A rope driving device with the function of reciprocating wire arrangement

A rope-driven, functional technology, applied in the mechanical field, can solve the problems of difficult to provide rope driving force, large volume and mass, etc., and achieve the effect of improving driving reliability, saving space, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings.

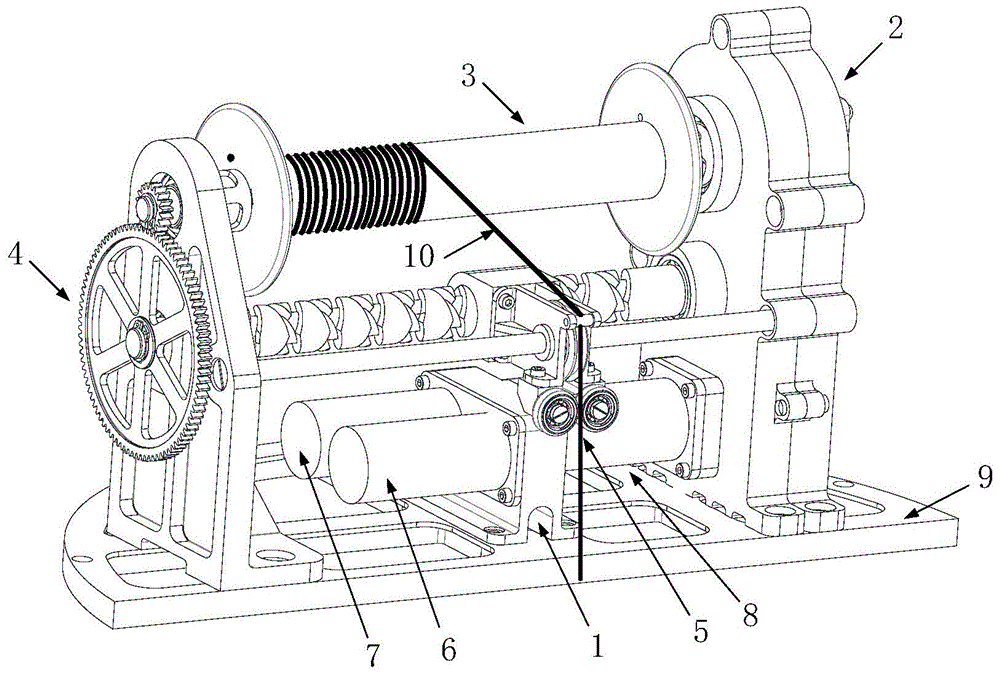

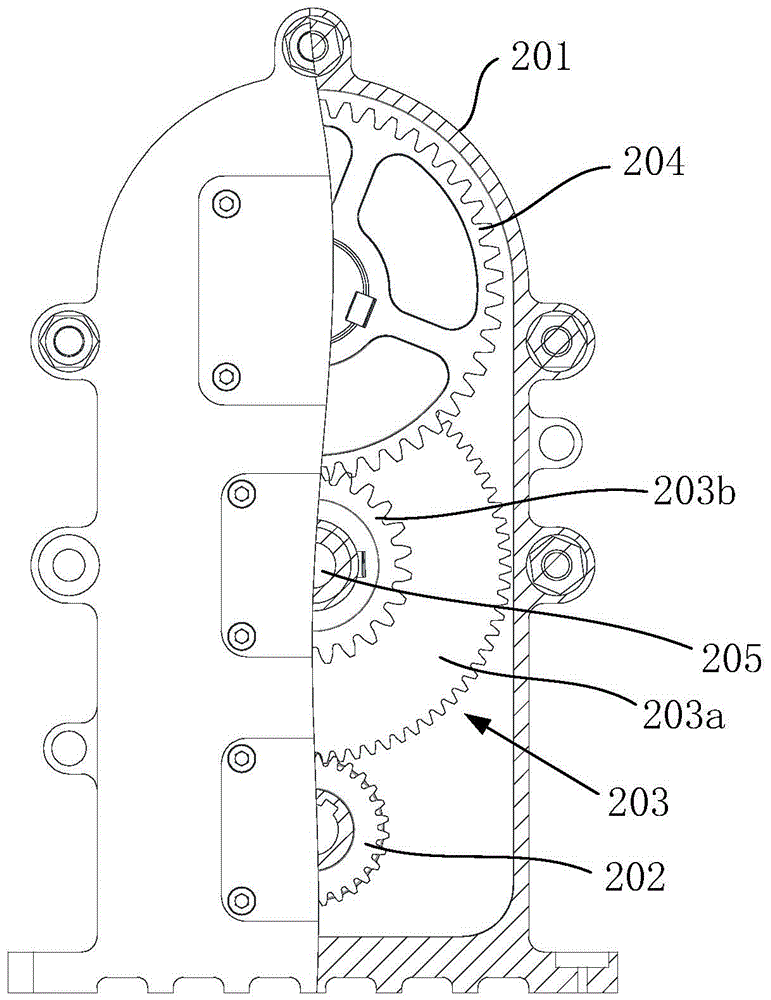

[0037] The present invention is a rope driving device with the function of reciprocating wire arranging, which includes a backup motor gearbox 1, a wire roller reducer 2, a winding roller 3, a reciprocating screw mechanism 4, and a wire arranging guide wheel group 5, such as figure 1 shown.

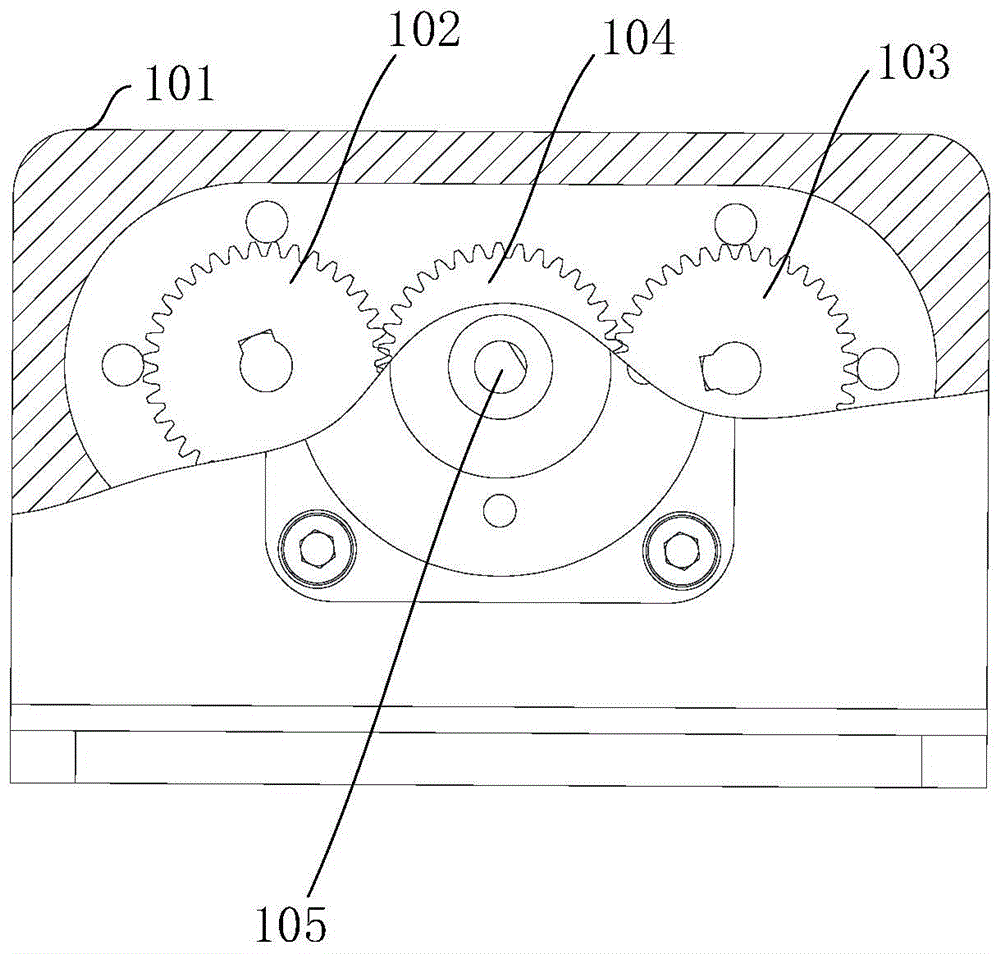

[0038] The backup motor gearbox 1 includes a gearbox casing 101, an input shaft gear A102, an input shaft gear B103, an output shaft gear 104 and an output shaft 105, such as figure 2 As shown; wherein, the gearbox case 101 is fixed on the installation base plate 9 by screws, the input shaft gear A102, the input shaft gear B103 and the output shaft gear 104 are located in the gearbox case 101; the input shaft gear A102 and the input shaft gear B103 is located on both sides of the output shaft gear 104 respectively, and both mesh with the output shaft gear 104 . The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com