Roll-type take-up device

A winding device and roller technology, which is applied in the direction of winding strips, transportation and packaging, and transportation of filamentous materials, etc., can solve the problems of damage to the winding object, easy separation from the winding roller, and disordered winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing;

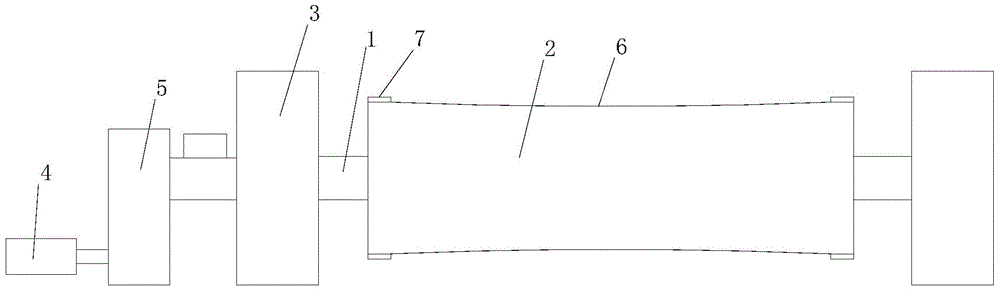

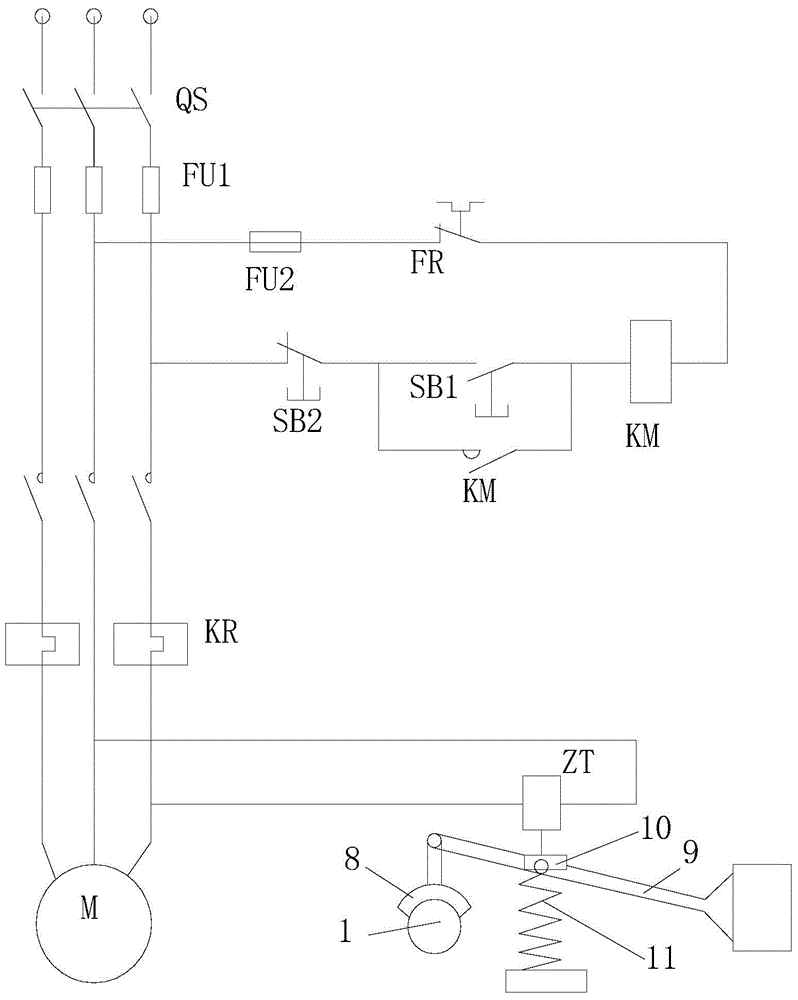

[0014] see figure 1 , figure 2 As shown, the roll-type winding device includes a winding shaft 1, a winding roller 2 that is arranged on the winding shaft and rotates with the winding shaft, and the two ends of the winding roller are respectively rotatably arranged on a support 3 through bearings, and drive The driving mechanism for the rotation of the winding roller. The driving mechanism includes a motor 4 and a speed reducer 5 between the winding roller and the motor. The shape is an arc surface, and the lowest surface of the arc surface coincides with the middle position of the winding roller. In the specific implementation, the difference between the most concave part and the most edge of the concave shape is between 1mm and 5mm, so that the winding can be guaranteed. orderly, there will be no detachment phenomenon, and it will not cause all the rewinding objects to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com