Electric hoist hoisting equipment capable of achieving ordered winding and reduction of swing amplitude

A technology of electric hoist and hoisting equipment, which is applied in the direction of hoisting device, spring mechanism, portable lifting device, etc., which can solve the problems of mixed winding of dangerous rewinding steel ropes and large increase in swing range, so as to prevent mixed winding and reduce The swing width and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

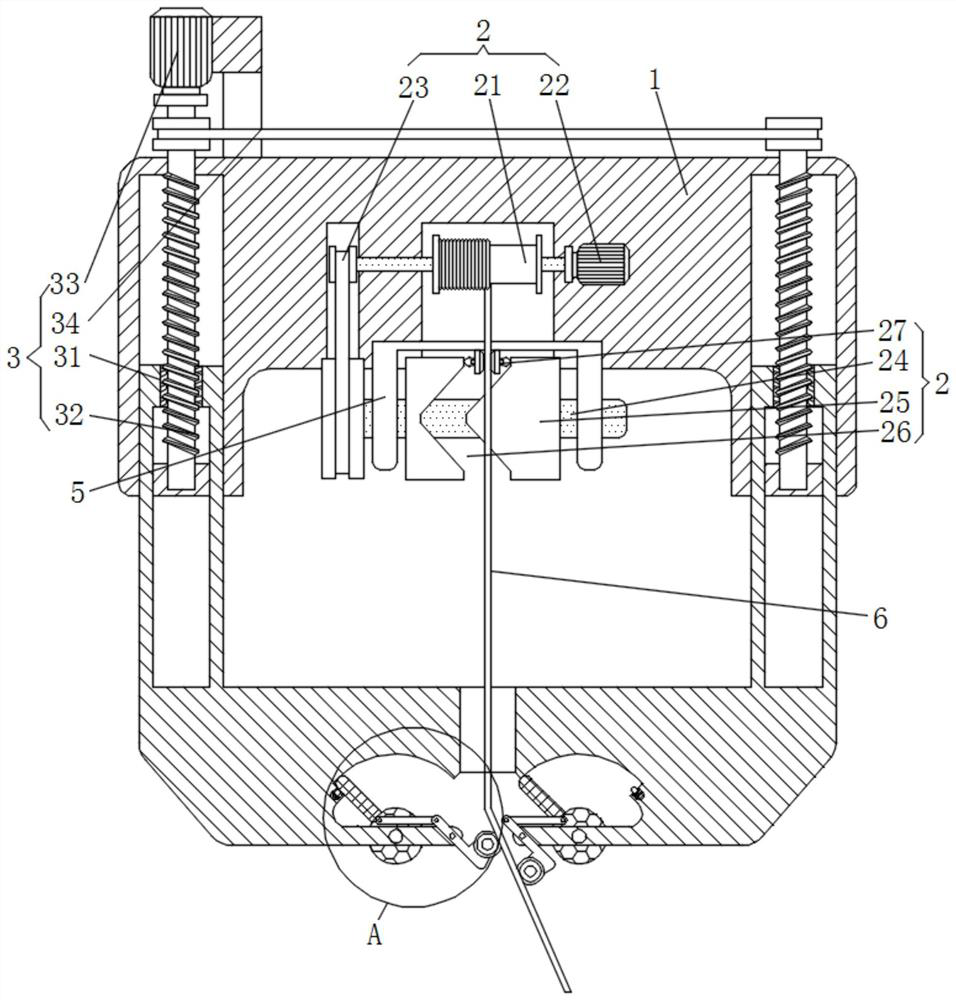

[0025] see figure 1 , 3 and 4, an electric hoist hoisting device for orderly winding and reducing swing amplitude, including a frame body 1, the top of the frame body 1 is rotatably connected to a winding mechanism 2, and the left and right ends of the frame body 1 are slidably connected to a lifting mechanism 3 , the lifting mechanism 3 comprises a sliding frame 31, a screw rod 32, a motor two 33, and a transmission belt two 34, the inner thread of the sliding frame 31 is connected with a screw rod 32, and the top of the screw rod 32 is connected with a motor two 33 for transmission, and the output end of the motor two 33 is connected with a transmission Drive belt 2 34 is arranged, and screw rod 32 is rotatably connected to the left and right ends of frame body 1, and the outside of screw rod 32 is compatible with the inside of slide frame 31, and is connected by drive belt 2 34 transmission between screw rod 32, and the outside of slide frame 31 and frame The inside of the...

Embodiment 2

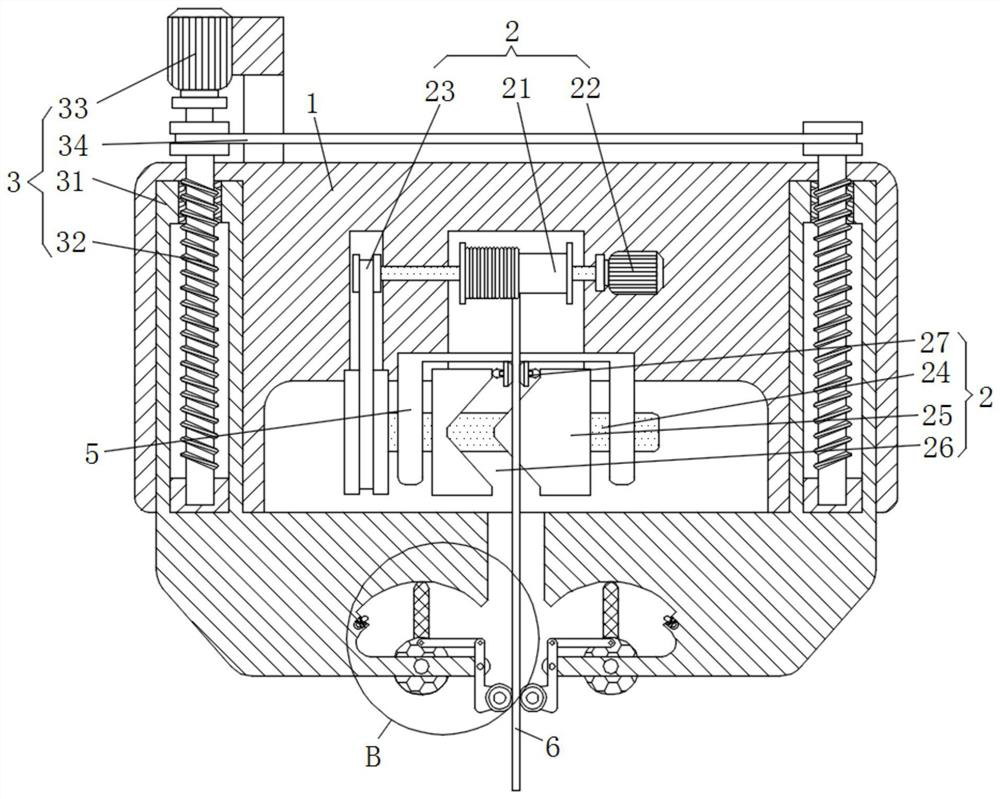

[0027] see figure 1 with 2 , an electric hoist hoisting device for orderly rewinding and reducing swing amplitude, comprising a frame body 1, the top of the frame body 1 is rotatably connected to a rewinding mechanism 2, and the rewinding mechanism 2 includes a rewinding shaft 21, a motor one 22, and a transmission belt one 23, rotating shaft one 24, groove plate 25, limit ring groove 26, guide roller 27, the right end transmission connection of winding shaft 21 is connected with motor one 22, and the left end of winding shaft 21 is connected with rotating shaft one 24 through transmission belt one 23 transmission, rotating shaft one The outside of 24 is fixedly connected with a grooved disc 25, and the inside of the grooved disc 25 is provided with a limit ring groove 26, and the inner limit of the limit ring groove 26 is connected with a guide roller 27, and the winding shaft 21 is rotatably connected to the top of the frame body 1. The periphery of the reel 21 is fixedly c...

Embodiment 3

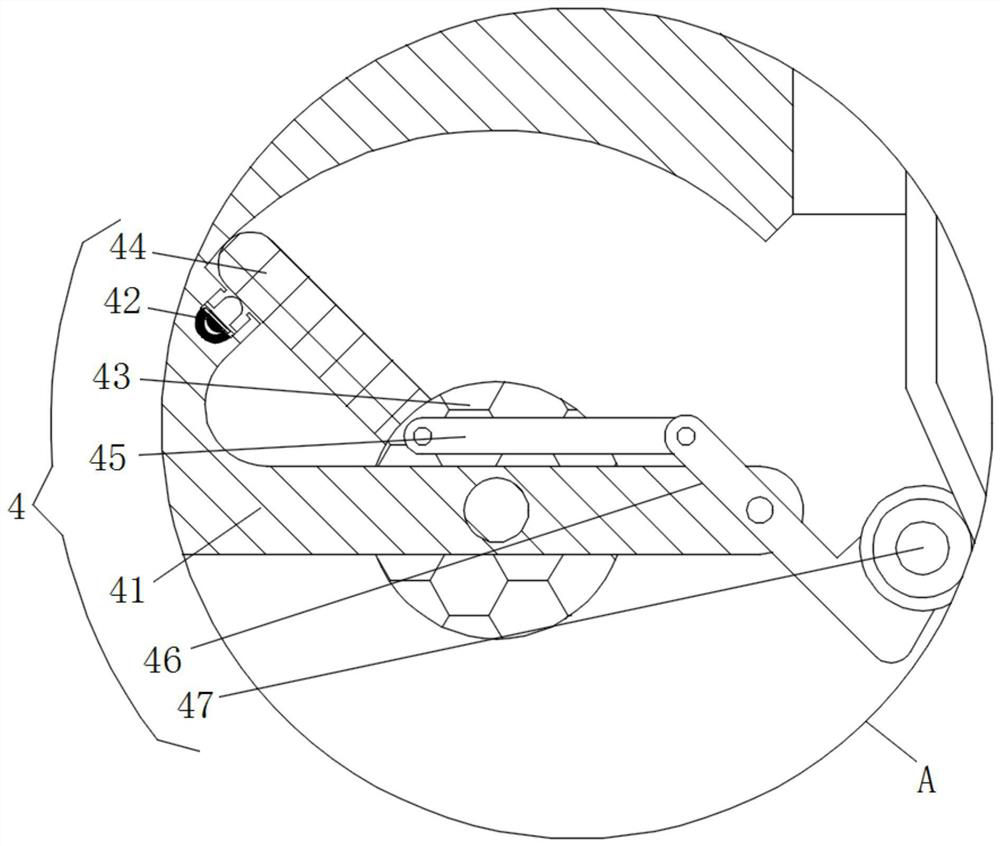

[0029] see Figure 1-4, an electric hoist hoisting device for orderly rewinding and reducing swing amplitude, comprising a frame body 1, the top of the frame body 1 is rotatably connected to a rewinding mechanism 2, and the rewinding mechanism 2 includes a rewinding shaft 21, a motor one 22, and a transmission belt one 23, rotating shaft one 24, groove plate 25, limit ring groove 26, guide roller 27, the right end transmission connection of winding shaft 21 is connected with motor one 22, and the left end of winding shaft 21 is connected with rotating shaft one 24 through transmission belt one 23 transmission, rotating shaft one The outside of 24 is fixedly connected with a grooved disc 25, and the inside of the grooved disc 25 is provided with a limit ring groove 26, and the inner limit of the limit ring groove 26 is connected with a guide roller 27, and the winding shaft 21 is rotatably connected to the top of the frame body 1. The periphery of the reel 21 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com