induction micromotor whose output voltage maintains a certain functional relationship with the rotor angle.

[0025] The optional codec is a device that decodes the output voltage of the resolver into the angular position of the rotor according to the functional relationship between the output voltage of the resolver and the rotor angle.

[0026] The motor controller is a device that controls the output parameters of the motor according to the motor output requirements of the vehicle controller. In order to control the rotation output of the motor, the motor controller needs accur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com